Calibration of a Constitutive Model from Tension and Nanoindentation for Lead-Free Solder

Abstract

1. Introduction

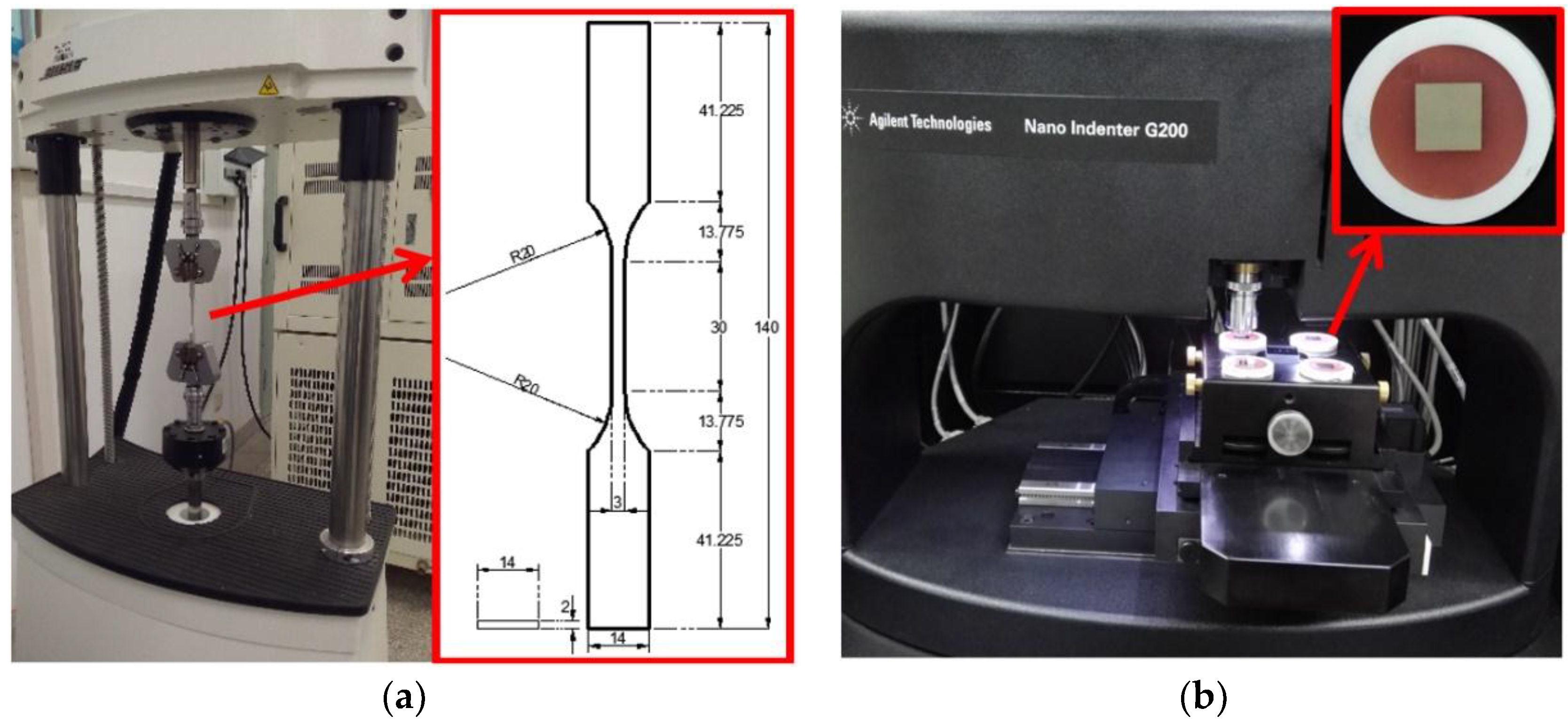

2. Sample Preparation and Experimental Setup

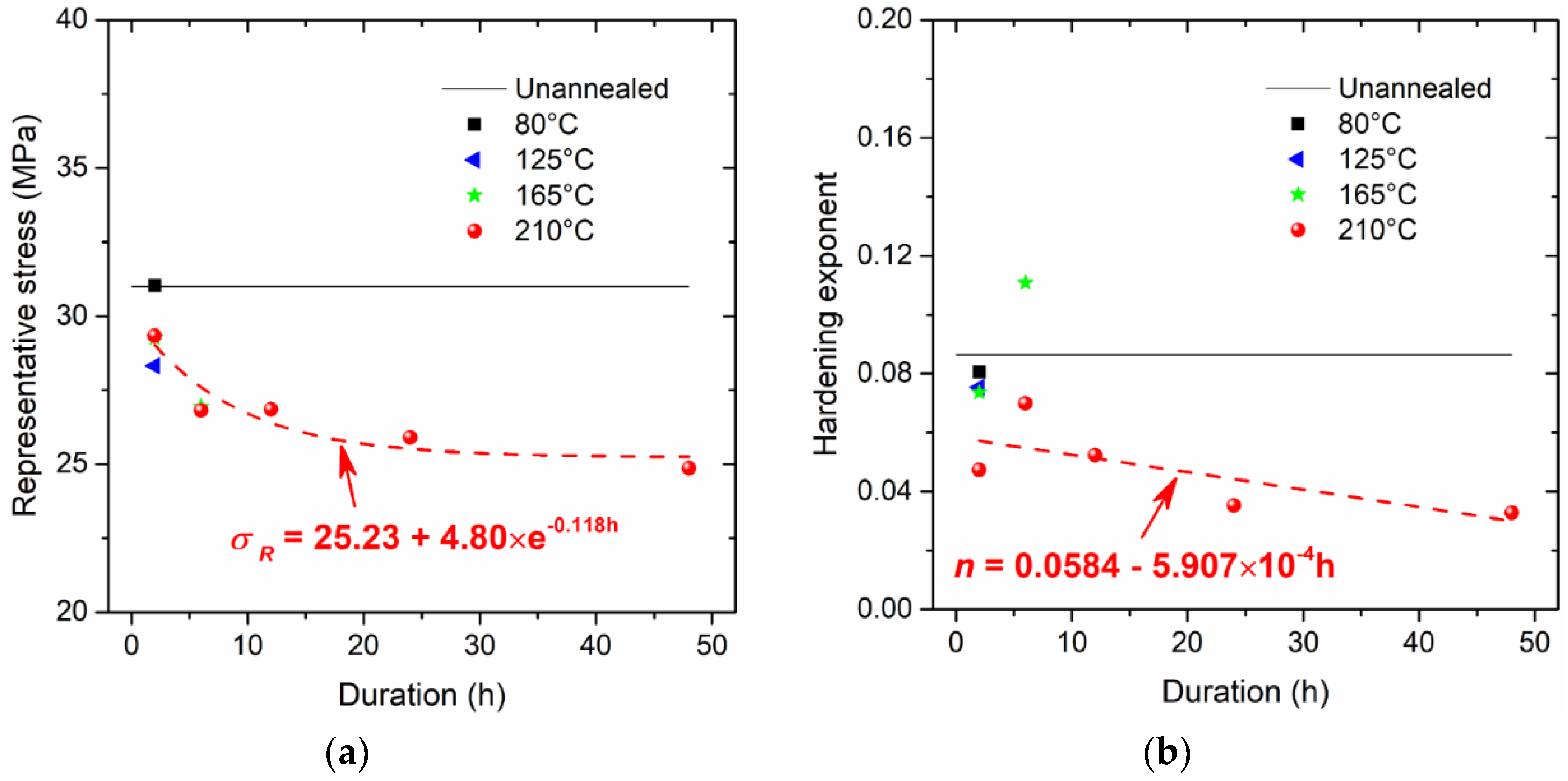

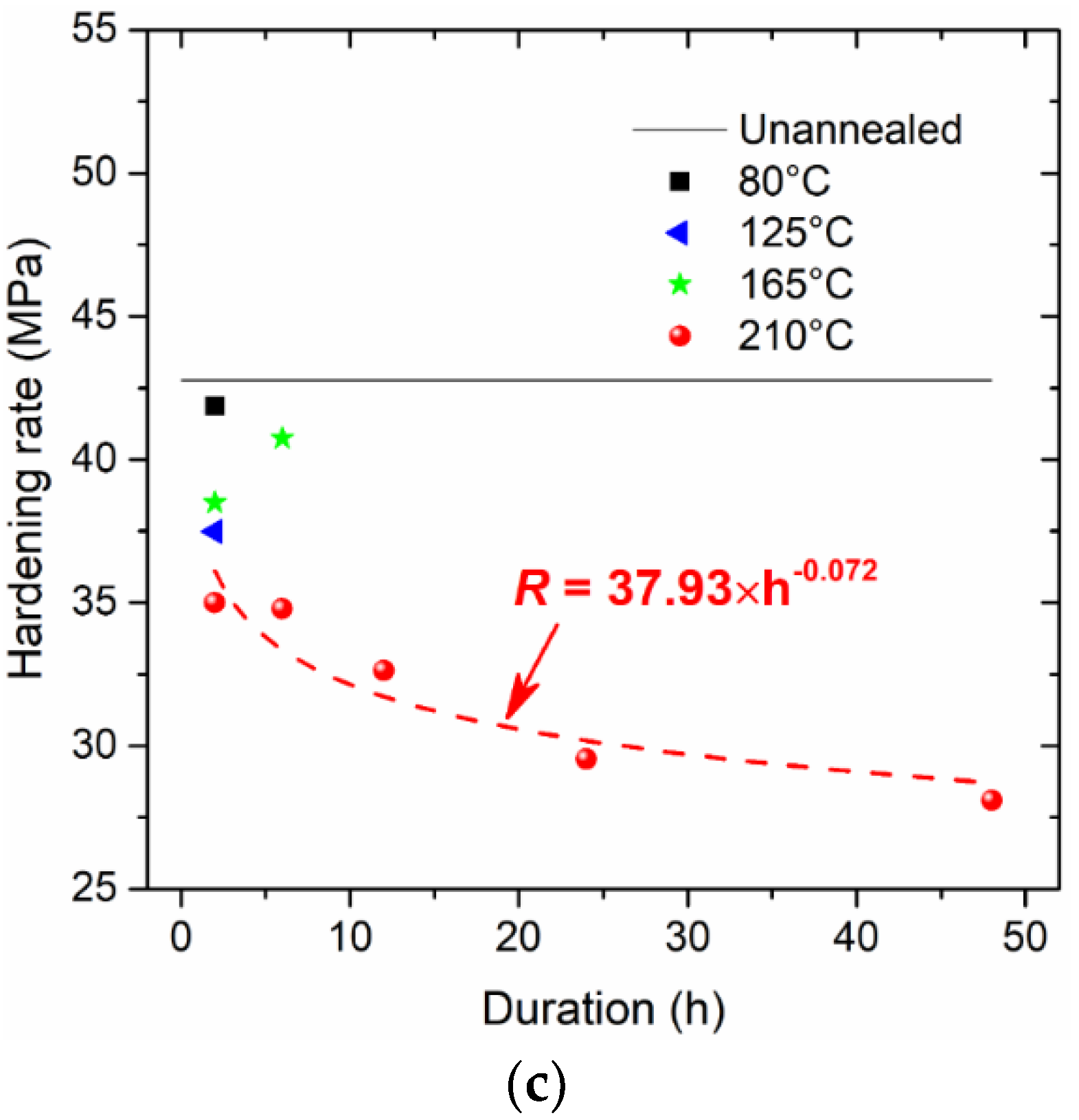

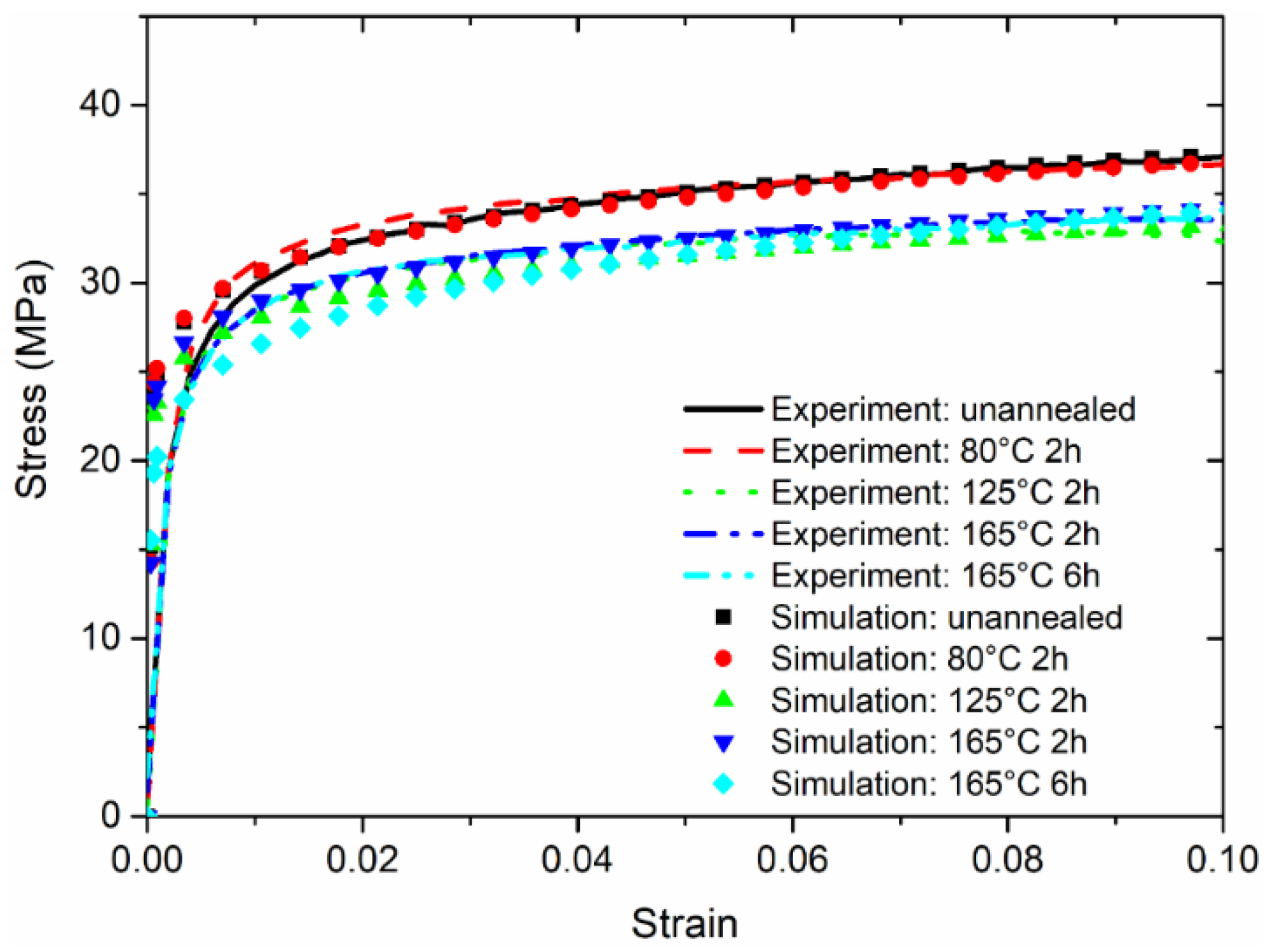

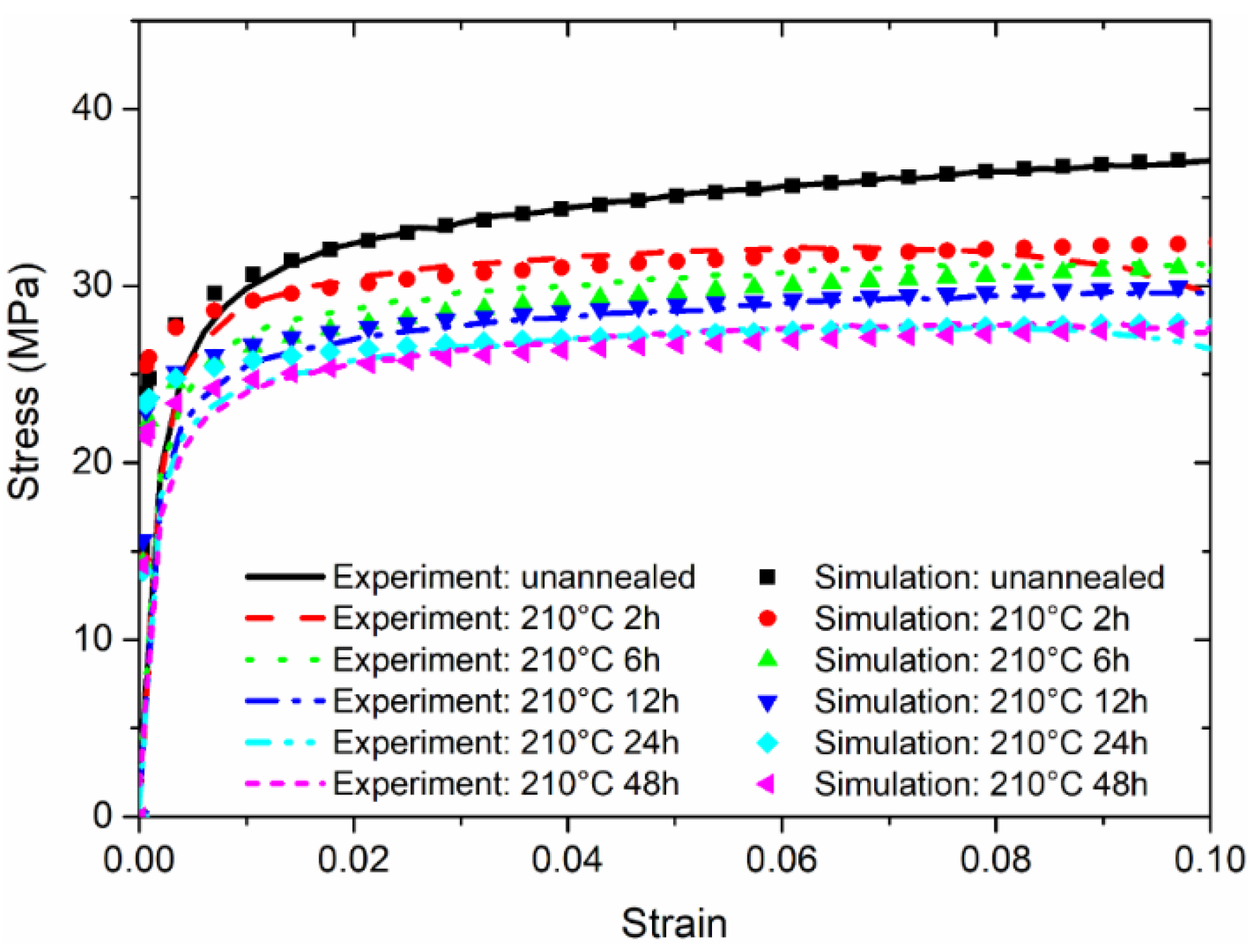

3. Experimental Results

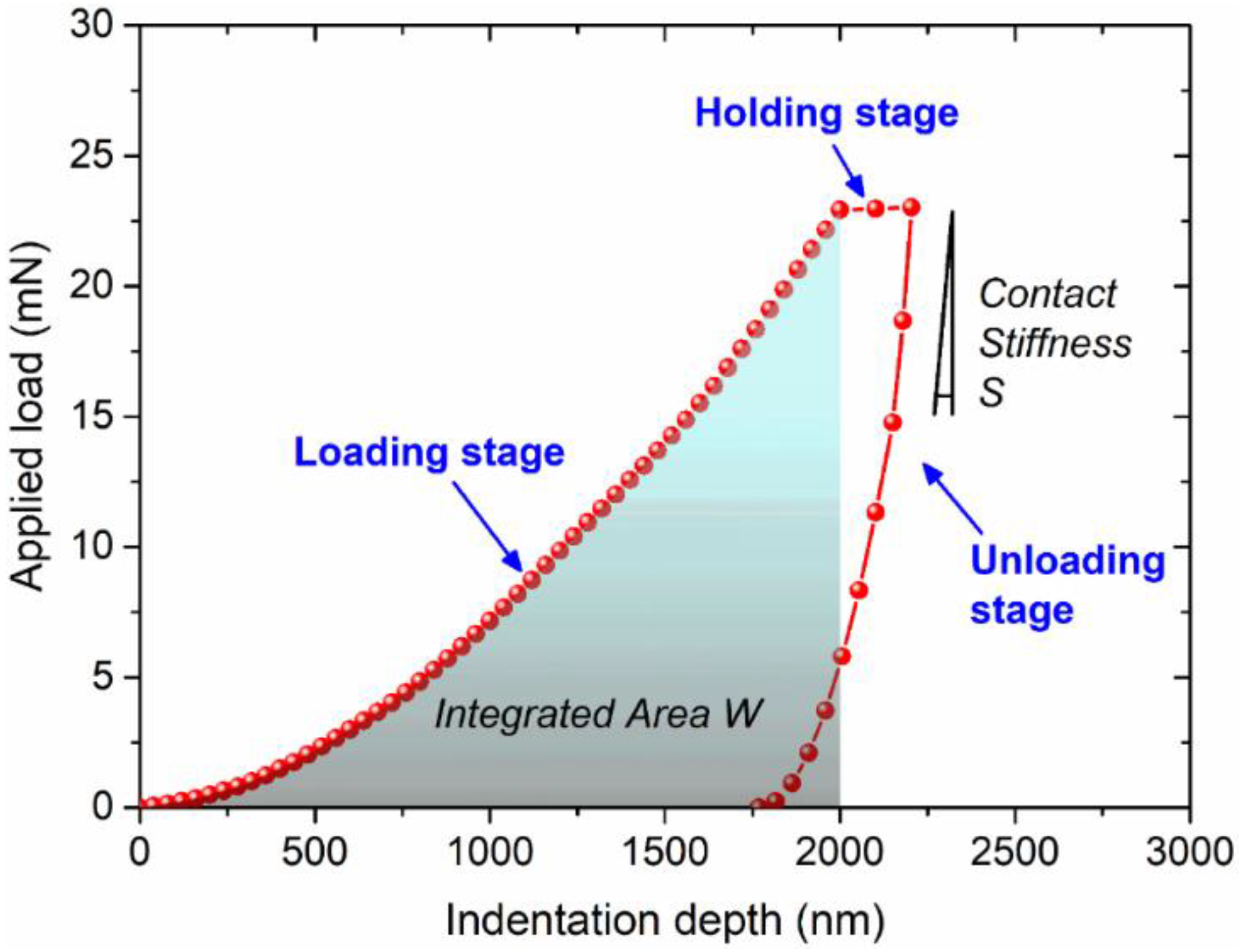

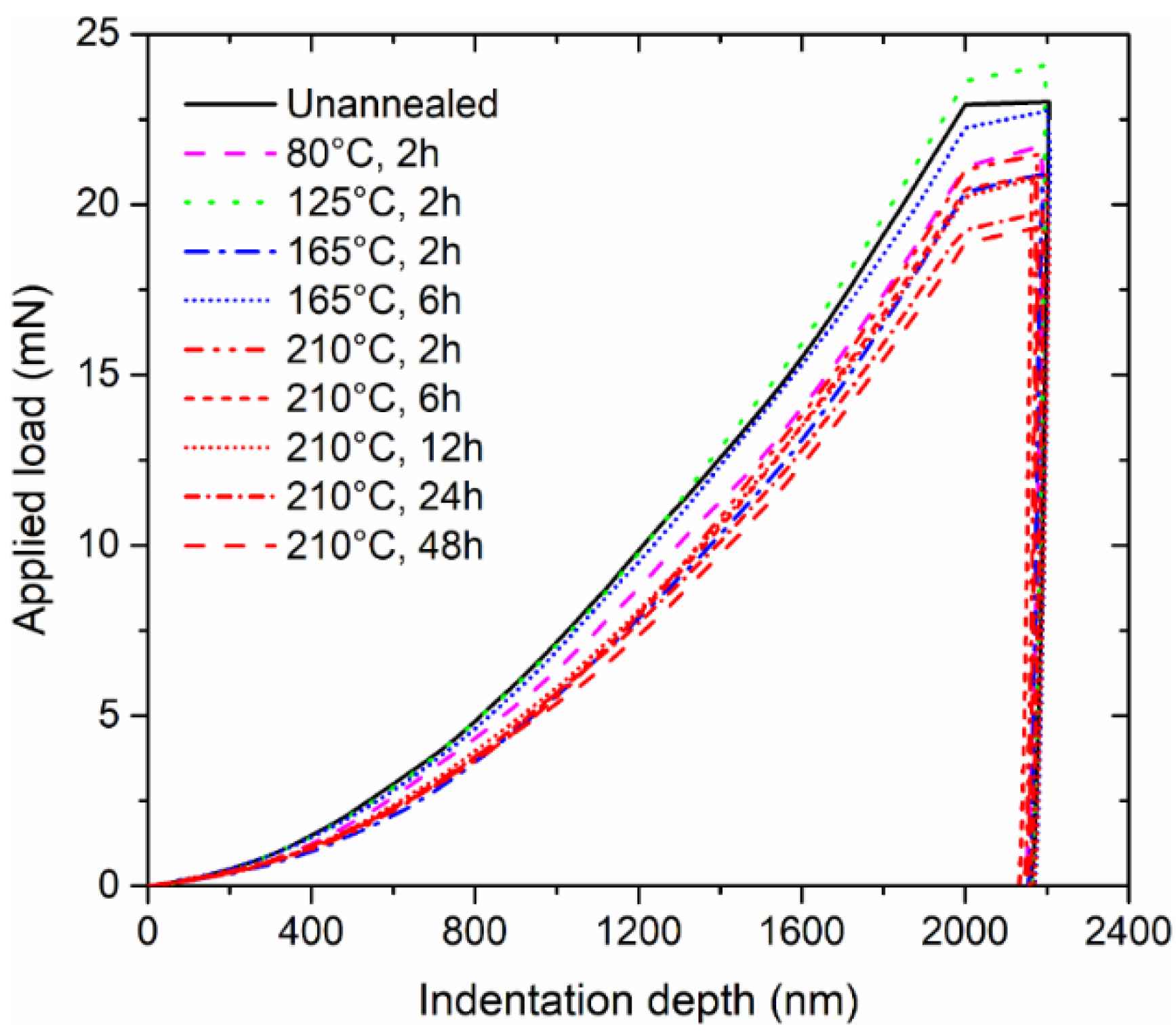

3.1. Averaged Nanoindentation Response

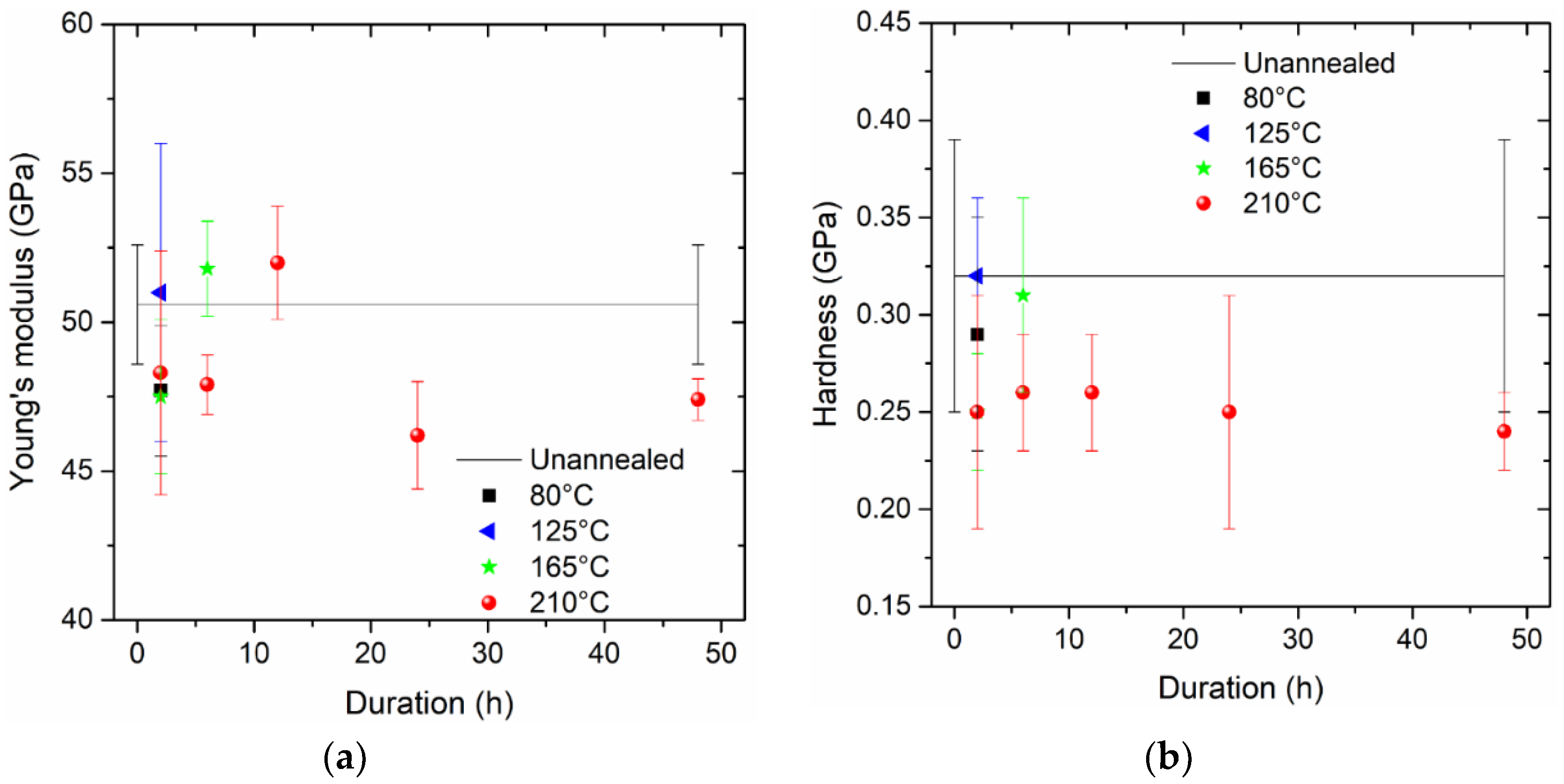

3.2. Young’s Modulus and Hardness

4. Theoretical Analysis

5. Conclusions

- A high annealing temperature close to the melting temperature, with a sufficient duration, benefits the alleviation of residual stress and the stabilization of microstructure, with fewer micro-defects. The constitutive behaviour of SAC305 solder annealed at 210 °C can be used for parameter calibrations.

- Rate factors and are proposed and determined to be 0.52 and 0.10, to respectively multiply the representative stress and stress exponent for characterizing the integrated work done and the contact stiffness for the loading and unloading stages of nanoindentation responses.

- The proposed analytical methodology and rate factors can be applicable to other metals and alloys, provided that the material sample of interest is without significant residual stress.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Keyes, R.W. The Impact of Moore’s Law. IEEE Solid-State Circuits Soc. Newsl. 2006, 11, 25–27. [Google Scholar] [CrossRef]

- Saleh, M.S.; Hu, C.; Panat, R. Three-dimensional microarchitected materials and devices using nanoparticle assembly by pointwise spatial printing. Sci. Adv. 2017, 3, e1601986. [Google Scholar] [CrossRef] [PubMed]

- Frear, D.R. Issues related to the implementation of Pb-free electronic solders in consumer electronics. J. Mater. Sci. Mater. Electron. 2007, 18, 319–330. [Google Scholar] [CrossRef]

- Zhang, L.; Tu, K.N. Structure and properties of lead-free solders bearing micro and nano particles. Mater. Sci. Eng. R 2014, 82, 1–32. [Google Scholar] [CrossRef]

- Xu, S.; Habib, A.H.; Pickel, A.D.; Mchenry, M.E. Magnetic nanoparticle-based solder composites for electronic packaging applications. Prog. Mater. Sci. 2015, 67, 95–160. [Google Scholar] [CrossRef]

- Long, X.; Tang, W.; Feng, Y.; Chang, C.; Keer, L.M.; Yao, Y. Strain rate sensitivity of sintered silver nanoparticles using rate-jump indentation. Int. J. Mech. Sci. 2018, 140, 60–67. [Google Scholar] [CrossRef]

- Zhang, Z.L.; Ni, Y.S.; Zhang, J.M.; Wang, C.; Ren, X.D. Multiscale analysis of size effect of surface pit defect in nanoindentation. Micromachines 2018, 9, 11. [Google Scholar] [CrossRef] [PubMed]

- Bo, W.; Wang, W.; Wang, Y.; Liu, B.; Liu, L. Dynamical modeling and analysis of viscoelastic properties of single cells. Micromachines 2017, 8, 171. [Google Scholar]

- Rengel, M.A.M.; Gomez, F.J.; Rico, A.; Ruiz-Hervias, J.; Rodriguez, J. Obtention of the constitutive equation of hydride blisters in fuel cladding from nanoindentation tests. J. Nucl. Mater. 2017, 487, 220–228. [Google Scholar] [CrossRef]

- Lee, D.-H.; Choi, I.-C.; Yang, G.; Lu, Z.; Kawasaki, M.; Ramamurty, U.; Schwaiger, R.; Jang, J.-I. Activation energy for plastic flow in nanocrystalline CoCrFeMnNi high-entropy alloy: A high temperature nanoindentation study. Scr. Mater. 2018, 156, 129–133. [Google Scholar] [CrossRef]

- Chu, Q.; Zhang, M.; Li, J.; Yan, F.; Yan, C. Investigation of microstructure and fracture toughness of Fe-Zr welded joints. Mater. Lett. 2018, 231, 134–136. [Google Scholar] [CrossRef]

- Hsueh, C.H.; Liao, M.J.; Wang, S.H.; Tsai, Y.T.; Yang, J.R.; Lee, W.S. Size effect and strain induced double twin by nanoindentation in DSS weld metal of vibration-assisted GTAW. Mater. Chem.Phys. 2018, 219, 40–50. [Google Scholar] [CrossRef]

- Schwaiger, R.; Moser, B.; Dao, M.; Chollacoop, N.; Suresh, S. Some critical experiments on the strain-rate sensitivity of nanocrystalline nickel. Acta Mater. 2003, 51, 5159–5172. [Google Scholar] [CrossRef]

- Phani, P.S.; Oliver, W.C. A direct comparison of high temperature nanoindentation creep and uniaxial creep measurements for commercial purity aluminum. Acta Mater. 2016, 111, 31–38. [Google Scholar] [CrossRef]

- Humphrey, R.T.; Jankowski, A.F. Strain-rate sensitivity of strength in macro-to-micro-to-nano crystalline nickel. Surf. Coat. Technol. 2011, 206, 1845–1849. [Google Scholar] [CrossRef]

- Dean, J.; Wheeler, J.M.; Clyne, T.W. Use of quasi-static nanoindentation data to obtain stress–strain characteristics for metallic materials. Acta Mater. 2010, 58, 3613–3623. [Google Scholar] [CrossRef]

- Fu, K.; Chang, L.; Zheng, B.; Tang, Y.; Wang, H. On the determination of representative stress–strain relation of metallic materials using instrumented indentation. Mater. Des. 2015, 65, 989–994. [Google Scholar] [CrossRef]

- Tho, K.K.; Swaddiwudhipong, S.; Liu, Z.S.; Zeng, K. Simulation of instrumented indentation and material characterization. Mater. Sci. Eng. A 2005, 390, 202–209. [Google Scholar] [CrossRef]

- Long, X.; Feng, Y.; Yao, Y. Cooling and annealing effect on indentation response of lead-free solder. Int. J. Appl. Mech. 2017, 9, 1750057. [Google Scholar] [CrossRef]

- Long, X.; Du, C.Y.; Li, Z.; Guo, H.C.; Yao, Y.; Lu, X.Z.; Hu, X.W.; Ye, L.L.; Liu, J. Finite element analysis of constitutive behaviour of sintered silver nanoparticles under nanoindentation. Int. J. Appl. Mech. 2018, 10, 1–17. [Google Scholar]

- Long, X.; He, X.; Yao, Y. An improved unified creep-plasticity model for SnAgCu solder under a wide range of strain rates. J. Mater. Sci. 2017, 52, 6120–6137. [Google Scholar] [CrossRef]

- Long, X.; Tang, W.; Xu, M.; Keer, L.M.; Yao, Y. Electric current-assisted creep behaviour of Sn–3.0Ag–0.5Cu solder. J. Mater. Sci. 2018, 53, 6219–6229. [Google Scholar] [CrossRef]

- Annual Book of ASTM Standards. Standard Test Methods for Tension Testing of Metallic Materials; American Association State: West Conshohocken, PA, USA, 2009. [Google Scholar]

- Long, X.; Wang, S.; Feng, Y.; Yao, Y.; Keer, L.M. Annealing effect on residual stress of Sn-3.0Ag-0.5Cu solder measured by nanoindentation and constitutive experiments. Mater. Sci. Eng. A 2017, 696, 90–95. [Google Scholar] [CrossRef]

- Long, X.; Wang, S.; He, X.; Yao, Y. Annealing optimization for tin-lead eutectic solder by constitutive experiment and simulation. J. Mater. Res. 2017, 32, 1–11. [Google Scholar] [CrossRef]

- Bai, N.; Chen, X. A new unified constitutive model with short- and long-range back stress for lead-free solders of Sn–3Ag–0.5Cu and Sn–0.7Cu. Int. J. Plast. 2009, 25, 2181–2203. [Google Scholar] [CrossRef]

- Kim, K.S.; Huh, S.H.; Suganuma, K. Effects of cooling speed on microstructure and tensile properties of Sn–Ag–Cu alloys. Mater. Sci. Eng. A 2002, 333, 106–114. [Google Scholar] [CrossRef]

- Ochoa, F.; Williams, J.J.; Chawla, N. Effects of cooling rate on the microstructure and tensile behavior of a Sn-3.5wt.%Ag solder. J. Electron. Mater. 2003, 32, 1414–1420. [Google Scholar] [CrossRef]

- Long, X.; Tang, W.; Wang, S.; He, X.; Yao, Y. Annealing effect to constitutive behavior of Sn–3.0Ag–0.5Cu solder. J. Mater. Sci. Mater. Electron. 2018, 29, 1–11. [Google Scholar] [CrossRef]

- Hay, J.; Agee, P.; Herbert, E. Continuous stiffness measurement during instrumented indentation testing. Exp. Tech. 2010, 34, 86–94. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. Improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Ogasawara, N.; Chiba, N.; Chen, X. Measuring the plastic properties of bulk materials by single indentation test. Scr. Mater. 2006, 54, 65–70. [Google Scholar] [CrossRef]

- Lucas, B.N.; Oliver, W.C. Indentation power-law creep of high-purity indium. Metall. Mater. Trans. A 1999, 30, 601–610. [Google Scholar] [CrossRef]

- Atkins, A.G.; Tabor, D. Plastic indentation in metals with cones. J. Mech. Phys. Solids 1965, 13, 149–164. [Google Scholar] [CrossRef]

- Maier, V.; Durst, K.; Mueller, J.; Backes, B.; Höppel, H.W.; Göken, M. Nanoindentation strain-rate jump tests for determining the local strain-rate sensitivity in nanocrystalline Ni and ultrafine-grained Al. J. Mater. Res. 2011, 26, 1421–1430. [Google Scholar] [CrossRef]

- Patel, D.K.; Kalidindi, S.R. Correlation of spherical nanoindentation stress-strain curves to simple compression stress-strain curves for elastic-plastic isotropic materials using finite element models. Acta Mater. 2016, 112, 295–302. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Long, X.; Zhang, X.; Tang, W.; Wang, S.; Feng, Y.; Chang, C. Calibration of a Constitutive Model from Tension and Nanoindentation for Lead-Free Solder. Micromachines 2018, 9, 608. https://doi.org/10.3390/mi9110608

Long X, Zhang X, Tang W, Wang S, Feng Y, Chang C. Calibration of a Constitutive Model from Tension and Nanoindentation for Lead-Free Solder. Micromachines. 2018; 9(11):608. https://doi.org/10.3390/mi9110608

Chicago/Turabian StyleLong, Xu, Xiaodi Zhang, Wenbin Tang, Shaobin Wang, Yihui Feng, and Chao Chang. 2018. "Calibration of a Constitutive Model from Tension and Nanoindentation for Lead-Free Solder" Micromachines 9, no. 11: 608. https://doi.org/10.3390/mi9110608

APA StyleLong, X., Zhang, X., Tang, W., Wang, S., Feng, Y., & Chang, C. (2018). Calibration of a Constitutive Model from Tension and Nanoindentation for Lead-Free Solder. Micromachines, 9(11), 608. https://doi.org/10.3390/mi9110608