1. Introduction

In the past years, there has been a significant increase in the use of continuous flow reactors in organic syntheses [

1,

2,

3,

4,

5]. A variety of reactors have been demonstrated in the synthesis of numerous organic reactions [

6]. One of the fastest areas of development is photochemical organic synthesis [

1,

7]. These reactions have found a wide application in the fields of pharmaceutical, polymer, analytical and medicinal chemistry. For many years, bath reactors were used frequently both in industry and academia. Two general types of bath reactors are commonly used: immersion-well and chamber reactors. The first one uses a single low, medium or high-pressure mercury (Hg) lamp placed in the very center of double-walled immersion well: the reaction medium surrounds the Hg lamp in a separate vessel, which makes the process effective. Chamber reactors use an external array of fluorescent tubes with internal reaction flasks (e.g., flash tubes or Schlenk flasks). This configuration of source of light and reaction flasks allows for multiple reaction synthesis at the same time. Both types are widely known and used, despite their disadvantages, e.g., they are big and expensive, parts of a reactor are exposed to strong UV radiation and thermal stresses, thus have to be exchanged regularly, and the immense volume of reagents causes poor mass and heat transfer. Due to these limitations of the bath reactors, coil based reactors (CBR) for photochemistry have become popular [

8]. They are usually made of commercially available tubings made of inert fluoropolymers like polytetrafluoroethylene (PTFE), ethylene-tetrafluoroethylene (ETFE) or perfluoroalkoxy copolymer (PFA), and the most popular—fluorinated ethylene propylene (FEP). The tubings typically have an outer diameter of 1/8″ or 1/16″ and various inner diameters (e.g., 0.01″, 0.02″, 0.03″, etc.). The design of CBR usually involves a long FEP tubing wrapped tightly around a cylindrical ultraviolet (UV) lamp. After being mixed, the reagents run through the tube, which has a sufficiently low inner diameter for the light to penetrate through it and interact with reagents. To increase the efficiency of the reactor, multiple layers of the tube can be used [

9]. In the CBR photoreactor the residence time of reactants in the tube is determined by the volume of the tubing and the flow of the liquid (parameter set on the syringe pumps). The temperature can be easily controlled by putting tubes inside a thermostatic unit. This type of a microreactor is widely and successfully used in many applications, mostly because it is easy to build with FEP tubes and cost-effective.

For organic photosynthesis involving UV irradiation, FEP is an ideal material due to its good transmission properties, excellent physical properties (e.g., it can withstand relatively high temperatures and mechanical stresses) and superb chemical resistance to organic solvents. FEP is commercially available in a wide range of diameters, thus its use in photo-reactors is cost-efficient. However, the use of fluorpolymer tube for microreactors has disadvantages. Tube microreactors are prone to clogging, especially if the product precipitates. These reactors are not easy to disassemble for cleaning and general maintenance, e.g., FEP and other polymers degrade after long irradiation times. Finally, high purity polymers have to be used in the leaching of plasticizers from polymer which can have a negative impact of photocatalytic process.

Together with the rise of microfluidics, a new type of flow reactors, known as microfluidic reactors, were developed [

10,

11]. They consist of two plates of polymer (i.e., polycarbonate (PC) or polymethylmethacrylate (PMMA)), elastomer (i.e., PDMS) or glass with a microchannels cross-section of below 1 mm

2. The channels are usually micromachinned via computer numerical controlled (CNC) milling machines (PC, PTFE, PMMA and other polymers with high Young module), made via soft photolithography (polydimethylsiloxane (PDMS)) or hot embossing (PMMA, cyclic olefin copolymer (COC)). Usually, bonding of two separate plates of polymer is done at elevated temperatures (i.e., heating both plates to temperature around of melting point of polymer and using high pressure to merge them [

12]) or chemical methods, where both plates are modified chemically on the surface to ensure permanent covalent connection [

13]. Also, different types of glue can be used to bond two plates [

14]. All these methods fail when our material of choice for the microreactor is a fluorinated polymer, i.e., PTFE or FEP. Fluorinated polymers possess high melting temperature (for FEP it is ca. 260 °C). Therefore, thermal bonding can be challenging. They are also chemically inert and possess low surface energy; thus, no chemical modification or gluing is possible. Existing microfabrication techniques suitable for fluoropolymers include synchrotron radiation direct photoetching [

15,

16], argon ion beam [

17,

18], or magnetically controlled reactive ion etching [

19]. None of these techniques was applied for developing a microfluidic device. Sahlin et al. demonstrated a method of making microfluidic channels with the sizes down to 13 µm in FEP [

20]. The technique is based on dual-layer tubing consisting of an outer layer of PTFE and inner layer of FEP. When heated above 350 °C the outer PTFE layer shrinks, whereas the inner layer of FEP melts, thus filling all empty space inside the tubing with FEP. The structure of a channel is formed using tungsten wire as a template, which is pulled out after completion of the shrinking and melting process. This process, however, was used only for the tubing and is not applicable for raw FEP plates.

In our recent publication [

21], we have demonstrated a new approach for bonding of materials with high melting temperature or high chemical inertness. We proposed a ‘click’ system, where one plate (male) possess a tenon, whereas a second plate (female) possess a grove. The cross-section of the tenon is rectangular, its height is smaller than the depth of the groove. In addition, the width of the tenon is bigger than the width of the mortise. After placing these two plates together and compressing with a press, the tenon is pushed into the mortise. The channels for the flow of reagents are micromachinned in the male plate, so after mechanical bonding with a press there is a microfluidic channel between plates. To ensure the tightness of the chip, the difference between the width of the tenon and the width of groove should be between 30 µm and 50 µm. Detailed parameters and information about the ‘click’ system can be found in Szymborski et al. [

21].

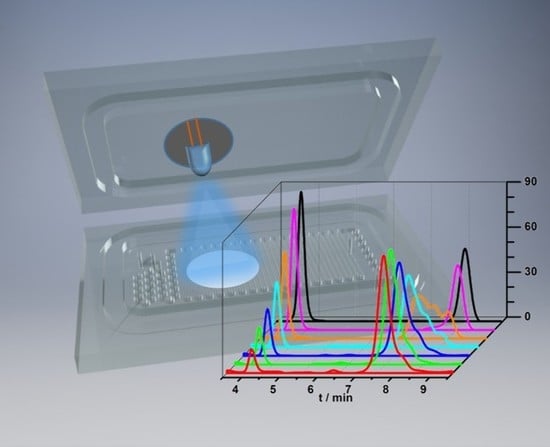

In this paper, we demonstrate the use of a ‘click’ system for development of an FEP based photoreactor. We have used transparent FEP plates with micromachinned ‘click’ system and microchannel for performing organic photosynthesis. Also, we developed a special holder made of non-transparent materials with an opening for UV-lamp or custom-made UV-module. The photoreactor is compressed with a holder and M5 screws, which ensures no leakage and makes no UV radiation available outside the microreactor. Our microreactor is compact (consists of equivalent of 75 cm of FEP tube, yet the whole chip is 32 cm2), and easy to disassemble and clean. The use of CNC micromachining allows us to design any microfluidic geometry, which makes it a very versatile system.

Below we provide proof-of-concept demonstrations of two photoreactions: (i) bromination of indanone with N-bromosuccinimide and (ii) thiol-ene reaction. The simple design and properties of FEP-based microreactor (low cost, small dimensions, easy to disassemble and clean) makes them very attractive for photochemical applications.

2. Materials and Methods

2.1. Materials

Symalit® FEP was bought from Quadrant Group (Quadrant Group Limited, Burgess Hill, UK) in a form of 5 mm thick plates. For the holder, we used two different materials: the transparent holder (to visualize the flow inside the photoreactor) was cut from a 10 mm thick polycarbonate (PC) sheet Makrolon® (Covestro Plastics, Leverkusen, Germany). The non-transparent holder (for making photochemical synthesis) was made from an extruded 10 mm PE sheet, from Plastics Group Sp. z o.o. (Warsaw, Poland).

Substrates for organic synthesis: 1-indanon, N-bromosuccinimide, 2,4,6-tris(allyloxy)-1,3,5-triazine, methyl mercaptoacetate and diphenyl(2,4,6-trimethylbenzoyl)phosphine oxide were bought from Sigma-Aldrich (St. Louis, MO, USA) and used as received, without additional purification. Acetonitryle (HPLC grade) was bought from POCh S.A. (Gliwice, Poland).

Products were analyzed with high performance liquid chromatography (HPLC); refractive index detector (RID) RID-6A and ultraviolet–visible spectroscopy (UV/Vis) SPD-6A, both Shimadzu (Shimadzu Corporation, Kyoto, Japan) and column Kromasil 100-C18 Sigma-Aldrich, 5 µm. The column was 250 × 4 mm with additional precolumn.

2.2. Spectral Analysis of Fluorinated Ethylene Propylene (FEP)

First, we checked transparency of FEP plates for UV-Vis radiation at the typical range of wavelength that are used in photochemical reactions. We demonstrate a comparison of transmittance in the function of wavelength for three polymers: polytetrafluoroethylene (PTFE), polycarbonate (PC) and fluorinated ethylene propylene (FEP). For the test we used plates with 2 mm thickness and dimensions 10 mm × 40 mm. After cleaning the surface with isopropanol, the plate was placed in a UV/Vis spectrophotometer (Thermo Scientific™, type Evolution 201, Waltham, MA, USA) and transmittance was measured from 200 nm up to 650 nm. We also measured the density of power of the UV diode we used in the experiments. The measurements were performed with a laser power meter (Ophir, Vega, Ophir Optronics, Jerusalem, Israel) for air, 2 mm thick FEP and 5 mm thick FEP plate (see

Supplemental Figures S1–S3 for details).

2.3. Preparation of the FEP Microreactor

Fabrication of the microreactor comprised of several steps. We start with a computer aided design (AutoCAD, version 2017, Autodesk, Inc., San Rafael, CA, USA). A design of the microreactor including the ‘click’ system and the channels/holes inside the chip must be made in a CAD or computer aided manufacturing (CAM) software. We used MasterCAM X2 (CNC Software, Inc., Tolland, CT, USA), to design the chip and to prepare the G-code file for the CNC machine (MSG4025, Ergwind, Poland, operated with cncGraf).

Figure S4 shows the chip with channels, holes and a ‘click’ system on the edge of the chip. We then cut the FEP plate into a size suitable for a CNC machine holder (120 mm × 140 mm) and cleaned the plate with acetone to remove dust and organic pollutants. We milled the ‘click’ system and the microchannels in a single session without removing the FEP plate from the work table. Afterwards, we drilled holes of 0.80 mm in diameter for the inlets and outlets. After machining we removed the plate, cut the microreactor out from the plate, removed residues of FEP particles with compressed air and washed it with water and acetone. After drying we placed both parts of the microreactor against each other and pressed them together with a hand press. In order to interface the reactor with PTFE/FEP tubing, we placed short steel needles into the ports.

Due to the low friction coefficient of FEP we used an additional holder with openings for M6 bolts to additionally compress both plates. The holder was CNC machined with black, non-transparent polyethylene (PE) plate (10 mm thick), thus it cuts off the UV light from inside of the microreactor. In the center of the holder we created a circular opening (23 mm in diameter) for placing a commercial UV lamp or custom-made UV light-emitting diode (LED) illumination.

2.4. Leak Tests of the Microreactor

Fluidic tightness of microreactors used for organic synthesis is essential. Firstly, many reactions, especially organometallic, are very sensitive to oxygen and moisture contained in the air. Therefore, it is essential to isolate reactants inside the microreactor from the external environment (i.e., air). Secondly, leaks of the reactants or their products may be hazardous, e.g., BuLi can ignite in contact with the air. Also, products of reaction can be toxic; therefore, nothing should leak from the reactor. We have already thoroughly checked the microreactor with a ‘click’ system for tightness [

21]. We verified the tightness of the tenon-grove junction and possible flow between microchannels. The microreactor was placed in the holder which consisted of two plates made of PC (both 10 mm thick). The results for PTFE showed that this junction is very tight, and no flow outside the channels is possible. In this paper, since the FEP is a transparent polymer, to visualize the flow inside the microreactor we used ethanol (99.8%) with Oil Blue and isopropanol with Red Oil to increase the contrast of the liquid inside the microchannel and visualize the flow. That gave us information about the flow inside microchannels and possible leakages to the grove. Additionally, we tested our microreactor for maximum working pressure. To do that we placed the microreactor with tubings into a water container. Then the outlet was closed and we pumped pressurized air to the inlet of the chip. In addition we monitored the pressure using the manometer attached to the inlet of the chip. The air pressure was increased till we observed the unsealing of the microreactor, i.e., the air bubbles. Please see

Supplemental Materials, Figure S5 for the picture of the experimental setup.

2.5. Photoreactions Using the FEP Microreactor

We give a proof-of-concept by making two photochemical synthesises. The first reaction was bromination of 1-indanon (

1) with N-bromosuccinimide (

2) in acetonitrile and second was thiol-ene reaction with the use of 2,4,6-tris(allyloxy)-1,3,5-triazine (

4), methyl mercaptoacetate (

5) and diphenyl(2,4,6-trimethylbenzoyl)phosphine oxide (

6) as an organic photoinitiator. The scheme of synthesis is demonstrated in

Figure 1.

4. Conclusions

For organic photosynthesis involving UV irradiation, FEP is an ideal material due to its good transmission properties, excellent physical properties (e.g., the ability to withstand relatively high temperatures and mechanical stresses) and superb chemical resistance to organic solvents. Moreover, FEP is commercially available in a wide range of diameters; thus, its use in photo-reactors is cost-efficient. Therefore, FEP is an attractive material that can be used in the mass-production of microfluidic devices, that are dedicated to photochemical reactions. However, the level of transmittance (ca. 4% for wavelength 371 nm) may be too low for some photochemical reactions which need higher power density. This problem can be overcome with more powerful UV LED or a matrix of UV diodes, which should increase power density. Also, we can increase the length of the main channel, and thus increase the time of interaction of UV radiation with substrates.

Here, we have presented the use of an FEP microrector for photochemical reactions. Two different types of organic reaction: bromination and thiol-ene ‘click’ reactions were tested in the function of UV power and/or flow rate. We demonstrated that our FEP microreactor can be used in the laboratory during the photochemical reactions without the use of a fume hood or Schlenk line. Moreover, commonly-used FEP tubing reactors can be replaced by FEP compact microreactors that can be easily designed to the established photochemical reaction. The simplicity and versatility of our system makes our microreactor a potential new tool in every organic or metaloorganic laboratory.