CO2 Laser-Based Rapid Prototyping of Micropumps

Abstract

:1. Introduction

2. Materials and Methods

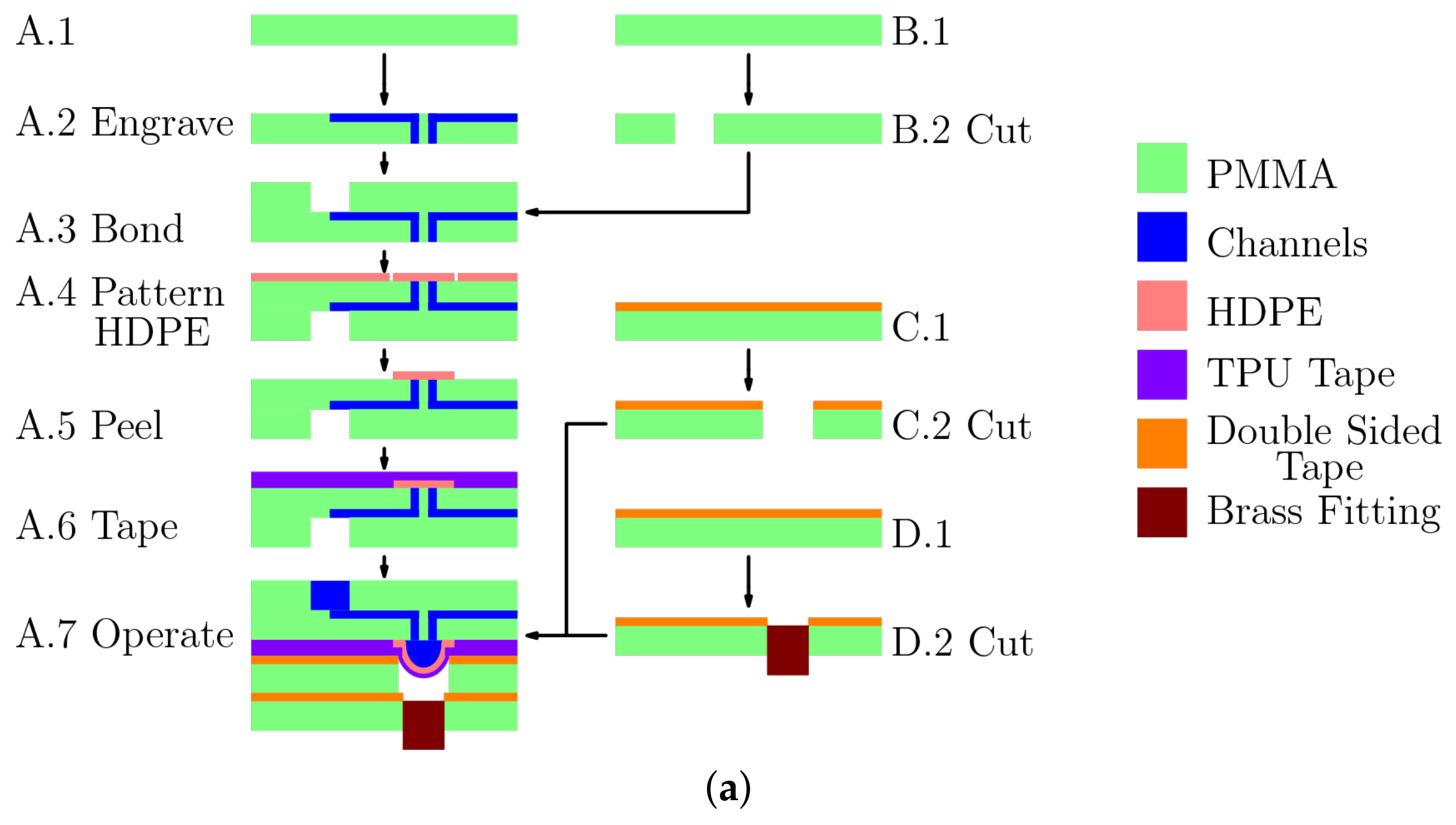

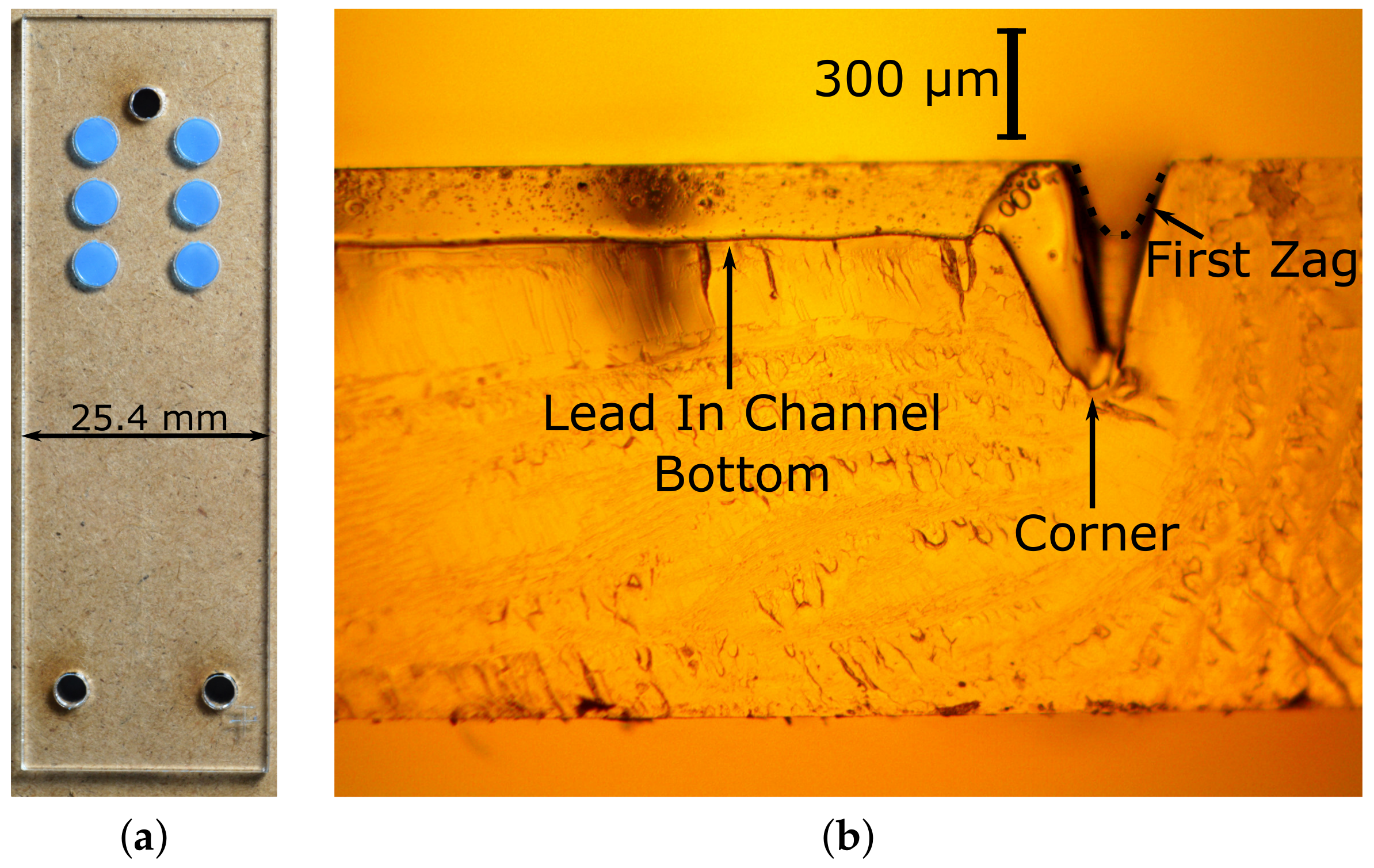

2.1. Fabrication

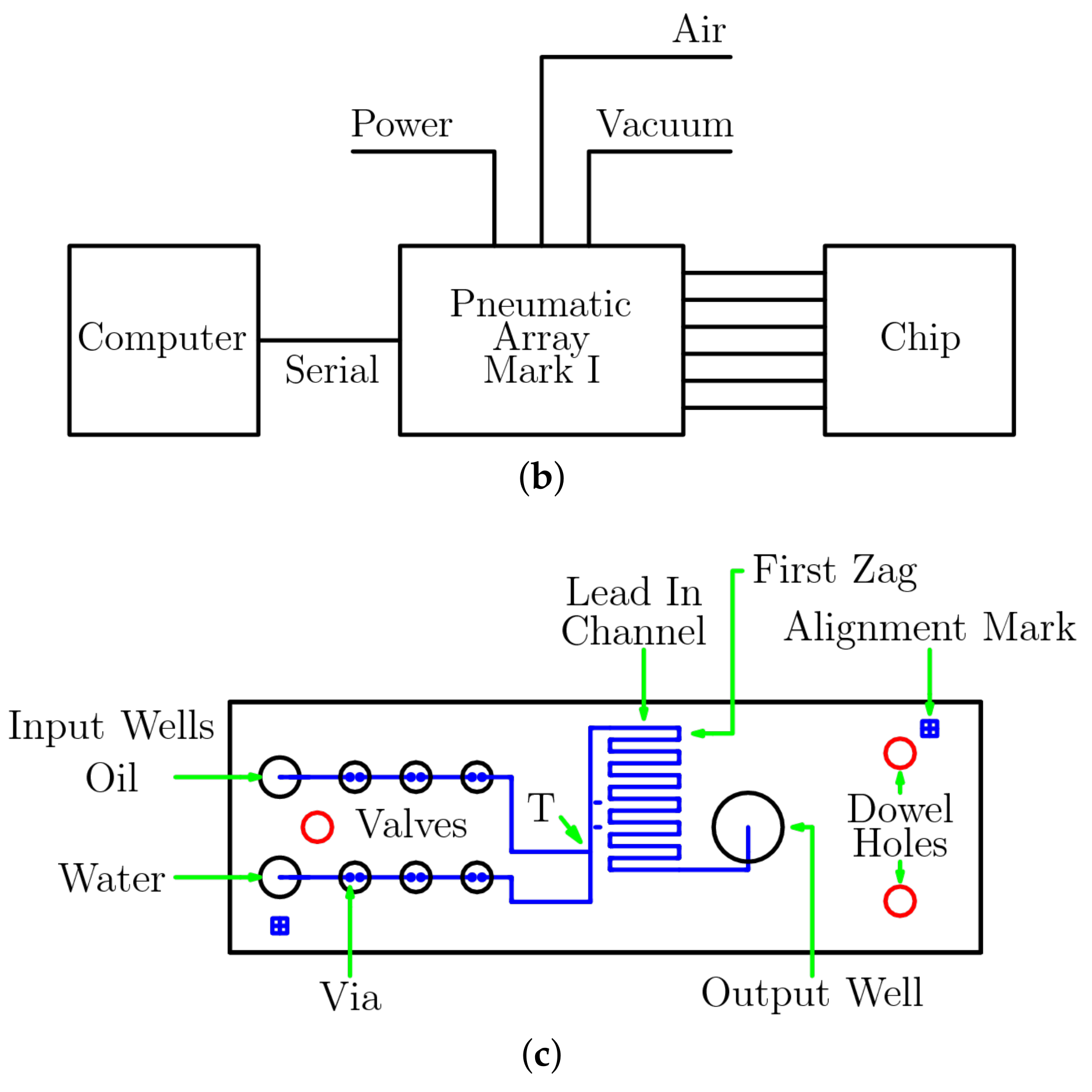

2.2. Operation

2.3. Measurement

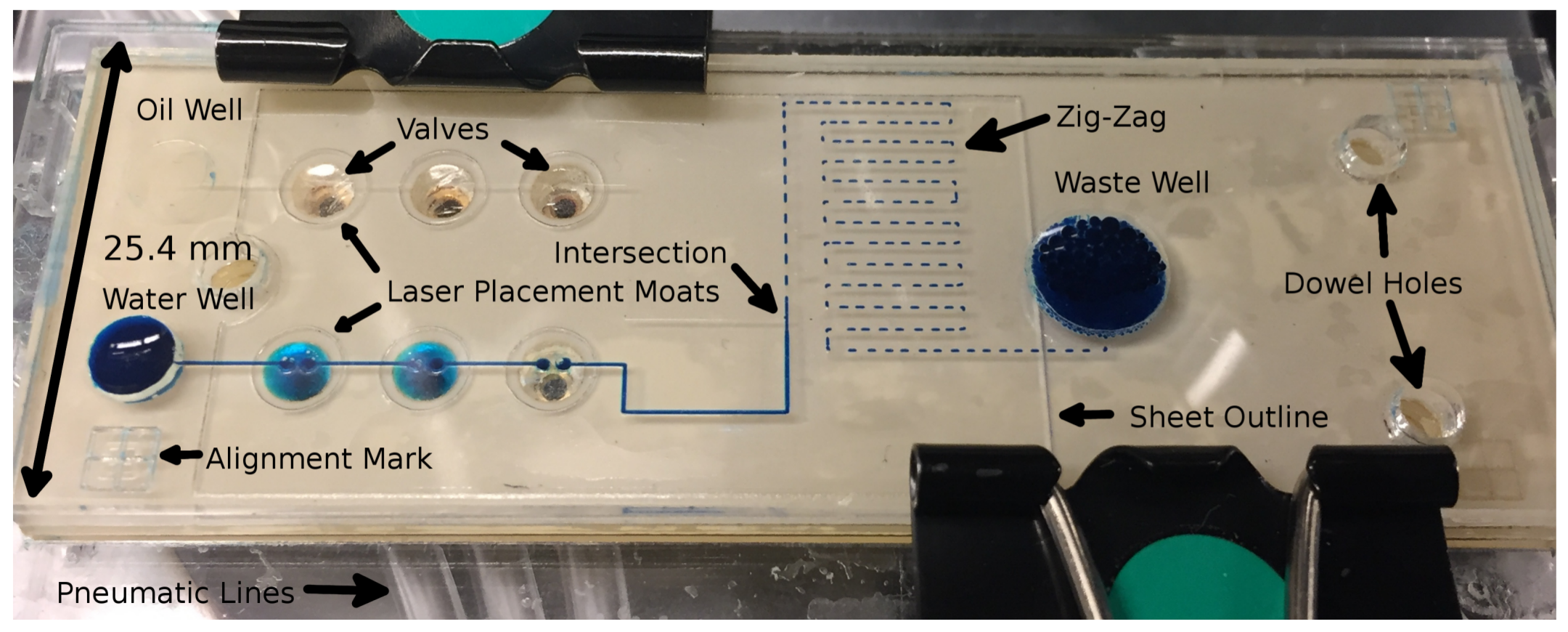

3. Results

4. Discussion

Supplementary Materials

Author Contributions

Acknowledgments

Conflicts of Interest

Abbreviations

| CAM-LEM | computer-aided manufacturing of laminated engineering materials |

| COC | cyclic olefin copolymer |

| HDPE | high density polyethylene |

| LOM | laminated object manufacturing |

| LATP | laser-assisted tape placement |

| MDM | mechanical displacement micropumps |

| PC | polycarbonate |

| PDMS | polydimethylsiloxane |

| PET | polyethylene terephthalate |

| PMMA | poly(methyl methacrylate) |

| PS | polystyrene |

| PTFE | polytetrafluoroethylene |

| TPU | thermoplastic polyurethane |

| USB | universal serial bus |

References

- Au, A.K.; Lai, H.; Utela, B.R.; Folch, A. Microvalves and micropumps for bioMEMS. Micromachines 2011, 2, 179–220. [Google Scholar] [CrossRef]

- Iverson, B.D.; Garimella, S.V. Recent advances in microscale pumping technologies: A review and evaluation. Microfluid. Nanofluid. 2008, 5, 145–174. [Google Scholar] [CrossRef]

- Laser, D.J.; Santiago, J.G. A review of micropumps. J. Micromech. Microeng. 2004, 14, R35–R64. [Google Scholar] [CrossRef]

- Oh, K.W.; Ahn, C.H. A review of microvalves. J. Micromech. Microeng. 2006, 16, R13–R39. [Google Scholar] [CrossRef]

- Unger, M.A.; Chou, H.P.; Thorsen, T.; Scherer, A.; Quake, S.R. Monolithic microfabricated valves and pumps by multilayer soft lithography. Science 2000, 288, 113–116. [Google Scholar] [CrossRef] [PubMed]

- Grover, W.H.; Skelley, A.M.; Liu, C.N.; Lagally, E.T.; Mathies, R.A. Monolithic membrane valves and diaphragm pumps for practical large-scale integration into glass microfluidic devices. Sens. Actuators B Chem. 2003, 89, 315–323. [Google Scholar] [CrossRef]

- Becker, H.; Gartner, C. Polymer microfabrication methods for microfluidic analytical applications. Electrophoresis 2000, 21, 12–26. [Google Scholar] [CrossRef]

- Becker, H.; Gartner, C. Polymer microfabrication technologies for microfluidic systems. Anal. Bioanal. Chem. 2008, 390, 89–111. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.F. Fabrication techniques for production of thermoplastic-based microfluidics Devices. J. Mol. Eng. Mater. 2016, 4, 1640016. [Google Scholar] [CrossRef]

- Liu, K.; Fan, Z.H. Thermoplastic microfluidic devices and their applications in protein and DNA analysis. Analyst 2011, 136, 1288–1297. [Google Scholar] [CrossRef] [PubMed]

- Gencturk, E.; Mutlu, S.; Ulgen, K.O. Advances in microfluidic devices made from thermoplastics used in cell biology and analyses. Biomicrofluidics 2017, 11, 051502. [Google Scholar] [CrossRef] [PubMed]

- Sollier, E.; Murray, C.; Maoddi, P.; Di Carlo, D. Rapid prototyping polymers for microfluidic devices and high pressure injections. Lab Chip 2011, 11, 3752–3765. [Google Scholar] [CrossRef] [PubMed]

- Tsao, C.W.; DeVoe, D.L. Bonding of thermoplastic polymer microfluidics. Microfluid. Nanofluid. 2009, 6, 1–16. [Google Scholar] [CrossRef]

- Weerakoon-Ratnayake, K.M.; O’Neil, C.E.; Uba, F.I.; Soper, S.A. Thermoplastic nanofluidic devices for biomedical applications. Lab Chip 2017, 17, 362–381. [Google Scholar] [CrossRef] [PubMed]

- Shaegh, S.A.M.; Pourmand, A.; Nabavina, M.; Avci, H.; Tamayol, A.; Mostafalu, P.; Ghavifekr, H.B.; Aghdam, E.N.; Dokmeci, M.R.; Khademhosseini, A.; et al. Rapid prototyping of whole-thermoplastic microfluidics with built-in microvalves using laser ablation and thermal fusion bonding. Sens. Actuators B Chem. 2018, 255, 100–109. [Google Scholar] [CrossRef]

- Pourmand, A.; Shaegh, S.A.M.; Ghavifekr, H.B.; Aghdam, E.N.; Dokmeci, M.R.; Khademhosseini, A.; Zhang, Y.S. Fabrication of whole-thermoplastic normally closed microvalve, micro check valve, and micropump. Sens. Actuators B 2018, 262, 625–636. [Google Scholar] [CrossRef]

- Huang, S.S.; He, Q.H.; Hu, X.Q.; Chen, H.W. Fabrication of micro pneumatic valves with double-layer elastic poly(dimethylsiloxane) membranes in rigid poly(methyl methacrylate) microfluidic chips. J. Micromech. Microeng. 2012, 22, 085008. [Google Scholar] [CrossRef]

- Hu, C.; Lin, S.; Li, W.B.; Sun, H.; Chen, Y.F.; Chan, C.W.; Leung, C.H.; Ma, D.L.; Wu, H.K.; Ren, K.N. A one-step strategy for ultra-fast and low-cost mass production of plastic membrane microfluidic chips. Lab Chip 2016, 16, 3909–3918. [Google Scholar] [CrossRef] [PubMed]

- Malek, C.G.K. Laser processing for bio-microfluidics applications (part I). Anal. Bioanal. Chem. 2006, 385, 1351–1361. [Google Scholar] [CrossRef] [PubMed]

- Klank, H.; Kutter, J.P.; Geschke, O. CO2-laser micromachining and back-end processing for rapid production of PMMA-based microfluidic systems. Lab Chip 2002, 2, 242–246. [Google Scholar] [CrossRef] [PubMed]

- Chung, C.K.; Chang, H.C.; Shih, T.R.; Lin, S.L.; Hsiao, E.J.; Chen, Y.S.; Chang, E.C.; Chen, C.C.; Lin, C.C. Water-assisted CO2 laser ablated glass and modified thermal bonding for capillary-driven bio-fluidic application. Biomed. Microdevices 2010, 12, 107–114. [Google Scholar] [CrossRef] [PubMed]

- Ben Azouz, A.; Vazquez, M.; Paull, B.; Brabazon, D. Laser Processing of Quartz for Microfluidic Device Fabrication. In Advanced Materials Research; Trans Tech Publications: Zürich, Switzerland, 2012; Volume 445, pp. 436–441. [Google Scholar]

- Flowers, J.; Liu, C.Q.; Mitchell, S.; Harland, A.; Esliger, D. Conductive Microfluidic Interconnects to Enable Scalable 3D Manufacturing of Wearable Electronics. In Proceedings of the IEEE 66th Electronic Components and Technology Conference (ectc), Las Vegas, NV, USA, 31 May–3 June 2016; pp. 2140–2145. [Google Scholar]

- Zhan, Y.L.; Ruan, M.; Li, W.; Li, H.; Hu, L.Y.; Ma, F.M.; Yu, Z.L.; Feng, W. Fabrication of anisotropic PTFE superhydrophobic surfaces using laser microprocessing and their self-cleaning and anti-icing behavior. Coll. Surf. A Phys. Eng. Asp. 2017, 535, 8–15. [Google Scholar] [CrossRef]

- Li, H.W.; Fan, Y.Q.; Conchouso, D.; Foulds, I.G. CO2 laser-induced bump formation and growth on polystyrene for multi-depth soft lithography molds. J. Micromech. Microeng. 2012, 22, 115037. [Google Scholar] [CrossRef]

- Chen, X.Y.; Hu, Z.L. Study aspect ratio of microchannel on different polymer substrates with CO2 laser and hot bonding for microfluidic chip. Aip Adv. 2018, 8, 015116. [Google Scholar] [CrossRef]

- Hu, Z.L.; Chen, X.Y. Fabrication of polyethylene terephthalate microfluidic chip using CO2 laser system. Int. Polym. Proc. 2018, 33, 106–109. [Google Scholar] [CrossRef]

- Cai, J.C.; Jiang, J.Y.; Gao, F.; Jia, G.N.; Zhuang, J.; Tang, G.; Fan, Y.Q. Rapid prototyping of cyclic olefin copolymer based microfluidic system with CO2 laser ablation. Microsyst. Technol. Micro Nanosyst. Inf. Storage Proc. Syst. 2017, 23, 5063–5069. [Google Scholar] [CrossRef]

- Dos Santos, G.P.; Correa, C.C.; Kubota, L.T. A simple, sensitive and reduced cost paper-based device with low quantity of chemicals for the early diagnosis of Plasmodium falciparum malaria using an enzyme-based colorimetric assay. Sens. Actuators B Chem. 2018, 255, 2113–2120. [Google Scholar] [CrossRef]

- Liu, K.; Xiang, J.Z.; Ai, Z.; Zhang, S.K.; Fang, Y.; Chen, T.; Zhou, Q.W.; Li, S.Z.; Wang, S.X.; Zhang, N.G. PMMA microfluidic chip fabrication using laser ablation and low temperature bonding with OCA film and LOCA. Microsyst. Technol. Micro Nanosyst. Inf. Storage Proc. Syst. 2017, 23, 1937–1942. [Google Scholar] [CrossRef]

- Couceiro, P.; Alonso-Chamarro, J. Microfabrication of monolithic microfluidic platforms using low temperature Co-fired ceramics suitable for fluorescence imaging. Anal. Chem. 2017, 89, 9147–9153. [Google Scholar] [CrossRef] [PubMed]

- Romoli, L.; Tantussi, G.; Dini, G. Experimental approach to the laser machining of PMMA substrates for the fabrication of microfluidic devices. Opt. Lasers Eng. 2011, 49, 419–427. [Google Scholar] [CrossRef]

- Hong, T.F.; Ju, W.J.; Wu, M.C.; Tai, C.H.; Tsai, C.H.; Fu, L.M. Rapid prototyping of PMMA microfluidic chips utilizing a CO2 laser. Microfluid. Nanofluid. 2010, 9, 1125–1133. [Google Scholar] [CrossRef]

- Yang, C.H.; Huang, K.S.; Chang, J.Y. Manufacturing monodisperse chitosan microparticles containing ampicillin using a microchannel chip. Biom. Microdev. 2007, 9, 253–259. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Kwok, Y.C.; Nguyen, N.T. Low-pressure, high-temperature thermal bonding of polymeric microfluidic devices and their applications for electrophoretic separation. J. Micromech. Microeng. 2006, 16, 1681–1688. [Google Scholar] [CrossRef]

- Hoople, G.D.; Rolfe, D.A.; McKinstry, K.C.; Noble, J.R.; Dornfeld, D.A.; Pisano, A.P. Comparison of Microscale Rapid Prototyping Techniques For Microfluidic Applications. In Proceedings of the Asme 9th International Manufacturing Science and Engineering Conference, Detroit, MI, USA, 9–13 June 2014; Volume 1, p. V001T03A001. [Google Scholar]

- Prakash, S.; Kumar, S. Experimental investigations and analytical modeling of multi-pass CO2 laser processing on PMMA. Prec. Eng. J. Int. Soc. Prec. Eng. Nanotechnol. 2017, 49, 220–234. [Google Scholar]

- Chen, X.; Li, T.; Shen, J. CO2 laser ablation of microchannel on PMMA substrate for effective fabrication of microfluidic chips. Int. Polym. Proc. 2016, 31, 233–238. [Google Scholar] [CrossRef]

- Genna, S.; Leone, C.; Lopresto, V.; Tagliaferri, V. An experimental study on the surface mechanisms formation during the laser milling of PMMA. Polym. Compos. 2015, 36, 1063–1071. [Google Scholar] [CrossRef]

- Huang, Y.G.; Liu, S.B.; Yang, W.; Yu, C.X. Surface roughness analysis and improvement of PMMA-based microfluidic chip chambers by CO2 laser cutting. Appl. Surf. Sci. 2010, 256, 1675–1678. [Google Scholar] [CrossRef]

- Mohammed, M.I.; Alam, M.N.H.Z.; Kouzani, A.; Gibson, I. Fabrication of microfluidic devices: Improvement of surface quality of CO2 laser machined poly( methylmethacrylate) polymer. J. Micromech. Microeng. 2017, 27, 015021. [Google Scholar] [CrossRef]

- Prakash, S.; Kumar, S. Profile and depth prediction in single-pass and two-pass CO2 laser microchanneling processes. J. Micromech. Microeng. 2015, 25, 035010. [Google Scholar] [CrossRef]

- Wang, Z.K.; Zheng, H.Y.; Lim, R.Y.H.; Wang, Z.F.; Lam, Y.C. Improving surface smoothness of laser-fabricated microchannels for microfluidic application. J. Micromech. Microeng. 2011, 21, 095008. [Google Scholar] [CrossRef]

- Weigl, B.H.; Badrell, R.; Schulte, T.; Battrell, F.; Hayenga, J. Design and rapid prototyping of thin-film laminate-based microfluidic devices. Biom. Microdev. 2001, 3, 267–274. [Google Scholar] [CrossRef]

- Bartholomeusz, D.A.; Boutte, R.W.; Andrade, J.D. Xurography: Rapid prototyping of microstructures using a cutting plotter. J. Microelectromech. Syst. 2005, 14, 1364–1374. [Google Scholar] [CrossRef]

- Pfleging, W.; Baldus, O. Laser patterning and welding of transparent polymers for microfluidic device fabrication. Laser Based Micropackag. 2006, 6107, 610705. [Google Scholar]

- Li, J.M.; Liu, C.; Ke, X.; Xu, Z.; Li, M.; Duan, Y.J.; Fan, Y.; Wang, L.D. Fabrication of a thermoplastic multilayer microfluidic chip. J. Mater. Proc. Technol. 2012, 212, 2315–2320. [Google Scholar] [CrossRef]

- Casalino, G.; Ghorbel, E. Numerical model of CO2 laser welding of thermoplastic polymers. J. Mater. Proc. Technol. 2008, 207, 63–71. [Google Scholar] [CrossRef]

- Coelho, J.M.P.; Abreu, M.A.; Rodrigues, F.C. Thermal modeling CO2 laser radiation transmission welding of superposed thermoplastic films. Opt. Eng. 2003, 42, 3365–3373. [Google Scholar] [CrossRef]

- Teh, K.S. Additive direct-write microfabrication for MEMS: A review. Front. Mechan. Eng. 2017, 12, 490–509. [Google Scholar] [CrossRef]

- Vaezi, M.; Seitz, H.; Yang, S.F. A review on 3D micro-additive manufacturing technologies. Int. J. Adv. Manuf. Technol. 2013, 67, 1721–1754. [Google Scholar] [CrossRef]

- Schaefer, P.M.; Gierszewski, D.; Kollmannsberger, A.; Zaremba, S.; Drechsler, K. Analysis and improved process response prediction of laser- assisted automated tape placement with PA-6/carbon tapes using Design of Experiments and numerical simulations. Compos. Part A Appl. Sci. Manuf. 2017, 96, 137–146. [Google Scholar] [CrossRef]

- Parandoush, P.; Tucker, L.; Zhou, C.; Lin, D. Laser assisted additive manufacturing of continuous fiber reinforced thermoplastic composites. Mater. Des. 2017, 131, 186–195. [Google Scholar] [CrossRef]

- Kaigala, G.V.; Behnam, M.; Bidulock, A.C.E.; Bargen, C.; Johnstone, R.W.; Elliott, D.G.; Backhouse, C.J. A scalable and modular lab-on-a-chip genetic analysis instrument. Analyst 2010, 135, 1606–1617. [Google Scholar] [CrossRef] [PubMed]

- Ogilvie, I.R.G.; Sieben, V.J.; Cortese, B.; Mowlem, M.C.; Morgan, H. Chemically resistant microfluidic valves from Viton (R) membranes bonded to COC and PMMA. Lab Chip 2011, 11, 2455–2459. [Google Scholar] [CrossRef] [PubMed]

- Roy, E.; Galas, J.C.; Veres, T. Thermoplastic elastomers for microfluidics: Towards a high-throughput fabrication method of multilayered microfluidic devices. Lab Chip 2011, 11, 3193–3196. [Google Scholar] [CrossRef] [PubMed]

- Gu, P.; Nishida, T.; Fan, Z.H. The use of polyurethane as an elastomer in thermoplastic microfluidic devices and the study of its creep properties. Electrophoresis 2014, 35, 289–297. [Google Scholar] [CrossRef] [PubMed]

- Zeng, Y.; Shin, M.; Wang, T. Programmable active droplet generation enabled by integrated pneumatic micropumps. Lab Chip 2013, 13, 267–273. [Google Scholar] [CrossRef] [PubMed]

- Moon, B.U.; Jones, S.G.; Hwang, D.K.; Tsai, S.S.H. Microfluidic generation of aqueous two-phase system (ATPS) droplets by controlled pulsating inlet pressures. Lab Chip 2015, 15, 2437–2444. [Google Scholar] [CrossRef] [PubMed]

- Hwang, S.J.; Moon, S.K.; Kim, S.E.; Kim, J.H.; Choi, S.W. Production of uniform emulsion droplets using a simple fluidic device with a peristaltic pump. Macromol. Res. 2014, 22, 557–561. [Google Scholar] [CrossRef]

- Bowman, J.C.; Hammerlindl, A. Asymptote: A vector graphics language. Commun. TeX Users Group 2008, 29, 288–294. [Google Scholar]

- Rueden, C.T.; Schindelin, J.; Hiner, M.C.; DeZonia, B.E.; Walter, A.E.; Arena, E.T.; Eliceiri, K.W. ImageJ2: ImageJ for the next generation of scientific image data. BMC Bioinform. 2017, 18, 529. [Google Scholar] [CrossRef] [PubMed]

- Preibisch, S.; Saalfeld, S.; Tomancak, P. Globally optimal stitching of tiled 3D microscopic image acquisitions. Bioinformatics 2009, 25, 1463–1465. [Google Scholar] [CrossRef] [PubMed]

- Schindelin, J.; Arganda-Carreras, I.; Frise, E.; Kaynig, V.; Longair, M.; Pietzsch, T.; Preibisch, S.; Rueden, C.; Saalfeld, S.; Schmid, B.; et al. Fiji: An open-source platform for biological-image analysis. Nat. Method. 2012, 9, 676–682. [Google Scholar] [CrossRef] [PubMed]

| Feature | Power (%) | Speed (%) | DPI | Passes | Focus Depth (mm) |

|---|---|---|---|---|---|

| Vias | 18 | 25 | 1000 | 10 | 0.7 |

| Channels | 18 | 25 | 1000 | 2 | 0.7 |

| Wells/Through-cuts | 20 | 3 | 1000 | 1 | 1.5 |

| Valve | A1 | A2 | A3 | B1 | B2 | B3 |

|---|---|---|---|---|---|---|

| Step 1 | X | O | O | O | O | X |

| Step 2 | O | X | O | O | O | X |

| Step 3 | O | O | X | O | O | X |

| Step 4 | O | O | X | X | O | O |

| Step 5 | O | O | X | O | X | O |

| Step 6 | O | O | X | O | O | X |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Strike, Z.; Ghofrani, K.; Backhouse, C. CO2 Laser-Based Rapid Prototyping of Micropumps. Micromachines 2018, 9, 215. https://doi.org/10.3390/mi9050215

Strike Z, Ghofrani K, Backhouse C. CO2 Laser-Based Rapid Prototyping of Micropumps. Micromachines. 2018; 9(5):215. https://doi.org/10.3390/mi9050215

Chicago/Turabian StyleStrike, Zachary, Kamyar Ghofrani, and Chris Backhouse. 2018. "CO2 Laser-Based Rapid Prototyping of Micropumps" Micromachines 9, no. 5: 215. https://doi.org/10.3390/mi9050215

APA StyleStrike, Z., Ghofrani, K., & Backhouse, C. (2018). CO2 Laser-Based Rapid Prototyping of Micropumps. Micromachines, 9(5), 215. https://doi.org/10.3390/mi9050215