1. Introduction

Knowing the die temperature of transistors employed in precision sensor systems is often quite important because this information can be used to mitigate the cross sensitivity of a system to temperature [

1,

2]. In this manner, temperature sensors have been employed to compensate for the temperature dependence of MEMS resonators [

1], to compensate for the curvature in a band-gap voltage reference [

2], or in temperature measurements and over-temperature protection directly. In such systems, the inaccuracy of temperature sensors is a significant component of the total error budget, and thus often limits their ultimate performance.

Wu et al. [

3] presented a thermistor-based sensor that achieved an inaccuracy of ±0.5 °C from 0 °C to 100 °C with one-point calibration. Although a thermistor-based sensor has the advantage of low power consumption, it usually requires multi-point calibration to attain high accuracy because of the non-linearity between resistance and temperature. Chen et al. [

4] proposed a time-to-digital converter based temperature sensor that achieved an inaccuracy of −0.7/+0.9 °C from 0 °C to 100 °C. Testi et al. [

5] presented a ring oscillator-based temperature sensor that achieved a maximum inaccuracy of ±3 °C from 0 °C to 120 °C after two-point calibration. While both of these latter temperature sensors have the advantage of low power consumption, they failed to achieve high accuracies.

Sensors based on bipolar junction transistors (BJTs) can achieve high accuracy because the base-emitter voltage

VBE offers advantageous temperature characteristics. Lee et al. [

6] proposed a BJT-based temperature sensor that achieved an inaccuracy of ±1 °C from −55 °C to 125 °C. Aita et al. [

7] presented a BJT-based temperature sensor that achieved an inaccuracy of ±0.25 °C from −70 °C to 130 °C using dynamic element matching (DEM).

This paper proposes a temperature sensor circuit based on BJTs for operation over the temperature range of 0 °C to 100 °C. Compared with the DEM approaches employed previously to reduce mismatch related errors [

8,

9], we propose a new DEM approach, denoted as all DEM (ALL-DEM), that provides greater temperature measurement precision by dynamically matching all current sources in the front-end circuit. Moreover, compared with the employment of a second-order sigma-delta analog-to-digital converter (ADC) [

10] and a first-order zoom ADC [

11], the sensor employs a second-order zoom ADC, which can improve the resolution and reduce the required conversion time. In addition, the temperature sensor employs voltage calibration to improve its performance.

The remainder of this paper is organized as follows.

Section 2 describes the operation of the BJT-based temperature sensor front-end circuit, and discusses its main error sources.

Section 3 discusses the proposed temperature sensor front-end circuit employing the ALL-DEM approach in detail.

Section 4 describes the structure and operating modes of a zoom ADC.

Section 5 discusses the voltage calibration and the means of conducting first-order fitting and third-order fitting.

Section 6 presents the simulation and measurement results of the chip and discusses this work.

Section 7 concludes the paper.

2. Sensor Operating Principles and Error Budgeting

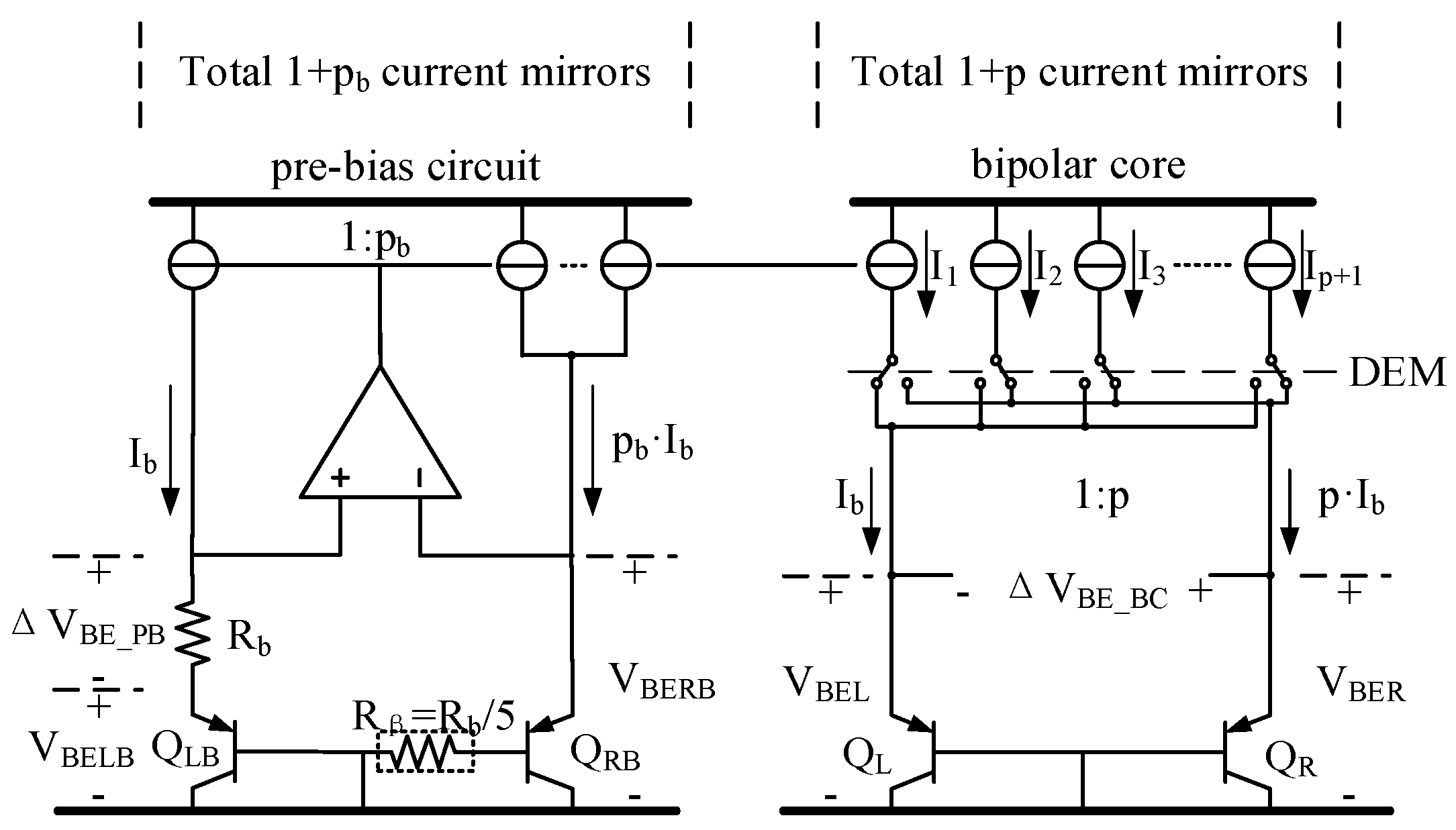

As shown in

Figure 1, the front-end circuit consists of a pre-bias circuit and a bipolar core built around several current sources, four substrate PNP transistors, and an opamp. Two branches of current with a ratio of 1:

pb bias a pair of PNPs (Q

LB and Q

RB).

The base-emitter voltages

VBE of the PNPs (

VBELB and

VBERB) are complementary to the absolute temperature (CTAT), whereas the difference between the two values of

VBE, denoted as ∆

VBE_PB, is proportional to the absolute temperature (PTAT). For a BJT, these voltages can be given by

respectively, where

η is a process-dependent nonideality factor,

k is the Boltzmann constant,

q is the electron charge,

T is the temperature in Kelvin, and

IC and

IS are the collector and saturation currents of the BJT. An opamp forces ∆

VBE_PB across a resistance of

Rb to generate a PTAT bias current

Ib = ∆

VBE_PB/

Rb. The PTAT current is mirrored to the bipolar core, and two current branches with a ratio of 1:

p are directed to two PNPs (Q

L and Q

R) to generate two additional

VBE (

VBEL and

VBER) and ∆

VBE_BC values.

Because the current gain

β of the PNPs is finite and the biasing current is directed to a PNP via its emitter, the ratio of

IC (Q

LB and Q

RB) is not the same as a current branch. Using a

β-compensating resistance of

Rβ =

Rb/5 in the pre-bias circuit suppresses the effect of

β on

VBE [

12].

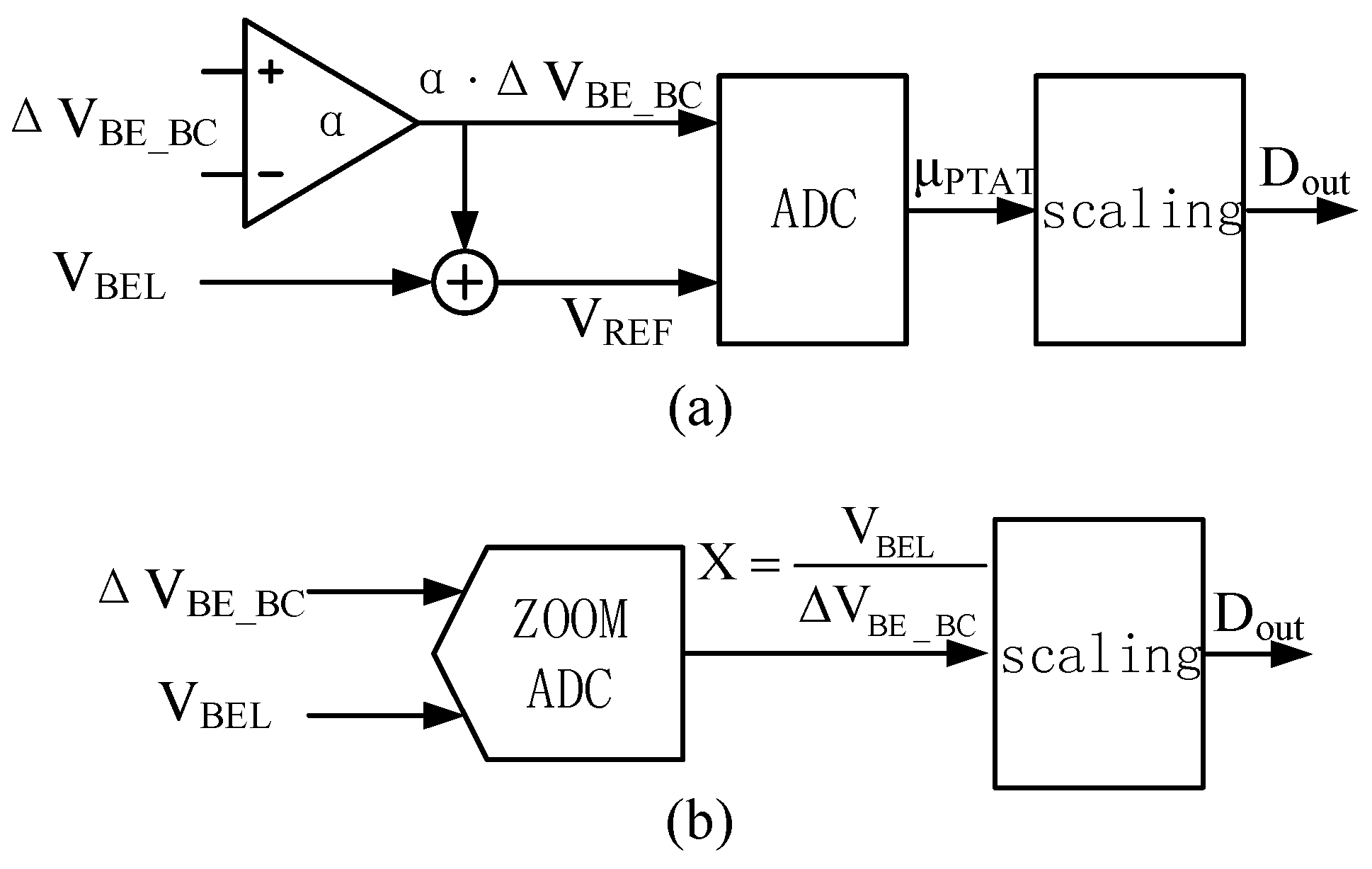

Generally, as shown in

Figure 2a, temperature can be measured as α·∆

VBE with respect to a reference voltage

VREF =

VBEL + α·∆

VBE_BC, where α is a constant [

9]. This provides the parameter

μPTAT = α·∆

VBE_BC/

VREF, which varies linearly from ~0.3 to ~0.7 over the temperature range considered [

12]. Alternatively, as shown in

Figure 2b, a zoom ADC is employed for this purpose to reduce the power consumption, die area, and required conversion time [

8,

13].

The ADC provides the parameter

X =

VBEL/∆

VBE_BC, which varies nonlinearly from ~28 to ~8 over the temperature range considered [

8]. In this case, the parameter

μPTAT can be determined in the digital back-end according to the relationship

μPTAT =

X/(

α +

X), where

α is a calibration parameter. The discretized output

Dout based on the parameter

μPTAT can then be converted to units of °C by a linear fit as follows [

8]:

Here, A and B are calibration parameters with approximate values of 600 and −273, respectively.

According to Equation (3), the sensitivity of

Dout to error in

VBEL and ∆

VBE_BC can be respectively expressed by

where the approximation

μPTAT ≈

T/

A has been employed in the final forms. For example, supposing that

VREF = 1.2 V,

A = 600, and

α = 14, a 0.1 °C temperature error is approximately equal to a 0.3 mV error in

VBEL at +126.85 °C or a 0.02 mV error in ∆

VBE_BC at −73.15 °C. Therefore, the accuracy of the sensor is limited by the error in

VBEL and ∆

VBE_BC.

The main source of error in ∆

VBE_BC is a current ratio mismatch ∆

p between the two current branches in the bipolar core. The absolute error in ∆

VBE_BC can then be given as follows:

Here,

T is in units of Kelvin. With a carefully designed layout of the current sources, ∆

p/

p = 0.1% can be expected [

14], and the temperature error due to mismatch is then 0.091 K according to Equation (5).

Error due to ∆

p can be reduced by dynamically interchanging the current sources in the bipolar core [

15] using DEM [

16]. This is illustrated for the case of the bipolar core in

Figure 1. One of the current sources is directed to Q

L, whereas the other current sources are directed to Q

R. This averaging process cancels the first-order error in ∆

VBE_BC whereas the second-order error remains, which is given as follows [

12]:

If, for instance, ∆p/p = 1%, this corresponds to a temperature error of at most 4.6 mK, which is sufficient to obtain a temperature error well below 0.1 K.

Similarly, a current ratio mismatch exists in the pre-bias circuit, which results in PTAT errors in

Ib and

VBEL. The absolute error in

VBEL can then be given as follows:

If, for example, ∆p/p = 1%, the error in VBEL corresponds to a temperature error of at most 65 mK.

To reduce temperature measurement errors, most conventional circuits match only current sources in the bipolar core dynamically [

8,

9,

13], and the mismatch in the pre-bias circuit is regarded as a relatively minor problem.

3. Temperature Sensor Front-End Circuit

According to the discussion in the previous section, a conventional circuit reduces temperature measurement errors by averaging ∆

p to some extent, but cannot make full use of the circuit because current sources in the pre-bias circuit do not participate in the averaging process. Therefore, we employed the proposed ALL-DEM approach in the temperature sensor front-end circuit, which matches all current sources in both the pre-bias circuit and bipolar core dynamically. Assuming that

pb =

p = 5, the proposed circuit is illustrated in

Figure 3.

The ALL-DEM approach employs the following steps:

Step 1: Number all current sources from 1 to 12.

Step 2: Under the control of ALL-DEM, current source 1 is directed to QLB, current sources 2–6 are directed to QRB, current source 7 is directed to QL, and current sources 8–12 are directed to QR.

Step 3: After a single integral sampling period, current sources are cyclically shifted, and Step 2 is repeated, i.e., current source 2 is directed to QLB, current sources 3–7 are directed to QRB, current source 8 is directed to QL, and current sources 9–12 and current source 1 are directed to QR.

An ALL-DEM cycle consists of 12 periods. In addition to dynamically matching the current sources in the pre-bias circuit (rather than only in the bipolar core), the ALL-DEM approach offers another advantage, in that it provides a greater number of conditions in the bipolar core compared with conventional DEM, which is increased from 6 to 12.

The ALL-DEM approach can reduce the mismatch in the pre-bias circuit, and, hence, can reduce temperature measurement errors caused by the pre-bias circuit. In addition, the proposed circuit employs chopping to suppress the offset of the opamp. The benefits of the ALL-DEM approach are demonstrated by the simulation results presented in

Figure 4, which shows the maximum temperature errors obtained with different DEM schemes. As the results show, the maximum temperature error caused by the ALL-DEM approach is at least 0.82 °C less than that obtained without the DEM approach. Moreover, the average maximum temperature error caused by the ALL-DEM approach is 0.07 °C less than that of the conventional DEM approach. The ALL-DEM approach can therefore achieve a higher accuracy than the conventional DEM approach.

5. Calibration

Figure 6 presents an overview of the temperature sensor. It consists of a front-end circuit that generates

VBE and ∆

VBE, which are fed to the zoom ADC. The output of the zoom ADC in the normal operating mode is the ratio

XN =

VBE/∆

VBE. However, the ADC can be configured to output

Xc =

Vext /∆

VBE when the temperature sensor chip is placed in the calibration mode. A PT-100 thermistor, which was calibrated to an error of less than 1 mK and placed in good thermal contact with the temperature sensor, was used to obtain the reference temperature

Tchip [

17].

We adopted voltage calibration, which employs the following steps.

Step 1: Change the operating mode of the temperature sensor chip into the calibration mode. Then, input testing voltage

Vext, and obtain ∆

VBE as follows:

We can then calculate η using ∆VBE and Tchip according to Equation (2).

Step 2: Change the operating mode of the temperature sensor chip into the normal operating mode. Take 20 temperature reading samples over 11 testing points in the temperature range from 0 °C to +100 °C, and obtain X and Dout from each testing point, respectively. The average value XAVG at each testing point can be calculated from the values of X obtained at each testing point. Then, the calibration parameters A, B, and α can be calculated according to Equation (3).

Step 3: The voltage calibration temperature TD can be calculated using η, Equations (2) and (9).

Step 4: Then, the ideal voltage calibration output Xideal can be calculated using TD, A, B, and α according to Equation (3). In addition, we can obtain the actual output XD from the chip.

Step 5: Output

D is then obtained from

A,

B,

α,

Xideal, and

XD as follows:

Here, Equation (10) represents the first-order fitting. Actually, the fitting accuracy can be improved by adopting the following fixed third-order polynomial:

where

X’ =

X +

Xideal −

XD,

A,

B,

C, and

E are calibration parameters that are calculated in Step 1. In this paper, the voltage calibration employed single-point calibration, and the value

TD was set to 37 °C.

6. Experimental Results and Discussion

The circuit was implemented in 0.18 μm CMOS technology provided by Semiconductor Manufacturing International Corp. (SMIC, Shanghai, China), and all current sources employed a current of 180 nA. The chip consumed 6.1 μA with a 1.8 V supply voltage, where the current consumption of the front-end circuit was 4.6 μA and the current consumption of the zoom ADC was 1.5 μA. The core area of the chip was 860 μm × 580 μm. A micrograph of the chip is shown in

Figure 7.

Figure 8 presents the simulation results of the front-end circuit obtained via 20 Monte Carlo simulations. Here,

Figure 8a presents the simulation results of the first-order fitting, which exhibits 3σ-inaccuracies of +0.12/−0.06 °C from −55 °C to +125 °C. In addition,

Figure 8b presents the simulation results of the third-order fitting, which exhibits 3σ-inaccuracies of ±0.08 °C from −55 °C to +125 °C.

The simulation results of the chip are presented in

Figure 9. Here,

Figure 9a presents the results of first-order fitting, which exhibits 3σ-inaccuracies of +0.25/−0.13 °C over the temperature range considered. In addition,

Figure 9b presents the results of third-order fitting, which exhibits 3σ-inaccuracies of +0.18/−0.13 °C over the temperature range considered.

Figure 10 presents the measurement results of the chip. During measurements, we added a shielding box to improve the accuracy of the temperature sensor. As shown in

Figure 10a, the chip exhibits 3σ-inaccuracies of +0.15/−0.3 °C from 0 °C to +100 °C with first-order fitting.

Figure 10b presents the measurement results of third-order fitting, which shows that the chip can achieve 3σ-inaccuracies of ±0.2 °C from 0 °C to +100 °C.

As demonstrated by the simulation and measurement results, third-order fitting can achieve a greater measurement than first-order fitting. The measured performance of the temperature sensor is compared with the performances of previously reported state-of-the-art temperature sensor implementations in

Table 1. Because of the employment of the second-order zoom ADC, the parameter figure-of-merit (FOM) of the sensor is better than those presented in References [

6,

15], which shows that the proposed sensor provides better resolution and a reduced conversion time. However, the measurement temperature range of this work is only from 0 °C to 100 °C because of the limitations of the measurement equipment. As a result, the

Rel.InAcc value of the proposed circuit is 0.4%.

The present work has taken errors into account as much as possible and employs the ALL-DEM approach and calibration to improve the accuracy of the proposed temperature sensor. Among the remaining errors, the curvature error is the largest source of error. Therefore, a curvature calibration or a curvature compensation technology can be expected to improve the accuracies of the temperature sensor. In addition, while the BJT-based temperature sensors provide higher accuracy than thermistor-based sensors, they also require greater power consumption. A higher-order zoom ADC can reduce the power consumption, although its implementation will also require a greater die area. The miniaturization of BJT-based temperature sensors is also an important consideration, and the means of reducing the die area while simultaneously reducing the power consumption of the temperature sensor will be the objective of future research.