Manipulation of the Superhydrophobicity of Plasma-Etched Polymer Nanostructures

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

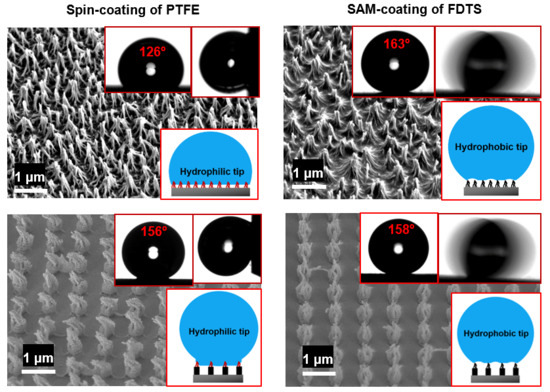

3.1. Superhydrophobicity of the Plasma-Etched Polymer Surface with Monotonous Nanostructures

3.2. Superhydrophobicity of the Plasma-Etched Polymer Surface with Hierarchical Nanostructures

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Naik, R.R.; Singamaneni, S. Introduction: Bioinspired and biomimetic materials. Chem. Rev. 2017, 117, 12581–12583. [Google Scholar] [CrossRef] [PubMed]

- Jin, S.; Wang, Y.; Motlag, M.; Gao, S.; Xu, J.; Nian, Q.; Wu, W.; Cheng, G.J. Large-area direct laser-shock imprinting of a 3D biomimic hierarchical metal surface for triboelectric nanogenerators. Adv. Mater. 2018, 30. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.H.; Warner, C.M.; Jin, H.-E.; Barnes, E.; Poda, A.R.; Perkins, E.J.; Lee, S.-W. Production of tunable nanomaterials using hierarchically assembled bacteriophages. Nat. Protoc. 2017, 12, 1999–2013. [Google Scholar] [CrossRef] [PubMed]

- Mukhopadhyay, R.D.; Vedhanarayanan, B.; Ajayaghosh, A. Creation of “rose petal” and “lotus leaf” effects on alumina by surface functionalization and metal-ion coordination. Angew. Chem. Int. Ed. 2017, 56, 16018–16022. [Google Scholar] [CrossRef] [PubMed]

- Long, J.; Fan, P.; Gong, D.; Jiang, D.; Zhang, H.; Li, L.; Zhong, M. Superhydrophobic surfaces fabricated by femtosecond laser with tunable water adhesion: From lotus leaf to rose petal. ACS Appl. Mater. Interfaces 2015, 7, 9858–9865. [Google Scholar] [CrossRef] [PubMed]

- Han, H.; Lee, J.S.; Kim, H.; Shin, S.; Lee, J.; Kim, J.; Hou, X.; Cho, S.-W.; Seo, J.; Lee, T. Single-droplet multiplex bioassay on a robust and stretchable extreme wetting substrate through vacuum-based droplet manipulation. ACS Nano 2018, 12, 932–941. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Huang, J.; Chen, Z.; Lai, Y. Bioinspired special wettability surfaces: From fundamental research to water harvesting applications. Small 2017, 13. [Google Scholar] [CrossRef] [PubMed]

- Fernández, A.; Francone, A.; Thamdrup, L.H.; Johansson, A.; Bilenberg, B.; Nielsen, T.; Guttmann, M.; Sotomayor Torres, C.M.; Kehagias, N. Design of hierarchical surfaces for tuning wetting characteristics. ACS Appl. Mater. Interfaces 2017, 9, 7701–7709. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Varshney, P.; Mohapatra, S.S.; Kumar, A. Fabrication of mechanically stable superhydrophobic aluminium surface with excellent self-cleaning and anti-fogging properties. Biomimetics 2017, 2. [Google Scholar] [CrossRef]

- Marmur, A. Wetting on hydrophobic rough surfaces: To be heterogeneous or not to be? Langmuir 2003, 19, 8343–8348. [Google Scholar] [CrossRef]

- Liu, M.; Wang, S.; Jiang, L. Nature-inspired superwettability systems. Nat. Rev. Mater. 2017, 2. [Google Scholar] [CrossRef]

- Li, H.J.; Fan, W.Z.; Pan, H.H.; Wang, C.W.; Qian, J.; Zhao, Q.Z. Fabrication of “petal effect” surfaces by femtosecond laser-induced forward transfer. Chem. Phys. Lett. 2017, 667, 20–24. [Google Scholar]

- Dorrer, C.; Ruehe, J. Wetting of silicon nanograss: From superhydrophilic to superhydrophobic surfaces. Adv. Mater. 2008, 20, 159–163. [Google Scholar] [CrossRef]

- Hu, H.; Siu, V.S.; Gifford, S.M.; Kim, S.; Lu, M.; Meyer, P.; Stolovitzky, G.A. Bio-inspired silicon nanospikes fabricated by metal-assisted chemical etching for antibacterial surfaces. Appl. Phys. Lett. 2017, 111. [Google Scholar] [CrossRef]

- Hizal, F.; Rungraeng, N.; Lee, J.; Jun, S.; Busscher, H.J.; Van der Mei, H.C.; Choi, C.H. Nanoengineered superhydrophobic surfaces of aluminum with extremely low bacterial adhesivity. ACS Appl. Mater. Interfaces 2017, 9, 12118–12129. [Google Scholar] [CrossRef] [PubMed]

- Du, K.; Liu, Y.; Wathuthanthri, I.; Choi, C.H. Dual applications of free-standing holographic nanopatterns for lift-off and stencil lithography. J. Vac. Sci. Technol. B 2012, 30. [Google Scholar] [CrossRef]

- Du, K.; Liu, Y.; Wathuthanthri, I.; Choi, C.H. Fabrication of hierarchical nanostructures using free-standing trilayer membrane. J. Vac. Sci. Technol. B 2013, 31. [Google Scholar] [CrossRef]

- Du, K.; Ding, J.; Liu, Y.; Wathuthanthri, I.; Choi, C.H. Stencil lithography for scalable micro-and nanomanufacturing. Micromachines 2017, 8, 131. [Google Scholar] [CrossRef]

- Du, K.; Ding, J.; Wathuthanthri, I.; Choi, C.H. Selective hierarchical patterning of silicon nanostructures via soft nanostencil lithography. Nanotechnology 2017, 28. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Du, K.; Wathuthanthri, I.; Xu, W.; Choi, C.H. 3-D nanofabrication using nanostructured photoresist film as free-standing appliqué. In Proceedings of the 25th International Conference on Micro Electro Mechanical Systems (MEMS), Paris, France, 29 January–2 February 2012. [Google Scholar]

- Hu, H.; Kim, H.J.; Somnath, S. Tip-based nanofabrication for scalable manufacturing. Micromachines 2017, 8, 90. [Google Scholar] [CrossRef]

- Zyla, G.; Kovalev, A.; Grafen, M.; Gurevich, E.L.; Esen, C.; Ostendorf, A.; Gorb, S. Generation of bioinspired structural colors via two-photon polymerization. Sci. Rep. 2017, 7. [Google Scholar] [CrossRef] [PubMed]

- Saive, R.; Bukowsky, C.R.; Atwater, H.A. Three-dimensional nanoimprint lithography using two-photon lithography master samples. arXiv. 2017. Available online: https://arxiv.org/abs/1702.04012 (accessed on 23 April 2018).

- Du, K.; Jiang, Y.; Huang, P.S.; Ding, J.; Gao, T.; Choi, C.H. Self-formation of polymer nanostructures in plasma etching: Mechanisms and applications. J. Micromech. Microeng. 2017, 28. [Google Scholar] [CrossRef]

- Jiang, Y.; Xu, J.; Lee, J.; Du, K.; Yang, E.H.; Moon, M.W.; Choi, C.H. Nanotexturing of conjugated polymers via one-step maskless oxygen plasma etching for enhanced tunable wettability. Langmuir 2017, 33, 6885–6894. [Google Scholar] [CrossRef] [PubMed]

- Fernández-Blázquez, J.P.; Del Campo, A. Templateless nanostructuration of polymer surfaces. Soft Matter 2012, 8, 2503–2508. [Google Scholar]

- Wohlfart, E.; Fernández-Blázquez, J.P.; Knoche, E.; Bello, A.; Pérez, E.; Arzt, E.; Del Campo, A. Nanofibrillar patterns by plasma etching: The influence of polymer crystallinity and orientation in surface morphology. Macromolecules 2010, 43, 9908–9917. [Google Scholar] [CrossRef]

- Ostrikov, K.; Neyts, E.; Meyyappan, M. Plasma nanoscience: From nano-solids in plasmas to nano-plasmas in solids. Adv. Phys. 2013, 62, 113–224. [Google Scholar] [CrossRef]

- Gogolides, E.; Constantoudis, V.; Kokkoris, G.; Kontziampasis, D.; Tsougeni, K.; Boulousis, G.; Vlachopoulou, M.; Tserepi, A. Controlling roughness: From etching to nanotexturing and plasma-directed organization on organic and inorganic materials. J. Phys. D 2011, 44. [Google Scholar] [CrossRef]

- De Volder, M.F.; Vansweevelt, R.; Wagner, P.; Reynaerts, D.; Van Hoof, C.; Hart, A.J. Hierarchical carbon nanowire microarchitectures made by plasma-assisted pyrolysis of photoresist. ACS Nano 2011, 5, 6593–6600. [Google Scholar] [CrossRef] [PubMed]

- Ramires, P.; Mirenghi, L.; Romano, A.; Palumbo, F.; Nicolardi, G. Plasma-treated PET surfaces improve the biocompatibility of human endothelial cells. J. Biomed. Mater. Res. 2000, 51, 535–539. [Google Scholar] [CrossRef]

- Tsougeni, K.; Ellinas, K.; Koukouvinos, G.; Petrou, P.S.; Tserepi, A.; Kakabakos, S.E.; Gogolides, E. Three-dimensional (3D) plasma micro-nanotextured slides for high performance biomolecule microarrays: Comparison with epoxy-silane coated glass slides. Colloids Surf. B. Biointerfaces 2018, 165, 270–277. [Google Scholar] [CrossRef] [PubMed]

- Ellinas, K.; Tserepi, A.; Gogolides, E. Durable superhydrophobic and superamphiphobic polymeric surfaces and their applications: A review. Adv. Colloid Interface Sci. 2017, 250, 132–157. [Google Scholar] [CrossRef] [PubMed]

- Kontziampasis, D.; Boulousis, G.; Smyrnakis, A.; Ellinas, K.; Tserepi, A.; Gogolides, E. Biomimetic, antireflective, superhydrophobic and oleophobic PMMA and PMMA-coated glass surfaces fabricated by plasma processing. Microelectron. Eng. 2014, 121, 33–38. [Google Scholar] [CrossRef]

- Di Mundo, R.; Palumbo, F.; d’Agostino, R. Influence of chemistry on wetting dynamics of nanotextured hydrophobic surfaces. Langmuir 2009, 26, 5196–5201. [Google Scholar] [CrossRef] [PubMed]

- Di Mundo, R.; Bottiglione, F.; Notarnicola, M.; Palumbo, F.; Pascazio, G. Plasma-textured teflon: Repulsion in air of water droplets and drag reduction underwater. Biomimetics 2017, 2, 1. [Google Scholar] [CrossRef]

- Du, K.; Wathuthanthri, I.; Liu, Y.; Kang, Y.T.; Choi, C.H. Fabrication of polymer nanowires via maskless O2 plasma etching. Nanotechnology 2014, 25. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.; Fadeev, A.Y.; Hsieh, M.C.; Öner, D.; Youngblood, J.; McCarthy, T.J. Ultrahydrophobic and ultralyophobic surfaces: Some comments and examples. Langmuir 1999, 15, 3395–3399. [Google Scholar] [CrossRef]

- Martines, E.; Seunarine, K.; Morgan, H.; Gadegaard, N.; Wilkinson, C.D.; Riehle, M.O. Superhydrophobicity and superhydrophilicity of regular nanopatterns. Nano Lett. 2005, 5, 2097–2103. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Jiang, Y.; Choi, C.H.; Xie, G.; Liu, Q.; Drelich, J.W. Direct measurements of adhesion forces of water droplets on smooth and patterned polymers. Surface Innov. 2018, 6, 93–105. [Google Scholar] [CrossRef]

- Lu, Y.; Sarshar, M.A.; Du, K.; Chou, T.; Choi, C.H.; Sukhishvili, S.A. Large-amplitude, reversible, pH-triggered wetting transitions enabled by layer-by-layer films. ACS Appl. Mater. Interfaces 2013, 5, 12617–12623. [Google Scholar] [CrossRef] [PubMed]

- Wathuthanthri, I.; Liu, Y.; Du, K.; Xu, W.; Choi, C.H. Simple holographic patterning for high-aspect-ratio three-dimensional nanostructures with large coverage area. Adv. Funct. Mater. 2013, 23, 608–618. [Google Scholar] [CrossRef]

- Srinivasan, U.; Houston, M.R.; Howe, R.T.; Maboudian, R. Alkyltrichlorosilane-based self-assembled monolayer films for stiction reduction in silicon micromachines. J. Microelectromech. Syst. 1998, 7, 252–260. [Google Scholar] [CrossRef]

- Wenzel, R.N. Resistance of solid surfaces to wetting by water. Ind. Eng. Chem. 1936, 28, 988–994. [Google Scholar] [CrossRef]

- Jeong, C.; Lee, J.; Sheppard, K.; Choi, C.H. Air-impregnated nanoporous anodic aluminum oxide layers for enhancing the corrosion resistance of aluminum. Langmuir 2015, 31, 11040–11050. [Google Scholar] [CrossRef] [PubMed]

- Scriven, L. Physics and applications of dip coating and spin coating. MRS Proc. 1988, 121. [Google Scholar] [CrossRef]

- Spangler, L.L.; Torkelson, J.M.; Royal, J.S. Influence of solvent and molecular weight on thickness and surface topography of spin-coated polymer films. Polym. Eng. Sci. 1990, 30, 644–653. [Google Scholar] [CrossRef]

- Yang, S.; Dai, X.; Stogin, B.B.; Wong, T.S. Ultrasensitive surface-enhanced Raman scattering detection in common fluids. Proc. Natl. Acad. Sci. USA 2016, 113, 268–273. [Google Scholar] [CrossRef] [PubMed]

- Hong, X.; Gao, X.; Jiang, L. Application of superhydrophobic surface with high adhesive force in no lost transport of superparamagnetic microdroplet. J. Am. Chem. Soc. 2007, 129, 1478–1479. [Google Scholar] [CrossRef] [PubMed]

- Ito, Y.; Nogawa, M. Preparation of a protein micro-array using a photo-reactive polymer for a cell-adhesion assay. Biomaterials 2003, 24, 3021–3026. [Google Scholar] [CrossRef]

- Zhao, N.; Xie, Q.; Kuang, X.; Wang, S.; Li, Y.; Lu, X.; Tan, S.; Shen, J.; Zhang, X.; Zhang, Y. A novel ultra-hydrophobic surface: Statically non-wetting but dynamically non-sliding. Adv. Funct. Mater. 2007, 17, 2739–2745. [Google Scholar] [CrossRef]

- Jiang, Y.; Sun, Y.; Drelich, J.W.; Choi, C.H. Spontaneous spreading of a droplet: The role of solid continuity and advancing contact angle. Langmuir 2018, 34, 4945–4951. [Google Scholar] [CrossRef] [PubMed]

- Choi, W.; Tuteja, A.; Mabry, J.M.; Cohen, R.E.; McKinley, G.H. A modified cassie–baxter relationship to explain contact angle hysteresis and anisotropy on non-wetting textured surfaces. J. Colloid Interface Sci. 2009, 339, 208–216. [Google Scholar] [CrossRef] [PubMed]

- Dufour, R.; Harnois, M.; Thomy, V.; Boukherroub, R.; Senez, V. Contact angle hysteresis origins: Investigation on super-omniphobic surfaces. Soft Matter 2011, 7, 9380–9387. [Google Scholar] [CrossRef]

- Butt, H., Jr.; Gao, N.; Papadopoulos, P.; Steffen, W.; Kappl, M.; Berger, R.D. Energy dissipation of moving drops on superhydrophobic and superoleophobic surfaces. Langmuir 2016, 33, 107–116. [Google Scholar] [CrossRef] [PubMed]

- Liu, D.; Wang, Q.; Shen, W.; Wang, D. Self-cleaning antireflective coating with a hierarchical texture for light trapping in micromorph solar cells. J. Mater. Chem. C 2017, 5, 103–109. [Google Scholar] [CrossRef]

- Miljkovic, N.; Wang, E.N. Condensation heat transfer on superhydrophobic surfaces. MRS Bull. 2013, 38, 397–406. [Google Scholar] [CrossRef] [Green Version]

- Shen, Y.; Tao, J.; Wang, G.; Zhu, C.; Chen, H.; Jin, M.; Xie, Y. Bio-inspired fabrication of hierarchical structure superhydrophobic surfaces to understand droplet bouncing dynamics for enhancing water-repellency. J. Phys. Chem. C 2018, 122, 7312–7320. [Google Scholar] [CrossRef]

- Park, K.C.; Chhatre, S.S.; Srinivasan, S.; Cohen, R.E.; McKinley, G.H. Optimal design of permeable fiber network structures for fog harvesting. Langmuir 2013, 29, 13269–13277. [Google Scholar] [CrossRef] [PubMed]

- Zheng, D.; Jiang, Y.; Yu, W.; Jiang, X.; Zhao, X.; Choi, C.H.; Sun, G. Salvinia-effect-inspired “sticky” superhydrophobic surfaces by meniscus-confined electrodeposition. Langmuir 2017, 33, 13640–13648. [Google Scholar] [CrossRef] [PubMed]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, K.; Jiang, Y.; Liu, Y.; Wathuthanthri, I.; Choi, C.-H. Manipulation of the Superhydrophobicity of Plasma-Etched Polymer Nanostructures. Micromachines 2018, 9, 304. https://doi.org/10.3390/mi9060304

Du K, Jiang Y, Liu Y, Wathuthanthri I, Choi C-H. Manipulation of the Superhydrophobicity of Plasma-Etched Polymer Nanostructures. Micromachines. 2018; 9(6):304. https://doi.org/10.3390/mi9060304

Chicago/Turabian StyleDu, Ke, Youhua Jiang, Yuyang Liu, Ishan Wathuthanthri, and Chang-Hwan Choi. 2018. "Manipulation of the Superhydrophobicity of Plasma-Etched Polymer Nanostructures" Micromachines 9, no. 6: 304. https://doi.org/10.3390/mi9060304

APA StyleDu, K., Jiang, Y., Liu, Y., Wathuthanthri, I., & Choi, C.-H. (2018). Manipulation of the Superhydrophobicity of Plasma-Etched Polymer Nanostructures. Micromachines, 9(6), 304. https://doi.org/10.3390/mi9060304