Structural and Mechanical Properties of Al-SiC-ZrO2 Nanocomposites Fabricated by Microwave Sintering Technique

Abstract

:1. Introduction

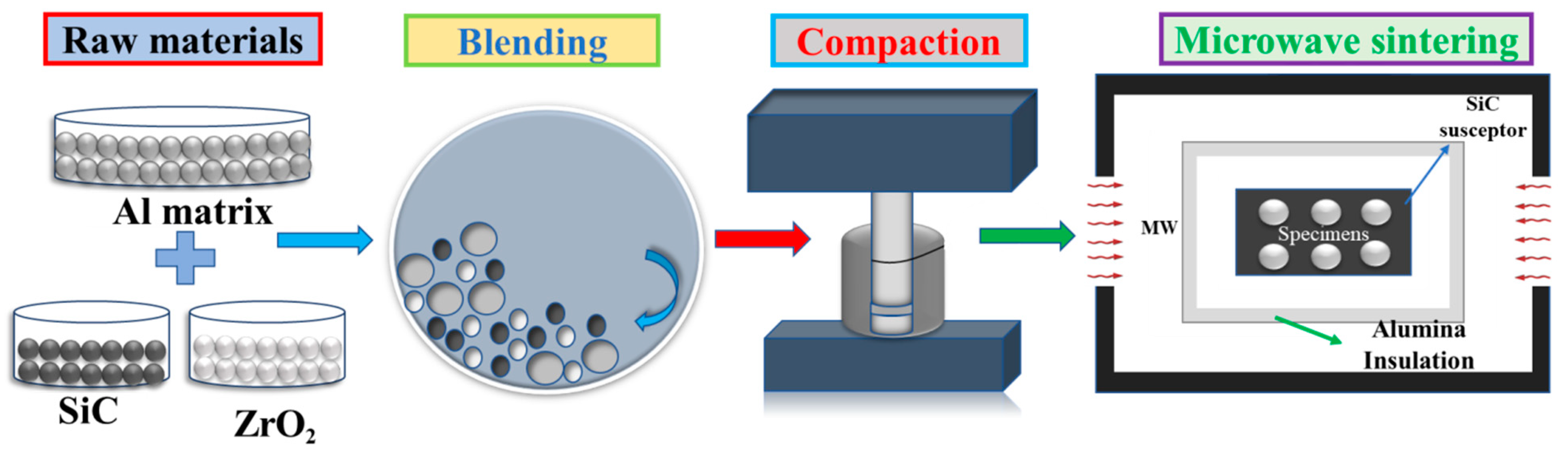

2. Materials and Methods

3. Results and Discussion

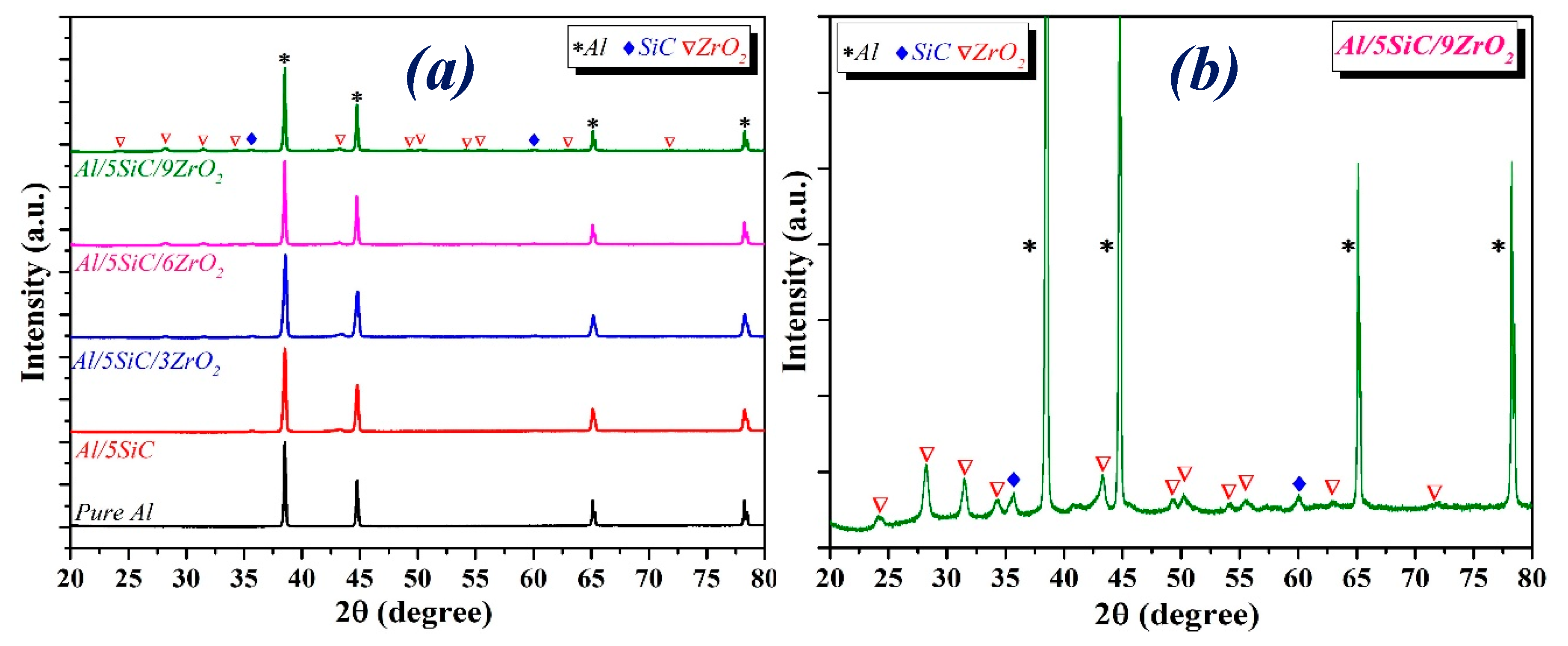

3.1. XRD Analysis

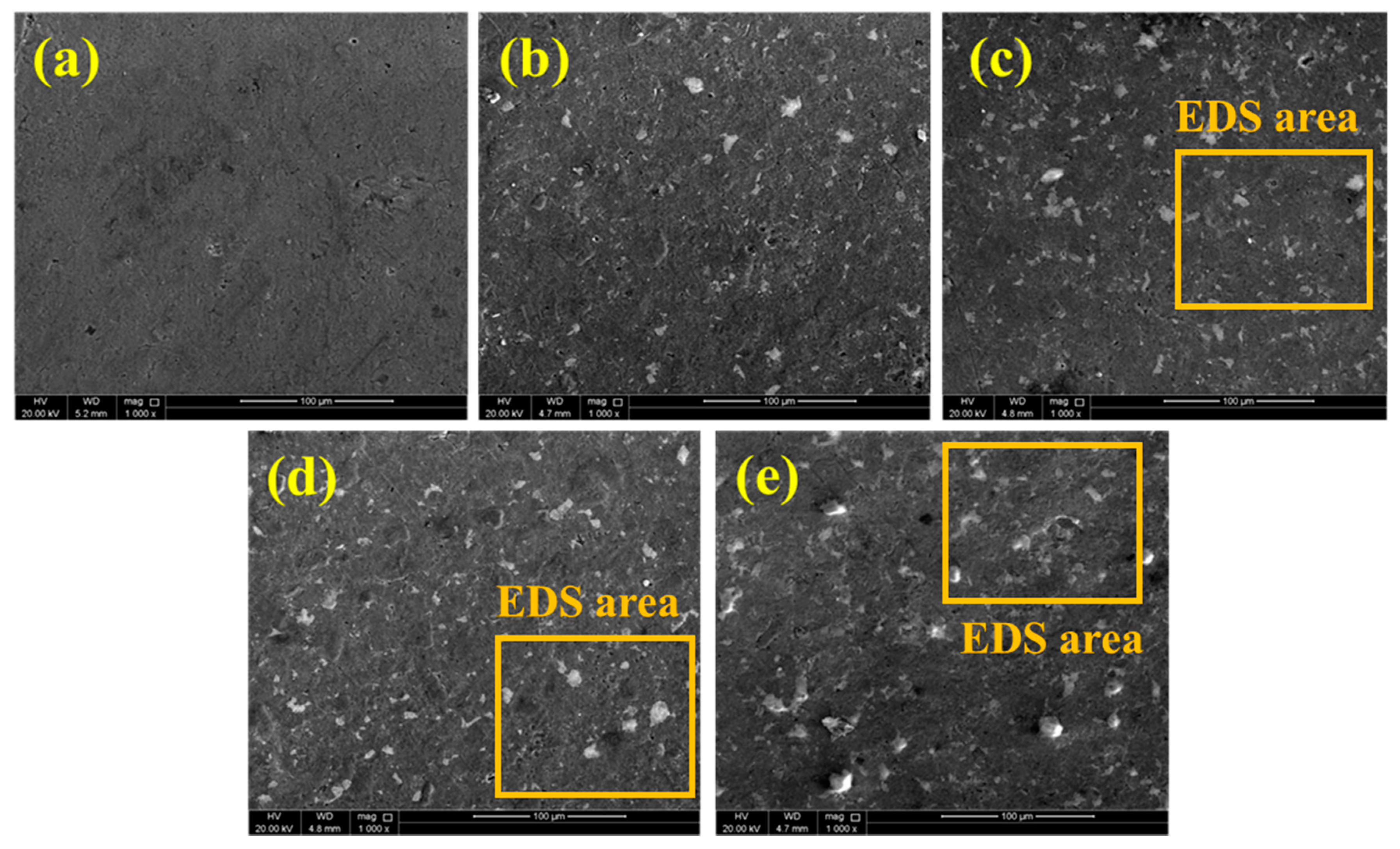

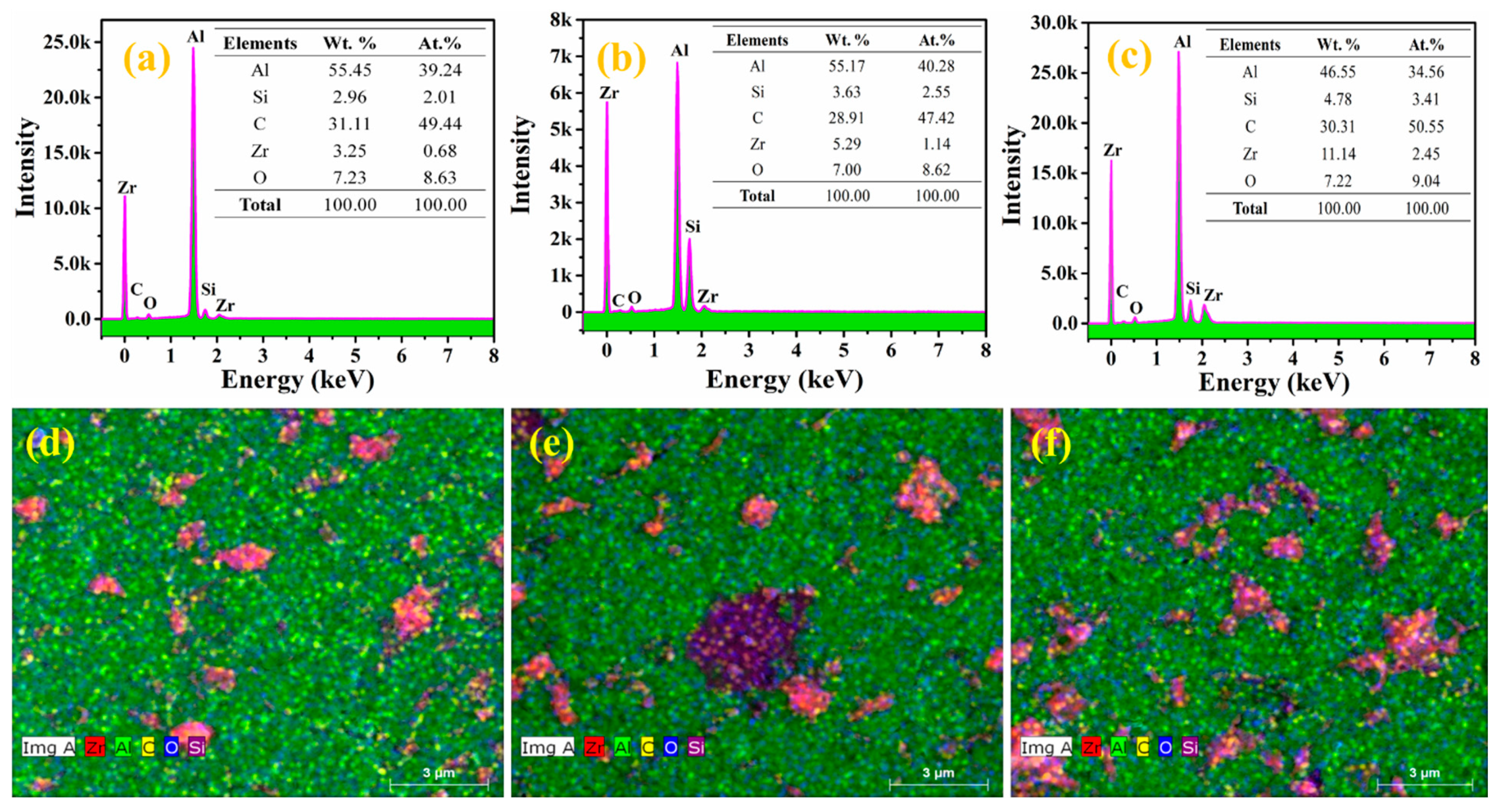

3.2. Microstructural Analysis

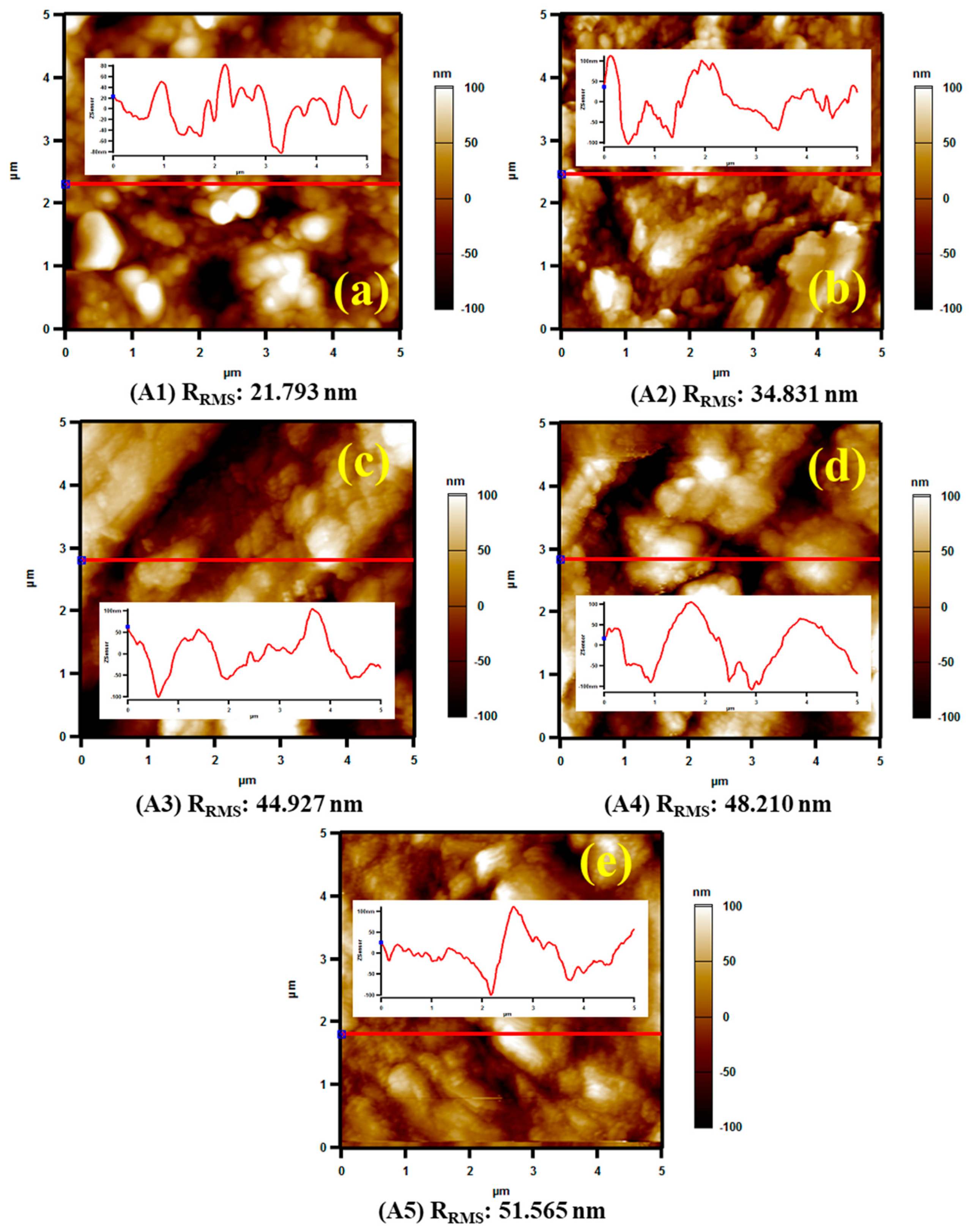

3.3. AFM Analysis

3.4. Relative Density and Hardness

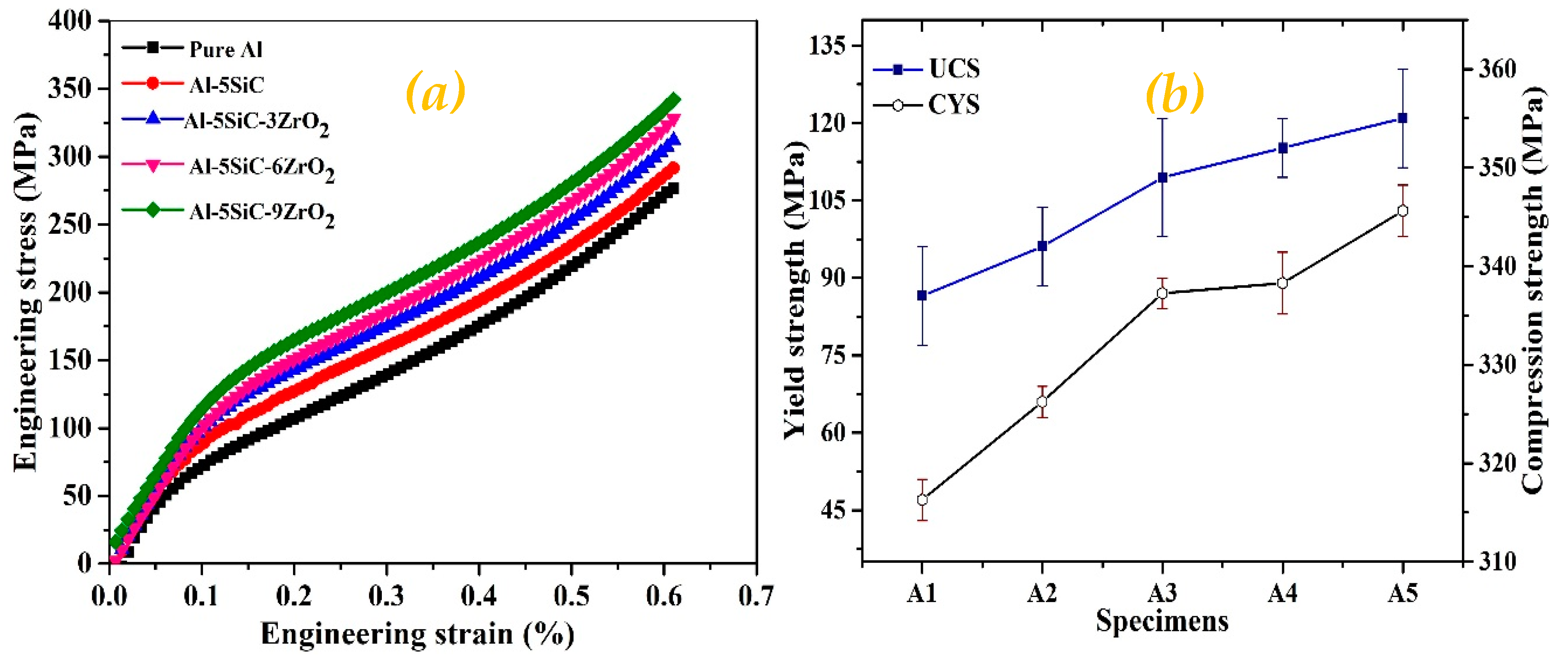

3.5. Compressive Analysis

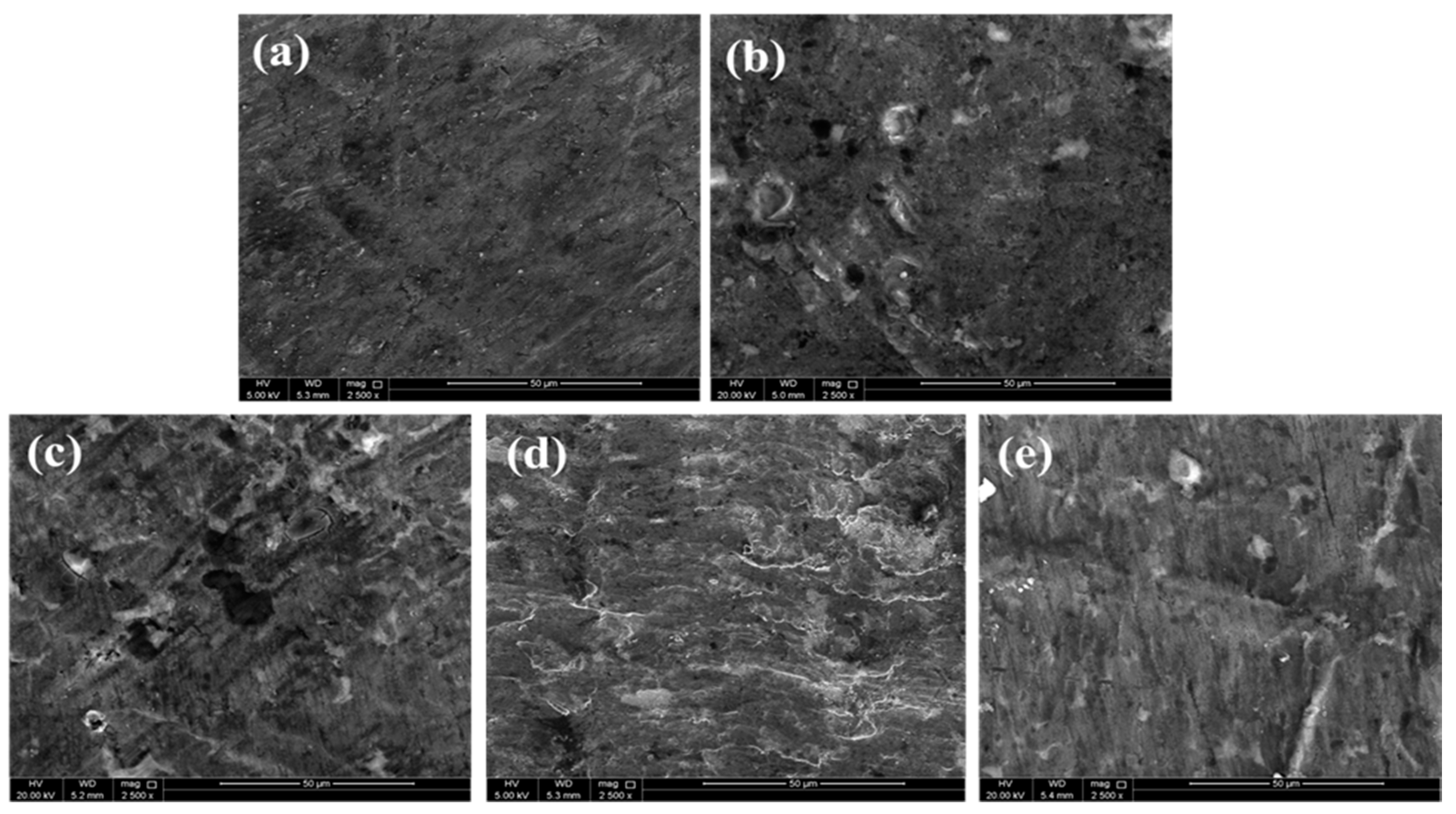

3.6. Fractography

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Dieter, G. Mechanical Metallurgy. McGRAW-HILL BOOK COMPANY, US. 1961, pp. 370–371. Available online: http://stu.westga.edu/~bthibau1/MEDT%207477-Cooper/Calibre%20Library/Dieter_%20George%20Ellwood/Mechanical%20metallurgy%20(13)/Mechanical%20metallurgy%20-%20Dieter_%20George%20Ellwood.pdf (accessed on 6 October 2020).

- Song, W.; Veca, L.M.; Anderson, A.; Cao, M.; Cao, L.; Sun, Y. Light-weight nanocomposite materials with enhanced thermal transport properties. Nanotechnol. Rev. 2012, 1, 363–376. [Google Scholar] [CrossRef]

- Khan, A.; Matli, P.R.; Nawaz, M.; Mattli, M.R. Microstructure and Mechanical Behavior of Hot Extruded Aluminum/Tin-Bismuth Composites Produced by Powder Metallurgy. Appl. Sci. 2020, 10, 2812. [Google Scholar] [CrossRef] [Green Version]

- Reddy, M.; Khan, A.; Reddy, P.; Yusuf, M.; Ashraf, A.A.; Shakoor, R.A.; Gupta, M. Effect of Inconel625 particles on the microstructural, mechanical, and thermal properties of Al-Inconel625 composites. Mater. Today Commun. 2020, 25, 101564. [Google Scholar]

- Alem, S.A.A.; Latifi, R.; Angizi, S.; Hassanaghaei, F.; Aghaahmadi, M.; Ghasali, E.; Rajabi, M. Microwave sintering of ceramic reinforced metal matrix composites and their properties: A review. Mater. Manuf. Process. 2020, 35, 303–327. [Google Scholar] [CrossRef]

- Ibrahim, M.A. Mechanical Properties of Aluminium Matrix Composite Including SiC/Al2O3 by Powder Metallurgy-A Review. GSJ J. Public 2019, 7, 23–37. [Google Scholar]

- Mattli, M.; Matli, P.; Shakoor, A.; Amer Mohamed, A. Structural and Mechanical Properties of Amorphous Si3N4 Nanoparticles Reinforced Al Matrix Composites Prepared by Microwave Sintering. Ceramics 2019, 2, 126–134. [Google Scholar] [CrossRef] [Green Version]

- Bouaeshi, W.B.; Li, D.Y. Effects of Y2O3 addition on microstructure, mechanical properties, electrochemical behavior, and resistance to corrosive wear of aluminum. Tribol. Int. 2007, 40, 188–199. [Google Scholar] [CrossRef]

- Zhao, N.Q.; Jiang, B.; Du, X.W.; Li, J.J.; Shi, C.S.; Zhao, W.X. Effect of Y2O3 on the mechanical properties of open cell aluminum foams. Mater. Lett. 2006, 60, 1665–1668. [Google Scholar] [CrossRef]

- Mattli, M.R.; Shakoor, A.; Matli, P.R.; Mohamed, A.M.A. Microstructure and compressive behavior of Al–Y2O3 nanocomposites prepared by microwave-assisted mechanical alloying. Metals (Basel) 2019, 9, 414. [Google Scholar] [CrossRef] [Green Version]

- Ubaid, F.; Matli, P.R.; Shakoor, R.A.; Parande, G.; Manakari, V.; Amer Mohamed, A.M.; Gupta, M. Using B4C nanoparticles to enhance thermal and mechanical response of aluminum. Materials (Basel) 2017, 10, 621. [Google Scholar] [CrossRef] [Green Version]

- Ghasali, E.; Fazili, A.; Alizadeh, M.; Shirvanimoghaddam, K.; Ebadzadeh, T. Evaluation of microstructure and mechanical properties of Al-TiC metal matrix composite prepared by conventional, microwave and spark plasma sintering methods. Materials (Basel) 2017, 10, 1255. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Patoliya, D.M.; Sharma, S. Preparation and Characterization of Zirconium Dioxide Reinforced Aluminium Metal Matrix Composites. Eng. Technol. 2015, 4, 3315–3321. [Google Scholar]

- Ravichandran, M.; Naveen Sait, A.; Anandakrishnan, V. Al–TiO2–Gr powder metallurgy hybrid composites with cold upset forging. Rare Met. 2014, 33, 686–696. [Google Scholar] [CrossRef]

- Elango, G.; Raghunath, B.K. Tribological behavior of hybrid (LM25Al + SiC+ TiO2) metal matrix composites. Procedia Eng. 2013, 64, 671–680. [Google Scholar] [CrossRef] [Green Version]

- El Mahallawi, I.; Shash, Y.; Rashad, R.M.; Abdelaziz, M.H.; Mayer, J.; Schwedt, A. Hardness and Wear Behaviour of Semi-Solid Cast A390 Alloy Reinforced with Al2O3 and TiO2 Nanoparticles. Arab. J. Sci. Eng. 2014, 39, 5171–5184. [Google Scholar] [CrossRef]

- Mohapatra, S.; Mishra, D.K.; Mishra, G.; Roy, G.S.; Behera, D.; Mantry, S.; Singh, S.K. A study on sintered TiO2 and TiO2/SiC composites synthesized through chemical reaction based solution method. J. Compos. Mater. 2013, 47, 3081–3089. [Google Scholar] [CrossRef]

- Muley, A.V.; Aravindan, S.; Singh, I.P. Nano and hybrid aluminum based metal matrix composites: An overview. Manuf. Rev. 2015, 2, 15. [Google Scholar] [CrossRef] [Green Version]

- Mahna, S.; Singh, H.; Tomar, S.; Bhagat, D.; Patnaik, A.; Ranjan, S. Dynamic mechanical behavior of nano-ZnO reinforced dental composite. Nanotechnol. Rev. 2019, 8, 90–99. [Google Scholar] [CrossRef]

- Karwowska, E. Antibacterial potential of nanocomposite-based materials—A short review. Nanotechnol. Rev. 2017, 6, 243–254. [Google Scholar] [CrossRef]

- Bodunrin, M.O.; Alaneme, K.K.; Chown, L.H. Aluminium matrix hybrid composites: A review of reinforcement philosophies; Mechanical, corrosion and tribological characteristics. J. Mater. Res. Technol. 2015, 4, 434–445. [Google Scholar] [CrossRef] [Green Version]

- Mohapatra, S. Processing, Microstructure and Properties of Hybrid Metallic and Ceramic Reinforced Aluminium Composites, National Institute Of Technology, Rourkela. 2013. Available online: http://ethesis.nitrkl.ac.in/5362/1/211MM1363.pdf (accessed on 6 October 2020).

- Madhukar, P.; Selvaraj, N.; Rao, C.S.P. Manufacturing of aluminium nano hybrid composites: A state of review. IOP Conf. Ser. Mater. Sci. Eng. 2016, 149. [Google Scholar] [CrossRef]

- Iacob, G.; Ghica, V.G.; Buzatu, M.; Buzatu, T.; Petrescu, M.I. Studies on wear rate and micro-hardness of the Al/Al2O3/Gr hybrid composites produced via powder metallurgy. Compos. Part B Eng. 2015, 69, 603–611. [Google Scholar] [CrossRef]

- Alizadeh, A.; Abdollahi, A.; Biukani, H. Creep behavior and wear resistance of Al 5083 based hybrid composites reinforced with carbon nanotubes (CNTs) and boron carbide (B4C). J. Alloys Compd. 2015, 650, 783–793. [Google Scholar] [CrossRef]

- Ghasali, E.; Pakseresht, A.H.; Alizadeh, M.; Shirvanimoghaddam, K.; Ebadzadeh, T. Vanadium carbide reinforced aluminum matrix composite prepared by conventional, microwave and spark plasma sintering. J. Alloys Compd. 2016, 688, 527–533. [Google Scholar] [CrossRef]

- Ahlatci, H.; Koçer, T.; Candan, E.; Çimenoǧlu, H. Wear behaviour of Al/(Al2O3p+SiCp) hybrid composites. Tribol. Int. 2006, 39, 213–220. [Google Scholar] [CrossRef]

- Zhang, X.N.; Geng, L.; Wang, G.S. Fabrication of Al-based hybrid composites reinforced with SiC whiskers and SiC nanoparticles by squeeze casting. J. Mater. Process. Technol. 2006, 176, 146–151. [Google Scholar] [CrossRef]

- Arif, S.; Alam, M.T.; Ansari, A.H.; Siddiqui, M.A.; Mohsin, M. Investigation of Mechanical and Morphology of Al-SiC composites processed by PM Route. IOP Conf. Ser. Mater. Sci. Eng. 2017, 225. [Google Scholar] [CrossRef]

- Liu, G.; Wang, Q.; Liu, T.; Ye, B.; Jiang, H.; Ding, W. Effect of T6 heat treatment on microstructure and mechanical property of 6101/A356 bimetal fabricated by squeeze casting. Mater. Sci. Eng. A 2017, 696, 208–215. [Google Scholar] [CrossRef]

- Kannan, C.; Ramanujam, R. Comparative study on the mechanical and microstructural characterisation of AA 7075 nano and hybrid nanocomposites produced by stir and squeeze casting. J. Adv. Res. 2017, 8, 309–319. [Google Scholar] [CrossRef]

- Materials, H.; Ghasali, E.; Baghchesaraee, K.; Orooji, Y. International Journal of Refractory Metals Study of the potential effect of spark plasma sintering on the preparation of complex FGM / laminated WC-based cermet. Int. J. Refract. Metals Hard Mater. 2020, 92, 105328. [Google Scholar]

- Ghasali, E.; Orooji, Y.; Niknam, H. Heliyon Investigation on in-situ formed Al 3 V-Al-VC nano composite through conventional, microwave and spark plasma sintering. Heliyon 2019, 5, e01754. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sambathkumar, M.A.; Navaneethakrishnan, P.; Ponappa, K.S.K.S. Mechanical and Corrosion Behavior of Al7075 (Hybrid) Metal Matrix Composites by Two Step Stir Casting Process. Lat. Am. J. Solids Struct. 2016, 7075, 243–255. [Google Scholar]

- James, S.J.; Ganesan, M.; Santhamoorthy, P.; Kuppan, P. Development of hybrid aluminium metal matrix composite and study of property. Mater. Today Proc. 2018, 5, 13048–13054. [Google Scholar] [CrossRef]

- Arif, S.; Alam, M.T.; Ansari, A.H.; Siddiqui, M.A.; Mohsin, M. Study of mechanical and tribological behaviour of Al/SiC/ZrO 2 hybrid composites fabricated through powder metallurgy technique. Mater. Res. Express 2017, 4. [Google Scholar] [CrossRef]

- Sekar, K.; Jayachandra, G.; Aravindan, S. Mechanical and Welding Properties of A6082-SiC-ZrO2 Hybrid Composite Fabricated by Stir and Squeeze Casting. Mater. Today Proc. 2018, 5, 20268–20277. [Google Scholar] [CrossRef]

- Kumar, V.; Sharma, V. Effects of SiC, Al2O3, and ZrO2 particles on the LBMed characteristics of Al/SiC, Al/Al2O3, and Al/ZrO2 MMCs prepared by stir casting process. Part. Sci. Technol. 2018, 37, 770–780. [Google Scholar] [CrossRef]

- Lahiri, D.; Singh, V.; Li, L.H.; Xing, T.; Seal, S.; Chen, Y.; Agarwal, A. Insight into reactions and interface between boron nitride nanotube and aluminum. J. Mater. Res. 2012, 27, 2760–2770. [Google Scholar] [CrossRef] [Green Version]

- MA, B.; YU, J. Phase composition of SiC-ZrO2 composite materials synthesized from zircon doped with La2O3. J. Rare Earths 2009, 27, 806–810. [Google Scholar] [CrossRef]

- Singh, J.; Chauhan, A. ARTICLE IN PRESS Characterization of hybrid aluminum matrix composites for advanced applications—A review ARTICLE IN PRESS. Integr. Med. Res. 2015, 5, 159–169. [Google Scholar]

- Ramezanalizadeh, H.; Emamy, M.; Shokouhimehr, M. A novel aluminum based nanocomposite with high strength and good ductility. J. Alloys Compd. 2015, 649, 461–473. [Google Scholar] [CrossRef]

- Alalkawi, H.J.M.; Aziz, G.A.; Aljawad, H.A. Preparation of new aluminum matrix composite reinforced with hybrid nano reinforcements Fe2O3 and Al2O3 via (P/M) route. Int. J. Mech. Eng. Technol. 2019, 10, 2046–2058. [Google Scholar]

- Subrahmanyam, A.P.S.V.R.; Madhukiran, J.; Naresh, G.; Madhusudhan, S. Fabrication and Characterization of Al356.2, Rice Husk Ash and Fly Ash Reinforced Hybrid Metal Matrix Composite. Int. J. Adv. Sci. Technol. 2016, 94, 49–56. [Google Scholar] [CrossRef]

- Ahmadi, M.; Siadati, M.H. Synthesis, mechanical properties and wear behavior of hybrid Al/(TiO2 + CuO) nanocomposites. J. Alloys Compd. 2018, 769, 713–724. [Google Scholar] [CrossRef]

- Dileep, B.P.; Ravikumar, V.; Vital, H.R. Mechanical and Corrosion Behavior of Al-Ni-Sic Metal Matrix Composites by Powder Metallurgy. Mater. Today Proc. 2018, 5, 12257–12264. [Google Scholar] [CrossRef]

- Bhoria, V.; Suri, N.M. Effect on Mechanical Properties of Aluminium 6063 Reinforced with Silicon Carbide—Graphite Hybrid Composites. Procedia Eng. 2016, 4, 821–823. [Google Scholar]

- Senthil Murugan, S.; Jegan, V.; Velmurugan, M. Mechanical properties of SiC, Al2O3 reinforced aluminium 6061-T6 hybrid matrix composite. J. Inst. Eng. Ser. D 2017, 99, 71–77. [Google Scholar] [CrossRef]

- Matli, P.R.; Ubaid, F.; Shakoor, R.A.; Parande, G.; Manakari, V.; Yusuf, M.; Amer Mohamed, A.M.; Gupta, M. Improved properties of Al-Si3N4 nanocomposites fabricated through a microwave sintering and hot extrusion process. RSC Adv. 2017, 7, 34401–34410. [Google Scholar] [CrossRef] [Green Version]

- Penchal Reddy, M.; Manakari, V.; Parande, G.; Ubaid, F.; Shakoor, R.A.; Mohamed, A.M.A.; Gupta, M. Enhancing compressive, tensile, thermal and damping response of pure Al using BN nanoparticles. J. Alloys Compd. 2018, 762, 398–408. [Google Scholar] [CrossRef]

| S. No: | Samples Name | Compositions |

|---|---|---|

| 1 | A1 | Pure Al |

| 2 | A2 | Al-5wt.%SiC |

| 3 | A3 | Al-5wt.%SiC-3wt.%ZrO2 |

| 4 | A4 | Al-5wt.%SiC-6wt.%ZrO2 |

| 5 | A5 | Al-5wt.%SiC-9wt.%ZrO2 |

| Composition | Microhardness | Compressive Properties | References | ||

|---|---|---|---|---|---|

| (Hv) | CYS (MPa) | UCS (MPa) | Failure Strain (%) | ||

| Pure Al | 36 ± 3 | 47 ± 4 | 337 ± 5 | <60 | Present work |

| Al-5SiC | 54 ± 5 | 66 ± 3 | 342 ± 4 | <60 | |

| Al-5SiC-3ZrO2 | 58 ± 4 | 87 ± 3 | 349 ± 6 | <60 | |

| Al-5SiC-6ZrO2 | 62 ± 3 | 98 ± 6 | 352 ± 3 | <60 | |

| Al-5SiC- 9ZrO2 | 67 ± 4 | 103 ± 5 | 355 ± 5 | <60 | |

| Al-1.5Fe2O3-2Al2O3 | 47.2 | - | 152 | 0.64 | [43] |

| Al-2.5Fe2O3-2Al2O3 | 42.9 | - | 125 | 0.53 | |

| Al-5RHA-5FA | 58.66 | - | 213 | - | [44] |

| Al-6RHA-4FA | 63.0. | - | 216 | - | |

| Al-2.5TiO2-2.5CuO | 73 | 278 | 250 | - | [45] |

| Al-4Ni-8SiC | 48.12 | - | - | - | [46] |

| Al6063-6SiC-2Gr | 65.3 | - | 176 | - | [47] |

| Al6061-7Al2O3-20SiC | - | - | 300 | - | [48] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, A.; Abdelrazeq, M.W.; Mattli, M.R.; Yusuf, M.M.; Alashraf, A.; Matli, P.R.; Shakoor, R.A. Structural and Mechanical Properties of Al-SiC-ZrO2 Nanocomposites Fabricated by Microwave Sintering Technique. Crystals 2020, 10, 904. https://doi.org/10.3390/cryst10100904

Khan A, Abdelrazeq MW, Mattli MR, Yusuf MM, Alashraf A, Matli PR, Shakoor RA. Structural and Mechanical Properties of Al-SiC-ZrO2 Nanocomposites Fabricated by Microwave Sintering Technique. Crystals. 2020; 10(10):904. https://doi.org/10.3390/cryst10100904

Chicago/Turabian StyleKhan, Adnan, Motasem W. Abdelrazeq, Manohar Reddy Mattli, Moinuddin M. Yusuf, Abdullah Alashraf, Penchal Reddy Matli, and R. A. Shakoor. 2020. "Structural and Mechanical Properties of Al-SiC-ZrO2 Nanocomposites Fabricated by Microwave Sintering Technique" Crystals 10, no. 10: 904. https://doi.org/10.3390/cryst10100904

APA StyleKhan, A., Abdelrazeq, M. W., Mattli, M. R., Yusuf, M. M., Alashraf, A., Matli, P. R., & Shakoor, R. A. (2020). Structural and Mechanical Properties of Al-SiC-ZrO2 Nanocomposites Fabricated by Microwave Sintering Technique. Crystals, 10(10), 904. https://doi.org/10.3390/cryst10100904