Thermal Stability of YSZ Thick Thermal Barrier Coatings Deposited by Suspension and Atmospheric Plasma Spraying

Abstract

:1. Introduction

2. Experiments Procedure

2.1. Coating Preparation

2.2. Coating Characterization

3. Results and Discussion

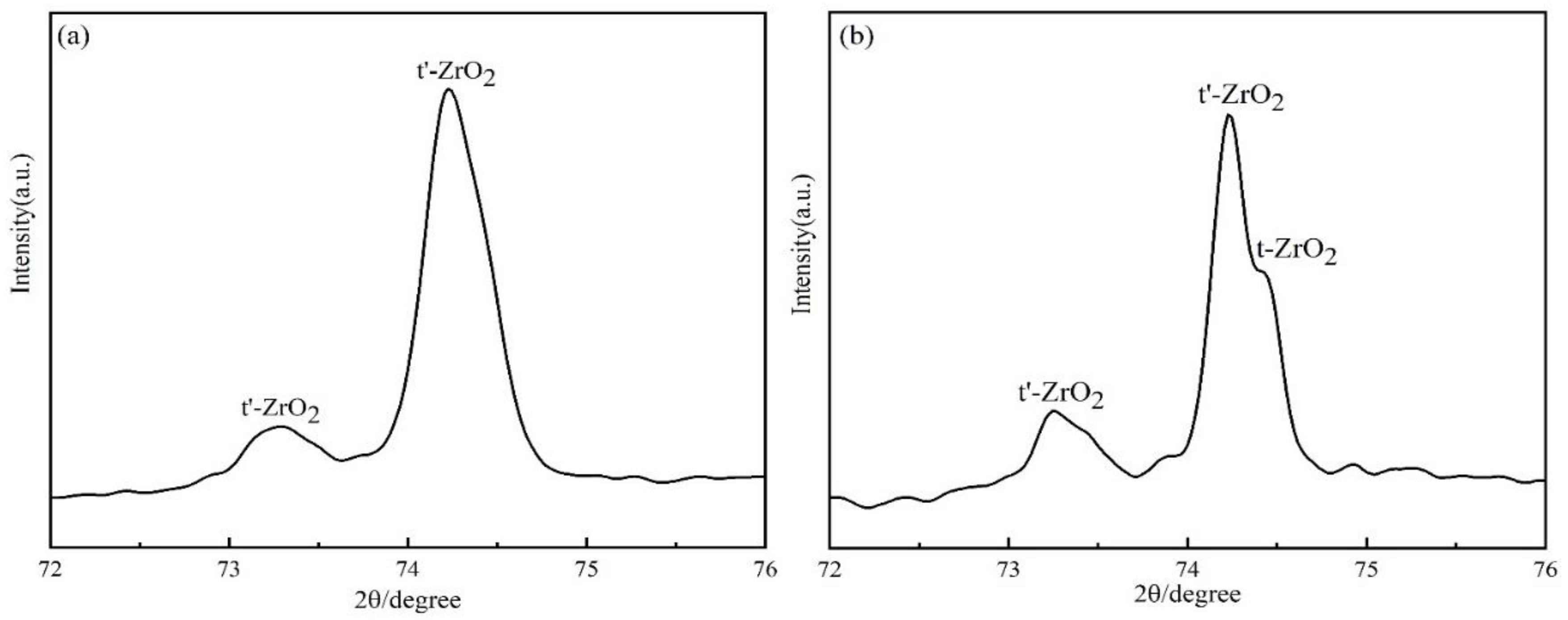

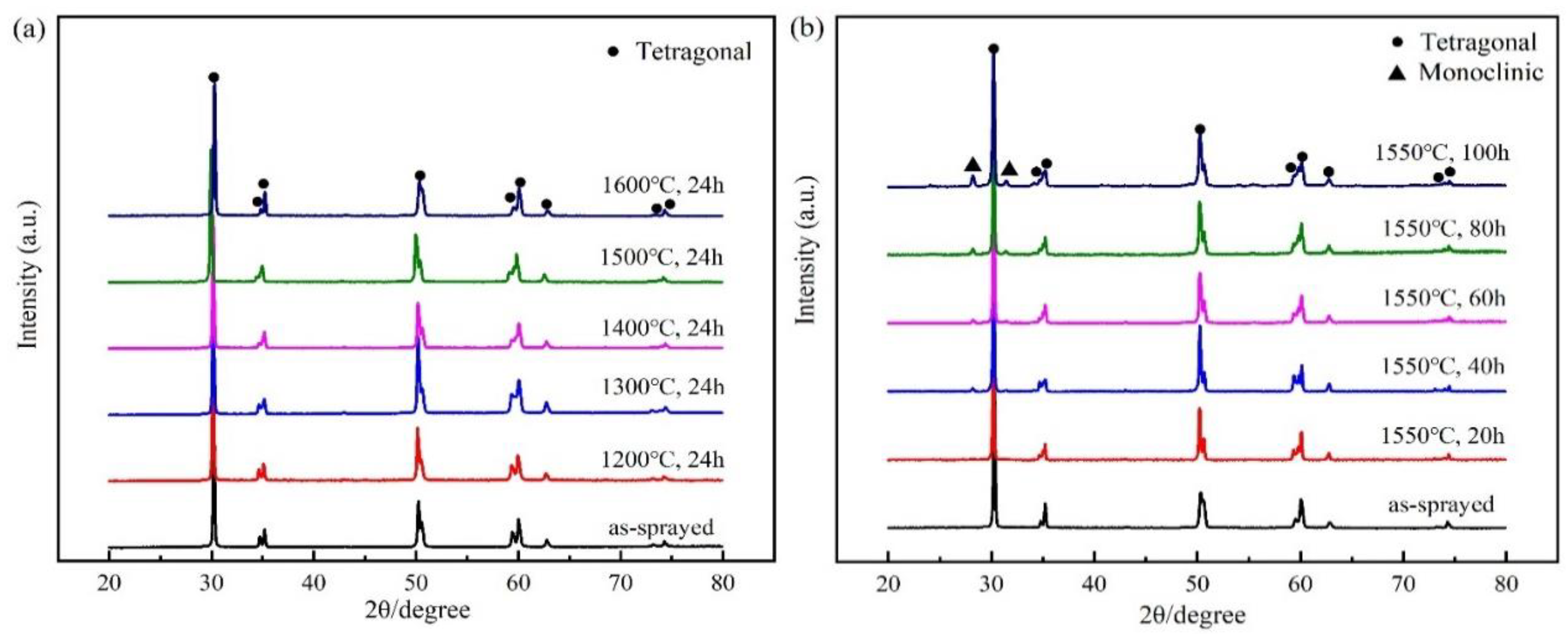

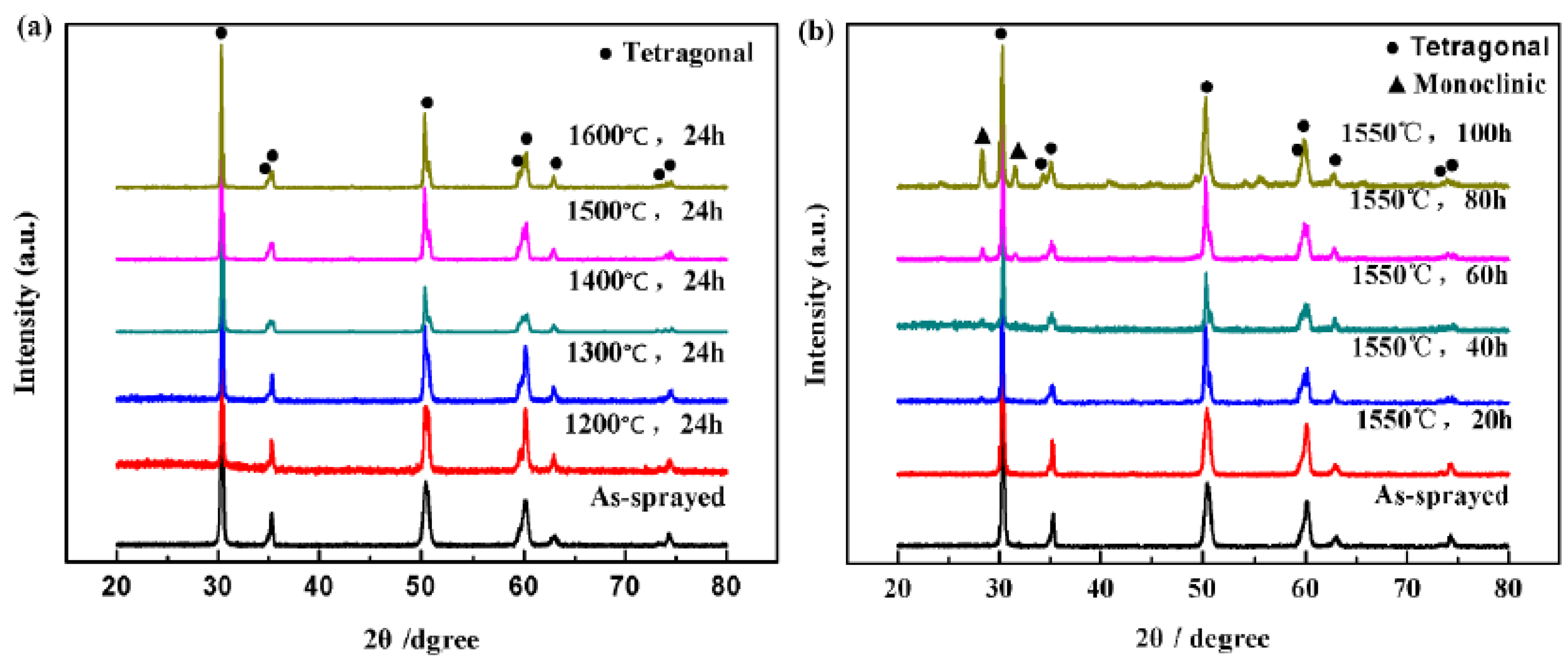

3.1. Phase Composition

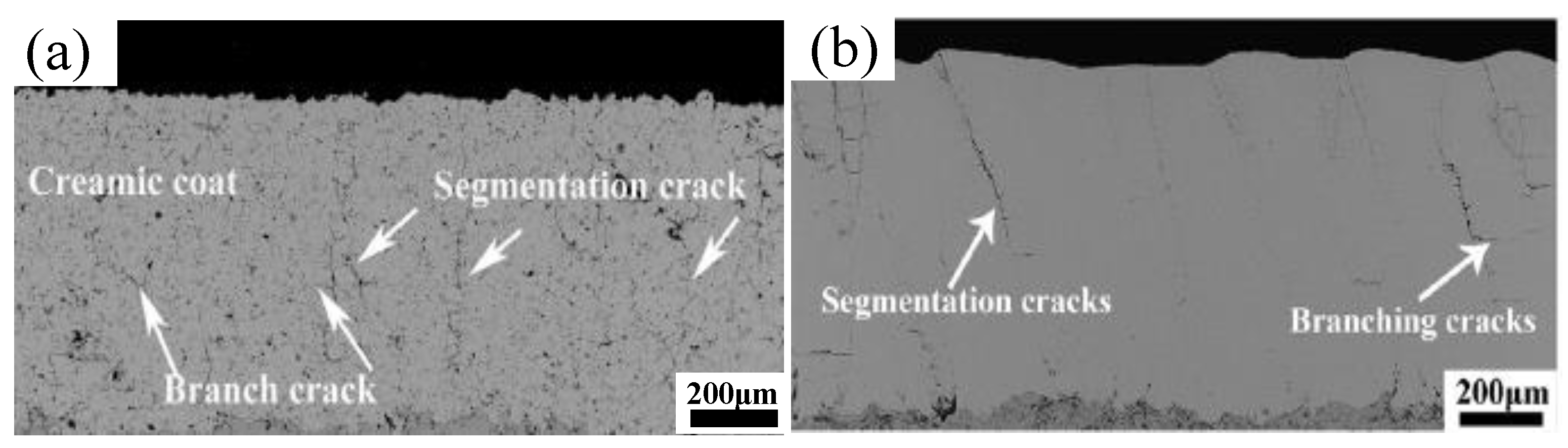

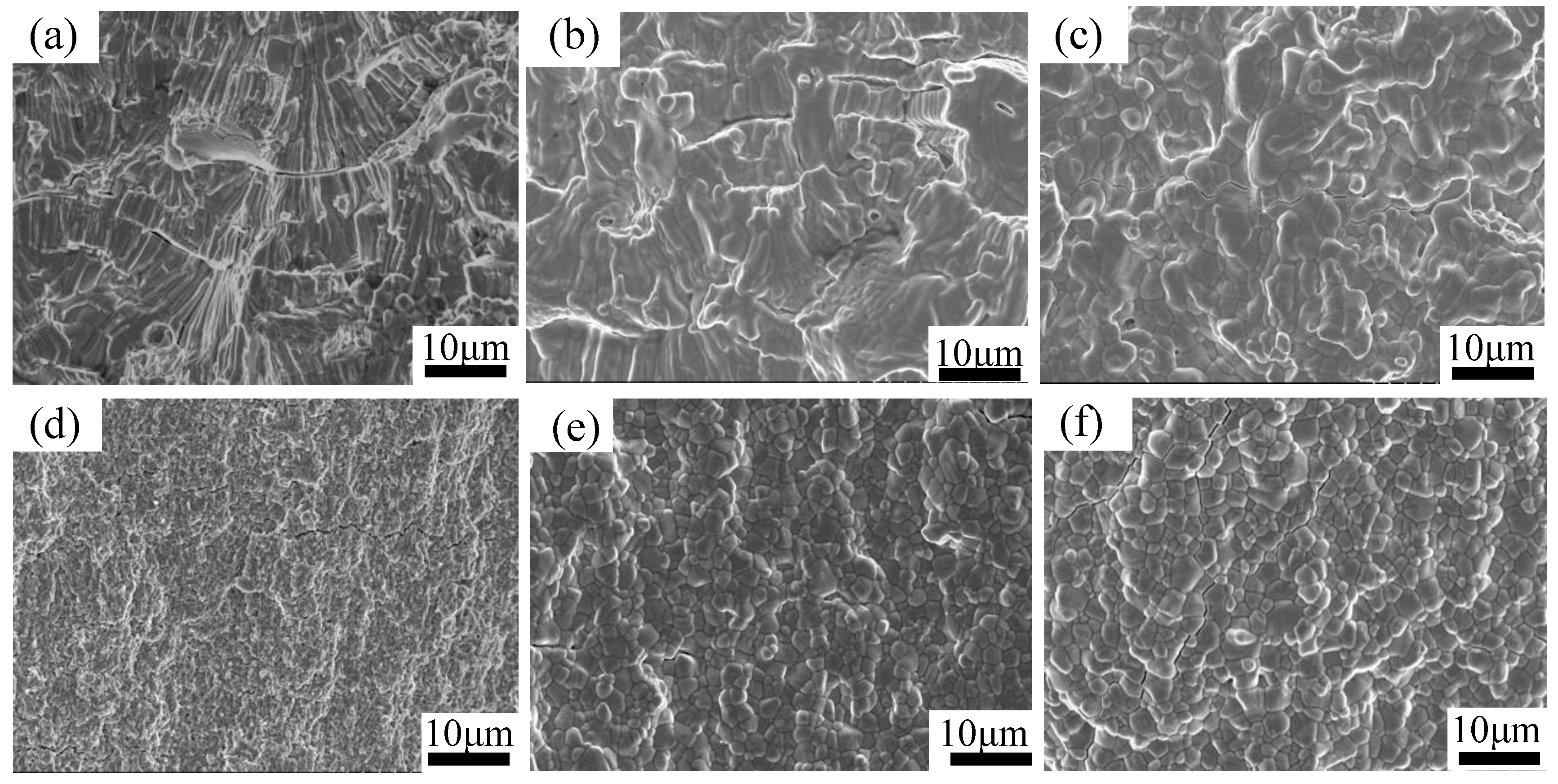

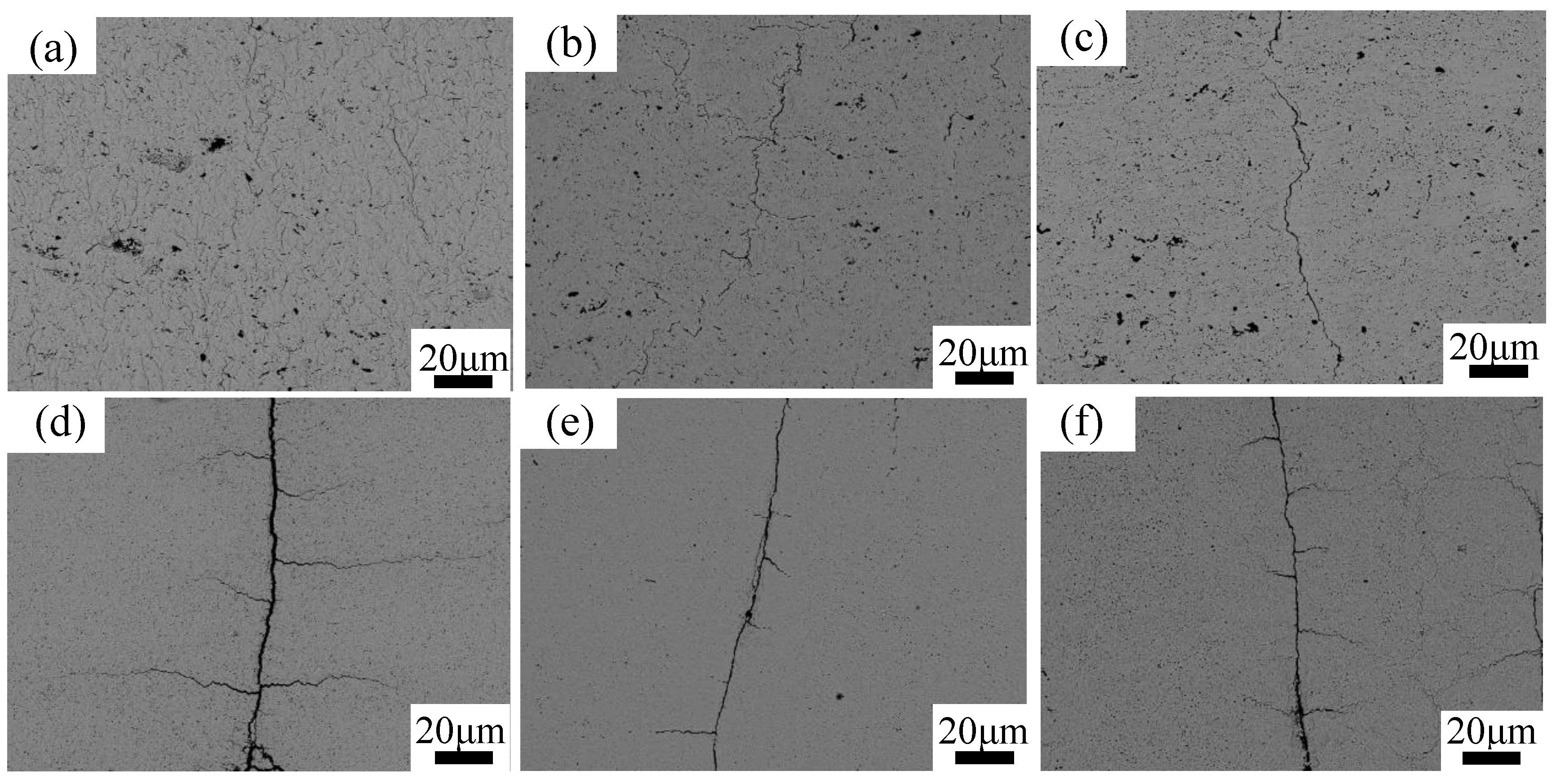

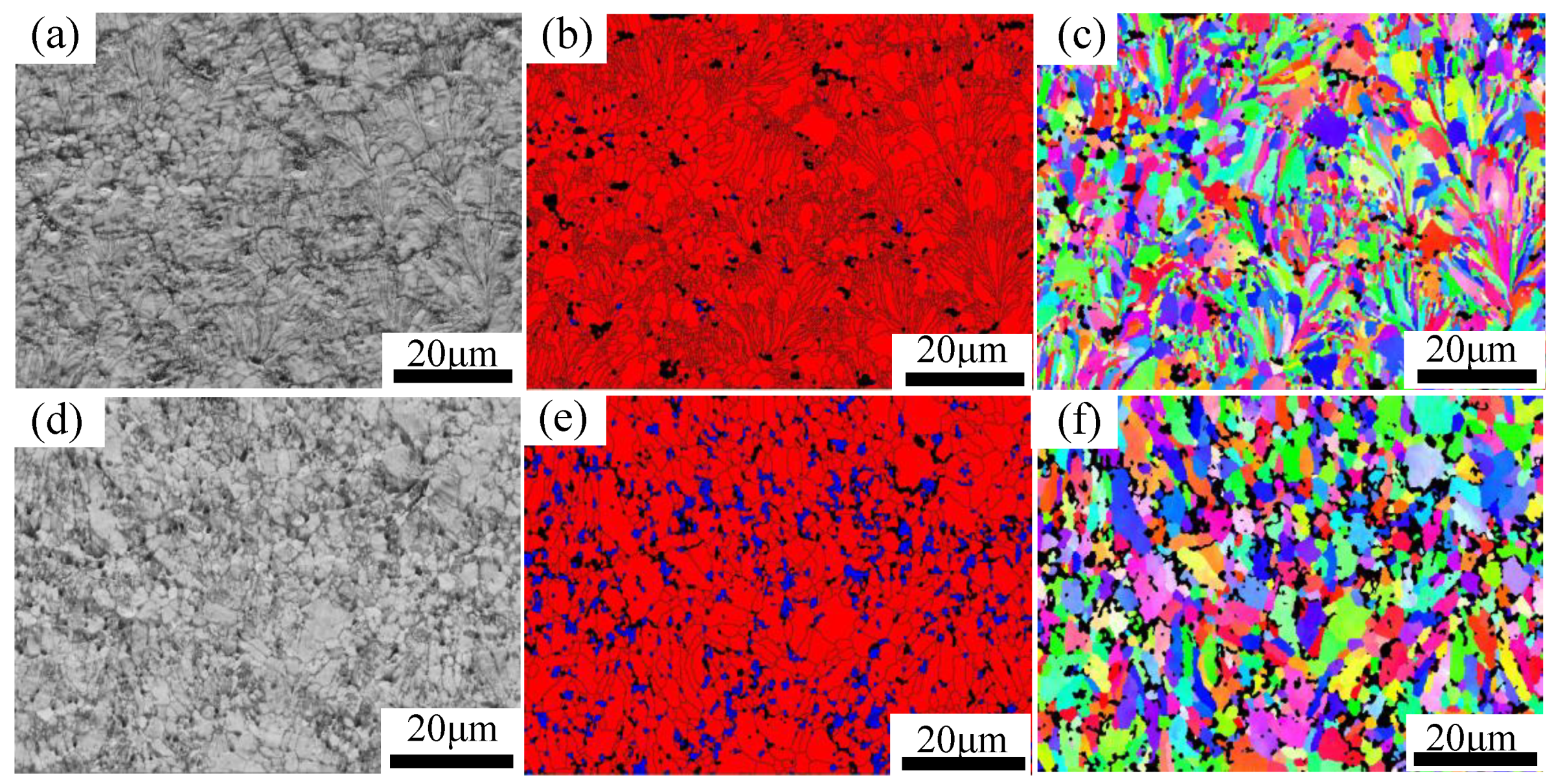

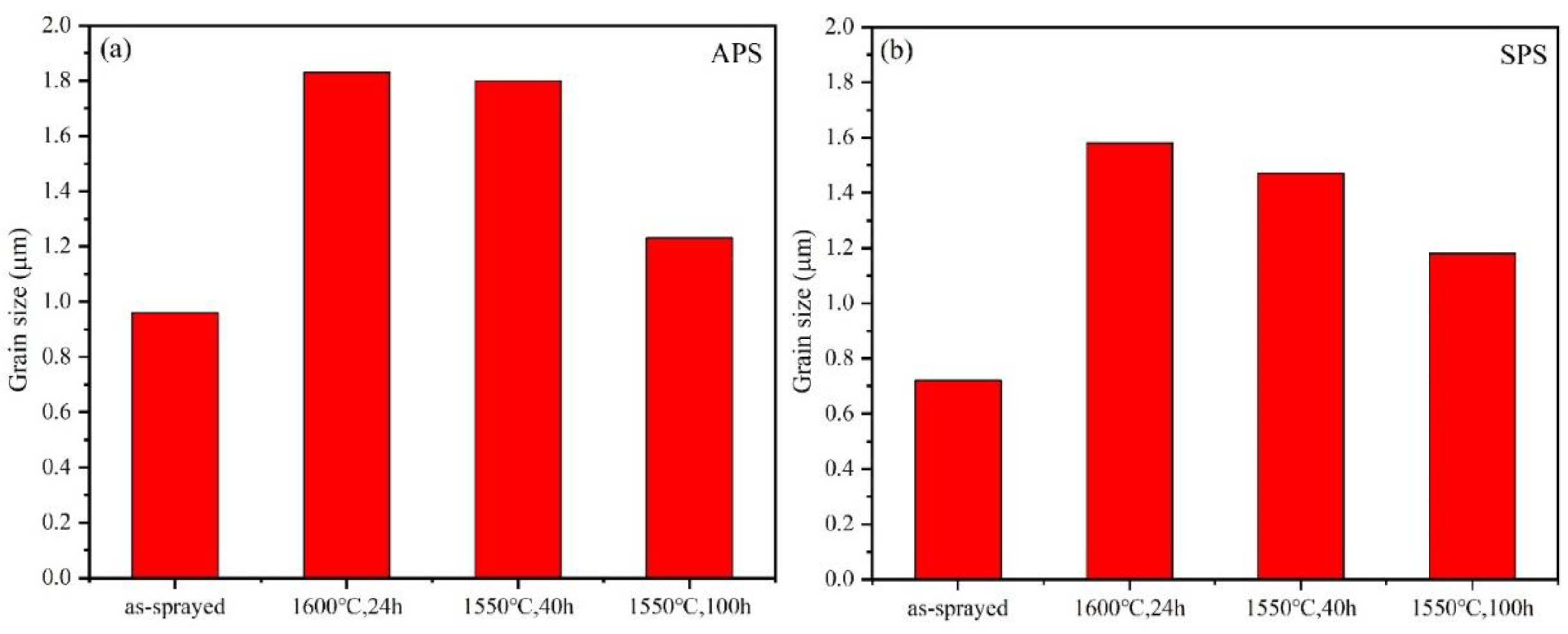

3.2. Microstructure

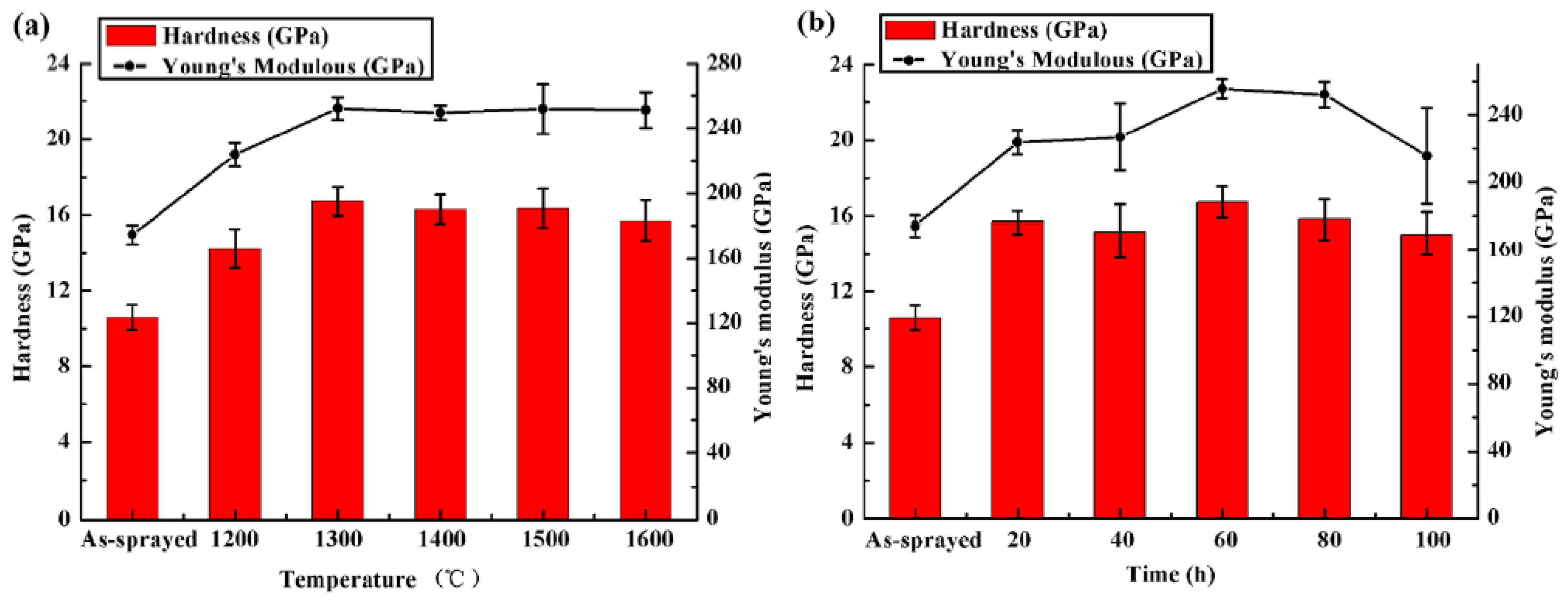

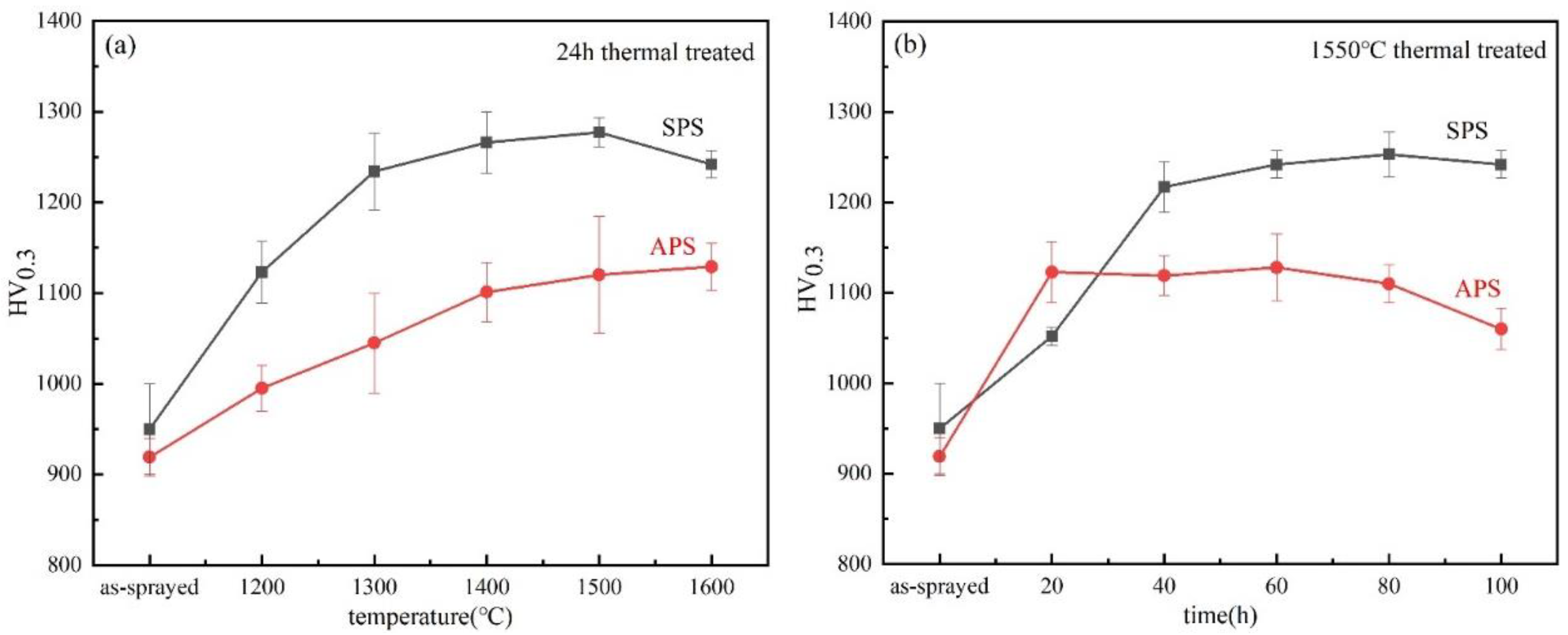

3.3. Mechanical Properties

4. Conclusions

- (1)

- Both of the coatings displayed a unique microstructure with some obvious segmentation cracks and branching cracks. The measured Ds of the nanostructured APS and SPS YSZ coatings was about 2.5 cracks mm−1 and 4 cracks mm−1, respectively.

- (2)

- There were two distinct grain types in the two as-sprayed coatings: Larger columnar grains in the APS coating and smaller equiaxed grains in the SPS coating, revealing the different microstructure of the lamellar interface. The SPS coating was short of splats, while the splat-splat interactions in the APS coating were evident.

- (3)

- The initial metastable tetragonal (t’) phase of the APS and SPS coatings underwent tetragonal-monoclinic phase transformation after 1550 °C/40 h heat treatment. The poorer phase stability of SPS TTBCs may have a connection with the smaller grain size.

- (4)

- Thermal-aged APS and SPS coatings exhibited a significant increase in H and E values accompanied by pores healing and grain growth, and for the samples thermal aged at 1550 °C, the H and E values increased sharply during the initial stage then decreased after 80 h due to the phase decomposition. The segmented APS coatings had weak bonding between the lamellaes and more uniform pores distribution during thermal exposure, which caused the mean Vickers hardness value of APS TTBCs to be much lower than that of SPS TTBCs.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Parks, W.; Hoffman, E.; Lee, W. Thermal barrier coatings issues in advanced land-based gas turbines. J. Therm. Spray Technol. 1997, 6, 187–192. [Google Scholar] [CrossRef] [Green Version]

- Padture, N.; Gell, M.; Jordan, E. Materials science-Thermal barrier coatings for gas-turbine engine applications. Science 2002, 296, 280–284. [Google Scholar] [CrossRef] [PubMed]

- Gurrappa, I.; Sambasiva, R. Thermal barrier coatings for enhanced efficiency of gas turbine engines. Surf. Coat. Technol. 2006, 201, 3016–3029. [Google Scholar] [CrossRef]

- Liu, Y.; Hu, X. Segregation and microstructural evolution at interfaces of atmospheric plasma sprayed thermal barrier coatings during thermal cycling. J. Alloys Compd. 2020, 819. in press. [Google Scholar] [CrossRef]

- Vassen, R.; Stuke, A.; Stover, D. Recent developments in the field of thermal barrier coatings. J. Therm. Spray Technol. 2009, 18, 181–186. [Google Scholar] [CrossRef]

- Levi, C. Emerging materials and processes for thermal barrier systems. Curr. Opin. Solid State Mater. Sci. 2004, 8, 77–91. [Google Scholar] [CrossRef]

- Steffens, H.D.; Babiak, Z.; Gramlich, M. Some aspects of thick thermal barrier coating lifetime prolongation. J. Therm. Spray Technol. 1998, 8, 517–522. [Google Scholar] [CrossRef]

- Zhu, D.; Miller, R. Sintering and creep behavior of plasma-sprayed zirconia-and hafnia-based thermal barrier coatings. Surf. Coat. Technol. 1998, 108, 114–120. [Google Scholar] [CrossRef] [Green Version]

- Eaton, H.; Novak, R. Sintering studies of plasma-sprayed zirconia. Surf. Coat. Technol. 1987, 32, 227–236. [Google Scholar] [CrossRef]

- Bengtsson, P.; Ericsson, T.; Wigren, J. Thermal shock testing of burner cans coated with a thick thermal barrier coating. J. Therm. Spray Technol. 1998, 7, 340–348. [Google Scholar] [CrossRef]

- Guo, H.; Vassen, R.; Stover, D. Atmospheric plasma sprayed thick thermal barrier coatings with high segmentation crack density. Surf. Coat. Technol. 2004, 186, 353–363. [Google Scholar] [CrossRef]

- Karger, M.; Vassen, R.; Stover, D. Atmospheric plasma sprayed thermal barrier coatings with high segmentation crack densities: Spraying process, microstructure and thermal cycling behavior. Surf. Coat. Technol. 2011, 206, 16–23. [Google Scholar] [CrossRef]

- Guo, H.; Murakami, H.; Kuroda, S. Thermal cycling behavior of plasma sprayed segmented thermal barrier coatings. Mater. Trans. 2006, 47, 306–309. [Google Scholar] [CrossRef] [Green Version]

- Tao, S.; Yang, J.; Li, W. Thermal stability of plasma-sprayed thick thermal barrier coatings using Triplex ProTM-200 torch. Coatings 2020, 10, 894. [Google Scholar] [CrossRef]

- Zhai, M.; Li, D.; Zhao, Y. Comparative study on thermal shock behavior of thick thermal barrier coatings fabricated with nano-based YSZ suspension and agglomerated particles. Ceram. Int. 2016, 153, 12172–12179. [Google Scholar] [CrossRef]

- Guo, H.; Murakami, H.; Kuroda, S. Effects of heat treatment on microstructures and physical properties of segmented thermal barrier coatings. Mater. Trans. 2005, 46, 1775–1778. [Google Scholar] [CrossRef] [Green Version]

- Thompson, J.; Clyne, T. The effect of heat treatment on the stiffness of zirconia top coats in plasma-sprayed TBCs. Acta Mater. 2001, 49, 1565–1575. [Google Scholar] [CrossRef]

- Witz, G.; Shklover, V.; Steurer, W. Phase evolution in yttria-stabilized zirconia thermal barrier coatings studied by rietveld refinement of X-ray powder diffraction patterns. J. Am. Ceram. Soc. 2007, 90, 2935–2940. [Google Scholar] [CrossRef]

- Keyvani, A.; Saremi, M.; Sohi, M. An investigation on oxidation, hot corrosion and mechanical properties of plasma sprayed conventional and nanostructured YSZ coatings. Surf. Coat. Technol. 2011, 206, 208–216. [Google Scholar] [CrossRef]

- Cheng, Z.; Yang, J.; Shao, F. Thermal Stability of YSZ Coatings Deposited by Plasma Spray–Physical Vapor Deposition. Coatings 2019, 9, 464. [Google Scholar] [CrossRef] [Green Version]

- Chevalier, J.; Gremillard, L.; Virkar, A.V.; Clarke, D.R. The tetragonal-monoclinic transformation in zirconia: Lessons learned and future trends. J. Am. Ceram. Soc. 2009, 92, 1901–1920. [Google Scholar] [CrossRef]

- Ganvir, A.; Markocsan, N.; Joshi, S. Influence of isothermal heat treatment on porosity and crystallite size in axial suspension plasma sprayed thermal barrier coatings for gas turbine applications. Coatings 2017, 7, 4. [Google Scholar] [CrossRef] [Green Version]

- Zhao, Y.; Wang, L.; Yang, J. Thermal aging behavior of axial suspension plasma-sprayed yttria-stabilized zirconia (YSZ) thermal barrier coatings. J. Therm. Spray Technol. 2015, 24, 338–347. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, D.; Zhong, X. Thermal shock behaviors of YSZ thick thermal barrier coatings fabricated by suspension and atmospheric plasma spraying. Surf. Coat. Technol. 2014, 249, 48–55. [Google Scholar] [CrossRef]

| Parameters | APS Coating | SPS Coating |

|---|---|---|

| Plasma gas mixture | H2 + Ar | H2 + Ar + N2 |

| Plasma gas flow rate (slpm) | H2: 7–9 | H2: 20–25 |

| Ar: 30–36 | Ar: 170–176 | |

| N2: 48–53 | ||

| Carrier gas (slpm) | Ar: 3.0–3.5 | 14.5–15.2 |

| Powder inject diameter (mm) | 1.8 | 1.5 |

| Stand-off distance (mm) | 80–85 | 70–90 |

| Feed rate (g/min) | 30 | 40 |

| Samples | Tetragonal Phase (%) | Monoclinic Phase (%) | Average Grain Size (μm) | |

|---|---|---|---|---|

| APS TTBCs | as-sprayed | 95.5 | 0.41 | 0.96 |

| 1600 °C/24 h | 97.8 | 0.79 | 1.83 | |

| 1550 °C/100 h | 82.6 | 9.38 | 1.23 | |

| SPS TTBCs | as-sprayed | 99.4 | 0.01 | 0.72 |

| 1600 °C/24 h | 95.6 | 2.45 | 1.58 | |

| 1550 °C/100 h | 70.4 | 21.1 | 1.18 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tao, S.; Yang, J.; Zhai, M.; Shao, F.; Zhong, X.; Zhao, H.; Zhuang, Y.; Ni, J.; Li, W.; Tao, S. Thermal Stability of YSZ Thick Thermal Barrier Coatings Deposited by Suspension and Atmospheric Plasma Spraying. Crystals 2020, 10, 984. https://doi.org/10.3390/cryst10110984

Tao S, Yang J, Zhai M, Shao F, Zhong X, Zhao H, Zhuang Y, Ni J, Li W, Tao S. Thermal Stability of YSZ Thick Thermal Barrier Coatings Deposited by Suspension and Atmospheric Plasma Spraying. Crystals. 2020; 10(11):984. https://doi.org/10.3390/cryst10110984

Chicago/Turabian StyleTao, Shiqian, Jiasheng Yang, Minglong Zhai, Fang Shao, Xinghua Zhong, Huayu Zhao, Yin Zhuang, Jinxing Ni, Wei Li, and Shunyan Tao. 2020. "Thermal Stability of YSZ Thick Thermal Barrier Coatings Deposited by Suspension and Atmospheric Plasma Spraying" Crystals 10, no. 11: 984. https://doi.org/10.3390/cryst10110984