On the Study of Dislocation Density in MBE GaSb-Based Structures

Abstract

:1. Introduction

2. Experiments

3. Results and Discussion

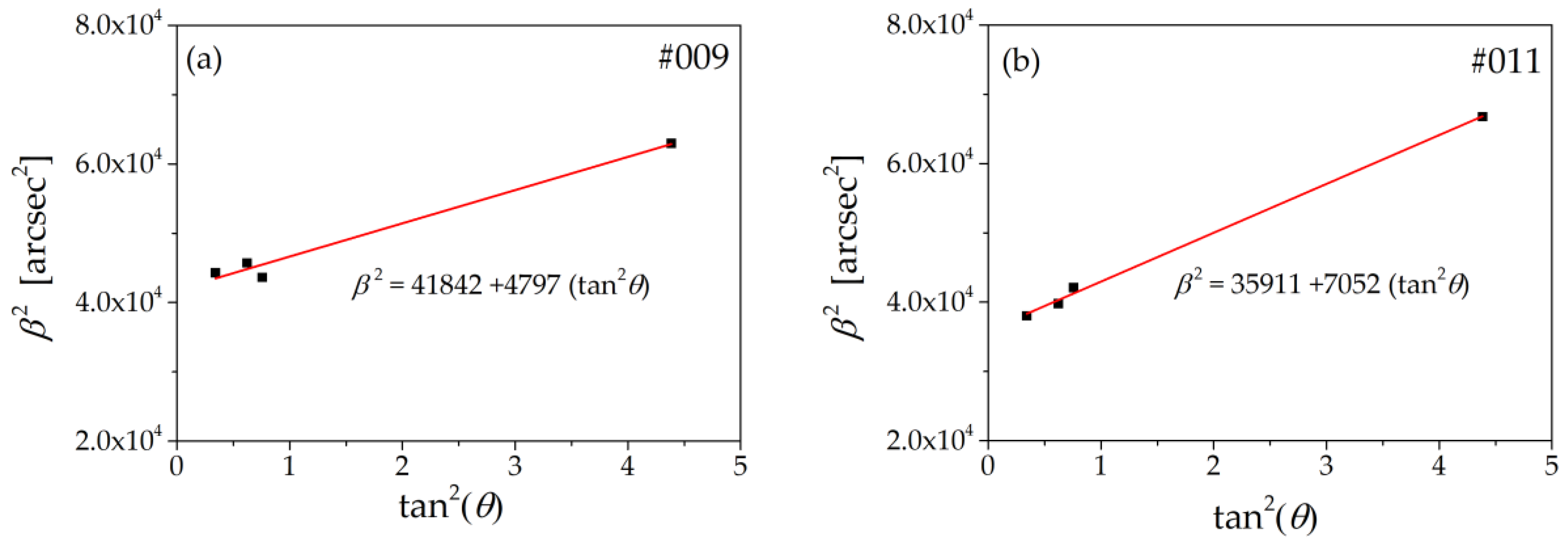

3.1. The Approach Based on HRXRD Measurements

3.2. The Approach Based on the Revealing of Etch Pits

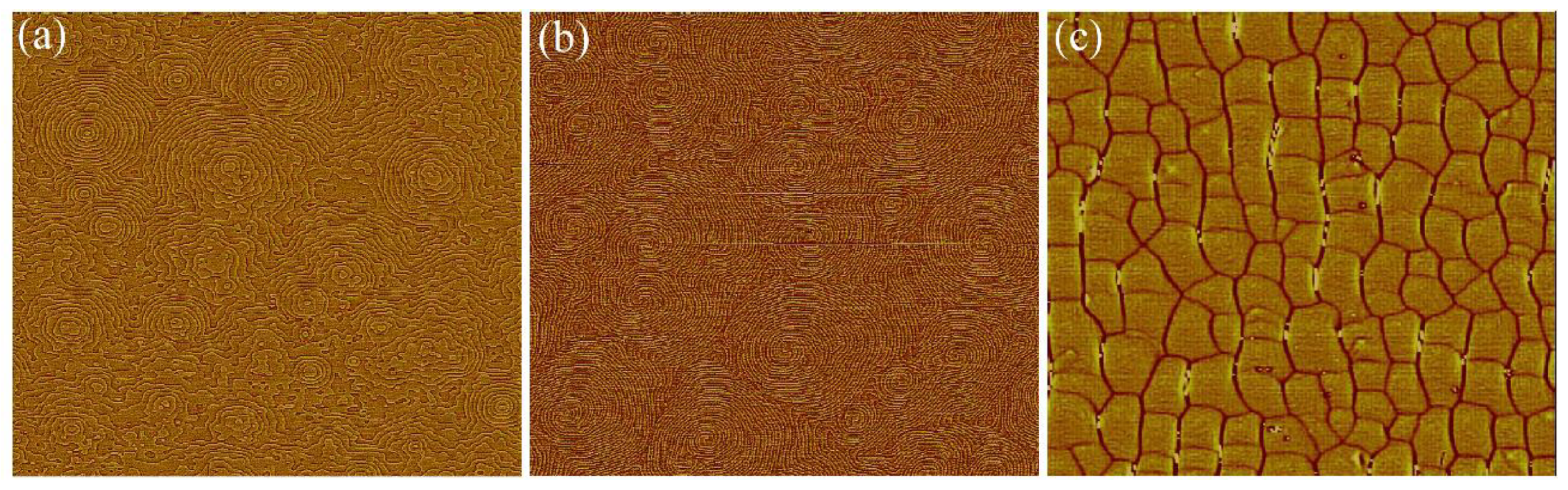

3.3. The Approach Based on Atomic Force Microscope (AFM) Observations

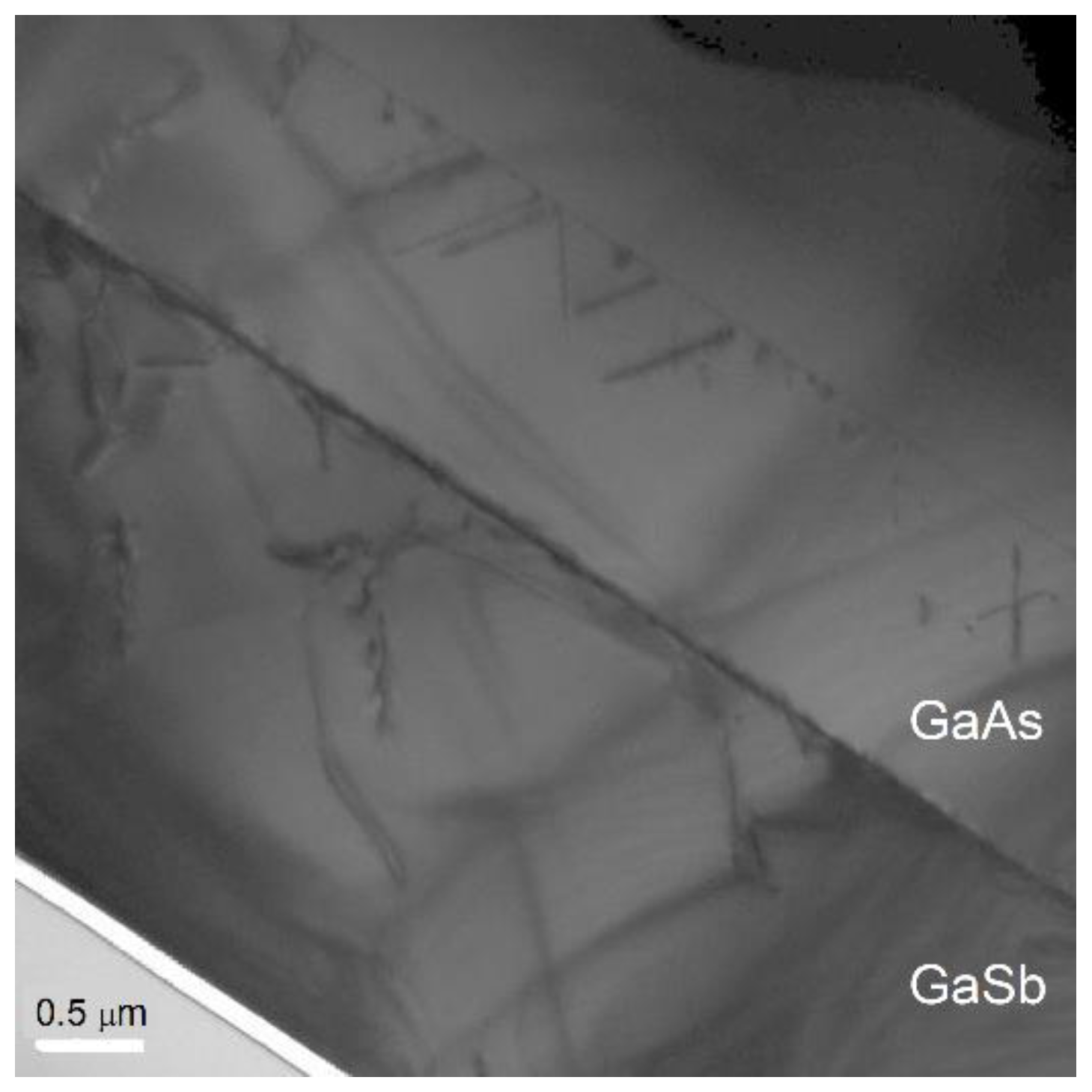

3.4. The Approach Based on High Resolution Transmission Electron Microscope (HRTEM) Observations

3.5. Discussion of Experimental Results

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Johnson, S.M. Effect of dislocations on the electrical and optical properties of long-wavelength infrared HgCdTe photovoltaic detectors. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. 1992, 10, 1499. [Google Scholar] [CrossRef]

- Dang, S.; Li, C.; Lu, M.; Guo, H.; He, Z. Threading dislocation density effect on the electrical and optical properties of InGaN light-emitting diodes. Optik 2018, 155, 26–30. [Google Scholar] [CrossRef]

- Dai, Q.; Schubert, E.F.; Kim, M.H.; Kim, J.K.; Koleske, D.D.; Crawford, M.H.; Lee, S.R.; Fischer, A.J.; Thaler, G.T.; Banas, M.A. Internal quantum efficiency and nonradiative recombination coefficient of GaInN/GaN multiple quantum wells with different dislocation densities. Appl. Phys. Lett. 2009, 94, 111109. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.-L.; Ruterana, P.; Kret, S.; El Kazzi, S.; Desplanque, L.; Wallart, X. The source of the threading dislocation in GaSb/GaAs hetero-structures and their propagation mechanism. Appl. Phys. Lett. 2013, 102, 052102. [Google Scholar] [CrossRef]

- Huang, S.; Khoshakhlagh, A.; Jallipalli, A.; Dawson, L.; Balakrishnan, G.; Huffaker, D. Strain relief by periodic misfit arrays for low defect density GaSb on GaAs. Appl. Phys. Lett. 2006, 88, 131911. [Google Scholar] [CrossRef] [Green Version]

- Jasik, A.; Sankowska, I.; Wawro, A.; Ratajczak, J.; Jakiela, R.; Pierścińska, D.; Smoczyński, D.; Czuba, K.; Regiński, K. Comprehensive investigation of the interfacial misfit array formation in GaSb/GaAs material system. Appl. Phys. A 2018, 124, 512. [Google Scholar] [CrossRef] [Green Version]

- Jasik, A.; Sankowska, I.; Ratajczak, J.; Wawro, A.; Smoczyński, D.; Czuba, K.; Wzorek, M. Atomically smooth interfaces of type-II InAs/GaSb superlattice on metamorphic GaSb buffer grown in 2D mode on GaAs substrate using MBE. Curr. Appl. Phys. 2019, 19, 120–127. [Google Scholar] [CrossRef]

- Huang, S.; Balakrishnan, G.; Huffaker, D.L. Interfacial misfit array formation for GaSb growth on GaAs. J. Appl. Phys. 2009, 105, 103104. [Google Scholar] [CrossRef]

- Jallipalli, A.; Balakrishnan, G.; Huang, S.H.; Rotter, T.J.; Nunna, K.; Liang, B.L.; Dawson, L.R.; Huffaker, D.L. Structural Analysis of Highly Relaxed GaSb Grown on GaAs Substrates with Periodic Interfacial Array of 90° Misfit Dislocations. Nanoscale Res. Lett. 2009, 4, 1458–1462. [Google Scholar] [CrossRef] [Green Version]

- Tan, K.; Jia, B.W.; Loke, W.; Wicaksono, S.; Yoon, S. Formation of interfacial misfit dislocation in GaSb/GaAs heteroepitaxy via anion exchange process. J. Cryst. Growth 2015, 427, 80–86. [Google Scholar] [CrossRef]

- Benyahia, D.; Kubiszyn, Ł.; Michalczewski, K.; Kębłowski, A.; Martyniuk, P.; Piotrowski, J.; Rogalski, A. Interfacial Misfit Array Technique for GaSb Growth on GaAs (001) Substrate by Molecular Beam Epitaxy. J. Electron. Mater. 2017, 47, 299–304. [Google Scholar] [CrossRef] [Green Version]

- Stirland, D.J. Quantitative defect etching of GaAs on Si: Is it possible? Appl. Phys. Lett. 1988, 53, 2432–2434. [Google Scholar] [CrossRef]

- Ayers, J. The measurement of threading dislocation densities in semiconductor crystals by X-ray diffraction. J. Cryst. Growth 1994, 135, 71–77. [Google Scholar] [CrossRef]

- Papis-Polakowska, E. Surface treatments of GaSb and related materials for the processing of mid-infrared semiconductor devices. Electron Technol. 2005, 37, 1–34. [Google Scholar]

- Brown, G.T.; Cockayne, B.; MacEwan, W.R.; Steward, V.W. A defect etchant for single crystal GaSb. J. Mater. Sci. Lett. 1982, 1, 253–256. [Google Scholar] [CrossRef]

- Cockayne, B.; Steward, V.; Brown, G.; MacEwan, W.; Young, M.; Courtney, S. The Czochralski growth of gallium antimonide single crystals under reducing conditions. J. Cryst. Growth 1982, 58, 267–272. [Google Scholar] [CrossRef]

- Reijnen, L.; Brunton, R.; Grant, I. GaSb single-crystal growth by vertical gradient freeze. J. Cryst. Growth 2005, 275, e595–e600. [Google Scholar] [CrossRef]

- Costa, E.; DeDavid, B.; Müller, A. Investigations of structural defects by etching of GaSb grown by the liquid-encapsulated Czochralski technique. Mater. Sci. Eng. B 1997, 44, 208–212. [Google Scholar] [CrossRef]

- Brar, B.; Leonard, D. Spiral growth of GaSb on (001) GaAs using molecular beam epitaxy. Appl. Phys. Lett. 1995, 66, 463–465. [Google Scholar] [CrossRef]

- Jasik, A.; Kubacka-Traczyk, J.; RegińskiK; Sankowska, I.; Jakieła, R.; Wawro, A.; Kaniewski, J. Method of determination of AlGaAsSb layer composition in molecular beam epitaxy processes with regard to unintentional As incorporation. J. Appl. Phys. 2011, 110, 073509. [Google Scholar] [CrossRef]

- Grabmaier, J.G.; Watson, C.B. Dislocation Etch Pits in Single Crystal GaAs. Phys. Status Solidi (b) 1969, 32, K13–K15. [Google Scholar] [CrossRef]

- Weiss, E.; Klin, O.; Grossmann, S.; Snapi, N.; Lukomsky, I.; Aronov, D.; Yassen, M.; Berkowicz, E.; Glozman, A.; Klipstein, P.C.; et al. InAsSb-based XBnn bariodes grown by molecular beam epitaxy on GaAs. J. Cryst. Growth 2012, 339, 31–35. [Google Scholar] [CrossRef]

- Gatos, H.C.; LaVine, M.C. Characteristics of the {111} Surfaces of the III–V Intermetallic Compounds. J. Electrochem. Soc. 1960, 107, 427. [Google Scholar] [CrossRef]

- Mirowska, A.; Orłowski, W.; Bańkowska, A.; Hruban, A. Growth of gallium antimonide single crystals in and directions by Czochralski method. Mater. Elektron. 2009, 37, 3. [Google Scholar]

- Kodama, M. Defect evaluation and electrical characteristics of GaSb and In0.17Ga0.83Sb films grown by molecular beam epitaxy. Phys. Status Solidi (a) 1994, 141, 145–154. [Google Scholar] [CrossRef]

| No. | Thickness (μm) | Material System |

|---|---|---|

| Substrates | ||

| #001 | 450 | p-type GaSb (100) ± 0.1°, undoped, one side polished, EPD ≤ 2 × 103 cm−2 |

| #002 | 450 | n-type GaAs (100) ± 0.5°, one side polished, EPD ≤ 5 × 102 cm−2 |

| Group 1: homoepitaxial layers (GaSb/GaSb) | ||

| #003 | 1.0 | thin and thick layers grown under optimized conditions |

| #004 | 8.0 | |

| #005 | 1.0 | thin layers grown under non-optimized conditions |

| #006 | 1.0 | |

| Group 2: heteroepitaxial structures | ||

| heteroepitaxial metamorphic systems (M-GaSb/GaAs) | ||

| #007 | 1.5 | layers with different thicknesses |

| #008 | 4.0 | |

| #009 | 8.0 | |

| heteroepitaxial structures deposited on GaAs substrates using interfacial misfit array (IMF-GaSb/GaAs) with different GaSb layer thickness | ||

| #010 | 4.0 | thick |

| #011 | 2.0 | medium |

| #012 | 2.5 | medium |

| #013 | 1.0 | thin (V/III = 2.3) |

| #014 | 1.0 | thin (V/III = 2.9) |

| #015 | 1.0 | thin (V/III = 3.2) |

| #016 | 5.0 | thick |

| heteroepitaxial structures deposited on GaAs substrates using IMF and low-temperature (LT) AlSb interlayer with different thicknesses (GaSb/LT-AlSb/GaAs) | ||

| #017 | 1.0 | 1.0 nm |

| #018 | 1.0 | 2.0 nm |

| #019 | 1.0 | 30.0 nm |

| Group 3: complex heterostructures | ||

| #020 | 0.5 | IMF-AlSb/GaAs heterostructure |

| #021 | 1.0 | Al0.5Ga0.5As0.05Sb0.95 layer deposited on GaSb substrate |

| #022 | 30 × (57.9 × 10-4) | InAs/GaSb superlattice deposited on GaSb substrate (thicknesses of InAs and GaSb layers in SL were 8 and 9 monolayers (ML), respectively) |

| No | Etchants | References | Etching Conditions | |||

|---|---|---|---|---|---|---|

| Ratio | Temperature | Time (s) | Rate (nm/s) | |||

| I | 20% KOH | [5] | 25 g diluted in 100 mL of H2O | RT and 80 °C | 1800 | - |

| II | H2O2-HCl | [15] | 2:1 | RT | 15 | 180–150 |

| III | H2O2-HCl-H2O | [17,22] | 2:4:1 | RT and 70 °C | 1200/15 | 2/135 |

| IV | H2O2-H2SO4 | [18] | 1:5 | 10 °C | 180 | 15 |

| V | FeCl3 (0.13 M)-HCl (13 M) | [24] | - | RT and 40 °C | 60 | 15 |

| No | Threading Dislocation Density (cm−2) | |||

|---|---|---|---|---|

| DA | DS | DEP | DAFM | |

| Substrates | ||||

| #001 | 2.5 × 106 | 8.1 × 107 | 3.7 × 103 | 2D |

| #002 | 1.8 × 107 | 1.5 × 108 | - | 2D |

| Group 1: homoepitaxial layers (GaSb/GaSb) | ||||

| #003 | 8.1 × 106 | 1.1 × 108 | 7.6 × 103 | 2D-T |

| #004 | 8.5 × 106 | 1.0 × 108 | 2.4 × 106 | 3D |

| #005 | 9.3 × 106 | 8.9 × 107 | 2.2 × 104 | 6.5 × 106 (t/c) |

| #006 | 9.5 × 106 | 9.3 × 107 | 3.6 × 104 | 1.2 × 108 (t/c) |

| Group 2: heteroepitaxial structures heteroepitaxial metamorphic systems (M-GaSb/GaAs) | ||||

| #007 | 4.9 × 108 | 3.4 × 108 | failed | 3.6 × 107 |

| #008 | 4.1 × 108 | 3.3 × 108 | 4.0 × 105 | 2D-T |

| #009 | 4.8 × 108 | 2.6 × 108 | 2.1 × 107 | 3D |

| heteroepitaxial structures deposited on GaAs substrates using interfacial misfit array (IMF-GaSb/GaAs) with different GaSb layer thicknesses | ||||

| #010 | 1.9 × 108 | 2.0 × 108 | 9.3 × 106 | 2D-T |

| #011 | 4.2 × 108 | 4.0 × 108 | 1.4 × 107 | 1.6 × 107 |

| #012 | 2.6 × 108 | 3.4 × 108 | 4.3 × 107 | 4.6 × 107 |

| #013 | 7.3 × 108 | 5.9 × 108 | 8.5 × 106 | 7.8 × 106 |

| #014 | 1.0 × 109 | 5.6 × 108 | 4.5 × 107 | 7.4 × 107 |

| #015 | 1.1 × 109 | 4.8 × 108 | 7.0 × 107 | 1.2 × 108 |

| #016 | 1.5 × 108 | 3.4 × 108 | 9.7 × 106 | 1.6 × 108 (c) |

| heteroepitaxial structures deposited on GaAs substrates using IMF and low-temperature (LT) AlSb interlayer with different thicknesses (GaSb/LT-AlSb/GaAs) | ||||

| #017 | 6.5 × 108 | 5.6 × 108 | 2.2 × 106 | 4.1 × 107 |

| #018 | 7.2 × 108 | 5.7 × 108 | 2.4 × 106 | 5.1 × 107 |

| #019 | 9.2 × 108 | 4.7 × 108 | 3.0 × 106 | 7.1 × 107 |

| Group 3: complex heterostructures | ||||

| #020 | 2.8 × 109 | 2.7 × 109 | - | 4.0 × 107 |

| #021 | 5.6 × 108 | 8.0 × 108 | - | 7.6 × 107 |

| #022 | 3.2 × 108 | 6.8 × 108 | - | 1.0 × 108 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jasik, A.; Smoczyński, D.; Sankowska, I.; Wawro, A.; Ratajczak, J.; Czuba, K.; Kozłowski, P. On the Study of Dislocation Density in MBE GaSb-Based Structures. Crystals 2020, 10, 1074. https://doi.org/10.3390/cryst10121074

Jasik A, Smoczyński D, Sankowska I, Wawro A, Ratajczak J, Czuba K, Kozłowski P. On the Study of Dislocation Density in MBE GaSb-Based Structures. Crystals. 2020; 10(12):1074. https://doi.org/10.3390/cryst10121074

Chicago/Turabian StyleJasik, Agata, Dariusz Smoczyński, Iwona Sankowska, Andrzej Wawro, Jacek Ratajczak, Krzysztof Czuba, and Paweł Kozłowski. 2020. "On the Study of Dislocation Density in MBE GaSb-Based Structures" Crystals 10, no. 12: 1074. https://doi.org/10.3390/cryst10121074