Ca-induced Plasticity in Magnesium Alloy: EBSD Measurements and VPSC Calculations

Abstract

:1. Introduction

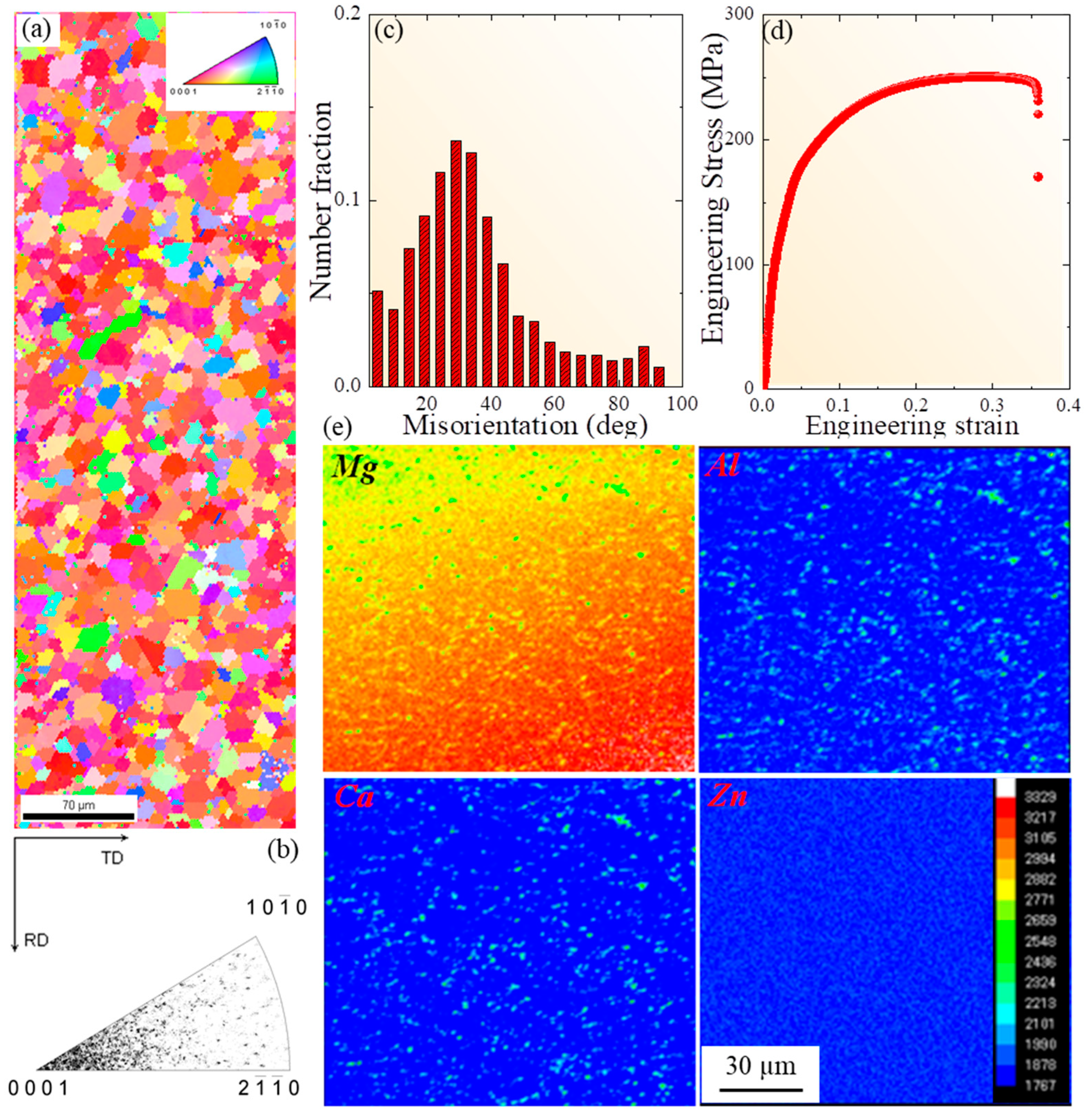

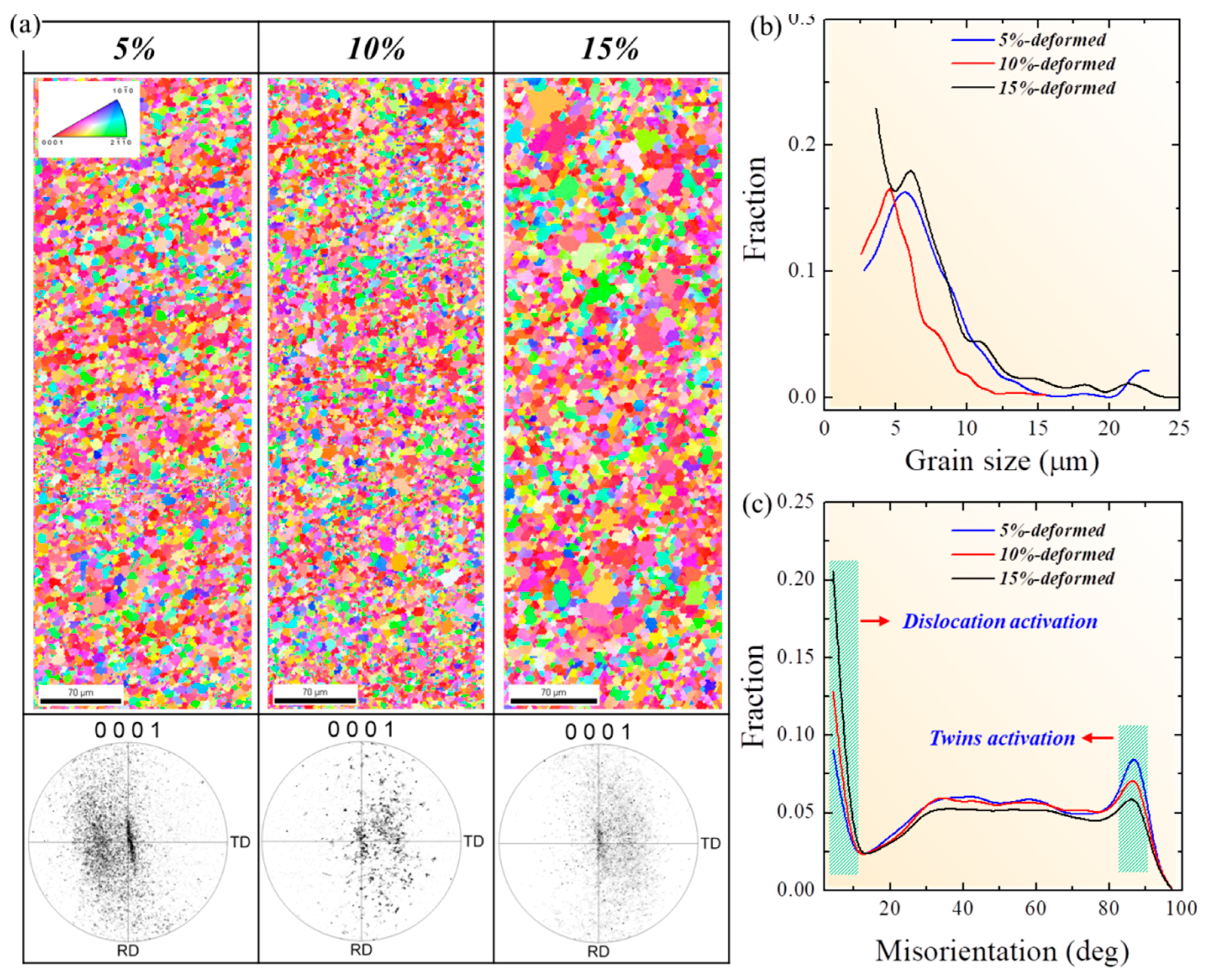

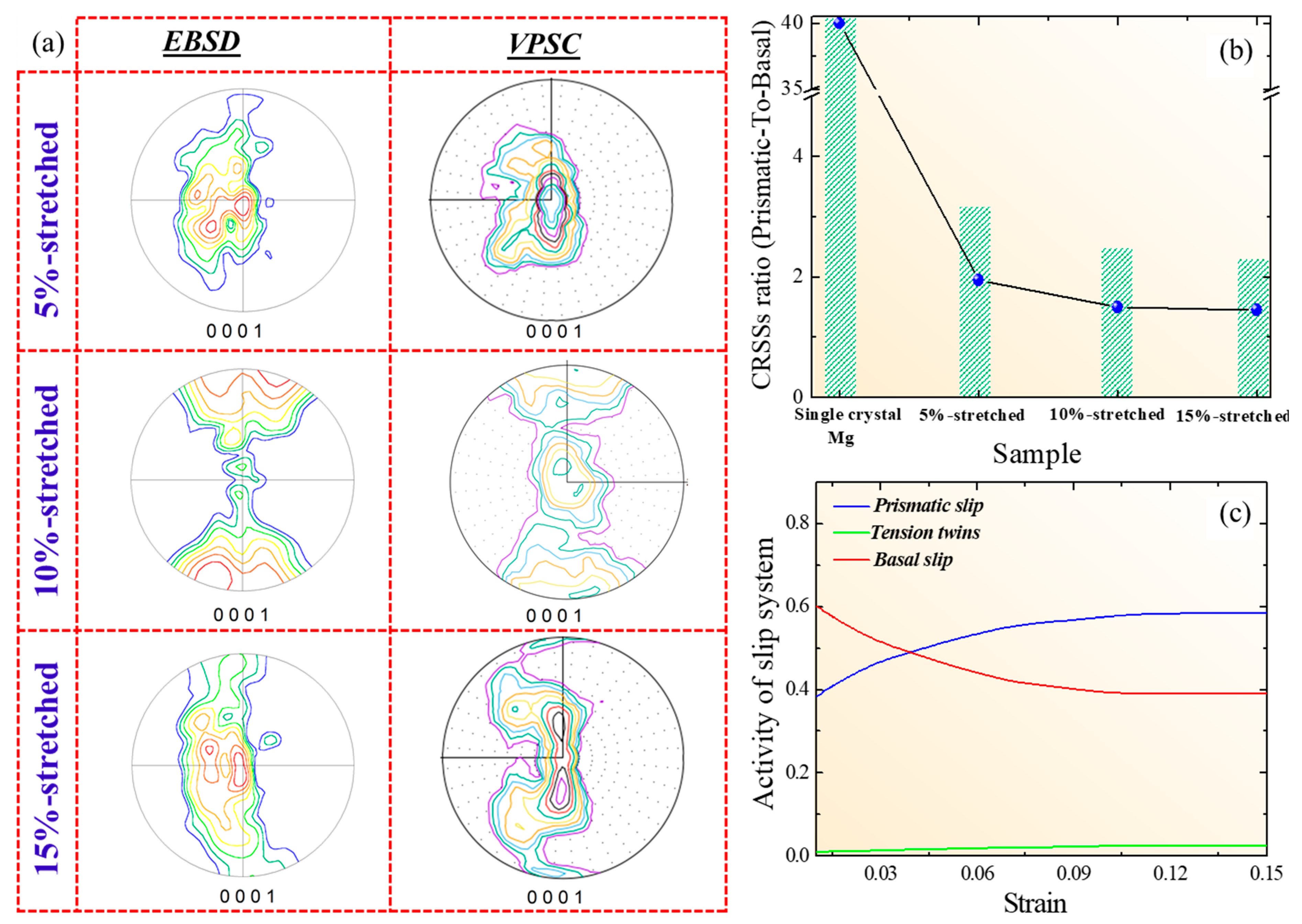

2. Experiments and VPSC Procedure

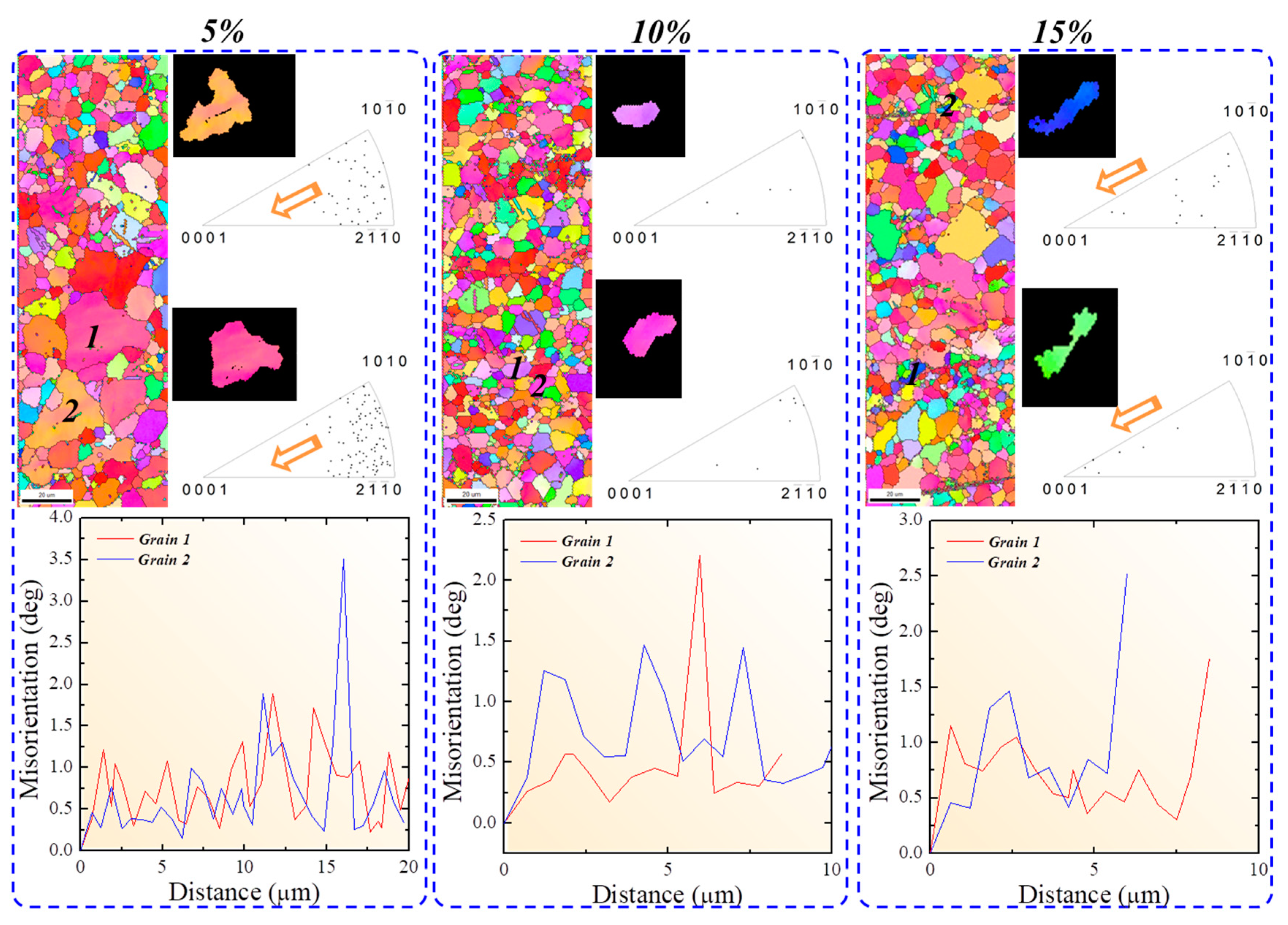

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Miller, V.M.; Berman, T.D.; Beyerlein, I.; Jones, J.W.; Pollock, T.M. Prediction of the plastic anisotropy of magnesium alloys with synthetic textures and implications for the effect of texture on formability. Mater. Sci. Eng. A 2016, 675, 345–360. [Google Scholar] [CrossRef] [Green Version]

- Chaudry, U.M.; Hamad, K.; Kim, J.G. On the ductility of magnesium based materials: A mini review. J. Alloys Compd. 2019, 792, 652–664. [Google Scholar] [CrossRef]

- Agnew, S.R.; Duygulu, O. Plastic anisotropy and the role of non-basal slip in magnesium alloy AZ31B. Int. J. Plast. 2005, 21, 1161–1193. [Google Scholar] [CrossRef]

- Luo, D.; Luo, D.; Wang, H.; Zhao, L.; Wang, C.; Liu, G.; Liu, Y.; Jiang, Q. Effect of differential speed rolling on the room and elevated temperature tensile properties of rolled AZ31 Mg alloy sheets. Mater. Charac. 2017, 124, 223–228. [Google Scholar] [CrossRef]

- Hamad, K.; Ko, Y.G. A cross-shear deformation for optimizing the strength and ductility of AZ31 magnesium alloys. Sci. Rep. 2016, 6, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Samman, T.Al.; Li, X. Sheet texture modification in magnesium-based alloys by selective rare earth alloying. Mater. Sci. Eng. A 2011, 528, 3809–3822. [Google Scholar] [CrossRef]

- Sandlobes, S.; Pie, Z.; Friak, M.; Zhu, L.F.; Wang, F.; Zaefferer, S.; Raabe, D.; Neugebauer, J. Ductility improvement of Mg alloys by solid solution: Ab initio modeling, synthesis and mechanical properties. Acta. Mater. 2014, 70, 92–104. [Google Scholar] [CrossRef]

- Chaudry, U.M.; Kim, T.H.; Park, S.D.; Kim, Y.S.; Hamad, K.; Kim, J.G. On the high formability of AZ31-0.5Ca magnesium alloy. Materials. 2018, 11, 1–15. [Google Scholar]

- Agnew, S.R.; Yoo, M.H.; Tomé, C.N. Application of texture simulation to understanding mechanical behavior of Mg and solid solution alloys containing Li or Y. Acta. Mater. 2001, 49, 4277–4289. [Google Scholar] [CrossRef]

- Lebensohn, R.A.; Tomé, C.N. A self-consistent anisotropic approach for the simulation of plastic deformation and texture development of polycrystals: Application to zirconium alloys. Acta. Metal et Mater. 1993, 41, 2611–2624. [Google Scholar] [CrossRef]

- Khan, A.S.; Pandey, A.; Herold, T.G.; Mishra, R.K. Mechanical response and texture evolution of AZ31 alloy at large strains for different strain rates and temperatures. Int. J. Plast. 2011, 27, 688–706. [Google Scholar] [CrossRef]

- Sandlobes, S.; Friak, M.; Kerzel, S.K.; Pie, Z.; Neugebauer, J.; Raabe, D. A rare-earth free magnesium alloy with improved intrinsic ductility. Sci. Rep. 2017, 7, 1–8. [Google Scholar] [CrossRef] [PubMed]

- He, J.; Jiang, B.; Yang, Q.; Li, X.; Xia, X.; Pan, F. Influence of pre-hardening on microstructure evolution and mechanical behavior of AZ31 magnesium alloy sheet. J. Alloys Compd. 2015, 621, 301–306. [Google Scholar] [CrossRef]

- Martin, R.S.; Prado, M.T.P.; Segurado, J.; Bohlen, J.; Urrutia, I.G.; Llorca, J.; Aldareguia, J.M.M. Measuring the critical resolved shear stress in Mg alloys by instrumented nanoindentation. Acta. Mater. 2014, 71, 283–292. [Google Scholar] [CrossRef] [Green Version]

- Manrique, H.P.; Yi, S.B.; Bohlen, J.; Letzig, D.; Perez, P.M.T. Effect of Nd additions on extrusion texture development and slip activity in a Mg-Mn alloy. Metall. Mater. Trans. A 2013, 44, 4819–4829. [Google Scholar] [CrossRef]

- Chaudry, U.M.; Kim, T.H.; Park, S.D.; Kim, Y.S.; Hamad, K.; Kim, J.G. Effect of calcium on the activity of slip systems in AZ31 magnesium alloy. Mater. Sci. Eng. A 2019, 739, 289–294. [Google Scholar] [CrossRef]

- Angew, S.R.; Tome, C.N.; Brown, D.W.; Holden, T.M.; Vogel, S.C. Study of slip mechanisms in a magnesium alloy by neutron diffraction and modeling. Scripta. Mater. 2003, 48, 1003–1008. [Google Scholar]

- Suh, B.C.; Kim, J.H.; Bae, J.H.; Hwang, J.H.; Shim, M.S.; Kim, N.J. Effect of Sn addition on the microstructure and deformation behavior of Mg-3Al alloy. Acta. Mater. 2017, 124, 268–279. [Google Scholar] [CrossRef]

- Chun, Y.B.; Battaini, M.; Davies, C.H.J.; Hwang, S.K. Distribution characteristics of in-grain misorientation axes in cold-rolled commercially pure titanium and their correlation with active slip modes. Metall. Mater. Trans. A 2010, 41, 3473–3487. [Google Scholar] [CrossRef]

- Chaudry, U.M.; Kim, Y.S.; Hamad, K. Effect of Ca addition on the room-temperature formability of AZ31 magnesium alloy. Mater. Lett. 2019, 238, 305–308. [Google Scholar] [CrossRef]

- Yuasa, M.; Miyazawa, N.; Hayashi, M.; Mabuchi, M.; Chino, Y. Effects of group II elements on the cold stretch formability of Mg-Zn alloys. Acta. Mater. 2015, 83, 294–303. [Google Scholar] [CrossRef]

- Trang, T.T.T.; Zhang, J.H.; Kim, J.H.; Zargaran, A.; Hwang, J.H.; Suh, B.C.; Kim, N.J. Designing a magnesium alloy with high strength and high formability. Nat. Comm. 2018, 9, 1–6. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.H.; Kang, N.E.; Yim, C.D.; Kim, B.K. Effect of calcium content on the microstructural evolution and mechanical properties of wrought Mg-3Al-1Zn alloy. Mater. Sci. Eng. A 2009, 525, 18–29. [Google Scholar] [CrossRef]

| Alloy Sample | Deformation Mode | τ0 | τ1 | θ0 | θ1 | CRSSP/CRSSB |

|---|---|---|---|---|---|---|

| 5% | <a> basal slip | 50 | 12 | 99 | 55 | 1.90 |

| <a> prismatic slip | 95 | 29 | 135 | 10 | ||

| <a + c> pyramidal slip | 315 | 38 | 57 | 19 | ||

| Tension twin | 14 | 170 | 105 | 50 | ||

| 10% | <a> basal slip | 57 | 9 | 115 | 62 | 1.50 |

| <a> prismatic slip | 91 | 37 | 148 | 8 | ||

| <a + c> pyramidal slip | 305 | 44 | 64 | 22 | ||

| Tension twin | 15 | 185 | 110 | 55 | ||

| 15% | <a> basal slip | 65 | 15 | 125 | 45 | 1.47 |

| <a> prismatic slip | 96 | 35 | 137 | 9 | ||

| <a + c> pyramidal slip | 302 | 195 | 58 | 33 | ||

| Tension twin | 20 | 178 | 112 | 58 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Masood Chaudry, U.; Hamad, K.; Kim, J.-G. Ca-induced Plasticity in Magnesium Alloy: EBSD Measurements and VPSC Calculations. Crystals 2020, 10, 67. https://doi.org/10.3390/cryst10020067

Masood Chaudry U, Hamad K, Kim J-G. Ca-induced Plasticity in Magnesium Alloy: EBSD Measurements and VPSC Calculations. Crystals. 2020; 10(2):67. https://doi.org/10.3390/cryst10020067

Chicago/Turabian StyleMasood Chaudry, Umer, Kotiba Hamad, and Jung-Gu Kim. 2020. "Ca-induced Plasticity in Magnesium Alloy: EBSD Measurements and VPSC Calculations" Crystals 10, no. 2: 67. https://doi.org/10.3390/cryst10020067