Mechanical and Magnetic Properties of the High-Entropy Alloys for Combinatorial Approaches

Abstract

1. Introduction

2. History of High-Entropy Alloys for Combinatorial Approaches

3. Mechanical Properties of High-Entropy Alloys

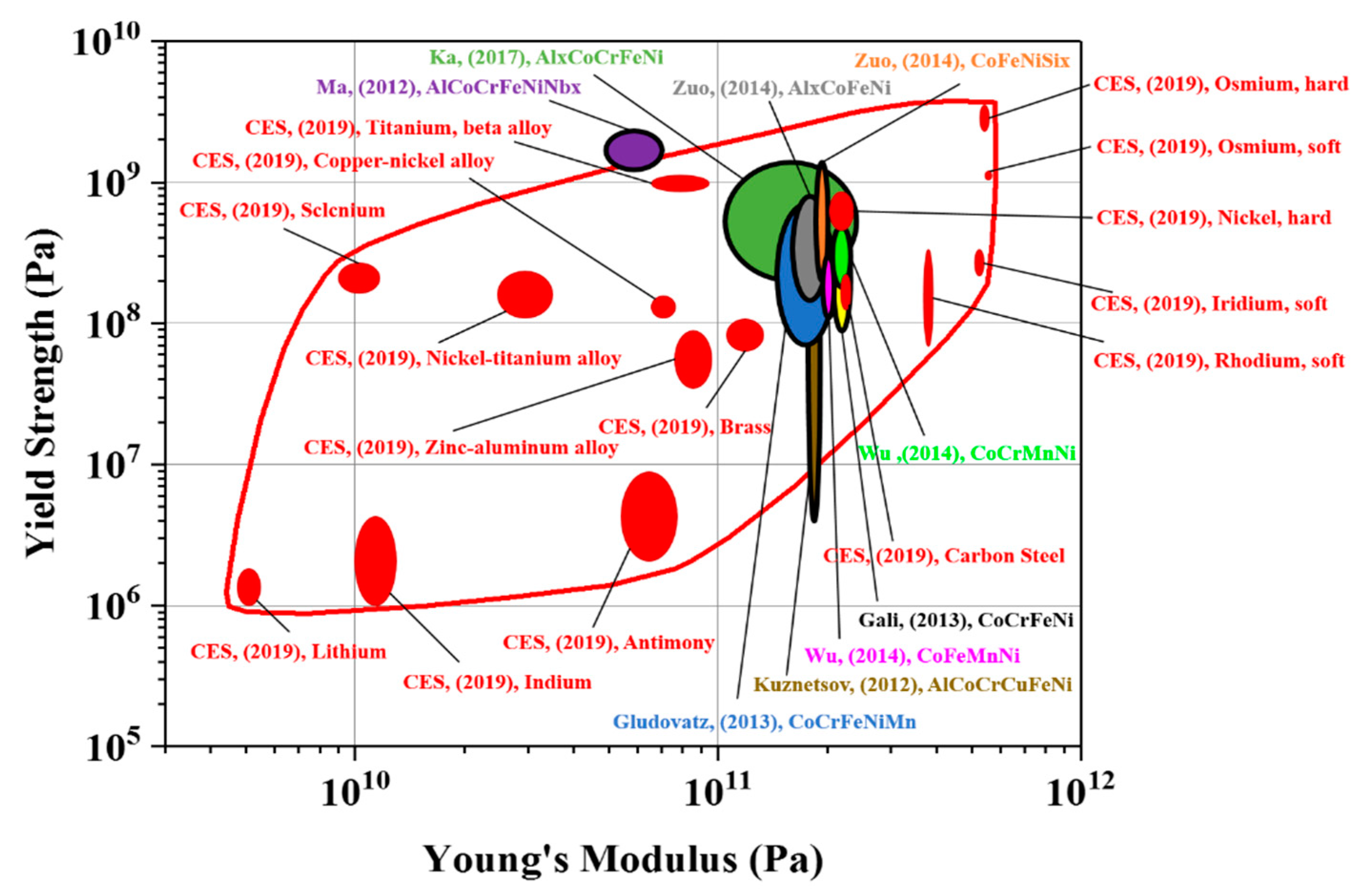

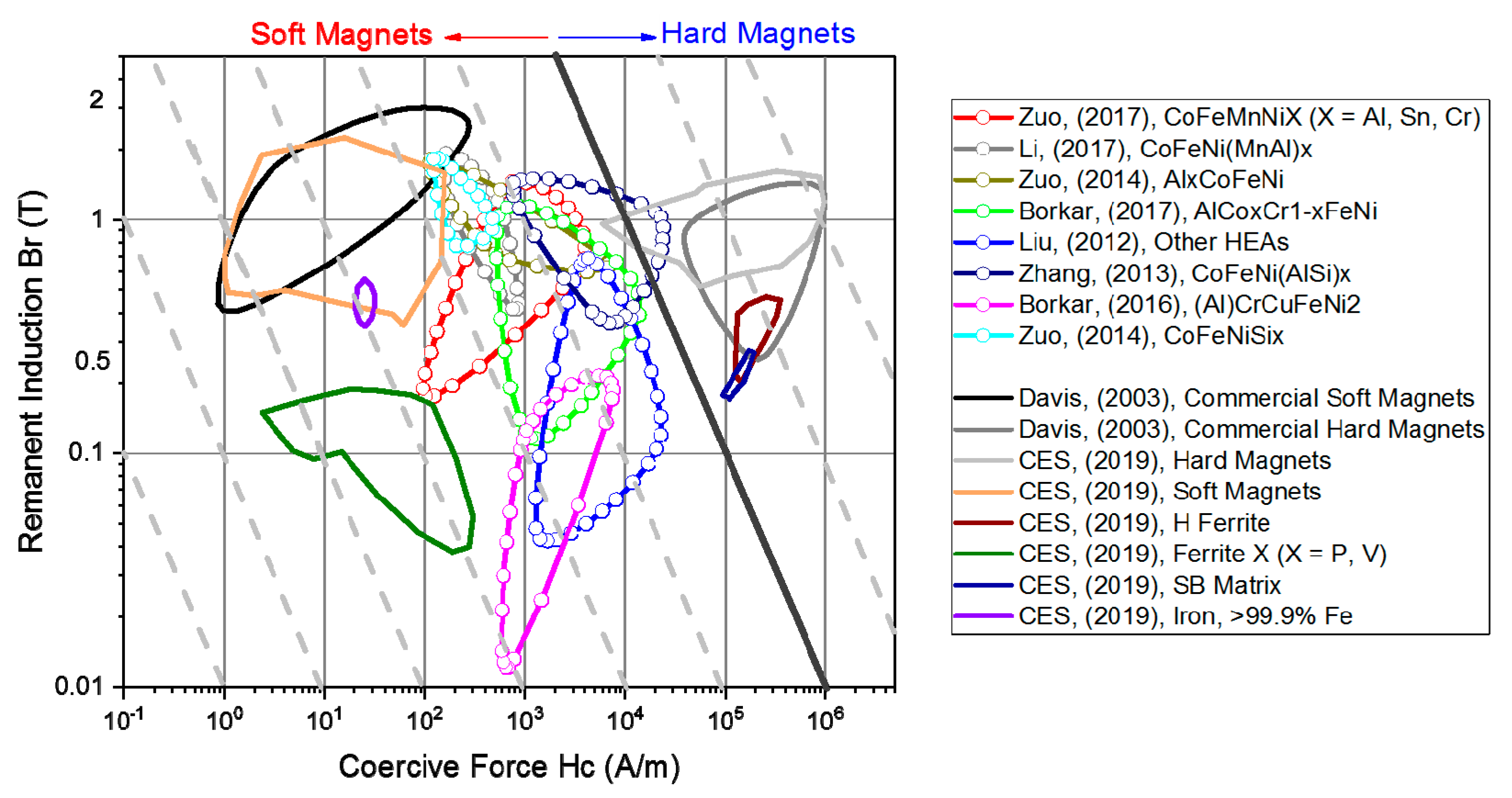

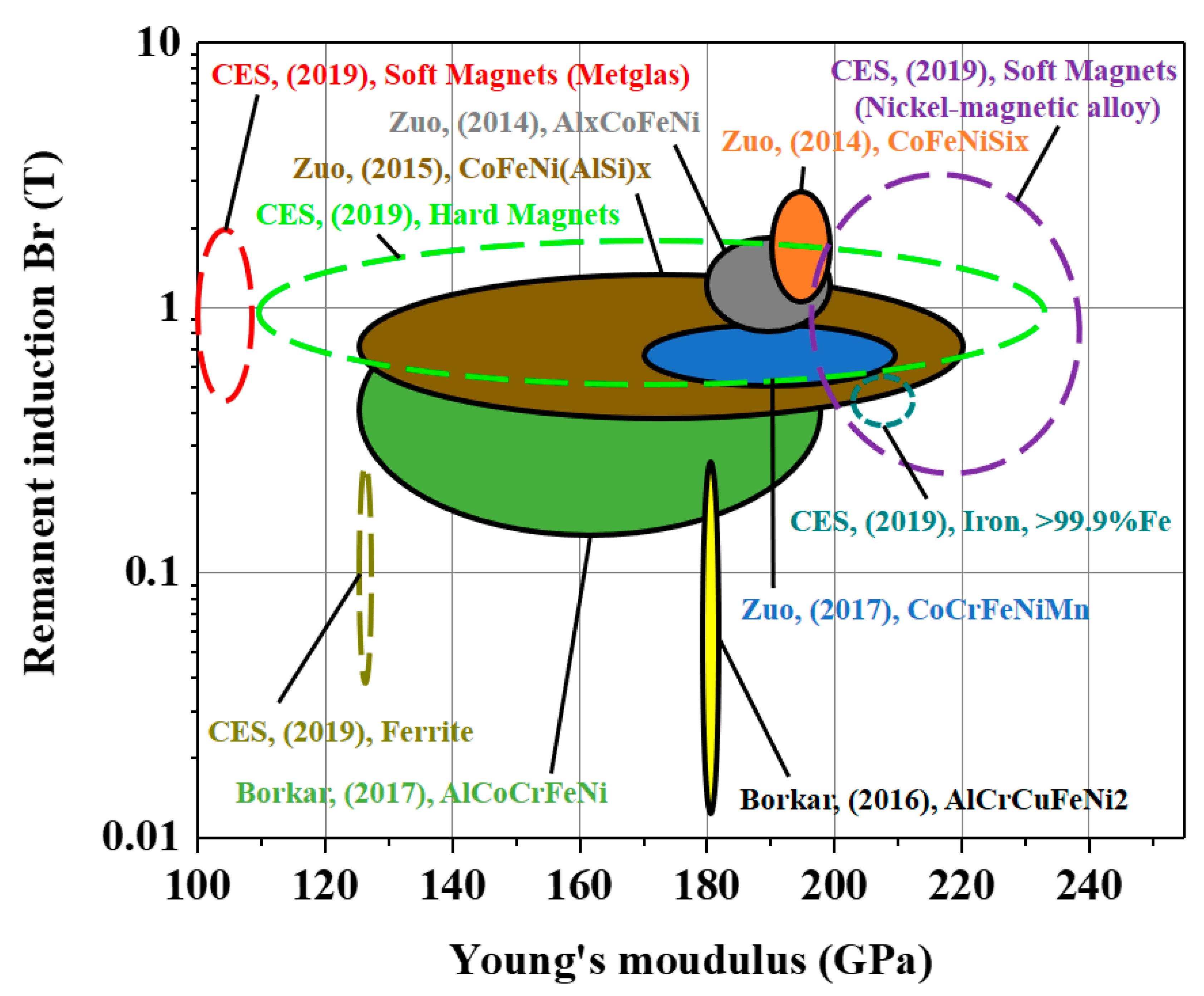

4. Combinatorial Approaches for Magnetic Features

5. Mechanical and Magnetic Maps for the Applications of High-Entropy Alloys

6. Discussion and Future Perspectives

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yeh, J.-W.; Chen, S.-K.; Lin, S.-J.; Gan, J.-Y.; Chin, T.-S.; Shun, T.-T.; Tsau, C.-H.; Chang, S.-Y. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Cantor, B.; Chang, I.T.H.; Knight, P.; Vincent, A.J.B. Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 2004, 375–377, 213–218. [Google Scholar] [CrossRef]

- Miracle, D.B.; Senkov, O.N. A critical review of high entropy alloys and related concepts. Acta Mater. 2017, 122, 448–511. [Google Scholar] [CrossRef]

- Diao, H.Y.; Feng, R.; Dahmen, K.A.; Liaw, P.K. Fundamental deformation behavior in high-entropy alloys: An overview. Curr. Opin. Solid State Mater. Sci. 2017, 21, 252–266. [Google Scholar] [CrossRef]

- Gludovatz, B.; Hohenwarter, A.; Catoor, D.; Chang, E.H.; George, E.P.; Ritchie, R.O. A fracture-resistant high-entropy alloy for cryogenic applications. Science 2014, 345, 1153–1158. [Google Scholar] [CrossRef]

- Senkov, O.N.; Wilks, G.B.; Miracle, D.B.; Chuang, C.P.; Liaw, P.K. Refractory high-entropy alloys. Intermetallics 2010, 18, 1758–1765. [Google Scholar] [CrossRef]

- Huang, E.W.; Liaw, P.K. High-temperature materials for structural applications: New perspectives on high-entropy alloys, bulk metallic glasses, and nanomaterials. MRS Bull. 2019, 44, 847–853. [Google Scholar] [CrossRef]

- Jones, D.R.H.; Ashby, M.F. Engneering Materials 2: An Introduction to Microstructures, Processing and Design; Elsevier Science: Amsterdam, The Netherlands, 2005. [Google Scholar]

- Ding, Q.; Zhang, Y.; Chen, X.; Fu, X.; Chen, D.; Chen, S.; Gu, L.; Wei, F.; Bei, H.; Gao, Y.; et al. Tuning element distribution, structure and properties by composition in high-entropy alloys. Nature 2019, 574, 223–227. [Google Scholar] [CrossRef]

- Zhang, Y.; Zuo, T.T.; Tang, Z.; Gao, M.C.; Dahmen, K.A.; Liaw, P.K.; Lu, Z.P. Microstructures and properties of high-entropy alloys. Prog. Mater. Sci. 2014, 61, 1–93. [Google Scholar] [CrossRef]

- Ma, S.G.; Zhang, S.F.; Gao, M.C.; Liaw, P.K.; Zhang, Y. A successful synthesis of the CoCrFeNiAl0.3 single-crystal, high-entropy alloy by bridgman solidification. JOM 2013, 65, 1751–1758. [Google Scholar] [CrossRef]

- Brif, Y.; Thomas, M.; Todd, I. The use of high-entropy alloys in additive manufacturing. Scr. Mater. 2015, 99, 93–96. [Google Scholar] [CrossRef]

- Santodonato, L.J.; Zhang, Y.; Feygenson, M.; Parish, C.M.; Gao, M.C.; Weber, R.J.K.; Neuefeind, J.C.; Tang, Z.; Liaw, P.K. Deviation from high-entropy configurations in the atomic distributions of a multi-principal-element alloy. Nat. Commun. 2015, 6, 5964. [Google Scholar] [CrossRef] [PubMed]

- Woo, W.; Huang, E.W.; Yeh, J.-W.; Choo, H.; Lee, C.; Tu, S.-Y. In-situ neutron diffraction studies on high-temperature deformation behavior in a CoCrFeMnNi high entropy alloy. Intermetallics 2015, 62, 1–6. [Google Scholar] [CrossRef]

- Huang, E.W.; Lin, C.-M.; Juang, J.-Y.; Chang, Y.-J.; Chang, Y.-W.; Wu, C.-S.; Tsai, C.-W.; Yeh, A.-C.; Shieh, S.R.; Wang, C.-P.; et al. Deviatoric deformation kinetics in high entropy alloy under hydrostatic compression. J. Alloys Compd. 2019, 792, 116–121. [Google Scholar] [CrossRef]

- Lam, T.-N.; Chou, Y.-S.; Chang, Y.-J.; Sui, T.-R.; Yeh, A.-C.; Harjo, S.; Lee, S.Y.; Jain, J.; Lai, B.-H.; Huang, E.-W. Comparing cyclic tension-compression effects on CoCrFeMnNi high-entropy alloy and ni-based superalloy. Crystals 2019, 9, 420. [Google Scholar] [CrossRef]

- Zhao, J.-C.; Zheng, X.; Cahill, D.G. High-throughput measurements of materials properties. JOM 2011, 63, 40–44. [Google Scholar] [CrossRef]

- Zhao, J.-C. High-throughput experimental tools for the materials genome initiative. Chin. Sci. Bull. 2014, 59, 1652–1661. [Google Scholar] [CrossRef]

- Widom, M.; Huhn, W.P.; Maiti, S.; Steurer, W. Hybrid monte carlo/molecular dynamics simulation of a refractory metal high entropy alloy. Metall. Mater. Trans. A 2014, 45, 196–200. [Google Scholar] [CrossRef]

- Huang, S.; Li, W.; Lu, S.; Tian, F.; Shen, J.; Holmström, E.; Vitos, L. Temperature dependent stacking fault energy of FeCrCoNiMn high entropy alloy. Scr. Mater. 2015, 108, 44–47. [Google Scholar] [CrossRef]

- Zhang, Y.H.; Zhuang, Y.; Hu, A.; Kai, J.J.; Liu, C.T. The origin of negative stacking fault energies and nano-twin formation in face-centered cubic high entropy alloys. Scr. Mater. 2017, 130, 96–99. [Google Scholar] [CrossRef]

- Niu, C.; LaRosa, C.R.; Miao, J.; Mills, M.J.; Ghazisaeidi, M. Magnetically-driven phase transformation strengthening in high entropy alloys. Nat. Commun. 2018, 9, 1363. [Google Scholar] [CrossRef] [PubMed]

- Kim, G.; Diao, H.; Lee, C.; Samaei, A.T.; Phan, T.; de Jong, M.; An, K.; Ma, D.; Liaw, P.K.; Chen, W. First-principles and machine learning predictions of elasticity in severely lattice-distorted high-entropy alloys with experimental validation. Acta Mater. 2019, 181, 124–138. [Google Scholar] [CrossRef]

- Chang, Y.-J.; Jui, C.-Y.; Lee, W.-J.; Yeh, A.-C. Prediction of the composition and hardness of high-entropy alloys by machine learning. JOM 2019, 71, 3433–3442. [Google Scholar] [CrossRef]

- Koželj, P.; Vrtnik, S.; Jelen, A.; Jazbec, S.; Jagličić, Z.; Maiti, S.; Feuerbacher, M.; Steurer, W.; Dolinšek, J. Discovery of a superconducting high-entropy alloy. Phys. Rev. Lett. 2014, 113, 107001. [Google Scholar] [CrossRef] [PubMed]

- Xie, P.; Yao, Y.; Huang, Z.; Liu, Z.; Zhang, J.; Li, T.; Wang, G.; Shahbazian-Yassar, R.; Hu, L.; Wang, C. Highly efficient decomposition of ammonia using high-entropy alloy catalysts. Nat. Commun. 2019, 10, 4011. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Zuo, T.; Cheng, Y.; Liaw, P.K. High-entropy alloys with high saturation magnetization, electrical resistivity, and malleability. Sci. Rep. 2013, 3, 1455. [Google Scholar] [CrossRef] [PubMed]

- Zuo, T.; Zhang, M.; Liaw, P.K.; Zhang, Y. Novel high entropy alloys of FexCo1-xNiMnGa with excellent soft magnetic properties. Intermetallics 2018, 100, 1–8. [Google Scholar] [CrossRef]

- Borkar, T.; Gwalani, B.; Choudhuri, D.; Mikler, C.V.; Yannetta, C.J.; Chen, X.; Ramanujan, R.V.; Styles, M.J.; Gibson, M.A.; Banerjee, R. A combinatorial assessment of AlxCrCuFeNi2 (0 < x < 1.5) complex concentrated alloys: Microstructure, microhardness, and magnetic properties. Acta Mater. 2016, 116, 63–76. [Google Scholar] [CrossRef]

- Li, Z.; Pradeep, K.G.; Deng, Y.; Raabe, D.; Tasan, C.C. Metastable high-entropy dual-phase alloys overcome the strength–ductility trade-off. Nature 2016, 534, 227. [Google Scholar] [CrossRef]

- Yang, T.; Zhao, Y.L.; Tong, Y.; Jiao, Z.B.; Wei, J.; Cai, J.X.; Han, X.D.; Chen, D.; Hu, A.; Kai, J.J.; et al. Multicomponent intermetallic nanoparticles and superb mechanical behaviors of complex alloys. Science 2018, 362, 933–937. [Google Scholar] [CrossRef]

- Ma, S.G.; Zhang, Y. Effect of Nb addition on the microstructure and properties of AlCoCrFeNi high-entropy alloy. Mater. Sci. Eng. A 2012, 532, 480–486. [Google Scholar] [CrossRef]

- Lim, K.R.; Lee, K.S.; Lee, J.S.; Kim, J.Y.; Chang, H.J.; Na, Y.S. Dual-phase high-entropy alloys for high-temperature structural applications. J. Alloys Compd. 2017, 728, 1235–1238. [Google Scholar] [CrossRef]

- Jiao, Z.-M.; Ma, S.-G.; Yuan, G.-Z.; Wang, Z.-H.; Yang, H.-J.; Qiao, J.-W. Plastic deformation of Al0.3CoCrFeNi and AlCoCrFeNi high-entropy alloys under nanoindentation. J. Mater. Eng. Perform. 2015, 24, 3077–3083. [Google Scholar] [CrossRef]

- Kao, Y.-F.; Chen, T.-J.; Chen, S.-K.; Yeh, J.-W. Microstructure and mechanical property of as-cast, -homogenized, and -deformed AlxCoCrFeNi (0 ≤ x ≤ 2) high-entropy alloys. J. Alloys Compd. 2009, 488, 57–64. [Google Scholar] [CrossRef]

- Kuznetsov, A.V.; Shaysultanov, D.G.; Stepanov, N.D.; Salishchev, G.A.; Senkov, O.N. Tensile properties of an AlCrCuNiFeCo high-entropy alloy in as-cast and wrought conditions. Mater. Sci. Eng. A 2012, 533, 107–118. [Google Scholar] [CrossRef]

- Shaysultanov, D.G.; Stepanov, N.D.; Kuznetsov, A.V.; Salishchev, G.A.; Senkov, O.N. Phase composition and superplastic behavior of a wrought AlCoCrCuFeNi high-entropy Alloy. JOM 2013, 65, 1815–1828. [Google Scholar] [CrossRef]

- Zhuang, Y.X.; Liu, W.J.; Chen, Z.Y.; Xue, H.D.; He, J.C. Effect of elemental interaction on microstructure and mechanical properties of FeCoNiCuAl alloys. Mater. Sci. Eng. A 2012, 556, 395–399. [Google Scholar] [CrossRef]

- Li, B.S.; Wang, Y.P.; Ren, M.X.; Yang, C.; Fu, H.Z. Effects of Mn, Ti and V on the microstructure and properties of AlCrFeCoNiCu high entropy alloy. Mater. Sci. Eng. A 2008, 498, 482–486. [Google Scholar] [CrossRef]

- Lohmuller, P.; Peltier, L.; Hazotte, A.; Zollinger, J.; Laheurte, P.; Fleury, E. Variations of the elastic properties of the CoCrFeMnNi High entropy alloy deformed by groove cold rolling. Materials 2018, 11, 1337. [Google Scholar] [CrossRef]

- Gali, A.; George, E.P. Tensile properties of high- and medium-entropy alloys. Intermetallics 2013, 39, 74–78. [Google Scholar] [CrossRef]

- Wu, Z.; Bei, H.; Pharr, G.M.; George, E.P. Temperature dependence of the mechanical properties of equiatomic solid solution alloys with face-centered cubic crystal structures. Acta Mater. 2014, 81, 428–441. [Google Scholar] [CrossRef]

- Zuo, T.T.; Li, R.B.; Ren, X.J.; Zhang, Y. Effects of Al and Si addition on the structure and properties of CoFeNi equal atomic ratio alloy. J. Magn. Magn. Mater. 2014, 371, 60–68. [Google Scholar] [CrossRef]

- Otto, F.; Dlouhý, A.; Somsen, C.; Bei, H.; Eggeler, G.; George, E.P. The influences of temperature and microstructure on the tensile properties of a CoCrFeMnNi high-entropy alloy. Acta Mater. 2013, 61, 5743–5755. [Google Scholar] [CrossRef]

- Chen, Y.U. NiAlFeCuCoCr-6-Component Alloy Metal Films Structure. Master’s Thesis, Chinese Culture University, Taipei City, Taiwan, 2002. [Google Scholar]

- Tsai, M.-H. Study on the Microstructure and Electrical Properties Evolution of High-Entropy Alloy Thin Films. Master’s Thesis, National Tsing Hua University, Hsinchu City, Taiwan, 2003. [Google Scholar]

- Lin, P.-C. Development on the High Frequency Soft-Magnetic Thin Films from High-Entropy Alloys. Master’s Thesis, National Tsing Hua University, Hsinchu City, Taiwan, 2003. [Google Scholar]

- Yu, C.-H. Research on the Bulks and Thin Film Properties of CrMoNbTiZr High-Entropy Alloys. Master’s Thesis, Chinese Culture University, Taipei City, Taiwan, 2004. [Google Scholar]

- Wu, N.F. Fabrication of Nanowires via High-Entropy Powders. Master’s Thesis, National Tsing Hua University, Hsinchu City, Taiwan, 2004. [Google Scholar]

- Jiayu, C. Development of Multicomponent High-Entropy Alloys for Thermal Spray Coating. Master’s Thesis, National Tsing Hua University, Hsinchu City, Taiwan, 2002. [Google Scholar]

- Huang, P.-K. Research of Multi-Component High-Entropy Alloys for Thermalspray Coating. Master’s Thesis, National Tsing Hua University, Hsinchu City, Taiwan, 2003. [Google Scholar]

- Lin, Y.-F. Particle Erosion Characteristics of a Plasma-Sprayed Zr-Based High-Entropy Alloy. Bachelor’s Thesis, National Cheng Kung University, Tainan City, Taiwan, 2004. [Google Scholar]

- Lin, M.-S. Study on the Corrosion Behavior and Thin Film Properties of Cr-Fe-Co-Ni-Cu-Alx High-Entropy Alloys. Master’s Thesis, Chinese Culture University, Taipei City, Taiwan, 2003. [Google Scholar]

- Hsu, Y.-J. Corrosion Behavior of FeCoNiCrCux High-Entropy Alloys in Various Aqueous Solutions. Master’s Thesis, National Taiwan Ocean University, Keelung City, Taiwan, 2004. [Google Scholar]

- Huang, C.-M. The Study of Different Welding With High-Entropy and SUS304 Stainless Steels. Master’s Thesis, National Chiao Tung University, Hsinchu City, Taiwan, 2004. [Google Scholar]

- Chung, S.-Y. Investigation of the Machinability of Five Kinds of High-Entropy Alloys and the Effects of Al, Cu, Co Elements Inclusion. Master’s Thesis, National Taiwan University, Taipei City, Taiwan, 2004. [Google Scholar]

- Chen, M.J. The Effect of V, Si, Ti Addition on the Microstructure and Wear Properties of Al(0.5)CrCuFeCoNi High-Entropy Alloys. Master’s Thesis, National Tsing Hua University, Hsinchu City, Taiwan, 2003. [Google Scholar]

- Wu, C.M. Research for the Adhesive Wear Properties of AlxCorCuFeNiTiy High-Entropy Alloys. Master’s Thesis, National Tsing Hua University, Hsinchu City, Taiwan, 2004. [Google Scholar]

- Huang, K.-H. A Study on the Multicomponent Alloy Systems Containing Equal-Mole Elements. Master’s Thesis, National Tsing Hua University, Hsinchu City, Taiwan, 1996. [Google Scholar]

- Lai, G.T. Properties of the Multicomponent Alloy System with Equal-Mole Elements. Master’s Thesis, National Tsing Hua University, Hsinchu City, Taiwan, 1998. [Google Scholar]

- Hsu, Y.-H. A Study on the Multicomponent Alloy Systems with Equal-Mole FCC or BCC Elements. Master’s Thesis, National Tsing Hua University, Hsinchu City, Taiwan, 2000. [Google Scholar]

- Hung, Y.-T. A Study on the Cu-Ni-Al-Co-Cr-Fe-Si-Ti Multicomponent Alloy System. Master’s Thesis, National Tsing Hua University, Hsinchu City, Taiwan, 2001. [Google Scholar]

- Bustamante, C.; Marko, J.; Siggia, E.; Smith, S. Entropic elasticity of lambda-phage DNA. Science 1994, 265, 1599–1600. [Google Scholar] [CrossRef] [PubMed]

- Gardel, M.L.; Shin, J.H.; MacKintosh, F.C.; Mahadevan, L.; Matsudaira, P.; Weitz, D.A. Elastic behavior of cross-linked and bundled actin networks. Science 2004, 304, 1301–1305. [Google Scholar] [CrossRef] [PubMed]

- Chaudhuri, O.; Parekh, S.H.; Fletcher, D.A. Reversible stress softening of actin networks. Nature 2007, 445, 295–298. [Google Scholar] [CrossRef] [PubMed]

- Zhang, F.; Wu, Y.; Lou, H.B.; Zeng, Z.D.; Prakapenka, V.B.; Greenberg, E.; Ren, Y.; Yan, J.Y.; Okasinski, J.S.; Liu, X.J.; et al. Polymorphism in a high-entropy alloy. Nat. Commun. 2017, 8. [Google Scholar] [CrossRef] [PubMed]

- Tracy, C.L.; Park, S.; Rittman, D.R.; Zinkle, S.J.; Bei, H.; Lang, M.; Ewing, R.C.; Mao, W.L. High pressure synthesis of a hexagonal close-packed phase of the high-entropy alloy CrMnFeCoNi. Nat. Commun. 2017, 8, 15634. [Google Scholar] [CrossRef]

- Huang, E.W.; Lin, C.-M.; Jain, J.; Shieh, S.R.; Wang, C.-P.; Chuang, Y.-C.; Liao, Y.-F.; Zhang, D.-Z.; Huang, T.; Lam, T.-N.; et al. Irreversible phase transformation in a CoCrFeMnNi high entropy alloy under hydrostatic compression. Mater. Today Commun. 2018, 14, 10–14. [Google Scholar] [CrossRef]

- Zhang, F.; Lou, H.; Song, C.; Chen, X.; Zeng, Z.; Yan, J.; Zhao, W.; Wu, Y.; Lu, Z.; Zeng, Q.S. Effects of non-hydrostaticity and grain size on the pressure-induced phase transition of the CoCrFeMnNi high-entropy alloy. J. Appl. Phys. 2018, 124, 115901. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, F.; Nie, Z.; Wang, F.; Wang, B.; Zhou, S.; Xue, Y.; Cheng, B.; Lou, H.; Chen, X.; et al. Abundant polymorphic transitions in the Al 0.6 CoCrFeNi high-entropy alloy. Mater. Today Phys. 2019, 8, 1–9. [Google Scholar] [CrossRef]

- Zhao, R.; Kim, Y.; Chester, S.A.; Sharma, P.; Zhao, X. Mechanics of hard-magnetic soft materials. J. Mech. Phys. Solids 2019, 124, 244–263. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, M.; Li, D.; Zuo, T.; Zhou, K.; Gao, M.; Sun, B.; Shen, T. Compositional design of soft magnetic high entropy alloys by minimizing magnetostriction coefficient in (Fe0.3Co0.5Ni0.2)100−x(Al1/3Si2/3)x System. Metals 2019, 9, 382. [Google Scholar] [CrossRef]

- Zhao, R.-F.; Ren, B.; Zhang, G.-P.; Liu, Z.-X.; Cai, B.; Zhang, J. CoCrxCuFeMnNi high-entropy alloy powders with superior soft magnetic properties. J. Magn. Magn. Mater. 2019, 491, 165574. [Google Scholar] [CrossRef]

- Koželj, P.; Vrtnik, S.; Jelen, A.; Krnel, M.; Gačnik, D.; Dražić, G.; Meden, A.; Wencka, M.; Jezeršek, D.; Leskovec, J.; et al. Discovery of a FeCoNiPdCu high-entropy alloy with excellent magnetic softness. Adv. Eng. Mater. 2019, 21, 1801055. [Google Scholar] [CrossRef]

- Borkar, T.; Chaudhary, V.; Gwalani, B.; Choudhuri, D.; Mikler, C.V.; Soni, V.; Alam, T.; Ramanujan, R.V.; Banerjee, R. A combinatorial approach for assessing the magnetic properties of high entropy alloys: Role of Cr in AlCoxCr1-xFeNi. Adv. Eng. Mater. 2017, 19. [Google Scholar] [CrossRef]

- Zuo, T.; Gao, M.C.; Ouyang, L.; Yang, X.; Cheng, Y.; Feng, R.; Chen, S.; Liaw, P.K.; Hawk, J.A.; Zhang, Y. Tailoring magnetic behavior of CoFeMnNiX (X = Al, Cr, Ga, and Sn) high entropy alloys by metal doping. Acta Mater. 2017, 130, 10–18. [Google Scholar] [CrossRef]

- Li, P.; Wang, A.; Liu, C.T. Composition dependence of structure, physical and mechanical properties of FeCoNi(MnAl) x high entropy alloys. Intermetallics 2017, 87, 21–26. [Google Scholar] [CrossRef]

- Feng, W.; Qi, Y.; Wang, S. Effects of short-range order on the magnetic and mechanical properties of FeCoNi(AlSi)x high entropy alloys. Metals 2017, 7, 482. [Google Scholar] [CrossRef]

- Ma, S.G.; Jiao, Z.M.; Qiao, J.W.; Yang, H.J.; Zhang, Y.; Wang, Z.H. Strain rate effects on the dynamic mechanical properties of the AlCrCuFeNi2 high-entropy alloy. Mater. Sci. Eng. A 2016, 649, 35–38. [Google Scholar] [CrossRef]

- Jin, P.; Ye, P.; Hui, Z.; Lu, Z. Microstructure and properties of AlCrFeCuNix (0.6 ≤ x ≤ 1.4) high-entropy alloys. Mater. Sci. Eng. A 2012, 534, 228–233. [Google Scholar] [CrossRef]

- Liu, L.; Zhu, J.B.; Li, J.C.; Jiang, Q. Microstructure and magnetic properties of FeNiCuMnTiSnxHigh entropy alloys. Adv. Eng. Mater. 2012, 14, 919–922. [Google Scholar] [CrossRef]

- Davis, J.R. Metals Handbook, DESK EDITION, 2nd ed.; ASM International: Materials Park, OH, USA, 2003. [Google Scholar]

- Diez-Jimenez, E.; Rizzo, R.; Gómez-García, M.-J.; Corral-Abad, E. Review of passive electromagnetic devices for vibration damping and isolation. Shock Vib. 2019, 2019, 16. [Google Scholar] [CrossRef]

- Aranke, O.; Algenaid, W.; Awe, S.; Joshi, S. Coatings for automotive gray cast iron brake discs: A review. Coatings 2019, 9, 552. [Google Scholar] [CrossRef]

- Trout, S. Material selection of permanent magnets, considering thermal properties correctly. In Proceedings of the Electrical Insulation Conference and Electrical Manufacturing and Coil Winding Conference (Cat. No.01CH37264), Cincinnati, OH, USA, 18 October 2001; pp. 365–370. [Google Scholar] [CrossRef]

- Fu, Z.; MacDonald, B.E.; Dupuy, A.D.; Wang, X.; Monson, T.C.; Delaney, R.E.; Pearce, C.J.; Hu, K.; Jiang, Z.; Zhou, Y.; et al. Exceptional combination of soft magnetic and mechanical properties in a heterostructured high-entropy composite. Appl. Mater. Today 2019, 15, 590–598. [Google Scholar] [CrossRef]

- Firstov, G.S.; Kosorukova, T.A.; Koval, Y.N.; Odnosum, V.V. High entropy shape memory alloys. Mater. Today Proc. 2015, 2, S499–S503. [Google Scholar] [CrossRef]

- Ma, L.; Wang, L.; Nie, Z.; Wang, F.; Xue, Y.; Zhou, J.; Cao, T.; Wang, Y.; Ren, Y. Reversible deformation-induced martensitic transformation in Al0.6CoCrFeNi high-entropy alloy investigated by in situ synchrotron-based high-energy X-ray diffraction. Acta Mater. 2017, 128, 12–21. [Google Scholar] [CrossRef]

- Fan, Z.; Wang, H.; Wu, Y.; Liu, X.J.; Lu, Z.P. Thermoelectric high-entropy alloys with low lattice thermal conductivity. RSC Adv. 2016, 6, 52164–52170. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Starr, T.; Rafi, H.; Stucker, B.; Scherzer, C.M. Controlling Phase Composition in Selective Laser Melted Stainless Steels; University of Louisville: Louisville, KY, USA, 2012; pp. 439–446. [Google Scholar]

- Tsai, P.-I.; Lam, T.-N.; Wu, M.-H.; Tseng, K.-Y.; Chang, Y.-W.; Sun, J.-S.; Li, Y.-Y.; Lee, M.-H.; Chen, S.-Y.; Chang, C.-K. Multi-scale mapping for collagen-regulated mineralization in bone remodeling of additive manufacturing porous implants. Mater. Chem. Phys. 2019, 230, 83–92. [Google Scholar] [CrossRef]

- Huang, E.-W.; Lee, S.Y.; Jain, J.; Tong, Y.; An, K.; Tsou, N.-T.; Lam, T.-N.; Yu, D.; Chae, H.; Chen, S.-W. Hardening steels by the generation of transient phase using additive manufacturing. Intermetallics 2019, 109, 60–67. [Google Scholar] [CrossRef]

- Hong, H.H.; Hong, A.; Wang, C.C.; Huang, E.W.; Chiang, C.C.; Yen, T.H.; Huang, Y.F. Calcitriol exerts a mineralization-inductive effect comparable to that of vitamin C in cultured human periodontium cells. Am. J. Transl. Res. 2019, 11, 2304–2316. [Google Scholar] [PubMed]

- Hadush Tesfay, A.; Chou, Y.-J.; Tan, C.-Y.; Fufa Bakare, F.; Tsou, N.-T.; Huang, E.-W.; Shih, S.-J. Control of dopant distribution in yttrium-doped bioactive glass for selective internal radiotherapy applications using spray pyrolysis. Materials 2019, 12, 986. [Google Scholar] [CrossRef] [PubMed]

- Chae, H.; Huang, E.W.; Jain, J.; Wang, H.; Woo, W.; Chen, S.-W.; Harjo, S.; Kawasaki, T.; Lee, S.Y. Plastic anisotropy and deformation-induced phase transformation of additive manufactured stainless steel. Mater. Sci. Eng. A 2019, 762, 138065. [Google Scholar] [CrossRef]

- Zhu, Z.G.; Nguyen, Q.B.; Ng, F.L.; An, X.H.; Liao, X.Z.; Liaw, P.K.; Nai, S.M.L.; Wei, J. Hierarchical microstructure and strengthening mechanisms of a CoCrFeNiMn high entropy alloy additively manufactured by selective laser melting. Scr. Mater. 2018, 154, 20–24. [Google Scholar] [CrossRef]

- Zhu, Z.G.; Ng, F.L.; Qiao, J.W.; Liaw, P.K.; Chen, H.C.; Nai, S.M.L.; Wei, J.; Bi, G.J. Interplay between microstructure and deformation behavior of a laser-welded CoCrFeNi high entropy alloy. Mater. Res. Express 2019, 6, 046514. [Google Scholar] [CrossRef]

- Chen, S.; Tong, Y.; Liaw, P.K. Additive manufacturing of high-entropy alloys: A review. Entropy 2018, 20, 937. [Google Scholar] [CrossRef]

- Zhou, R.; Liu, Y.; Zhou, C.; Li, S.; Wu, W.; Song, M.; Liu, B.; Liang, X.; Liaw, P.K. Microstructures and mechanical properties of C-containing FeCoCrNi high-entropy alloy fabricated by selective laser melting. Intermetallics 2018, 94, 165–171. [Google Scholar] [CrossRef]

| Title | Year | HEA System | Reference | Thesis Type |

|---|---|---|---|---|

| A study on the Multicomponent Alloy Systems Containing Equal-Mole Elements | 1996 | Al-Ti-V-Cr-Fe-Co-Ni-Cu-Zr-Mo-Pd | [59] | Master |

| Properties of the Multicomponent Alloy System with Equal-Mole Elements | 1998 | [60] | Master | |

| A Study on the Multicomponent Alloy Systems with Equal-Mole Face-Centered Cubic (FCC) or Body-Centered Cubic (BCC) Elements | 2000 | Ni-Co-Fe-Cu-V-Cr-Mo-Au-Ag-Ti-Al-Zr-Y-Nd | [61] | Master |

| A Study on the Cu-Ni-Al-Co-Cr-Fe-Si-Ti Multicomponent Alloy System | 2001 | Cu-Ni-Al-Co-Cr-Fe-Si-Ti | [62] | Master |

| Development of Multicomponent High-Entropy Alloys for Thermal Spray Coating | 2002 | Fe-Ni-Co-Cr-Si | [50] | Master |

| NiAlFeCuCoCr-6-Component Alloy Metal Films Structure | 2002 | Ni-Al-Fe-Cu-Co-Cr | [45] | Master |

| Study on the Corrosion Behavior and Thin Film Properties of Cr-Fe-Co-Ni-Cu-Alx High-Entropy Alloys | 2003 | Cr-Fe-Co-Ni-Cu-Alx | [53] | Master |

| Research of Multi-component High-Entropy Alloys for Thermal Spray Coating | 2003 | Mo0.5(Al-Si-Ti-Cr-Fe-Co-Ni-Mo)0.5 and Mo0.5(Al-Si-Ti-Cr-Fe-Ni-Mo)0.5 Zrx(Al-Si-Ti-Cr-Fe-Ni-Zr)1-x | [51] | Master |

| The Effect of V, Si, Ti Addition on the Microstructure and Wear Properties of Al(0.5)CrCuFeCoNi High-Entropy Alloys | 2003 | Al0.5Cr-Cu-Fe-Co-Ni | [57] | Master |

| Study on the Microstructure and Electrical Properties Evolution of High-Entropy Alloy Thin Films | 2003 | Cu0.5Ni-Al-Co-Cr-Fe-Ti | [46] | Master |

| Development on the High Frequency Soft-Magnetic Thin Films from High-Entropy Alloys | 2003 | Fe42Co37Ni10Al5B6 and Fe40Co35Al5Ni5Cr5Si10 | [47] | Master |

| Research on the Bulks and Thin Film Properties of CrMoNbTiZr High-entropy alloys | 2004 | Cr-Mo-Nb-Ti-Zr | [48] | Master |

| Corrosion Behavior of FeCoNiCrCux High-Entropy Alloys in Various Aqueous Solutions | 2004 | Fe-Co-Ni-Cr-Cux | [54] | Master |

| The Study of Different Welding with High-Entropy and SUS304 Stainless Steels | 2004 | [55] | Master | |

| Investigation of the Machinability of Five Kinds of High-Entropy Alloys and the Effects of Al, Cu, Co Elements Inclusion | 2004 | Fe1Co1Ni1Cr1Cu0.2Al1 | [56] | Master |

| Fabrication of Nanowires via High-Entropy Powders | 2004 | Al-Cr-Fe-Ni-Si-Ti-Zr | [49] | Master |

| Research for the Adhesive Wear Properties of AlxCoCuFeNiTiy High-Entropy Alloys | 2004 | AlxCo-Cu-Fe-Ni-Tiy | [58] | Master |

| Particle Erosion Characteristics of a Plasma-Sprayed Zr-Based High-Entropy Alloy | 2004 | Zr-Based High-Entropy Alloy | [52] | Master |

| HEA System | Properties | Year | Title | Reference |

|---|---|---|---|---|

| AlCoCrFeNiNbx | Yield Strength | 2012 | Effect of Nb addition on the microstructure and properties of AlCoCrFeNi high-entropy alloy. | [32] |

| Young’s Modulus | 2012 | Effect of Nb addition on the microstructure and properties of AlCoCrFeNi high-entropy alloy. | [32] | |

| AlxCoFeNi | Coercive Force Hc | 2014 | Effects of Al and Si addition on the structure and properties of CoFeNi equal atomic ratio alloy | [43] |

| Remanent Induction Br | 2014 | Effects of Al and Si addition on the structure and properties of CoFeNi equal atomic ratio alloy | [43] | |

| Yield Strength | 2014 | Effects of Al and Si addition on the structure and properties of CoFeNi equal atomic ratio alloy | [43] | |

| Young’s Modulus | 2014 | Effects of Al and Si addition on the structure and properties of CoFeNi equal atomic ratio alloy | [43] | |

| AlxCoCrFeNi | Coercive Force Hc | 2017 | A combinatorial approach for assessing the magnetic properties of high entropy alloys: Role of Cr in AlCoxCr1–xFeNi | [75] |

| Remanent Induction Br | 2017 | A combinatorial approach for assessing the magnetic properties of high entropy alloys: Role of Cr in AlCoxCr1–xFeNi | [75] | |

| Yield Strength | 2017 | Dual-phase high-entropy alloys for high-temperature structural applications | [33] | |

| Young’s Modulus | 2015 | Plastic deformation of Al0.3CoCrFeNi and AlCoCrFeNi high-entropy alloys under nanoindentation | [34] | |

| 2009 | Microstructure and mechanical property of as-cast, -homogenized, and -deformed AlxCoCrFeNi (0 ≤ x ≤ 2) high-entropy alloys | [35] | ||

| AlCoCrCuFeNi | Yield Strength | 2012 | Tensile properties of an AlCrCuNiFeCo high-entropy alloy in as-cast and wrought conditions | [36] |

| 2013 | Phase composition and superplastic behavior of a wrought AlCoCrCuFeNi high-entropy alloy | [37] | ||

| Young’s Modulus | 2012 | Effect of elemental interaction on microstructure and mechanical properties of FeCoNiCuAl alloys | [38] | |

| 2008 | Effects of Mn, Ti and V on the microstructure and properties of AlCrFeCoNiCu high entropy alloy | [39] | ||

| CoCrFeNiMn | Coercive Force Hc | 2017 | Tailoring magnetic behavior of CoFeMnNiX (X = Al, Cr, Ga, and Sn) high entropy alloys by metal doping | [76] |

| Remanent Induction Br | 2017 | Tailoring magnetic behavior of CoFeMnNiX (X = Al, Cr, Ga, and Sn) high entropy alloys by metal doping | [76] | |

| Yield Strength | 2014 | A fracture-resistant high-entropy alloy for cryogenic applications | [5] | |

| 2013 | The influences of temperature and microstructure on the tensile properties of a CoCrFeMnNi high-entropy alloy | [44] | ||

| Young’s Modulus | 2018 | Variations of the elastic properties of the CoCrFeMnNi high entropy alloy deformed by groove cold rolling | [40] | |

| CoCrFeNi | Yield Strength | 2013 | Tensile properties of high- and medium-entropy alloys | [41] |

| Young’s Modulus | 2014 | Temperature dependence of the mechanical properties of equiatomic solid solution alloys with face-centered cubic crystal structures | [42] | |

| CoCrMnNi | Yield Strength | 2014 | Temperature dependence of the mechanical properties of equiatomic solid solution alloys with face-centered cubic crystal structures | [42] |

| Young’s Modulus | 2014 | Temperature dependence of the mechanical properties of equiatomic solid solution alloys with face-centered cubic crystal structures | [42] | |

| CoFeMnNi | Yield Strength | 2014 | Temperature dependence of the mechanical properties of equiatomic solid solution alloys with face-centered cubic crystal structures | [42] |

| Young’s Modulus | 2014 | Temperature dependence of the mechanical properties of equiatomic solid solution alloys with face-centered cubic crystal structures | [42] | |

| CoFeNiSix | Coercive Force Hc | 2014 | Effects of Al and Si addition on the structure and properties of CoFeNi equal atomic ratio alloy | [43] |

| Remanent Induction Br | 2014 | Effects of Al and Si addition on the structure and properties of CoFeNi equal atomic ratio alloy | [43] | |

| Yield Strength | 2014 | Effects of Al and Si addition on the structure and properties of CoFeNi equal atomic ratio alloy | [43] | |

| Young’s Modulus | 2014 | Effects of Al and Si addition on the structure and properties of CoFeNi equal atomic ratio alloy | [43] | |

| CoFeNi(MnAl)x | Coercive Force Hc | 2017 | Composition dependence of structure, physical and mechanical properties of FeCoNi(MnAl) x high entropy alloys | [77] |

| Remanent Induction Br | 2017 | Composition dependence of structure, physical and mechanical properties of FeCoNi(MnAl) x high entropy alloys | [77] | |

| Yield Strength | 2017 | Composition dependence of structure, physical and mechanical properties of FeCoNi(MnAl) x high entropy alloys | [77] | |

| CoFeNi(AlSi)x | Coercive Force Hc | 2013 | High-entropy alloys with high saturation magnetization, electrical resistivity, and malleability | [27] |

| Remanent Induction Br | 2013 | High-entropy alloys with high saturation magnetization, electrical resistivity, and malleability | [27] | |

| Yield Strength | 2019 | Compositional design of soft magnetic high entropy alloys by minimizing magnetostriction coefficient in (Fe0.3Co0.5Ni0.2)100−x(Al1/3Si2/3)x system | [72] | |

| Young’s Modulus | 2017 | Effects of short-range order on the magnetic and mechanical properties of FeCoNi(AlSi)x high entropy alloys | [78] | |

| AlxCrCuFeNi2 | Coercive Force Hc | 2016 | A combinatorial assessment of AlxCrCuFeNi2 (0 < x < 1.5) complex concentrated alloys: Microstructure, microhardness, and magnetic properties | [29] |

| Remanent Induction Br | 2016 | A combinatorial assessment of AlxCrCuFeNi2 (0 < x < 1.5) complex concentrated alloys: Microstructure, microhardness, and magnetic properties | [29] | |

| Yield Strength | 2016 | Strain rate effects on the dynamic mechanical properties of the AlCrCuFeNi2 high-entropy alloy | [79] | |

| Young’s Modulus | 2012 | Microstructure and properties of AlCrFeCuNix (0.6 ≤ x ≤ 1.4) high-entropy alloys | [80] | |

| AlCoxCr1-xFeNi | Coercive Force Hc | 2017 | A combinatorial approach for assessing the magnetic properties of high entropy alloys: Role of Cr in AlCoxCr1–xFeNi | [75] |

| Remanent Induction Br | 2017 | A combinatorial approach for assessing the magnetic properties of high entropy | [75] | |

| CoFeMnNiGa | Coercive Force Hc | 2017 | Tailoring magnetic behavior of CoFeMnNiX (X = Al, Cr, Ga, and Sn) high entropy alloys by metal doping | [76] |

| Remanent Induction Br | 2017 | Tailoring magnetic behavior of CoFeMnNiX (X = Al, Cr, Ga, and Sn) high entropy alloys by metal doping | [76] | |

| CoFeMnNiAl | Coercive Force Hc | 2017 | Tailoring magnetic behavior of CoFeMnNiX (X = Al, Cr, Ga, and Sn) high entropy alloys by metal doping | [76] |

| Remanent Induction Br | 2017 | Tailoring magnetic behavior of CoFeMnNiX (X = Al, Cr, Ga, and Sn) high entropy alloys by metal doping | [76] | |

| Other HEAs | Coercive Force Hc | 2012 | Microstructure and magnetic properties of FeNiCuMnTiSnx high entropy alloys | [81] |

| Remanent Induction Br | 2012 | Microstructure and magnetic properties of FeNiCuMnTiSnx high entropy alloys | [81] | |

| CCA System | Properties | Year | Title | Reference |

| Commercial Soft Magnets | Coercive Force Hc | 2003 | Metals Handbook, Desk Edition 2nd Edition I | [82] |

| Remanent Induction Br | 2003 | Metals Handbook, Desk Edition 2nd Edition I | [82] | |

| Commercial Hard Magnets | Coercive Force Hc | 2003 | Metals Handbook, Desk Edition 2nd Edition I | [82] |

| Remanent Induction Br | 2003 | Metals Handbook, Desk Edition 2nd Edition I | [82] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, E.-W.; Hung, G.-Y.; Lee, S.Y.; Jain, J.; Chang, K.-P.; Chou, J.J.; Yang, W.-C.; Liaw, P.K. Mechanical and Magnetic Properties of the High-Entropy Alloys for Combinatorial Approaches. Crystals 2020, 10, 200. https://doi.org/10.3390/cryst10030200

Huang E-W, Hung G-Y, Lee SY, Jain J, Chang K-P, Chou JJ, Yang W-C, Liaw PK. Mechanical and Magnetic Properties of the High-Entropy Alloys for Combinatorial Approaches. Crystals. 2020; 10(3):200. https://doi.org/10.3390/cryst10030200

Chicago/Turabian StyleHuang, E-Wen, Guo-Yu Hung, Soo Yeol Lee, Jayant Jain, Kuan-Pang Chang, Jing Jhe Chou, Wen-Chi Yang, and Peter K. Liaw. 2020. "Mechanical and Magnetic Properties of the High-Entropy Alloys for Combinatorial Approaches" Crystals 10, no. 3: 200. https://doi.org/10.3390/cryst10030200

APA StyleHuang, E.-W., Hung, G.-Y., Lee, S. Y., Jain, J., Chang, K.-P., Chou, J. J., Yang, W.-C., & Liaw, P. K. (2020). Mechanical and Magnetic Properties of the High-Entropy Alloys for Combinatorial Approaches. Crystals, 10(3), 200. https://doi.org/10.3390/cryst10030200