Toward Programmed Complex Stress-Induced Mechanical Deformations of Liquid Crystal Elastomers

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Mechanical Testing

2.3. Localised Strain Mapping

2.4. Localised Director Mapping

2.5. Empirical Model Used for Analysis

3. Results

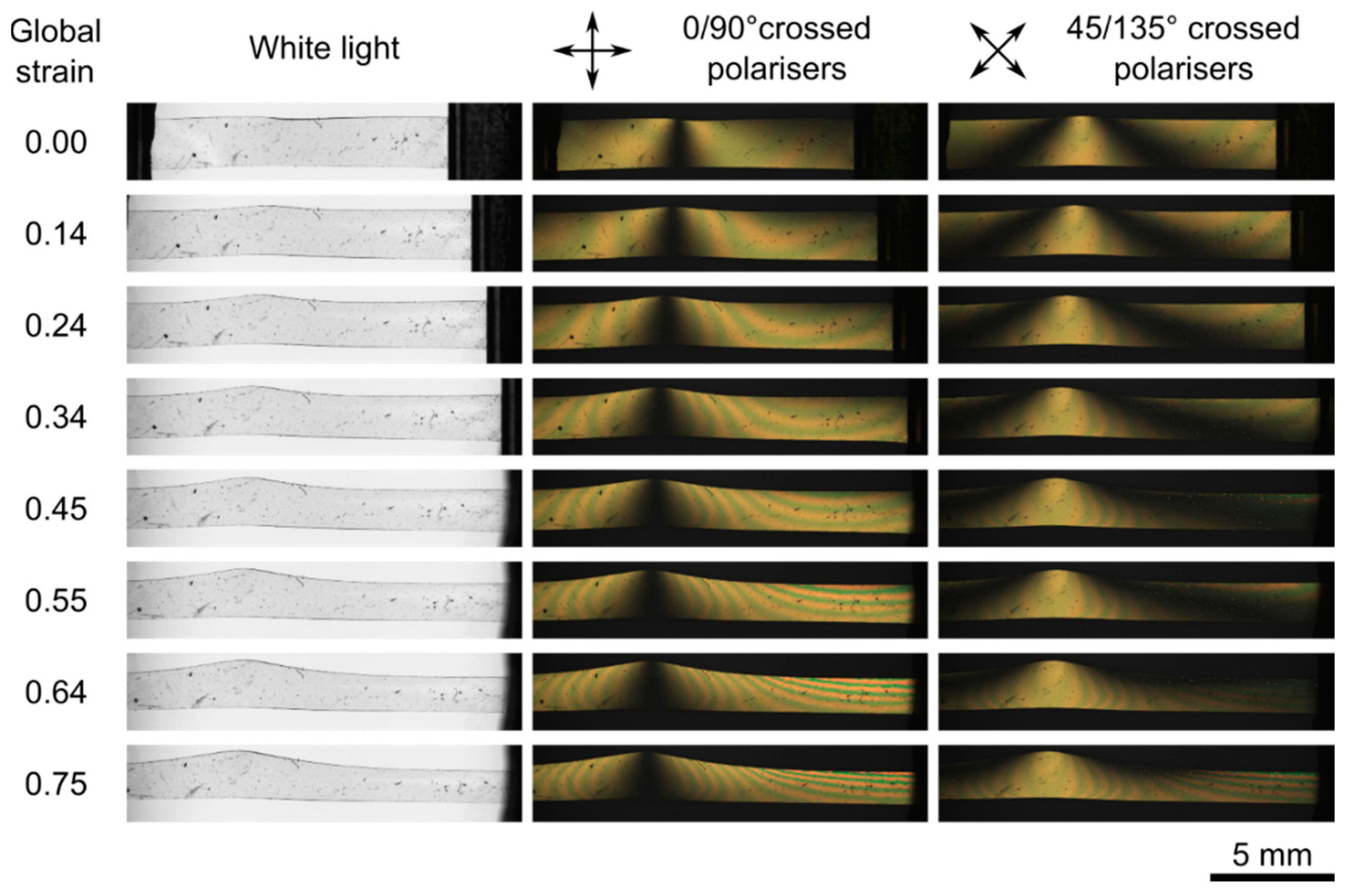

3.1. Photographs of Sample Deformation

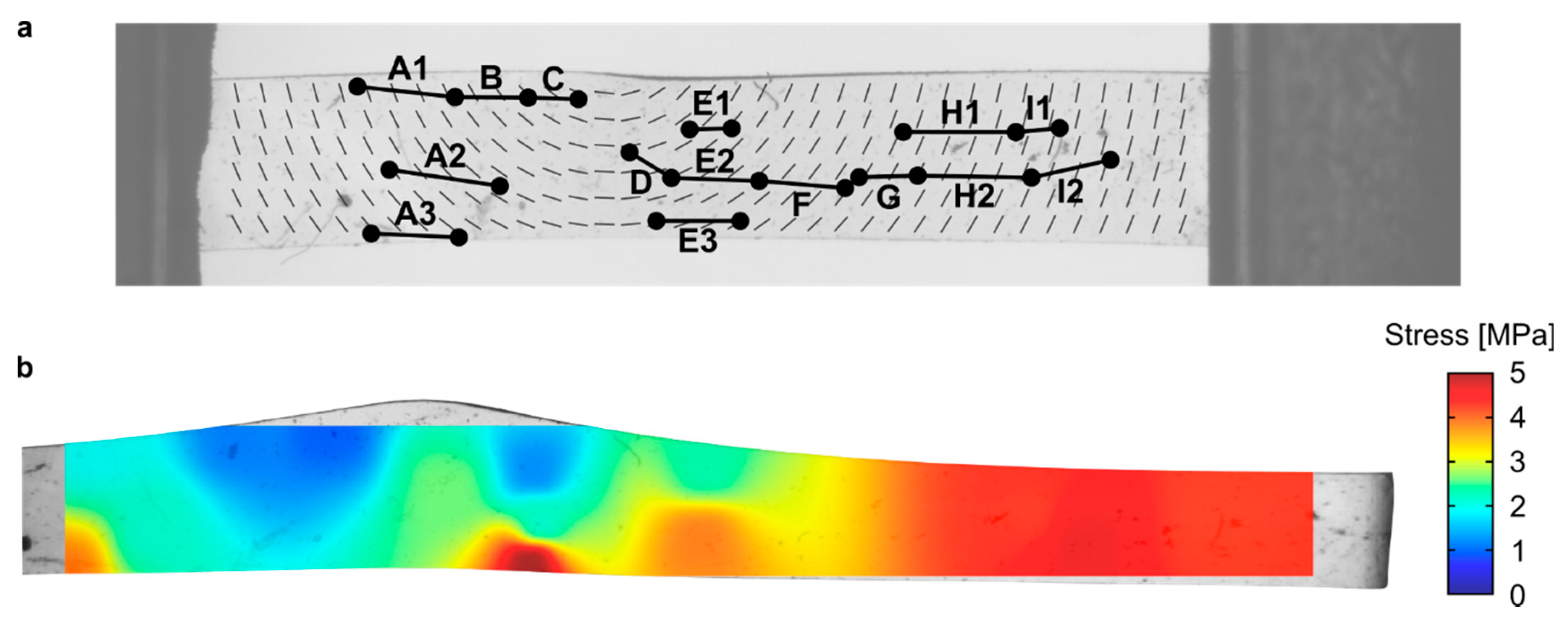

3.2. Localised Strains via Tracked Features

3.3. Eulerian Frame Director Rotations

3.4. Lagrangian Frame Director Rotations

4. Analysis and Discussion

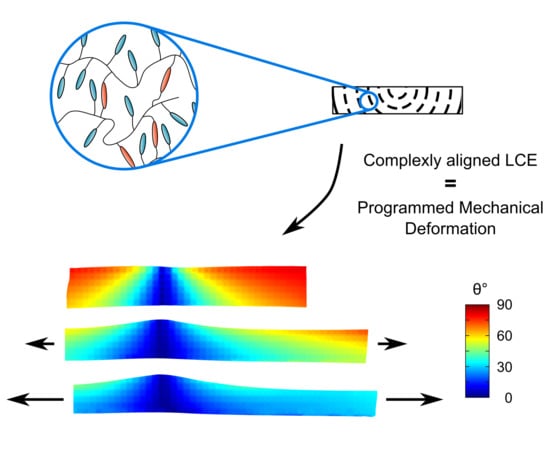

4.1. Designing Mechanical Deformations

4.2. Global Engineering Load Curve

4.3. Predictions of the Localised Stress Distribution

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yao, H.; Dao, M.; Carnelli, D.; Tai, K.; Ortiz, C. Size-dependent heterogeneity benefits the mechanical performance of bone. J. Mech. Phys. Solids 2011, 59, 64–74. [Google Scholar] [CrossRef]

- Yakubov, G.E.; Bonilla, M.R.; Chen, H.; Doblin, M.S.; Bacic, A.; Gidley, M.J.; Stokes, J.R. Mapping nano-scale mechanical heterogeneity of primary plant cell walls. J. Exp. Bot. 2016, 67, 2799–2816. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Raabe, D.; Sachs, C.; Romano, P. The crustacean exoskeleton as an example of a structurally and mechanically graded biological nanocomposite material. Acta Mater. 2005, 53, 4281–4292. [Google Scholar] [CrossRef]

- Liu, Z.; Meyers, M.A.; Zhang, Z.; Ritchie, R.O. Functional gradients and heterogeneities in biological materials: Design principles, functions, and bioinspired applications. Prog. Mater. Sci. 2017, 88, 467–498. [Google Scholar] [CrossRef]

- Wong, R.; Geyer, S.; Weninger, W.; Guimberteau, J.C.; Wong, J.K. The dynamic anatomy and patterning of skin. Exp. Dermatol. 2016, 25, 92–98. [Google Scholar] [CrossRef] [Green Version]

- Burgert, I.; Eder, M.; Gierlinger, N.; Fratzl, P. Tensile and compressive stresses in tracheids are induced by swelling based on geometrical constraints of the wood cell. Planta 2007, 226, 981–987. [Google Scholar] [CrossRef]

- Färber, H.; Lichtenegger, H.C.; Reiterer, A.; Stanzl-Tschegg, S.; Fratzl, P. Cellulose microfibril angles in a spruce branch. J. Mater. Sci. 2001, 36, 5087–5092. [Google Scholar] [CrossRef]

- Warner, M.; Terentjev, E.M. Liquid Crystal Elastomers; Clarendon Press: Oxford, UK, 2013; ISBN 9788578110796. [Google Scholar]

- Finkelmann, H.; Greve, A.; Warner, M. The elastic anisotropy of nematic elastomers. Eur. Phys. J. E 2001, 5, 281–293. [Google Scholar] [CrossRef]

- Clarke, S.M.; Tajbakhsh, A.R.; Terentjev, E.M.; Warner, M. Anomalous viscoelastic response of nematic elastomers. Phys. Rev. Lett. 2001, 86, 4044–4047. [Google Scholar] [CrossRef]

- Ware, T.H.; Biggins, J.S.; Shick, A.F.; Warner, M.; White, T.J. Localized soft elasticity in liquid crystal elastomers. Nat. Commun. 2016, 7, 10781. [Google Scholar] [CrossRef]

- Mistry, D.; Morgan, P.B.; Clamp, J.H.; Gleeson, H.F. New insights into the nature of semi-soft elasticity and “mechanical-Fréedericksz transitions” in liquid crystal elastomers. Soft Matter 2018, 14, 1301–1310. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mistry, D.; Connell, S.D.; Mickthwaite, S.L.; Morgan, P.B.; Clamp, J.H.; Gleeson, H.F. Coincident molecular auxeticity and negative order parameter in a liquid crystal elastomer. Nat. Commun. 2018, 9, 5095. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mistry, D.; Gleeson, H.F. Mechanical deformations of a liquid crystal elastomer at director angles between 0° and 90°: Deducing an empirical model encompassing anisotropic nonlinearity. J. Polym. Sci. Part B Polym. Phys. 2019, 57, 1367–1377. [Google Scholar] [CrossRef] [Green Version]

- de Haan, L.T.; Sánchez-Somolinos, C.; Bastiaansen, C.M.W.; Schenning, A.P.H.J.; Broer, D.J. Engineering of Complex Order and the Macroscopic Deformation of Liquid Crystal Polymer Networks. Angew. Chem. Int. Ed. 2012, 51, 12469–12472. [Google Scholar] [CrossRef] [PubMed]

- McConney, M.E.; Martinez, A.; Tondiglia, V.P.; Lee, K.M.; Langley, D.; Smalyukh, I.I.; White, T.J. Topography from Topology: Photoinduced Surface Features Generated in Liquid Crystal Polymer Networks. Adv. Mater. 2013, 25, 5880–5885. [Google Scholar] [CrossRef] [PubMed]

- Schuhladen, S.; Preller, F.; Rix, R.; Petsch, S.; Zentel, R.; Zappe, H. Iris-Like Tunable Aperture Employing Liquid-Crystal Elastomers. Adv. Mater. 2014, 26, 7247–7251. [Google Scholar] [CrossRef]

- Ahn, C.; Liang, X.; Cai, S. Inhomogeneous stretch induced patterning of molecular orientation in liquid crystal elastomers. Extrem. Mech. Lett. 2015, 5, 30–36. [Google Scholar] [CrossRef]

- Xia, Y.; Cedillo-Servin, G.; Kamien, R.D.; Yang, S. Guided Folding of Nematic Liquid Crystal Elastomer Sheets into 3D via Patterned 1D Microchannels. Adv. Mater. 2016, 28, 9637–9643. [Google Scholar] [CrossRef]

- Di Chen, Y.; Fuh, A.Y.G.; Liu, C.K.; Cheng, K.T. Radial liquid crystal alignment based on circular rubbing of a substrate coated with poly(N-vinyl carbazole) film. J. Phys. D Appl. Phys. 2011, 44, 215304. [Google Scholar] [CrossRef]

- Bailey, J.; Kaur, S.; Morgan, P.B.; Gleeson, H.F.; Clamp, J.H.; Jones, J.C. Design considerations for liquid crystal contact lenses. J. Phys. D Appl. Phys. 2017, 50, 485401. [Google Scholar] [CrossRef]

- Ambulo, C.P.; Burroughs, J.J.; Boothby, J.M.; Kim, H.; Shankar, M.R.; Ware, T.H. Four-dimensional Printing of Liquid Crystal Elastomers. ACS Appl. Mater. Interfaces 2017, 9, 37332–37339. [Google Scholar] [CrossRef] [PubMed]

- Godman, N.P.; Kowalski, B.A.; Auguste, A.D.; Koerner, H.; White, T.J. Synthesis of Elastomeric Liquid Crystalline Polymer Networks via Chain Transfer. ACS Macro Lett. 2017, 6, 1290–1295. [Google Scholar] [CrossRef]

- Kotikian, A.; Truby, R.L.; Boley, J.W.; White, T.J.; Lewis, J.A. 3D Printing of Liquid Crystal Elastomeric Actuators with Spatially Programed Nematic Order. Adv. Mater. 2018, 30, 1706164. [Google Scholar] [CrossRef] [PubMed]

- López-Valdeolivas, M.; Liu, D.; Broer, D.J.; Sánchez-Somolinos, C. 4D Printed Actuators with Soft-Robotic Functions. Macromol. Rapid Commun. 2018, 39, 3–9. [Google Scholar] [CrossRef]

- Volpe, R.H.; Mistry, D.; Patel, V.V.; Patel, R.R.; Yakacki, C.M. Dynamically Crystalizing Liquid-Crystal Elastomers for an Expandable Endplate-Conforming Interbody Fusion Cage. Adv. Healthc. Mater. 2020, 9, 1901136. [Google Scholar] [CrossRef]

- Bladon, P.; Terentjev, E.; Warner, M. Deformation-induced orientational transitions in liquid crystals elastomer. J. Phys. II 1994, 4, 75–91. [Google Scholar] [CrossRef]

- Cotton, D.P.J.; Popel, A.; Graz, I.M.; Lacour, S.P. Photopatterning the mechanical properties of polydimethylsiloxane films. J. Appl. Phys. 2011, 109, 054905. [Google Scholar] [CrossRef]

| Constant | Value |

|---|---|

| A | 4.39 MPa |

| c | 0.426 |

| d | 0.444 |

| α | 60.5° |

| β | 27.6° |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mistry, D.; Gleeson, H.F. Toward Programmed Complex Stress-Induced Mechanical Deformations of Liquid Crystal Elastomers. Crystals 2020, 10, 315. https://doi.org/10.3390/cryst10040315

Mistry D, Gleeson HF. Toward Programmed Complex Stress-Induced Mechanical Deformations of Liquid Crystal Elastomers. Crystals. 2020; 10(4):315. https://doi.org/10.3390/cryst10040315

Chicago/Turabian StyleMistry, Devesh, and Helen F. Gleeson. 2020. "Toward Programmed Complex Stress-Induced Mechanical Deformations of Liquid Crystal Elastomers" Crystals 10, no. 4: 315. https://doi.org/10.3390/cryst10040315

APA StyleMistry, D., & Gleeson, H. F. (2020). Toward Programmed Complex Stress-Induced Mechanical Deformations of Liquid Crystal Elastomers. Crystals, 10(4), 315. https://doi.org/10.3390/cryst10040315