Capacitance Properties in Ba0.3Sr0.7Zr0.18Ti0.82O3 Thin Films on Silicon Substrate for Thin Film Capacitor Applications

Abstract

:1. Introduction

2. Materials and Methods

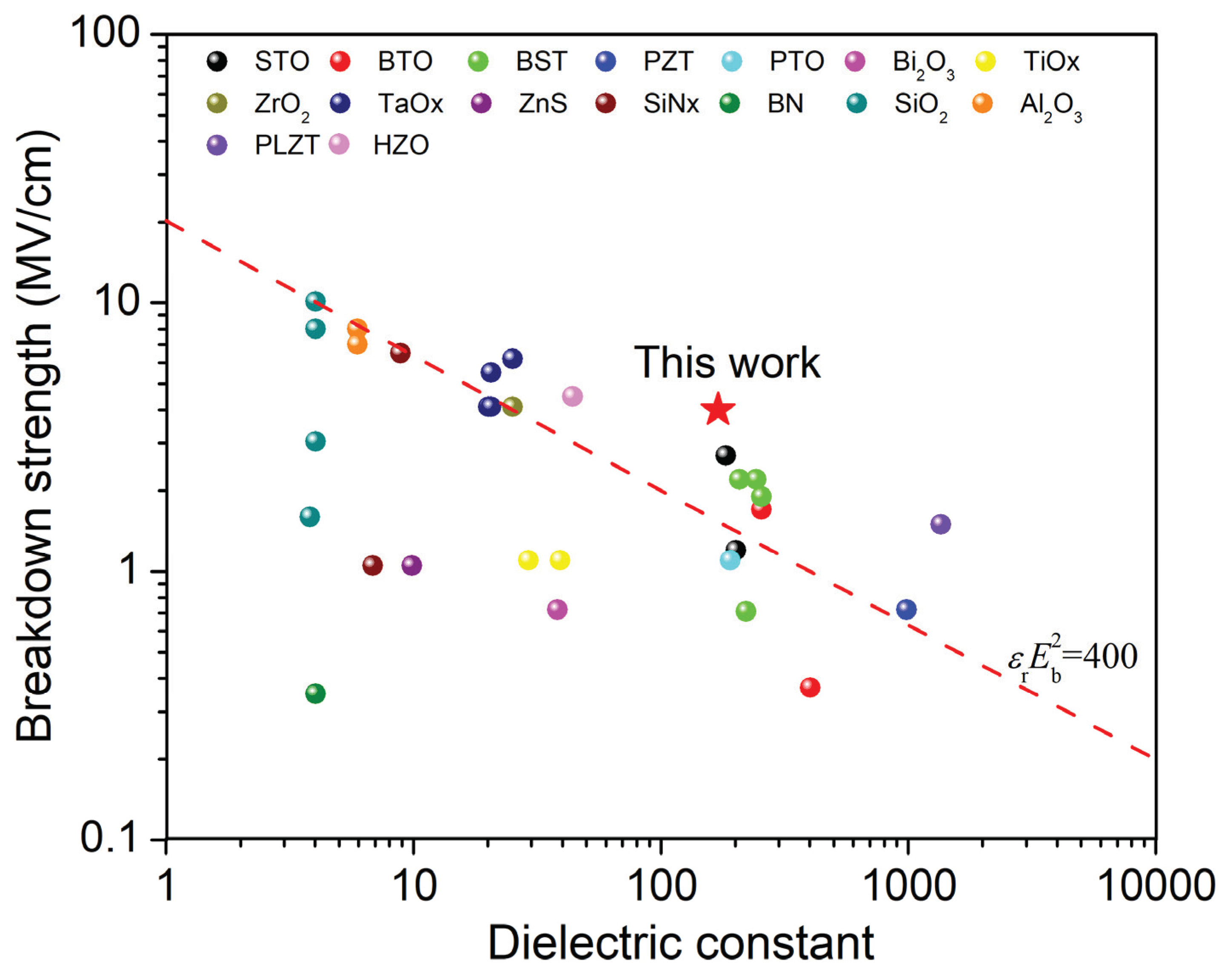

3. Results

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Chen, X.; Zhang, Y.; Xie, B.; Huang, K.; Wang, Z.; Yu, P. Thickness-Dependence of growth rate, dielectric response, and capacitance properties in Ba0.67Sr0.33TiO3/LaNiO3 hetero-structure thin films for film capacitor applications. Thin Solid Films 2019, 685, 269–274. [Google Scholar] [CrossRef]

- Johari, H.; Ayazi, F. High-Density Embedded Deep Trench Capacitors in Silicon with Enhanced Breakdown Voltage. IEEE Trans. Compon. Packag. 2010, 32, 808–815. [Google Scholar] [CrossRef]

- Perng, T.H.; Chien, C.H.; Chen, C.W.; Lehnen, P.; Chang, C.Y. High-Density MIM capacitors with HfO2 dielectrics. Thin Solid Films 2004, 469, 345–349. [Google Scholar] [CrossRef]

- Tuichai, W.; Danwittayakul, S.; Maensiri, S.; Thongbai, P. Investigation on temperature stability performance of giant permittivity (In + Nb) in co-Doped TiO2 ceramic: a crucial aspect for practical electronic applications. Rsc. Adv. 2016, 6, 5582–5589. [Google Scholar] [CrossRef]

- Pan, M.-J.; Randall, C.A. A brief introduction to ceramic capacitors. IEEE Electr. Insul. Mag. 2010, 26, 44–50. [Google Scholar] [CrossRef]

- Sugii, N.; Yamada, H.; Kagaya, O.; Yamasaki, M.; Sekine, K.; Yamashita, K.; Watanabe, M.; Murakami, S. High-Frequency properties of SrTiO3 thin-film capacitors fabricated on polymer-Coated alloy substrates. Appl. Phys. Lett. 1998, 72, 261–263. [Google Scholar] [CrossRef]

- Kozyrev, A.; Samoilova, T.; Golovkov, A.; Hollmann, E.; Kalinikos, D.; Loginov, V.; Prudan, A.; Soldatenkov, O.; Galt, D.; Mueller, C. Nonlinear behavior of thin film SrTiO3 capacitors at microwave frequencies. J. Appl. Phys. 1998, 84, 3326–3332. [Google Scholar] [CrossRef]

- Finstrom, N.H.; Gannon, J.A.; Pervez, N.K.; York, R.A.; Stemmer, S. Dielectric losses of SrTiO3 thin film capacitors with Pt bottom electrodes at frequencies up to 1 GHz. Appl. Phys. Lett. 2006, 89, 242910. [Google Scholar] [CrossRef] [Green Version]

- Konofaos, N.; Evangelou, E.; Wang, Z.; Helmersson, U. Properties of Al-SrTiO3-ITO capacitors for microelectronic device applications. IEEE Trans. Electron Devices 2004, 51, 1202–1204. [Google Scholar] [CrossRef]

- Takemura, K.; Kikuchi, K.; Ueda, C.; Baba, K.; Aoyagi, M.; Otsuka, K. SrTiO3 thin film decoupling capacitors on Si interposers for 3D system integration. In Proceedings of the 2009 IEEE International Conference on 3D System Integration, San Francisco, CA, USA, 28–30 September 2009; pp. 1–5. [Google Scholar]

- Takemura, K.; Ohuchi, A.; Shibuya, A. Si interposers integrated with SrTiO3 thin film decoupling capacitors and through-Si-vias. In Proceedings of the 2008 IEEE 9th VLSI Packaging Workshop of Japan, Kyoto, Japan, 1–2 December 2008; pp. 127–130. [Google Scholar]

- Jain, P.; Rymaszewski, E.J. Embedded thin film capacitors-Theoretical limits. IEEE Trans. Adv. Packag. 2002, 25, 454–458. [Google Scholar] [CrossRef]

- Chan, N.; Wang, D.; Wang, Y.; Dai, J.; Chan, H. The structural and in-Plane dielectric/ferroelectric properties of the epitaxial (Ba, Sr)(Zr, Ti)O3 thin films. J. Appl. Phys. 2014, 115, 234102. [Google Scholar] [CrossRef]

- Fu, S.L.; Ho, I.C.; Chen, L.S. Studies on semiconductive (Ba0.8Sr0.2)(Ti0.9Zr0.1)O3 ceramics. J. Mater. Sci. 1990, 25, 4042–4046. [Google Scholar] [CrossRef]

- Jiang, L.; Tang, X.; Jiang, Y.; Liu, Q.; Ma, C.; Chan, H. Epitaxial growth and dielectric properties of BSZT thin films on SrTiO3: Nb single crystal substrate prepared by pulsed laser deposition. Surf. Coat. Technol. 2013, 229, 162–164. [Google Scholar] [CrossRef]

- Fan, Y.; Yu, S.; Sun, R.; Li, L.; Yin, Y.; Du, R. Microstructure and electrical properties of Ba0.7Sr0.3(Ti1−xZrx)O3 thin films prepared on copper foils with sol–gel method. Thin Solid Films 2010, 518, 3610–3614. [Google Scholar] [CrossRef]

- Sharma, S.; Ram, M.; Thakur, S.; Sharma, H.; Negi, N.S. Structural Studies of Zirconium Doped Ba0.70Sr0.30TiO3 Lead Free Ferroelectric Thin Films. Aip Conf. Proc. 2016, 1728, 020192. [Google Scholar]

- Zhai, J.; Yao, X.I.; Chen, H. Structural and dielectric properties of (Ba0.85Sr0.15)(Zr0.18Ti0.82)O3 thin films grown by a sol–gel process. Ceram. Int. 2004, 30, 1237–12403. [Google Scholar] [CrossRef]

- Tang, X.; Jie, W.; Chan, L.W. Dielectric properties of columnar-grained (Ba0.75Sr0.25)(Zr0.25Ti0.75)O3 thin films prepared by pulsed laser deposition. J. Cryst. Growth 2005, 276, 453–457. [Google Scholar] [CrossRef]

- Chen, X.; Yang, C.; Zhang, X.; Li, J.; Liu, H.; Xiao, D.; Yu, P. The Effects of Buffers on the Microstructure and Electrical Properties of Mn/Y Co-Doped Ba0.67Sr0.33TiO3 Thin Films. Integr. Ferroelectr. 2012, 140, 132–139. [Google Scholar] [CrossRef]

- ABC of CLR in European Passive Components Institute (EPCI) Home Page. Available online: https://epci.eu/category/abc-of-clr/ (accessed on 26 March 2020).

- Park, M.H.; Kim, H.J.; Kim, Y.J.; Moon, T.; Kim, K.D.; Hwang, C.S. Thin HfxZr1−xO2 films: a new lead-Free system for electrostatic supercapacitors with large energy storage density and robust thermal stability. Adv. Energy Mater. 2014, 4, 1400610. [Google Scholar] [CrossRef]

- Ma, B.; Hu, Z.; Koritala, R.E.; Lee, T.H.; Dorris, S.E.; Balachandran, U. PLZT film capacitors for power electronics and energy storage applications. J. Mater. Sci. Mater. Electron. 2015, 26, 9279–9287. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.; Mo, T.; Huang, B.; Liu, Y.; Yu, P. Capacitance Properties in Ba0.3Sr0.7Zr0.18Ti0.82O3 Thin Films on Silicon Substrate for Thin Film Capacitor Applications. Crystals 2020, 10, 318. https://doi.org/10.3390/cryst10040318

Chen X, Mo T, Huang B, Liu Y, Yu P. Capacitance Properties in Ba0.3Sr0.7Zr0.18Ti0.82O3 Thin Films on Silicon Substrate for Thin Film Capacitor Applications. Crystals. 2020; 10(4):318. https://doi.org/10.3390/cryst10040318

Chicago/Turabian StyleChen, Xiaoyang, Taolan Mo, Binbin Huang, Yun Liu, and Ping Yu. 2020. "Capacitance Properties in Ba0.3Sr0.7Zr0.18Ti0.82O3 Thin Films on Silicon Substrate for Thin Film Capacitor Applications" Crystals 10, no. 4: 318. https://doi.org/10.3390/cryst10040318

APA StyleChen, X., Mo, T., Huang, B., Liu, Y., & Yu, P. (2020). Capacitance Properties in Ba0.3Sr0.7Zr0.18Ti0.82O3 Thin Films on Silicon Substrate for Thin Film Capacitor Applications. Crystals, 10(4), 318. https://doi.org/10.3390/cryst10040318