Thermal Performance of Alginate Concrete Reinforced with Basalt Fiber

Abstract

1. Introduction

2. Materials and Methods

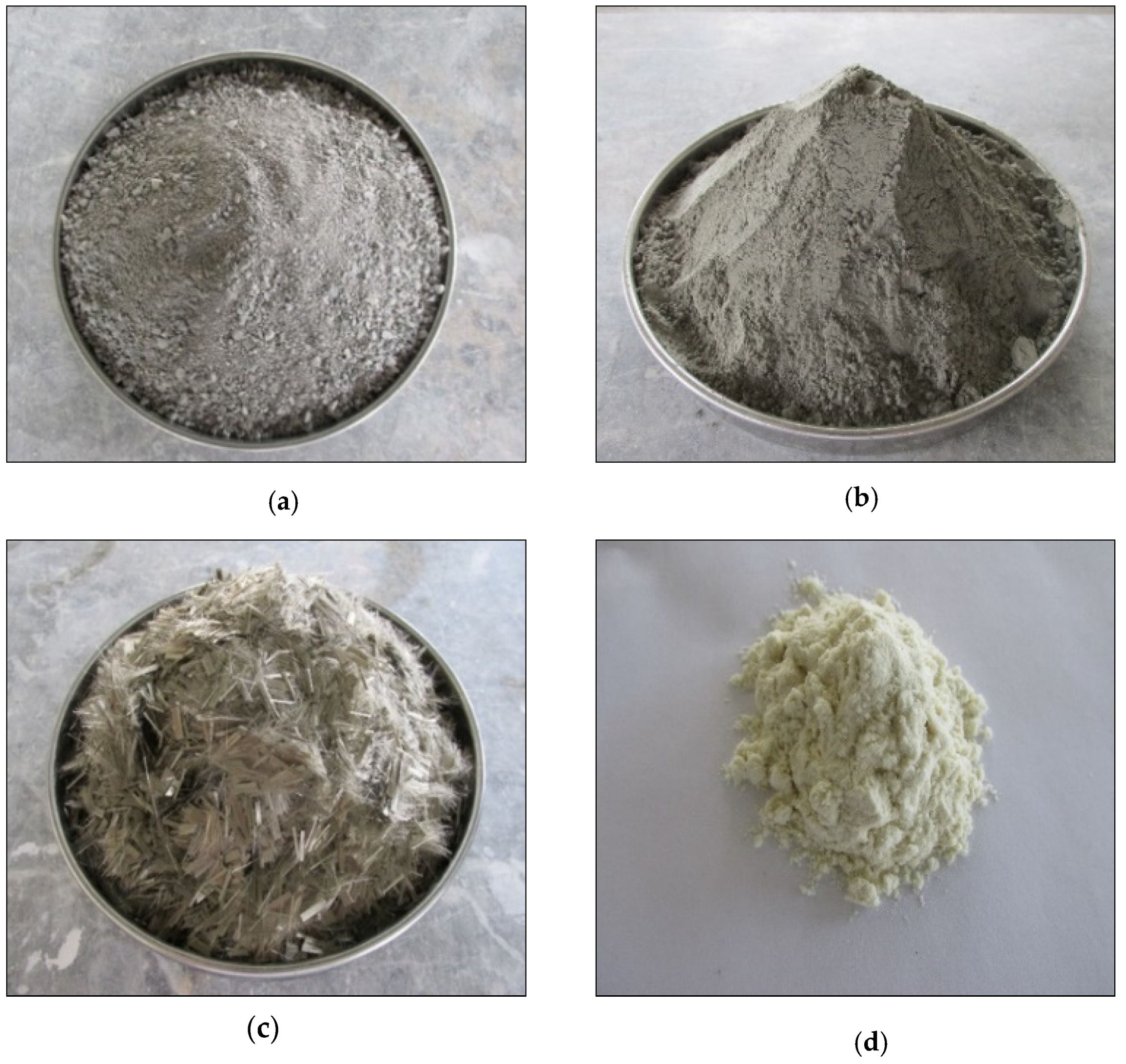

2.1. Materials

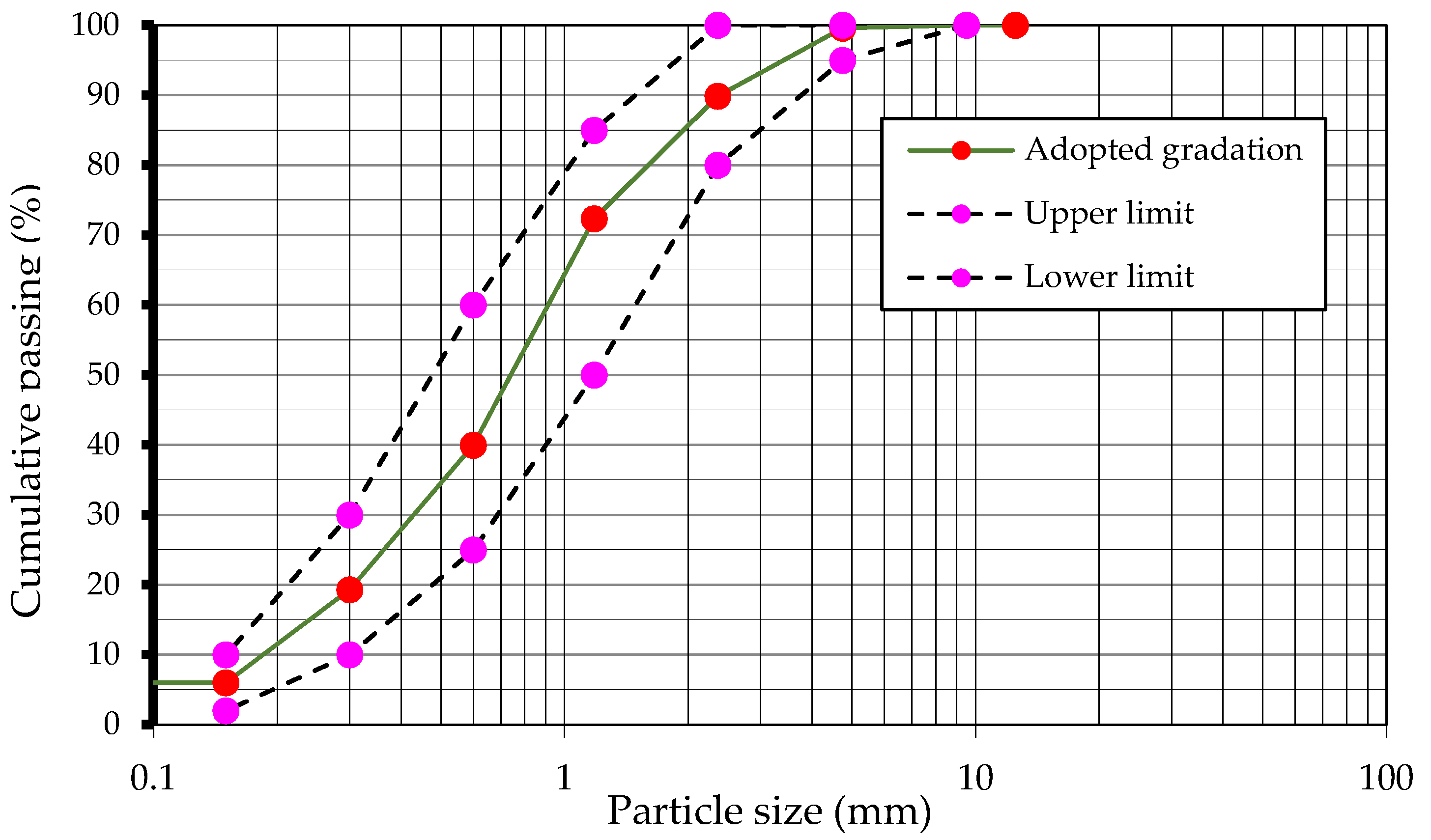

2.2. Mix Design and Specimen Preparation

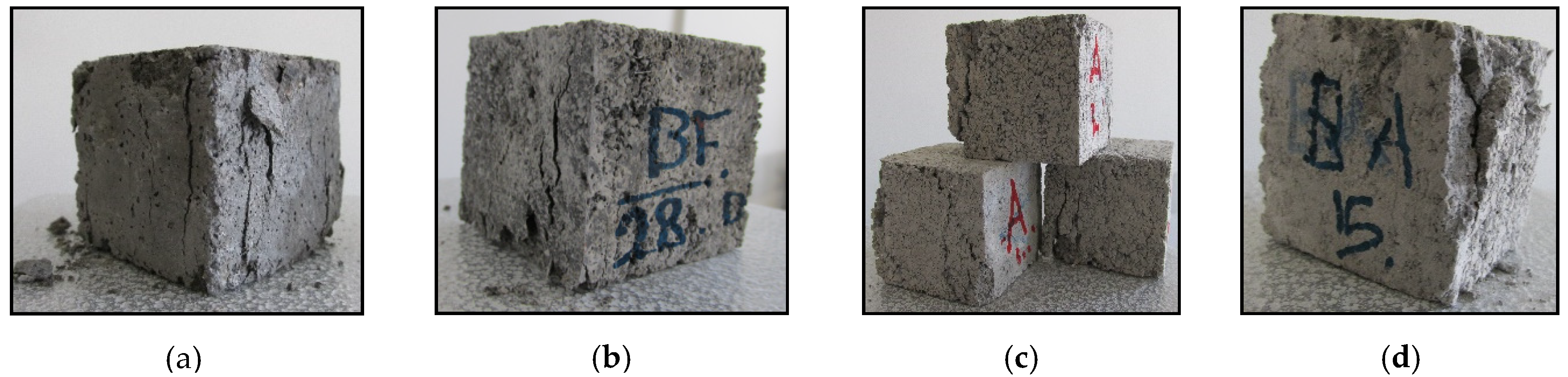

2.3. Compressive Strength Testing

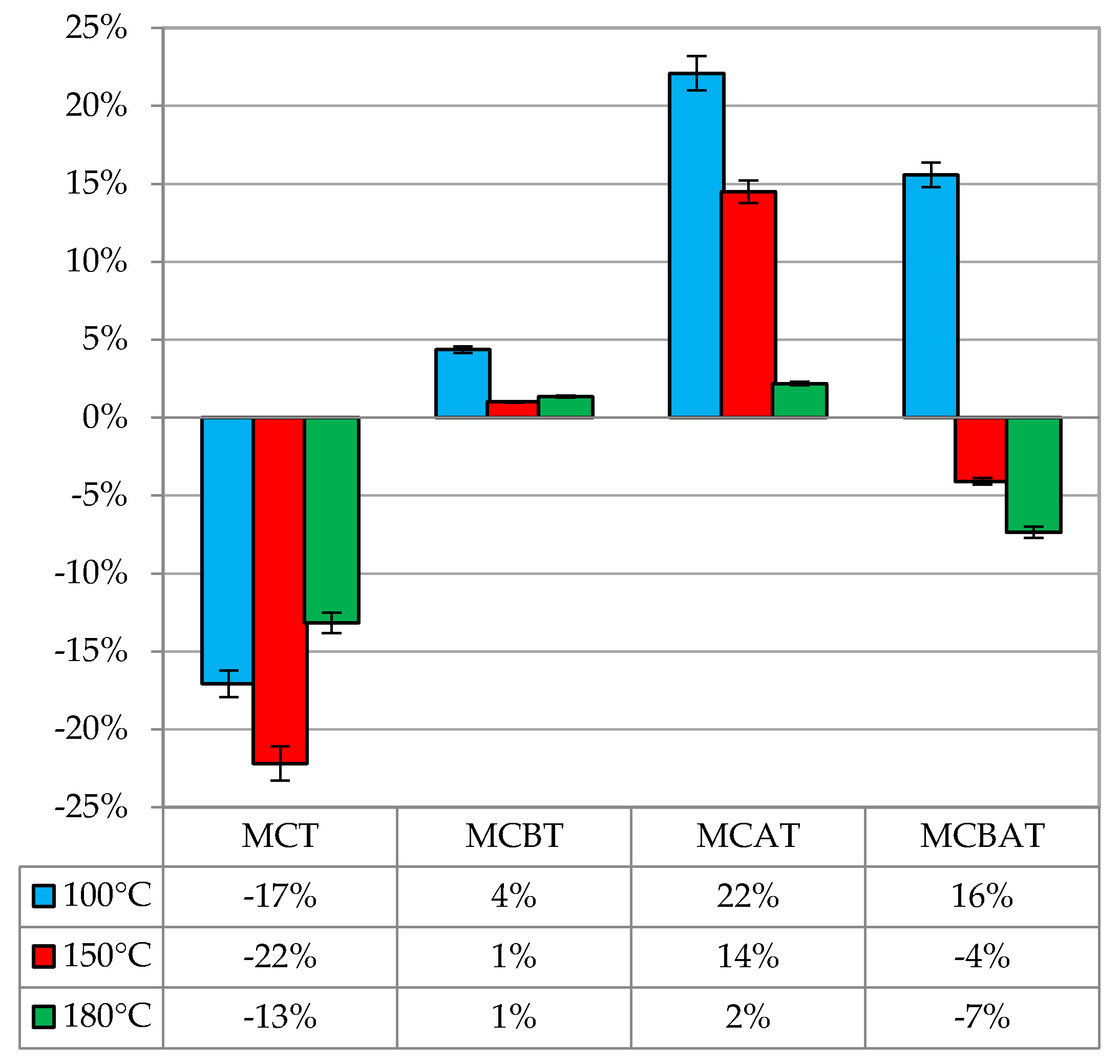

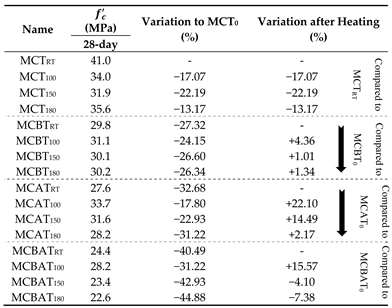

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mohammadyan-Yasouj, S.E.; Marsono, A.K.; Abdullah, R.; Moghadasi, M. Wide beam shear behavior with diverse types of reinforcement. ACI Struct. J. 2015, 112, 199–208. [Google Scholar] [CrossRef][Green Version]

- Moghadasi, M.; Marsono, A.K.; Mohammadyan-Yasouj, S.E. A study on rotational behaviour of a new industrialised building system connection. Steel Compos. Struct. 2017, 25, 245–255. [Google Scholar] [CrossRef]

- Shokravi, H.; Shokravi, H.; Bakhary, N.; Koloor, S.S.R.; Petrů, M. A Comparative Study of the Data-driven Stochastic Subspace Methods for Health Monitoring of Structures: A Bridge Case Study. Appl. Sci. 2020, 10, 3132. [Google Scholar] [CrossRef]

- Shokravi, H.; Shokravi, H.; Bakhary, N.; Koloor, S.S.R.; Petrů, M. Health Monitoring of Civil Infrastructures by Subspace System Identification Method: An Overview. Appl. Sci. 2020, 10, 2786. [Google Scholar] [CrossRef]

- Yuan, C.; Chen, W.; Pham, T.M.; Hao, H. Effect of aggregate size on bond behaviour between basalt fibre reinforced polymer sheets and concrete. Compos. Part B Eng. 2019, 158, 459–474. [Google Scholar] [CrossRef]

- Ahmed, A.A.M.; Jia, Y. Effect of Using Hybrid Polypropylene and Glass Fibre on the Mechanical Properties and Permeability of Concrete. Materials 2019, 12, 3786. [Google Scholar] [CrossRef]

- Alnahhal, W.; Aljidda, O. Effect of Fiber Volume Fraction on Behavior of Concrete Beams Made with Recycled Concrete Aggregates. In Proceedings of the MATEC Web of Conferences, 14 January 2019; EDP Sciences: Paris, France; Volume 253, p. 2004. [Google Scholar]

- Swathi, T.; Resmi, K.N. Experimental Studies on Fly Ash Based Basalt Fibre Reinforced Concrete. In Proceedings of the 3rd National Conference on Structural Engineering and Construction Management, 15–16 May 2019; Springer: Kerala, India, 2019; pp. 25–39. [Google Scholar]

- Wang, X.; He, J.; Mosallam, A.S.; Li, C.; Xin, H. The effects of fiber length and volume on material properties and crack resistance of basalt fiber reinforced concrete (BFRC). Adv. Mater. Sci. Eng. 2019, 2019. [Google Scholar] [CrossRef]

- Jiang, C.; Fan, K.; Wu, F.; Chen, D. Experimental study on the mechanical properties and microstructure of chopped basalt fibre reinforced concrete. Mater. Des. 2014, 58, 187–193. [Google Scholar] [CrossRef]

- Kizilkanat, A.B.; Kabay, N.; Akyüncü, V.; Chowdhury, S.; Akça, A.H. Mechanical properties and fracture behavior of basalt and glass fiber reinforced concrete: An experimental study. Constr. Build. Mater. 2015, 100, 218–224. [Google Scholar] [CrossRef]

- Fenu, L.; Forni, D.; Cadoni, E. Dynamic behaviour of cement mortars reinforced with glass and basalt fibres. Compos. Part B Eng. 2016, 92, 142–150. [Google Scholar] [CrossRef]

- Shafiq, N.; Ayub, T.; Khan, S.U. Investigating the performance of PVA and basalt fibre reinforced beams subjected to flexural action. Compos. Struct. 2016, 153, 30–41. [Google Scholar] [CrossRef]

- Sarkar, A.; Hajihosseini, M. Feasibility of Improving the Mechanical Properties of Concrete Pavement Using Basalt Fibers. J. Test. Eval. 2020, 48. [Google Scholar] [CrossRef]

- Mohammadyan-Yasouj, S.E.; Ghaderi, A. Experimental investigation of waste glass powder, basalt fibre, and carbon nanotube on the mechanical properties of concrete. Constr. Build. Mater. 2020, 252, 119115. [Google Scholar] [CrossRef]

- Pathak, T.S.; San Kim, J.; Lee, S.-J.; Baek, D.-J.; Paeng, K.-J. Preparation of alginic acid and metal alginate from algae and their comparative study. J. Polym. Environ. 2008, 16, 198–204. [Google Scholar] [CrossRef]

- Engbert, A.; Gruber, S.; Plank, J. The effect of alginates on the hydration of calcium aluminate cement. Carbohydr. Polym. 2020, 236, 116038. [Google Scholar] [CrossRef]

- Wang, J.; Mignon, A.; Snoeck, D.; Wiktor, V.; Van Vliergerghe, S.; Boon, N.; De Belie, N. Application of modified-alginate encapsulated carbonate producing bacteria in concrete: A promising strategy for crack self-healing. Front. Microbiol. 2015, 6, 1088. [Google Scholar] [CrossRef]

- Ouwerx, C.; Velings, N.; Mestdagh, M.M.; Axelos, M.A. V Physico-chemical properties and rheology of alginate gel beads formed with various divalent cations. Polym. Gels Networks 1998, 6, 393–408. [Google Scholar] [CrossRef]

- Abbas, W.A.; Mohsen, H.M. Effect of Biopolymer Alginate on some properties of concrete. J. Eng. 2020, 26, 121–131. [Google Scholar]

- Heidari, A.; Ghaffari, F.; Ahmadvand, H. Properties of self compacting concrete incorporating alginate and nano silica. Asian J. Civ. Eng. BHRC 2015, 16, 1–11. [Google Scholar]

- Mignon, A.; Snoeck, D.; D’Halluin, K.; Balcaen, L.; Vanhaecke, F.; Dubruel, P.; Van Vlierberghe, S.; De Belie, N. Alginate biopolymers: Counteracting the impact of superabsorbent polymers on mortar strength. Constr. Build. Mater. 2016, 110, 169–174. [Google Scholar] [CrossRef]

- DeBrouse, D.R. Alginate-Based Building Materials. U.S. Patent 8,246,733, 21 August 2012. [Google Scholar]

- Kabay, N. Abrasion resistance and fracture energy of concretes with basalt fiber. Constr. Build. Mater. 2014, 50, 95–101. [Google Scholar] [CrossRef]

- Ayub, T.; Shafiq, N.; Nuruddin, M.F. Mechanical properties of high-performance concrete reinforced with basalt fibers. Procedia Eng. 2014, 77, 131–139. [Google Scholar] [CrossRef]

- Girgin, Z.C.; Yıldırım, M.T. Usability of basalt fibres in fibre reinforced cement composites. Mater. Struct. 2016, 49, 3309–3319. [Google Scholar] [CrossRef]

- Zhao, Y.-R.; Wang, L.; Lei, Z.-K.; Han, X.-F.; Xing, Y.-M. Experimental study on dynamic mechanical properties of the basalt fiber reinforced concrete after the freeze-thaw based on the digital image correlation method. Constr. Build. Mater. 2017, 147, 194–202. [Google Scholar] [CrossRef]

- Katkhuda, H.; Shatarat, N. Improving the mechanical properties of recycled concrete aggregate using chopped basalt fibers and acid treatment. Constr. Build. Mater. 2017, 140, 328–335. [Google Scholar] [CrossRef]

- Sun, X.; Gao, Z.; Cao, P.; Zhou, C. Mechanical properties tests and multiscale numerical simulations for basalt fiber reinforced concrete. Constr. Build. Mater. 2019, 202, 58–72. [Google Scholar] [CrossRef]

- Cristescu, N.D.; Craciun, E.-M.; Soós, E. Mechanics of Elastic Composites; CRC Press: New York, NY, USA, 2003; Volume 1, ISBN 0203502817. [Google Scholar]

- Singh, A.; Das, S.; Craciun, E.-M. Effect of thermomechanical loading on an edge crack of finite length in an infinite orthotropic strip. Mech. Compos. Mater. 2019, 55, 285–296. [Google Scholar] [CrossRef]

- Abdi, B.; Koloor, S.S.R.; Abdullah, M.R.; Amran, A.; Bin Yahya, M.Y. Effect of strain-rate on flexural behavior of composite sandwich panel. Appl. Mech. Mater. Trans Tech. Publ. 2012, 229, 766–770. [Google Scholar]

- Koloor, S.S.R.; Tamin, M.N. Mode-II interlaminar fracture and crack-jump phenomenon in CFRP composite laminate materials. Compos. Struct. 2018, 204, 594–606. [Google Scholar] [CrossRef]

- Mancini, M.; Moresi, M.; Rancini, R. Mechanical properties of alginate gels: Empirical characterisation. J. Food Eng. 1999, 39, 369–378. [Google Scholar] [CrossRef]

- Wang, J.; Zhou, S.; Huang, J.; Zhao, G.; Liu, Y. Interfacial modification of basalt fiber filling composites with graphene oxide and polydopamine for enhanced mechanical and tribological properties. RSC Adv. 2018, 8, 12222–12231. [Google Scholar] [CrossRef]

| Ref. | Conducted Tests and Sample Monitoring | Test Age (day) | Codes and Sample Size (mm) | Fiber Type | Remarks | |||

|---|---|---|---|---|---|---|---|---|

| Amount (% of the Total Volume) | Diameter (μm) | Length (mm) | Name | |||||

| Jiang et al., 2014 [10] | Compression | 3-7-28-90 | Ø AS (1012.9-1999, 1012.10–2000, and 1012.11–1985) | (0.05, 0.1, 0.3, and 0.5) | 20 | 12 and 22 | Basalt (B) | Addition of fiber increased porosity and reduced workability |

| Tension | 100 × 200 cylinder | Small to moderate increase in compressive strength (by BF > by PP) at 7–28 day age. | ||||||

| Flexure | 150 × 300 cylinder | Higher toughness and splitting tensile strength (BF> PP) is achieved by increasing fiber contents. | ||||||

| Permeability | 75 × 75 × 305 prism | Addition to 0.3% fiber increases flexural strength; 0.5% BF content reduce flexural strength. | ||||||

| - | 4–19 | Polypropylene (PP) | 0.3% of BF content with the length of 22 mm increases tensile and flexure strength. | |||||

| Kabay 2014 [24] | Compression | 28 | Ø EN 12390-3 and ASTM C642 | (0.07 and 0.14) | 13–20 | 12 and 24 | B | Workability is reduced by increasing the length and/or volume of fibers. |

| Flexure | 71 × 71 cube | Compared to compressive strengthabrasion has a higher correlation with void content and flexural strength. | ||||||

| Fracture energy | 100 × 100 cube | Addition of fiber reduced compression strength. | ||||||

| 70 × 70 × 285 prism (with 30 mm depth and 3 mm thickness notch) | The addition of fibers reduces abrasive wear in the range of 2–18%. | |||||||

| Most improved flexure strength was seen in mixture with 60% w/c. | ||||||||

| Ayoub et al., 2014 [25] | Compression | 28-7 | Ø BS (1881-125: 1986, 1881-3:1970, 1881-102) | (1, 2, and 3) | 18 | 25 | B | Increased BF contents reduced compressive strength. |

| Tension | 100 × 200 cylinder | Higher tension strength is achieved for high-performance concrete with BF and 10% silica. | ||||||

| E-value | BF does not correlate with E-value. | |||||||

| Kizilkanat et al., 2015 [11] | Compression | 28-7 | EN 12390-3, ASTM (C469M, C496), and JCI-S-002 | (0.25, 0.5, 0.75, and 1) | 13-20 | 12 | B | Increasing fibers caused a significant increase in fracture energy where workability and E-value were decreased |

| Tension | 150 × 150 × 150 cube | Slight increase in compressive strength was observed in >0.25% fiber content | ||||||

| Flexure | 100 × 200 cylinder | 0.5% and 0.75% inclusion of BF improved compressive strength | ||||||

| E-value | 100 × 100 × 350 prism (with 30 mm notch) | BF has a higher impact on crack avoidancetensile strengthand ductility | ||||||

| Fracture energy | 13 | 12 | Glass (G) | GF is directly related with flexure strength | ||||

| Fenu et al., 2016 [12] | Compression | 28 | Ø EN (197-1, 196-1) | 3 and 5 | 14 | 12 | B | Fibers’ addition did not show a significant impact on the dynamic increase factor. |

| Tension | 40 × 40 × 160 prism (cut from bending); | A significant and slight increase in energy absorption at a high strain rate was achieved by GF and BFrespectively. | ||||||

| Flexure | 100 × 200 cylinder core from prism for dynamic test | Improved static flexural strength and post-peak behavior were achieved by GF and BF. | ||||||

| SEM | 14 | 12 | G | |||||

| Shafiqh et al., 2016 [13] | Flexure | 28 | Ø ASTM C192/C192M, C 494-86 Type G, C78, C 1609) | 1, 2, and 3 | 18 | 25 | B | Strain attaining capacity was achieved by the addition of GF and BF. |

| SEM | 100 × 200 × 1500 prism | Ductilitypost-cracking flexural responseand toughness were significantly improved by PVA fibers. | ||||||

| 660 | 30 | Polyvinyl Alcohol (PVA) | No correlation between BF in post-peak flexural behavior was observed. | |||||

| Girgin 2016 [26] | Compression | 17 and 28 | Ø EN (1170-4/5:1997, 12467) | 2 | 14–20 | 24 | B | Stress accumulation due to the cement hydration in the matrix–fiber interface influenced flexural strain capacity of BF. |

| Flexure | 50 × 50 cube | A 35% reduction in the average strain capacity of GF-reinforced concrete compared with the 7-day one was achieved. | ||||||

| Heating | 12 × 600 × 600 square sheet | |||||||

| SEM | 11 × 50 × 270 square sheet | |||||||

| 13–20 | 24 | G | ||||||

| Afroz et al., 2017 [9] | Compression | Ø AS (3972, 3582.1–1998, 1012.8, 1012.9, 1012.10, 1012.11) | 0.5 | 15 | 3 | B (Chinese) | Long-term compatibility of BF reinforcement fibers for chloride and sulfate solutions. | |

| Tension | 100 × 200 cylinder | Compared to non-modified BFmodified BFs had better stability in alkaline medium. | ||||||

| Flexure | 150 × 300 cylinder | Coating provided good protection while exposure to extensive alkaline ions from a physiochemical analysis point of view. | ||||||

| SEM | 100 × 100 × 350 prism | A reduction in the mechanical properties of concrete for treated fibers was observed. | ||||||

| EDX | 15 | 25 | B (Russian) | Improved long-term flexural strengths and splitting tensile for high volume fly ash concrete with silane coated BFs even after 56 days. Difference in compressive strength was not notably improved. | ||||

| Zhao et al., 2017 [27] | Impact | 120 | GB/T 50082-2009 | 1, 1.5, 2, and 2.5 | 15 | 18 | B | Gradual loss in performance was observed by freeze-thaw cycles. |

| Freeze-thaw | 40 × 40 × 160 prism | Improved anti-impact deformation characteristics were achieved using BF. | ||||||

| Anti-impact deformation characteristics were weakened by freeze-thaw cycles. | ||||||||

| Katkhuda and Shatarat 2017 [28] | Compression | 28 | Ø ASTM (C33, C127, C131, C1524, C143) | 0.1, 0.3, 0.5, 1, and 1.5 | 16 | 18 | B | Flexural and splitting tensile strength of BF-reinforced concrete was significantly improved while it was minimally enhanced for the compressive strength. |

| Tension | 100 × 100 cube | The optimum BF content to achieve the same compressive and splitting tensile strength as the natural aggregate was 0.5% for untreated recycled coarse aggregate (RCA) and 0.3% for treated RCA while the optimum BF content for flexural strength was 0.3% for untreated RCA and 0.1% for treated RCA. | ||||||

| Flexure | 150 × 300 cylinder | |||||||

| Permeability | 100 × 100 × 500 prism | |||||||

| Sun et al., 2019 [29] | Compression | 28 | Ø SL352-2006, CECS13:2009 | 1, 2, 3, 4, and 5 | 17.4 | 6 and 12 | B | The compressive and splitting tensile strengths of concrete reduced with the increase of fiber content while the bending strength increased. |

| Tension | 150 × 150 cube | Compared to BF with the length of 12 mm 6 mm BF had better splitting tensile performance and compressive strength while variation of bending strength is slight | ||||||

| Flexure | 100 × 100 × 400 prism | 2% of 6 mm BF achieved the maximum strength | ||||||

| Ref. | Conducted Tests and Sample Monitoring | Test Age (day) | Codes and Sample Designation (mm) | Details on Alginate | Remarks | |

|---|---|---|---|---|---|---|

| Amount | Type | |||||

| (% of Cement Weight) | ||||||

| Ouwerx et al., 1998 [19] | E-value | 1 | Solution | - | Alginate gel bead | Alginate concentration limits the elasticity of breads. |

| SEM | Properties of alginate gel bead are dependent on the concentration and polymer type. | |||||

| Pathak et al., 2008 [16] | TGA | - | Solution | - | Dried algae (Sea mustard) | Alginic acid and metal alginates were prepared from fresh algae using extraction method then compared. |

| FTIR | Conversion of alginic acid into metal alginate was confirmed by FTIR spectroscopy. | |||||

| DSC | Cobalt alginate became decomposed at a higher temperature in comparison to sodium and calcium alginate. | |||||

| SEM | Presence of metal ions impacted on pore size distribution of alginates. | |||||

| Porosity | Different thermal behavior was observed in different metal alginates due to the structural differences. | |||||

| Heidari et al., 2015 [21] | Slump Flow (L-box) | 7, 28, 56, and 90 | Ø ASTM (C 462) | 0.5 and 1 | Alginic acid | Decrease in compressive, tensile, and flexural strengths by alginate. |

| Compression | 100 × 100 × 100 cube | Increase in workability, permeability, and compressive strength by silica. | ||||

| Tension | 150 × 300 cylinder | Alginate improved performance of SCC in fresh state. | ||||

| Flexure | 160 × 400 × 400 prism | In mixes containing alginate, nano and micro silica together, use of nano and micro-silica in upper percent of alginate increased the strength. | ||||

| Permeability | ||||||

| Mignon et al., 2016 [22] | Compressive | 28 | Ø EN 196-1 | 0.5 and 1 | Alginate biopolymers (NaAlg, CaAlg) | Alginate was promising for internal curing and was effective when much of superabsorbent polymer was required. |

| Flexure | 40 × 40 × 160 prism | NaAlg was insoluble due to the divalent cations in cement filtrate and created a physically cross-linked hydrogel. | ||||

| Swelling | CaAlg beads of 1% reduced only 15% of the compression strength. | |||||

| NaAlg of 1%, due to the higher water uptake capacity and stronger macro-pore, led to a 28% decrease in strength. | ||||||

| Cutting Length (mm) | 10 |

|---|---|

| Diameter (μm) | 17 |

| Density (gr/cm3) | 2.65 |

| Elastic modulus (GPa) | 93–110 |

| Tensile strength (MPa) | 4100–4800 |

| Elongation (%) | 1.3–3.2 |

| Softening point (°C) | 1050 |

| Water absorption (%) | <0.5 |

| Name | Water–Cement Ratio | Cement (kg/m3) | Polymer (%) * | Aggregates Passed Through Sieve # 100 |

|---|---|---|---|---|

| MpW0.5C450I#100 ** | 0.5 | 450 | - | Included |

| MpW0.5C470I#100 | 0.5 | 470 | - | Included |

| MpW0.5C450E#100 | 0.5 | 450 | - | Excluded |

| MpW0.5C470E#100 | 0.5 | 470 | - | Excluded |

| MpW0.55C450E#100 | 0.55 | 450 | - | Excluded |

| MpW0.55C470E#100 | 0.55 | 470 | - | Excluded |

| Name ** | BF (%) * | Alginate (%) * | Evaluation Temperature (°C) |

|---|---|---|---|

| MCTRT *** | - | - | 0 |

| MCT100 | - | - | 100 |

| MCT150 | - | - | 150 |

| MCT180 | - | - | 180 |

| MCBTRT | 0.2 | - | 0 |

| MCBT100 | 0.2 | - | 100 |

| MCBT150 | 0.2 | - | 150 |

| MCBT180 | 0.2 | - | 180 |

| MCATRT | - | 0.1 | 0 |

| MCAT100 | - | 0.1 | 100 |

| MCAT150 | - | 0.1 | 150 |

| MCAT180 | - | 0.1 | 180 |

| MCBATRT | 0.2 | 0.1 | 0 |

| MCBAT100 | 0.2 | 0.1 | 100 |

| MCBAT150 | 0.2 | 0.1 | 150 |

| MCBAT180 | 0.2 | 0.1 | 180 |

| Name | Age Tested | (MPa) |

|---|---|---|

| MpW0.5C450I#100 | 7-day | 29.9 |

| MpW0.5C470I#100 | 28.8 | |

| MpW0.5C450E#100 | 30.6 | |

| MpW0.5C470E#100 | 32.8 | |

| MpW0.55C450E#100 | 23.0 | |

| MpW0.55C470E#100 | 19.3 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohammadyan-Yasouj, S.E.; Abbastabar Ahangar, H.; Ahevani Oskoei, N.; Shokravi, H.; Rahimian Koloor, S.S.; Petrů, M. Thermal Performance of Alginate Concrete Reinforced with Basalt Fiber. Crystals 2020, 10, 779. https://doi.org/10.3390/cryst10090779

Mohammadyan-Yasouj SE, Abbastabar Ahangar H, Ahevani Oskoei N, Shokravi H, Rahimian Koloor SS, Petrů M. Thermal Performance of Alginate Concrete Reinforced with Basalt Fiber. Crystals. 2020; 10(9):779. https://doi.org/10.3390/cryst10090779

Chicago/Turabian StyleMohammadyan-Yasouj, Seyed Esmaeil, Hossein Abbastabar Ahangar, Narges Ahevani Oskoei, Hoofar Shokravi, Seyed Saeid Rahimian Koloor, and Michal Petrů. 2020. "Thermal Performance of Alginate Concrete Reinforced with Basalt Fiber" Crystals 10, no. 9: 779. https://doi.org/10.3390/cryst10090779

APA StyleMohammadyan-Yasouj, S. E., Abbastabar Ahangar, H., Ahevani Oskoei, N., Shokravi, H., Rahimian Koloor, S. S., & Petrů, M. (2020). Thermal Performance of Alginate Concrete Reinforced with Basalt Fiber. Crystals, 10(9), 779. https://doi.org/10.3390/cryst10090779