GaN-Based LEDs Grown on Graphene-Covered SiO2/Si (100) Substrate

Abstract

:1. Introduction

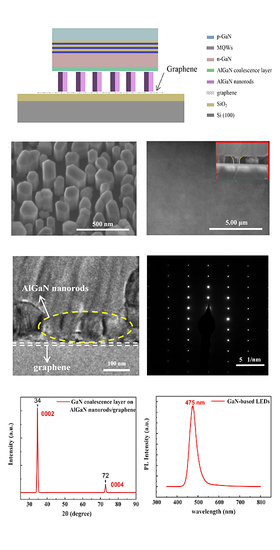

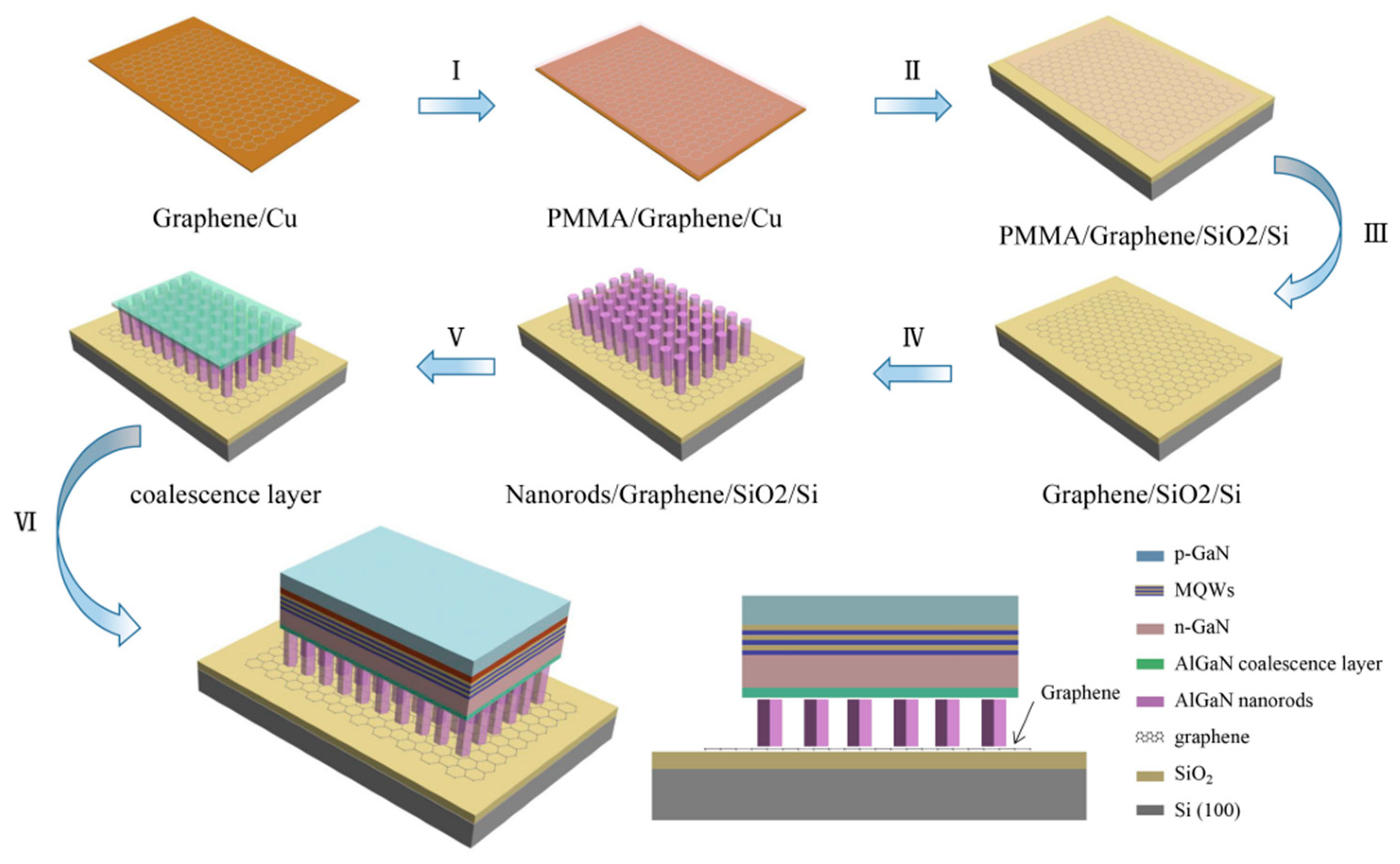

2. Materials and Methods

3. Results and Discussion

3.1. Effect of Reactor Pressure on AlGaN Nanorods

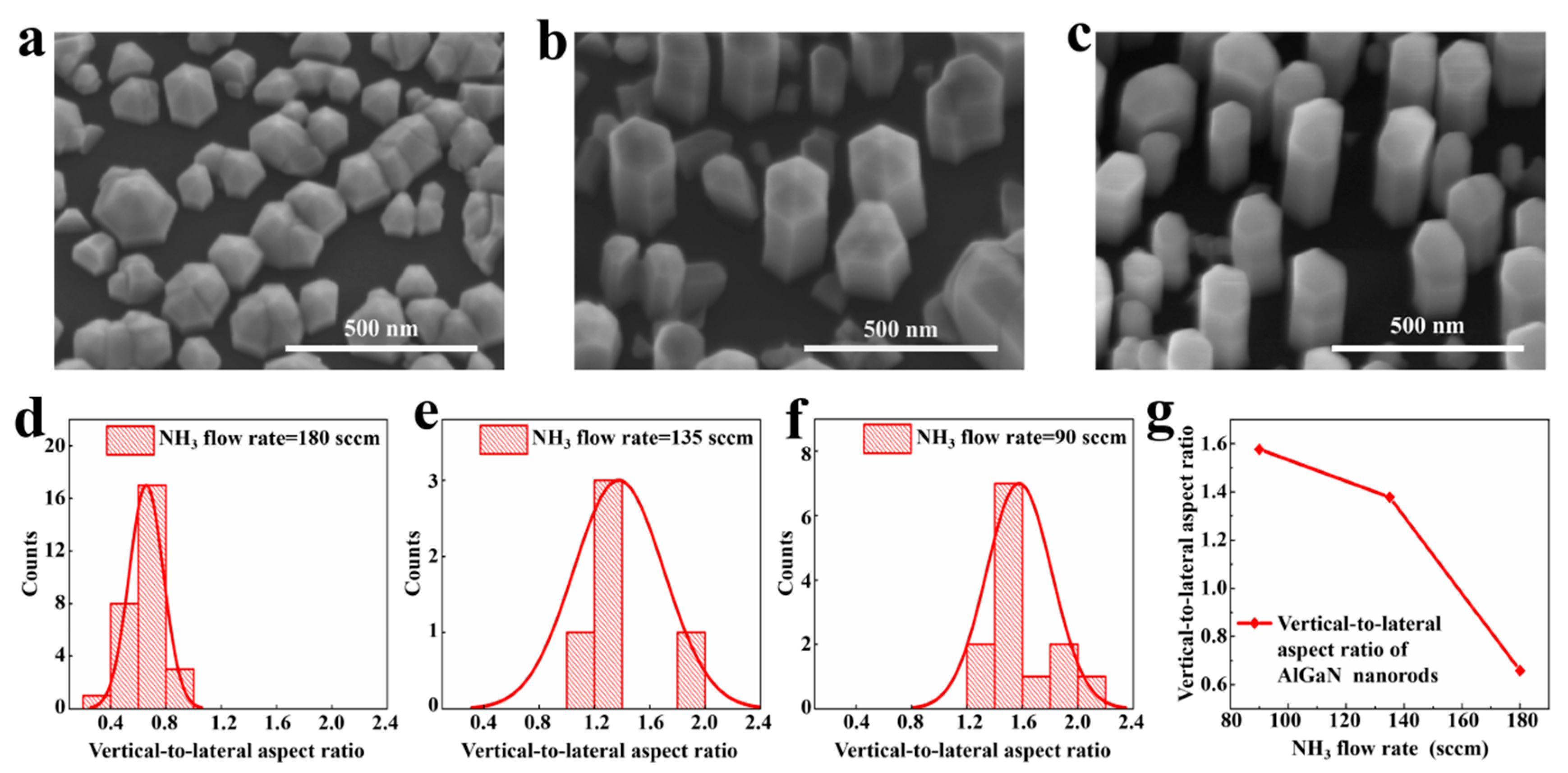

3.2. Effect of NH3 Flow Rate on AlGaN Nanorods

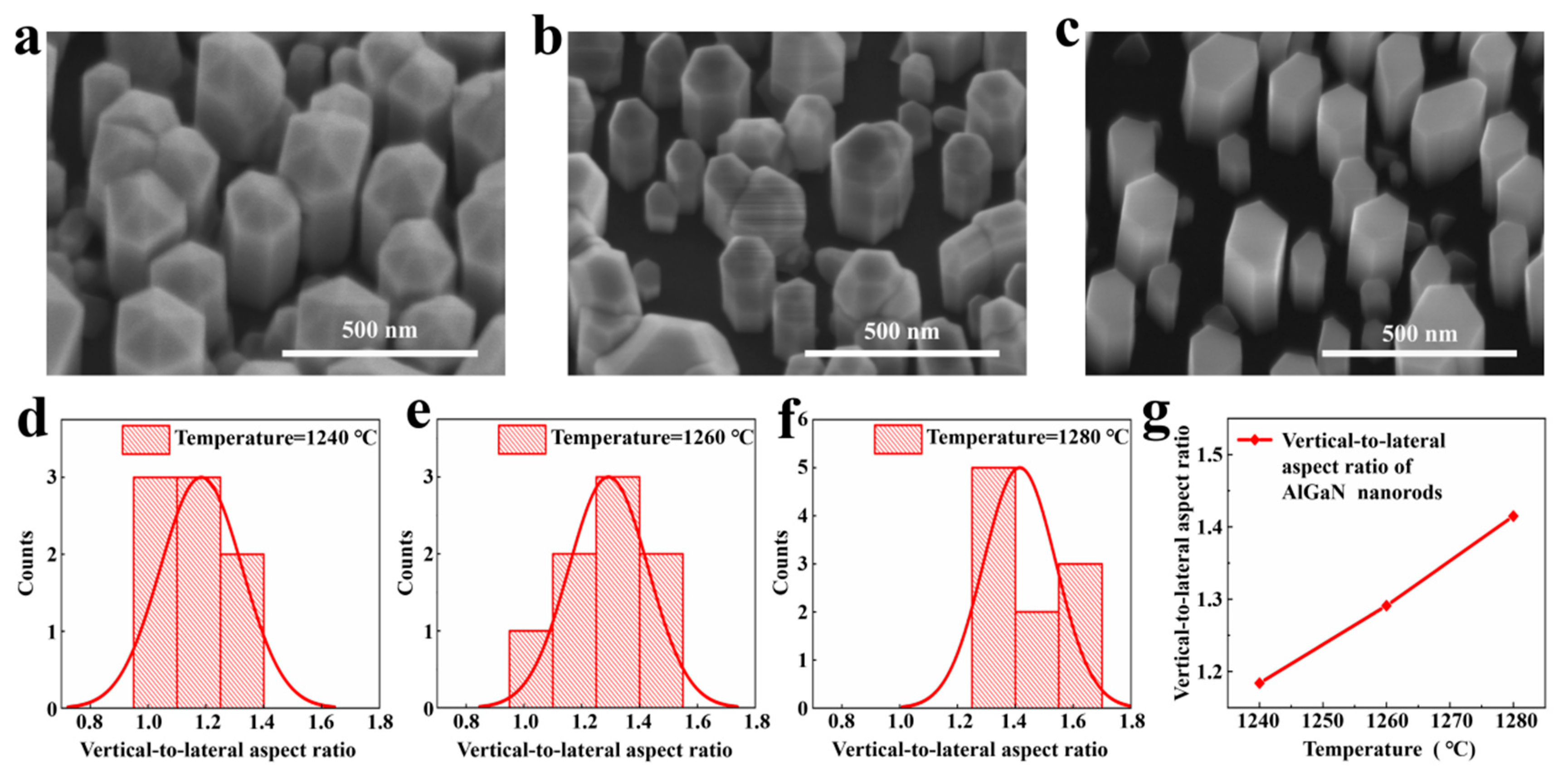

3.3. Effect of Reaction Temperature on AlGaN Nanorods

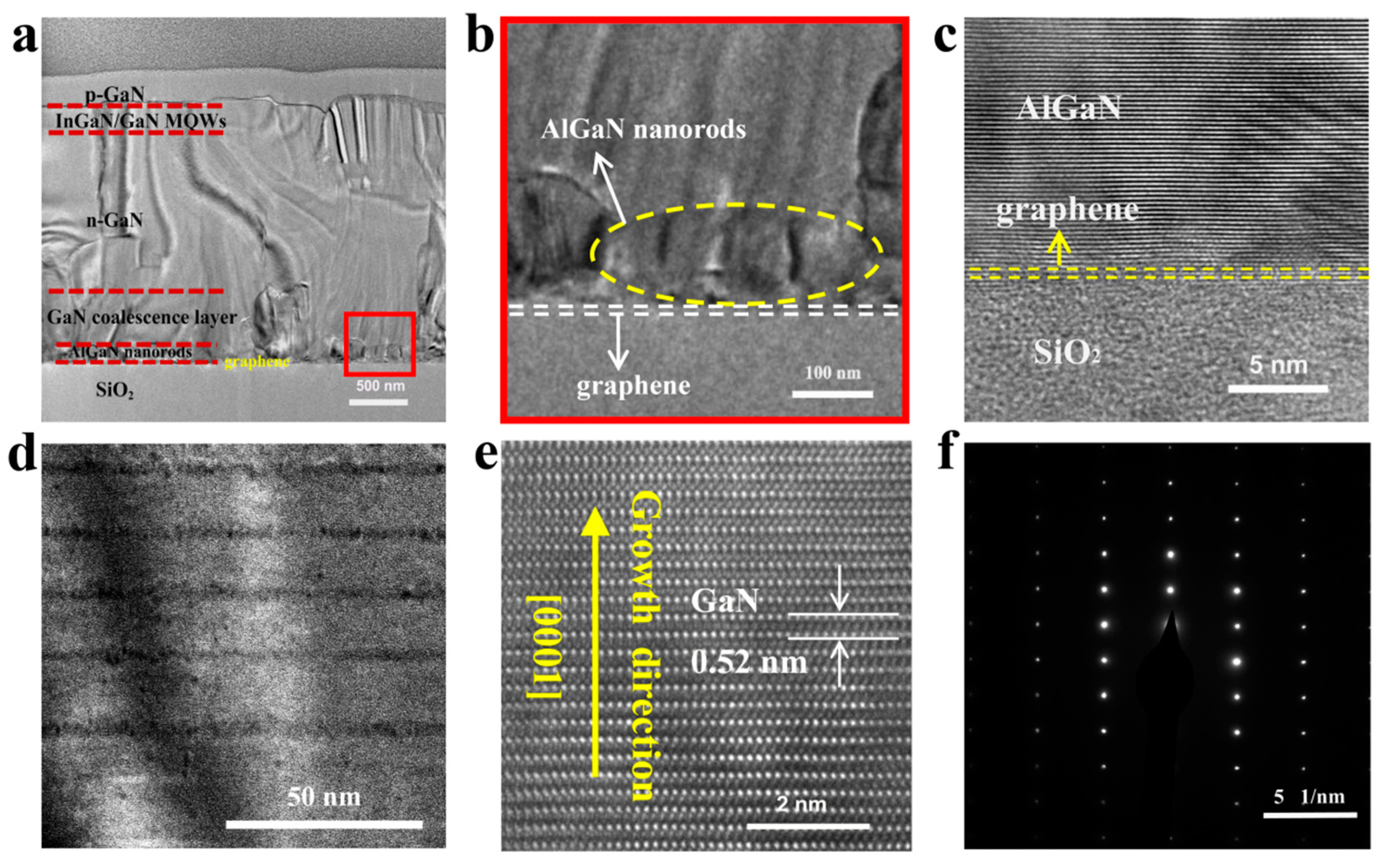

3.4. The Characterization of GaN Films

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Akasaki, I.; Amano, H. Crystal Growth and Conductivity Control of Group III Nitride Semiconductors and Their Application to Short Wavelength Light Emitters. Jpn. J. Appl. Phys. 1997, 36, 5393–5408. [Google Scholar] [CrossRef]

- Chung, K.; Lee, C.-H.; Yi, G.-C. Transferable GaN Layers Grown on ZnO-Coated Graphene Layers for Optoelectronic Devices. Science 2010, 330, 655–657. [Google Scholar] [CrossRef] [PubMed]

- Giannazzo, F.; Fisichella, G.; Greco, G.; La Magna, A.; Roccaforte, F.; Pécz, B.; Yakimova, R.; Dagher, R.; Michon, A.; Cordier, Y. Graphene integration with nitride semiconductors for high power and high frequency electronics. Phys. Status Solidi 2016, 214, 1600460. [Google Scholar] [CrossRef]

- Schlotter, P.; Schmidt, R.; Schneider, J. Luminescence conversion of blue light emitting diodes. Appl. Phys. A 1997, 64, 417–418. [Google Scholar] [CrossRef]

- Hahn, B.; Lugauer, H.-J.; Bader, S.; Baur, J.; Eisert, D.; Strauss, U.; Zehnder, U.; Lell, A.; Hiller, N. GaN-Based LEDs and Lasers on SiC. Phys. Status Solidi 2000, 180, 5–13. [Google Scholar] [CrossRef]

- Mo, C.; Fang, W.; Pu, Y.; Liu, H.; Jiang, F. Growth and characterization of InGaN blue LED structure on Si(111) by MOCVD. J. Cryst. Growth 2005, 285, 312–317. [Google Scholar] [CrossRef]

- Wang, L.; Wang, J.; Li, H.; Xi, G.; Jiang, Y.; Zhao, W.; Han, Y.; Luo, Y. Study on Injection Efficiency in InGaN/GaN Multiple Quantum Wells Blue Light Emitting Diodes. Appl. Phys. Express 2008, 1, 21101. [Google Scholar] [CrossRef]

- Choi, J.H.; Zoulkarneev, A.; Kim, S.I.; Baik, C.W.; Yang, M.H.; Park, S.S.; Suh, H.; Kim, U.J.; Bin Son, H.; Lee, J.S.; et al. Nearly single-crystalline GaN light-emitting diodes on amorphous glass substrates. Nat. Photonics 2011, 5, 763–769. [Google Scholar] [CrossRef]

- Yu, J.; Hao, Z.-B.; Wang, J.; Deng, J.; Yu, W.; Wang, L.; Luo, Y.; Han, Y.; Sun, C.; Xiong, B.; et al. Study on AlN buffer layer for GaN on graphene/copper sheet grown by MBE at low growth temperature. J. Alloy. Compd. 2019, 783, 633–642. [Google Scholar] [CrossRef]

- Hayashi, H.; Konno, Y.; Kishino, K. Self-organization of dislocation-free, high-density, vertically aligned GaN nanocolumns involving InGaN quantum wells on graphene/SiO2covered with a thin AlN buffer layer. Nanotechnology 2015, 27, 55302. [Google Scholar] [CrossRef]

- Littlejohn, A.J.; Xiang, Y.; Rauch, E.; Lu, T.-M.; Wang, G.-C. van der Waals epitaxy of Ge films on mica. J. Appl. Phys. 2017, 122, 185305. [Google Scholar] [CrossRef]

- Chen, Z.; Chang, H.; Cheng, T.; Wei, T.; Wang, R.; Yang, S.; Dou, Z.; Liu, B.; Zhang, S.; Xie, Y.; et al. Direct Growth of Nanopatterned Graphene on Sapphire and Its Application in Light Emitting Diodes. Adv. Funct. Mater. 2020, 30, 2001483. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, X.; Dou, Z.; Wei, T.; Liu, Z.; Qi, Y.; Ci, H.; Wang, Y.; Li, Y.; Chang, H.; et al. High-Brightness Blue Light-Emitting Diodes Enabled by a Directly Grown Graphene Buffer Layer. Adv. Mater. 2018, 30, 1801608. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Zhao, Y.; Wei, T.; Liu, Z.; Duan, R.; Wang, Y.; Zhang, X.; Wu, Q.; Yan, J.; Yi, X.; et al. Van der Waals epitaxy of GaN-based light-emitting diodes on wet-transferred multilayer graphene film. Jpn. J. Appl. Phys. 2017, 56, 85506. [Google Scholar] [CrossRef]

- Ren, F.; Yin, Y.; Wang, Y.; Liu, Z.; Liang, M.; Ou, H.; Ao, J.; Wei, T.; Yan, J.; Yuan, G.; et al. Direct Growth of AlGaN Nanorod LEDs on Graphene-Covered Si. Materials 2018, 11, 2372. [Google Scholar] [CrossRef] [Green Version]

- Zhao, S.; Lu, J.; Hai, X.; Yin, X. AlGaN Nanowires for Ultraviolet Light-Emitting: Recent Progress, Challenges, and Prospects. Micromachines 2020, 11, 125. [Google Scholar] [CrossRef] [Green Version]

- Min, J.-W.; Priante, D.; Tangi, M.; Liu, G.; Kang, C.H.; Prabaswara, A.; Zhao, C.; Al-Maghrabi, L.; Alaskar, Y.; Albadri, A.; et al. Unleashing the potential of molecular beam epitaxy grown AlGaN-based ultraviolet-spectrum nanowires devices. J. Nanophotonics 2018, 12, 43511. [Google Scholar] [CrossRef] [Green Version]

- Kim, J.; Bayram, C.; Park, H.; Cheng, C.-W.; Dimitrakopoulos, C.; Ott, J.A.; Reuter, K.B.; Bedell, S.W.; Sadana, D.K. Principle of direct van der Waals epitaxy of single-crystalline films on epitaxial graphene. Nat. Commun. 2014, 5, 4836. [Google Scholar] [CrossRef] [Green Version]

- Kovács, A.; Duchamp, M.; Dunin-Borkowski, R.E.; Yakimova, R.; Neumann, P.L.; Behmenburg, H.; Foltynski, B.; Giesen, C.; Heuken, M.; Pécz, B. Graphoepitaxy of High-Quality GaN Layers on Graphene/6H-SiC. Adv. Mater. Interfaces 2014, 2, 1400230. [Google Scholar] [CrossRef]

- Liu, Y.; Xu, Y.; Cao, B.; Li, Z.; Zhao, E.; Yang, S.; Wang, C.; Wang, J.; Xu, K. Transferable GaN Films on Graphene/SiC by van der Waals Epitaxy for Flexible Devices. Phys. Status Solidi 2019, 216, 1801027. [Google Scholar] [CrossRef]

- Mulyo, A.L.; Rajpalke, M.K.; Kuroe, H.; Vullum, P.-E.; Weman, H.; Fimland, B.-O.; Kishino, K. Vertical GaN nanocolumns grown on graphene intermediated with a thin AlN buffer layer. Nanotechnology 2018, 30, 15604. [Google Scholar] [CrossRef] [PubMed]

- Munshi, A.M.; Dheeraj, D.L.; Fauske, V.T.; Kim, D.-C.; Van Helvoort, A.T.J.; Fimland, B.-O.; Weman, H. Vertically Aligned GaAs Nanowires on Graphite and Few-Layer Graphene: Generic Model and Epitaxial Growth. Nano Lett. 2012, 12, 4570–4576. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Dheeraj, D.; Liu, Z.; Liang, M.; Li, Y.; Yi, X.; Wang, J.; Li, J.; Weman, H.J. AlGaN nanowires grown on SiO2/Si (100) using graphene as a buffer layer. Cryst. Growth Des. 2019, 19, 5516–5522. [Google Scholar] [CrossRef]

- Chae, S.J.; Seo, T.H.; Bae, J.J.; Suh, E.-K.; Yang, C.-W.; Duong, D.L.; Kim, Y.H.; Lee, S.M.; Park, M.H.; Jeong, M.S. Direct growth of etch pit-free GaN crystals on few-layer graphene. RSC Adv. 2015, 5, 1343–1349. [Google Scholar] [CrossRef]

- Araki, T.; Uchimura, S.; Sakaguchi, J.; Nanishi, Y.; Fujishima, T.; Hsu, A.; Kim, K.K.; Palacios, T.; Pesquera, A.; Centeno, A.; et al. Radio-frequency plasma-excited molecular beam epitaxy growth of GaN on graphene/Si(100) substrates. Appl. Phys. Express 2014, 7, 71001. [Google Scholar] [CrossRef]

- Lin, Y.-T.; Yeh, T.-W.; Nakajima, Y.; Dapkus, P.D. Catalyst-Free GaN Nanorods Synthesized by Selective Area Growth. Adv. Funct. Mater. 2014, 24, 3162–3171. [Google Scholar] [CrossRef]

- Lin, Y.-T.; Yeh, T.-W.; Dapkus, P.D. Mechanism of selective area growth of GaN nanorods by pulsed mode metalorganic chemical vapor deposition. Nanotechnology 2012, 23, 465601. [Google Scholar] [CrossRef]

- Willardson, R.K.; Weber, E.R.; Moustakas, T.D.; Pankove, J.I. Gallium-Nitride (GaN) II; Academic Press, 1998; Available online: https://www.elsevier.com/books/gallium-nitride-gan-ii/willardson/978-0-12-752166-4 (accessed on 5 September 2020).

- Song, K.M.; Kim, D.-H.; Kim, J.-M.; Cho, C.-Y.; Choi, J.; Kim, K.; Park, J.; Kim, H. White light emission of monolithic InGaN/GaN grown on morphology-controlled, nanostructured GaN templates. Nanotechnology 2017, 28, 225703. [Google Scholar] [CrossRef]

- Tabata, A.; Enderlein, R.; Leite, J.; Silva, A.S.; Galzerani, J.C.; Schikora, D.; Kloidt, M.; Lischka, K. Comparative Raman studies of cubic and hexagonal GaN epitaxial layers. J. Appl. Phys. 1996, 79, 4137. [Google Scholar] [CrossRef]

- Bülbül, M.; Smith, S.; Obradovic, B.; Cheng, T.; Foxon, C. Raman spectroscopy of optical phonons as a probe of GaN epitaxial layer structural quality. Eur. Phys. J. B 2000, 14, 423–429. [Google Scholar] [CrossRef]

| Experimental Set | Temperature [℃] | NH3 Flow Rate [sccm] | Reactor Pressure [Torr] |

|---|---|---|---|

| A | 1280 | 90 | 60–120 |

| B | 1280 | 90–180 | 60 |

| C | 1240–1280 | 90 | 60 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, W.; Ren, F.; Wang, Y.; Yin, Y.; Zhang, S.; Shi, B.; Feng, T.; Wang, J.; Liang, M.; Zhang, Y.; et al. GaN-Based LEDs Grown on Graphene-Covered SiO2/Si (100) Substrate. Crystals 2020, 10, 787. https://doi.org/10.3390/cryst10090787

Song W, Ren F, Wang Y, Yin Y, Zhang S, Shi B, Feng T, Wang J, Liang M, Zhang Y, et al. GaN-Based LEDs Grown on Graphene-Covered SiO2/Si (100) Substrate. Crystals. 2020; 10(9):787. https://doi.org/10.3390/cryst10090787

Chicago/Turabian StyleSong, Wurui, Fang Ren, Yunyu Wang, Yue Yin, Shuo Zhang, Bo Shi, Tao Feng, Jianwei Wang, Meng Liang, Yiyun Zhang, and et al. 2020. "GaN-Based LEDs Grown on Graphene-Covered SiO2/Si (100) Substrate" Crystals 10, no. 9: 787. https://doi.org/10.3390/cryst10090787