1. Introduction

Further scaling of integrated circuits is limited due to quantum effects when the device dimensions are near atomic scale. The development in zero-dimensional (0D) materials such as carbon nanoclusters can usher the era of advanced quantum-based electronic devices. Carbon-based low-dimensional systems including zero-dimensional (0D) fullerenes; one-dimensional (1D) carbon nanotubes (CNTs), and two-dimensional (2D) graphene are emerging suitable materials for next-generation nanoelectronics [

1]. The C-based nanoclusters have attracted a great deal of attention due to their size-specific characteristics that are different from corresponding bulk material. Carbon nanoclusters development in sooting atmospheres has led to the innovation of fullerenes in the laser-ablated graphite [

2]. The usual method for the fabrication of C60 consumes high-pressure and high-voltage arc discharges between graphite electrodes [

3] and is very costly. Arc discharge is a non-regenerative technique that is effective for assembling different “bucky-balls” [

4] depending on the limitations of discharge and the C soot collection approach. Whereas, in another technique established by our group known as “graphite hollow cathode” [

5,

6,

7,

8], discharge one recycles the graphite cathode-deposited C nanoclusters. Consequently, it is a technique of C nanoclusters creation that is dependent on the regeneration of the cathode-deposited C soot [

5]. By observing numerous steps of these regenerative sequences, we have been able to build a picture of the C nanoclusters’ evolution. The corresponding morphological roles played by the ionic as well as excited and neutral states of C

1, C

2, and C

3 and higher C nanoclusters [

6] in the formative and sooting phases of the regenerative carbonaceous discharges will be presented here.

Since the discovery of Buckminster fullerenes [

7], carbon (C) nanoclusters have been produced extensively with various techniques such as the production of carbon soot at high temperature and pressure [

8], the laser beam ablation of graphite [

9], and the electronic sputtering [

10] of graphite, to name a few. These techniques have their respective merits and demerits. There has been an emphasis in these techniques to selectively produce the C nanoclusters. Therefore, these bunches of few nanoparticles (nanoclusters) are expected to be promising candidates for the application of nanoscale electronics, optoelectronic, and spintronic devices. The C-based clusters have attracted a great deal of attention due to their size-specific characteristics that are often different from those of their corresponding bulk materials. Metal as well as non-metal nanoclusters play an important role in various fields of modern material science and technology [

11]. The C clusters are photosensitive and can be used for optical darkening and electrical conductivity modifications, and they have also been considered for their ion-induced chemical effects [

12]. In the last three decades, continuous research has established more techniques for the fabrication of C soot, which include the high-pressure arc discharge method exclusively for the production of C

60 and C

70 by Kr¨atschmer et al. [

3].

The nanoclustering process heavily depends on the synthesis parameters such as voltage, current, and geometry of ion sources for generating C soot. Previously, the production of C nanoclusters has been reported using numerous geometries of ion sources [

13,

14,

15,

16,

17]. The design of a tunable, soot regenerative ion source for the creation of a recyclable atmosphere of the carbon species plays an essential role in the production of C nanoclusters, and the production of shelled or carbon onion structures by the bombardment of high-energy electrons [

18,

19,

20]. The development of the carbon nanoclusters in sooting atmosphere is leading to the innovation of fullerenes during the laser ablation of the graphite [

2]. The fullerenes are an agglomeration of C nanoclusters into a closed cage-like nanostructure. The usual method for the fabrication of C

60 requires high-pressure and high-voltage arc discharges between graphite electrodes [

3], leading to high fabrication cost. Arc discharge is a non-regenerative technique for the assembly of different “bucky balls” [

4] while restricting C soot collection. Similarly, the energetic ion irradiation of organic compounds e.g., polymers can induce the nanoclustering of C atoms/ions into fullerenes [

21,

22]. The fullerene production as a function of ion (positive/negative) fluence-dependent nanoclustering is correlated to the ion-induced chemical variations [

21,

22]. The synthesis of fullerenes (e.g., C

60) by the bombardment of graphite using a Dy

22+ ion source has been described previously [

23]. An alternate technique was established by our group known as “graphite hollow cathode” [

5,

6,

7,

8]; in this technique, C nanoclusters were generated by regenerative C soot plasma [

5]. Our group has demonstrated the production of carbon nanocluster species (by emission spectroscopic studies) that are an indication of the ion-induced cluster development of nanoclusters by using 100 keV Ar

1+, Kr

1+, and Xe

1+ beams on amorphous graphite [

8].

The morphology-based physical properties of C nanoclusters deposited on metal/non-metal substrates are of considerable interest due to their potential applications in various devices [

6]. The study of the morphology of nanoclusters grown with different ion sources by the variation of current, voltage, and pressure are important synthesis parameters (for well-controlled growth sizes) [

24]. In fact, the chemical and physical properties of such functional materials are strongly correlated to their structure (size, shape, crystallinity, etc.) [

25]. These studies have attracted tremendous interest for the potential applications of these nanoclusters due to their size-dependent properties [

26]. The key point of such studies is the understanding of the cluster growth mechanisms to correlate morphological evolution to the process parameters such as deposition features (i.e., rate, voltage, current, time, gas pressure, etc.).

In the present study, we investigate the effect of synthesis parameters such as voltage, current, Ne-gas pressure, and geometry of the ion source on the morphology of C nanoclusters in regenerative soot plasma. The fragmentation of C nanoclusters during the sputtering of regenerative C soot using the specific geometry of graphite ion source plays a vital role. The designing as well as fabrication of graphite ions source is a challenging issue for the reproducible preparation of C nanoclusters. Among others, the hollow cathode (HC) graphite ion sources are very efficient in creating C soot in a noble gas environment whose regeneration can lead to the formation of C nanoclusters [

27]. We deposited nanoclusters of different sizes on the substrates during different Ne gas pressures, voltages, and currents. Atomic force microscopy (AFM) is an important technique to study the surface morphology [

28] of C nanoclusters. The top surface of nanoclusters can be provided to induce nanoclusters of various sizes, which are imaged using an AFM, and these images provide information about the morphological evolution. AFM images were analyzed to quantify the morphological evolution of the C nanoclusters as a function of the Ne gas pressure. Such a study allowed us to observe some features of the morphological evolution and to identify the nanocluster evolution mechanisms; in our case, the C nanocluster can become the major source of nucleation for the large-scale production of stabilized fullerenes for efficient devices. We deposited nanoclusters of different sizes on the substrates at different Ne gas pressures, potential voltages, and currents, to induce nanoclusters of various sizes. By using AFM images, the morphological evolution of the C nanoclusters was analyzed as a function of the Ne-gas pressure, quantitatively.

2. Experimental Section

The size and agglomeration process of the carbon nanoclusters can be controlled by optimizing several synthesis parameters such as geometry and pressure of discharge gas. The controlled size of the nanoclusters is highly desirable for the fabrication of nanodevices. The design of a tunable graphite ion source with optimized geometries for the production of C regenerative soot can play an essential role for the fabrication of C nanoclusters. Our group has designed and fabricated different graphite ion sources with the emission spectroscopy [

5,

6,

7,

8]. However, on the basis of these previous studies, we focused on the morphological studies of C nanoclusters using two different ion sources with different geometries. In this study, two types of ion source, cylindrical and U-shaped, were designed and fabricated as detailed below.

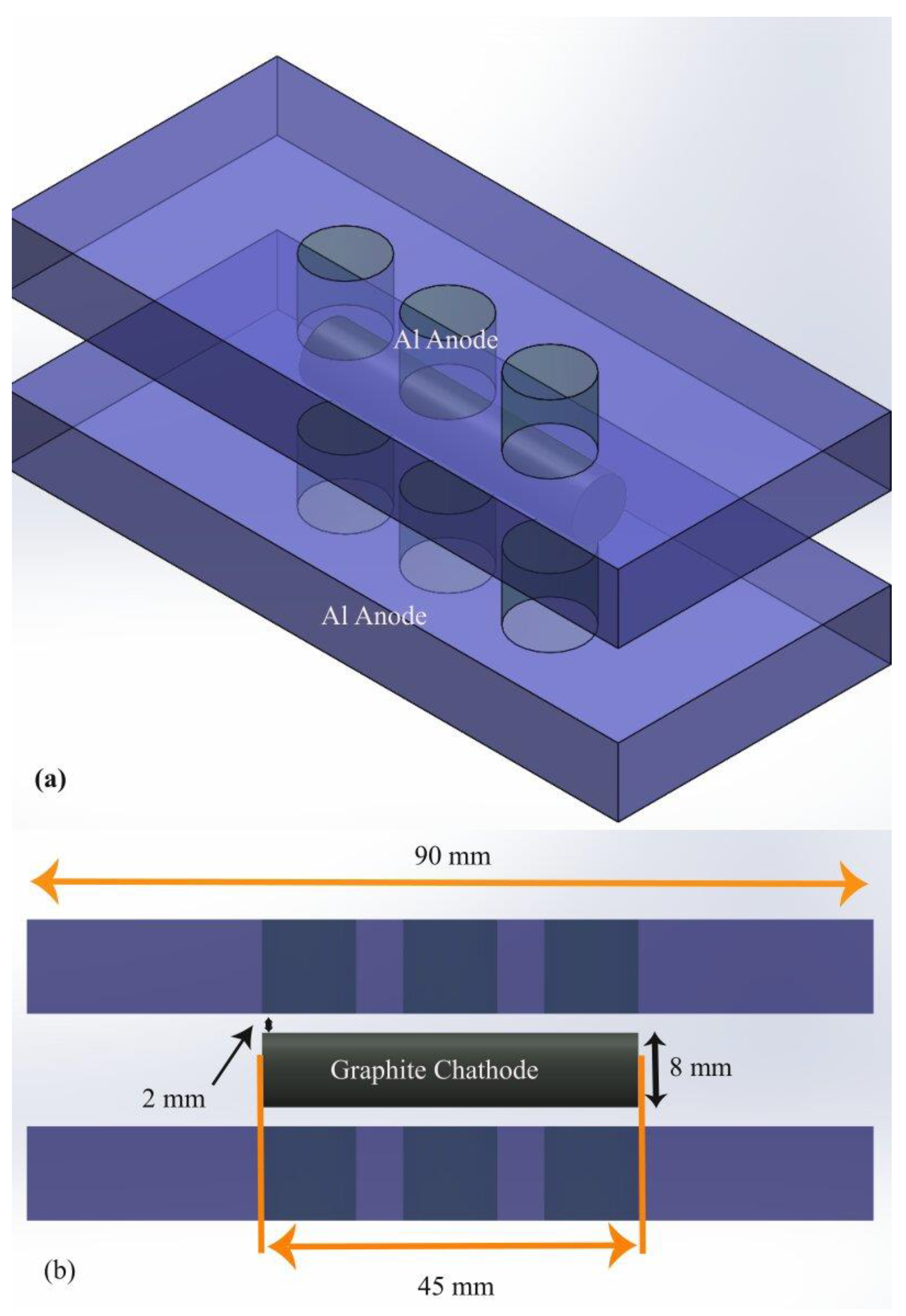

2.1. Cylindrical Graphite Ion Source

Figure 1 shows a schematic diagram of the cylindrical graphite ion source. The cylindrical graphite cathode with a diameter and length of 8 mm and 45 mm is surrounded by two aluminum (Al) anode plates, in which the total length of each anode plate was 90 mm with

holes of 5 mm at the central axis of each plate (the holes are shown in

Figure 1a,b).

The distance between graphite cathode and each anode plate was set as 2 mm. High vacuum pressure of approximately 10–5 mbar was attained in a chamber, and Ne gas was used for the sputtering of cylindrical graphite at 25 mbar pressure. A negative power supply with a maximum current of 240 mA was used for the efficient sputtering of the graphite during the DC glow discharge process. The process was iterated three times at constant gas pressure of 25 mbar and a maximum current of 240 mA. The discharge was initiated at the voltage between 0.43 and 0.45 kV.

2.2. Hollow Cathode Graphite Ion Source

Figure 2a,b shows the geometry of the hollow cathode and anode plate, which were used for the formation of carbonaceous discharge plasma. The graphite cathode has a length, inner diameter, and outer diameter of 45 mm, 20 mm, and 30 mm, respectively. The aluminum (Al) anode plate has a length and width of 50 mm and 7 mm, respectively.

The anode plate has a small slit with a length and width of 5 mm and 1 mm to allow the deposition of carbon nanoclusters on the substrate surface. The graphite hollow cathode target was mounted in the stainless steel vacuum chamber whose base pressure (high vacuum) of 10–5 mbar was attained by a turbo molecular pump and other accessories. The chamber was filled with neon (Ne) gas at pressures ranging from vacuum to 100 mbar. Neon can act as an efficient sputtering agent due to its higher ionization energy (21.56 eV). The discharge current was kept as 240 mA, while the voltage was varied at different pressures. The sputtering of a graphite hollow cathode ion source was performed during the ionization of Ne gas ions at different potentials (voltage between 0.43 and 0.45 kV) and pressures. Such arrangement provides a suitable environment to initiate carbonaceous plasma soot from the sputtering of internal walls of the target. As a result, carbon nanoclusters are deposited on the diamond-coated substrate at different pressures.

2.3. Growth Mechanism of Carbon Nanoclusters:

The source being was operated in HC graphite anode with Ne as the supporting gas (25–100 mbar) to initiate the DC glow discharge. The C soot discharge was initially created and sustained in the graphite hollow cathode and its inner surface was sputtered by the energetic Ne ions. The sputtered graphite having different C nanoclusters can actively participate in all of the discharged plasma activities such as inter and intra-species collisions. The pure Ne gas discharge is transformed into carbonaceous discharge plasma with variable densities of different C clusters. The transformation of the Ne discharge to the one with Ne+ and carbon clusters is accompanied by the substitution of the pure graphite cathode surface with the multiple layered (coated) C clusters. This agglomerate of carbon clusters subsequently forms a new cathode surface, and it is analyzed as a function of the glow discharge pressure. The most significant stage in the production of regenerative soot depends on the initiation of the glow discharge of the Ne gas pressure as a function of source parameters e.g., geometry, discharge, voltage, and current. The sputtering of an HC ion source introduces C into the plasma, and carbon nanoclusters are formed in the plasmas as well as on the walls of HC ion source, where all the neutral and excited species are deposited.

The C nanoclusters produce a sooted graphite surface while replacing the underlying graphite as the effective HC. All subsequent emissions, i.e., electrons, ions, and other constituents from the cathode, are in fact from these sooted layers [

16]. This process has similarities with the soot production by arc discharge [

17]; however, the main difference is in the continuous operation of the sooted HC ion source. The sooted HC recycles the carbon soot and causes the emission of carbon atoms, ions, and clusters into the discharge plasma. This process is called regeneration of the carbon soot and in this case, it is easier to manipulate the overall constitutions of the soot by adjusting the discharge parameters. Here, we investigate the regenerative carbon soot plasma environment forming the C nanoclusters. In addition, the surface morphology evolution of room temperature sputtered nanoscale C clusters on metal substrates using different geometries of ion sources by altering the Ne gas pressures was analyzed using AFM data for measuring the size and concentration of the C nanoclusters.

2.4. Atomic Force Microscopy (AFM)

Atomic force microscopy (AFM) is a proven technique to study the surface morphology [

28] of C nanoclusters. The surface of nanoclusters can be imaged using an AFM, and AFM images provide information about the morphological evolution of the nanoclusters that are grown at different conditions. A nanometric sharp probing tip of the AFM with an apex diameter of a few nanometers was used for sample scanning, wherein tip-sample separation was controlled by utilizing atomic forces, thus forming high-resolution images of the surface. The AFM imaging was performed using a Nanosurf easy Scan 2 AFM system operating in high-amplitude mode, and ultra-sharp Si tips were used (MSNL-10 from Veeco Instruments, with anisotropic geometry, radius of curvature approximately 2 nm, tip height of approximately 2.5 μm, front, back, and side angles were 15°, 25°, and 22.5°, respectively). The selection of the dynamic AFM mode ensures nondestructive sample characterization by intermittent contact of the tip with the sample. Image analysis, which included a line view (1-dimensional), top view (2-dimensional), and side view (3-dimensional), was performed using commercial easy scan software. All AFM scans were performed with slow and fast scanning directions on the x-axis and y-axis, respectively. The scanning steps for high and low-resolution scanning were set at 20 nm and 30 nm, respectively. The histograms were plotted for the frequency of nanoclusters of specific sizes, and nanocluster occurrence is statistically quantified according to their radius. The AFM images were analyzed by using the SPMLabAnalyses V7.00 software and Gwyddion (Open source AFM offline image analysis software).

3. Results, Analysis, and Discussion

The nanoscale flat and smooth surfaces provide a good environment for the deposition of small-scale nanomaterials. The substrate used here is a diamond-coated (polished) sharp cutting edge of a commercial Gillette-3 blade, which is a metals alloy (NiCrFe).

Figure 2c,d shows the 2-dimensional and the 3-dimensional AFM topography of the substrate. The image has a scan area of 4.29 µm × 4.39 µm with an average and maximum surface roughness of 5 ± 0.5 nm and 21.60 ± 0.5 nm, respectively. The AFM results show that the surface of the substrate has suitable smoothness for nanocluster growth. The carbonaceous soot plasma and species were deposited on a diamond-coated metal alloy substrate. The experiments were performed at four different Ne-gas pressures of 25, 50, 75, and 100 mbar. In each experiment, the discharge pressure and discharge voltage were varied with constant discharge current constant. After the deposition, the morphological evolution of the nanoclusters was studied using AFM.

Figure 3a,b shows the low-resolution AFM scans of the deposited carbon nanoclusters from a cylindrical graphite source.

Figure 3c,d shows the AFM line scan and carbon cluster distribution. The exposed nanoparticles have formed agglomerates on the substrate, rather than forming distinct and separate entities on the surface of substrate.

Figure 3e,f shows the high-resolution AFM scans of the deposited nanoclusters while using a cylindrical graphite source.

Figure 3g,h shows an AFM line scan and carbon cluster distribution for a high-resolution scan. The high-resolution scan can provide better understanding about the nature and size of the relatively smaller carbon nanoclusters and agglomerates on the same substrate. The smaller nanoclusters that were not evident by a low-resolution AFM scan are well manifested by the high-resolution AFM scan. However, low-resolution AFM scans provide a general trend in the growth of nanoclusters with various process parameters on comparatively large scan areas.

Figure 4a,b shows 2-dimensional and 3-dimensional perspectives of the low-resolution AFM scan of nanoclusters, which were deposited at a pressure, voltage, and current of 25 mbar, 0.25 kV, and 240 mA, respectively, using a hollow cathode graphite ion source.

Figure 4c shows the AFM line profile captured during AFM scanning. The AFM scan of 66.2 µm × 66.4 µm was performed with slow and fast scanning directions on the x-axis and y-axis, respectively, with a scanning step of 30 nm. Statistically, nanocluster occurrence was quantified according to their radius while, noise-filtering techniques (available in the Gwyddion) were applied for accurate quantification of the results.

Figure 4d shows that the nanoclusters with the radiuses of 118 nm, 198 nm, and 277 nm have frequencies of 4800, 2200, and 600, respectively. The

Figure 4d inset shows the sample count of the large-size clusters.

Figure 4e,f shows 2-dimensional and 3-dimensional views of the high-resolution AFM scan of the nanoclusters, which were deposited at the same conditions as described above.

Figure 4g shows the scan line captured during high-resolution AFM scanning. The AFM scan of 32.7 µm × 33.2 µm was performed with slow and fast scanning directions on the x-axis and y-axis, respectively, with a scanning step of 20 nm.

Figure 4h shows that the nanoclusters with the radiuses of 43 nm, 76 nm, and 127 nm have the count of 1320, 418, and 179 samples, respectively. The

Figure 4h inset shows the sample count of the large-size clusters wherein the 434 nm nanoclusters has a sample count of 33.

The AFM scan results show that at 25 mbar pressure, Ne gas particles started to form agglomerates and some nanoparticles were still stuck on the surface separately. The statistical quantification as illustrated in

Figure 4d,h suggest that nanoclusters with the nanometric size are formed at higher concentration while few clusters with large sizes up to a few micrometers are observed. The large cluster may be formed due to the fusion or nucleation of nanoclusters due to prolonged sputtering time, specifically at those areas where sputtering was initiated, firstly.

Figure 5a,b shows two-dimensional and three-dimensional views, whereas

Figure 5e,f show two-dimensional and three-dimensional views of the low and high-resolution respectively. AFM scans of nanoclusters that were deposited at a pressure, voltage, and current of 50 mbar, 0.23 kV, and 240 mA, respectively.

Figure 5c,f shows the scan line captured during the low and high-resolution AFM scanning.

Figure 5d shows that the nanoclusters with the radiuses of 30 nm, 150 nm, and 272 nm have frequencies of 2200, 26, and 30 samples, respectively. The

Figure 5d inset shows significant large-size clusters.

Figure 5h shows that the nanoclusters with the radiuses of 69 nm, 75 nm, and 131 nm have frequencies of 1085, 58 and 85, respectively.

An AFM scan of the exposed substrate at a pressure of 75 mbar, voltage of 0.19 kV, and current of 240 mA for low and high-resolution are shown in

Figure 6a,b,e,f, respectively.

Figure 6c,g shows line scans, whereas

Figure 6d,h shows nanocluster frequencies at different sizes. The high-resolution image resulted in 28.7 nm nanoclusters with a frequency of 8948, and the low-resolution image shows nanoclusters of 90.68 nm diameter that have a frequency of 5461. The results suggest that tiny nanoclusters are formed at greater concentration at a pressure of 75 mbar.

The AFM results of an exposed substrate at a pressure of 100 mbar, voltage of 0.20 kV, and current of 240 mA for low and high-resolution scans are shown in

Figure 7a,b,e,f, respectively.

Figure 7c,g shows line scans, whereas

Figure 7d,h shows the frequencies of nanoclusters of different sizes. The analysis of the high and low-resolution AFM images revealed a frequency of 3957 and 3061 for 19.5 nm and 48.9 nm-sized nanoclusters. The results suggest the formation of more tiny individual nanoclusters with the increasing discharge gas pressure.

To further illustrate the dependency of the size of the nanoclusters on the discharge gas pressure, overall results are plotted in

Figure 8. The data were extracted from high-resolution AFM images as they are more useful to observe tiny nanoclusters. These data reveal that the concentration of tiny individual nanoclusters increases with the increasing chamber pressure.

4. Conclusions

The graphite ion source was sputtered at different Ne-gas pressures using graphite cathodes (ion sources) with different geometries (cylindrical and hollow U-shaped). AFM imaging shows the morphological evolution of C nanoclusters with changing fabrication parameters. AFM image analysis suggests that a U-shaped hollow cathode ion source produces tiny and granular carbon nanoclusters at higher density than the cylindrical cathode. It was revealed that at lower pressure (such as 25 mbar), nanoclusters with a relatively large size were formed, which may be due to lesser collisions at lower pressure. Whereas with the increasing chamber pressure (e.g., 100 mbar), more and more tiny granular nanoclusters were formed. At 25 mbar, the C nanoclusters with the radiuses of 118 nm, 198 nm, and 277 nm with frequencies of 4800, 2200, and 600 were measured. The nanoclusters with the radiuses of 30 nm, 150 nm, and 272 nm have frequencies of 2200, 26, and 30, samples, respectively (at 50 mbar). Further increasing the pressure 75 mbar, the sputtering of hollow cathode graphite was enhanced greatly and 28.7 nm-sized nanoclusters with a frequency of 8948 were obtained from high-resolution AFM data and 90.68nm sized nanoclusters with a frequency of 5461 were measured from low-resolution AFM images. By observing the numerous steps of these regenerative sequences, we have been able to build a picture of the morphological evolution of the carbon nanoclusters, which may help in the growth of nanoclusters with the desired sizes, and such controlled growth can have applications in the next-generation nanodevices.