Thermal Stability of PS-PVD YSZ Coatings with Typical Dense Layered and Columnar Structures

Abstract

1. Introduction

2. Experimental Procedures

2.1. Preparation and Thermal Aging Treatment of PS-PVD Coatings

2.2. Characterization of the Coatings

3. Results and Discussion

3.1. Microstructure

3.2. Phase Transformation

3.3. Texture

4. Conclusions

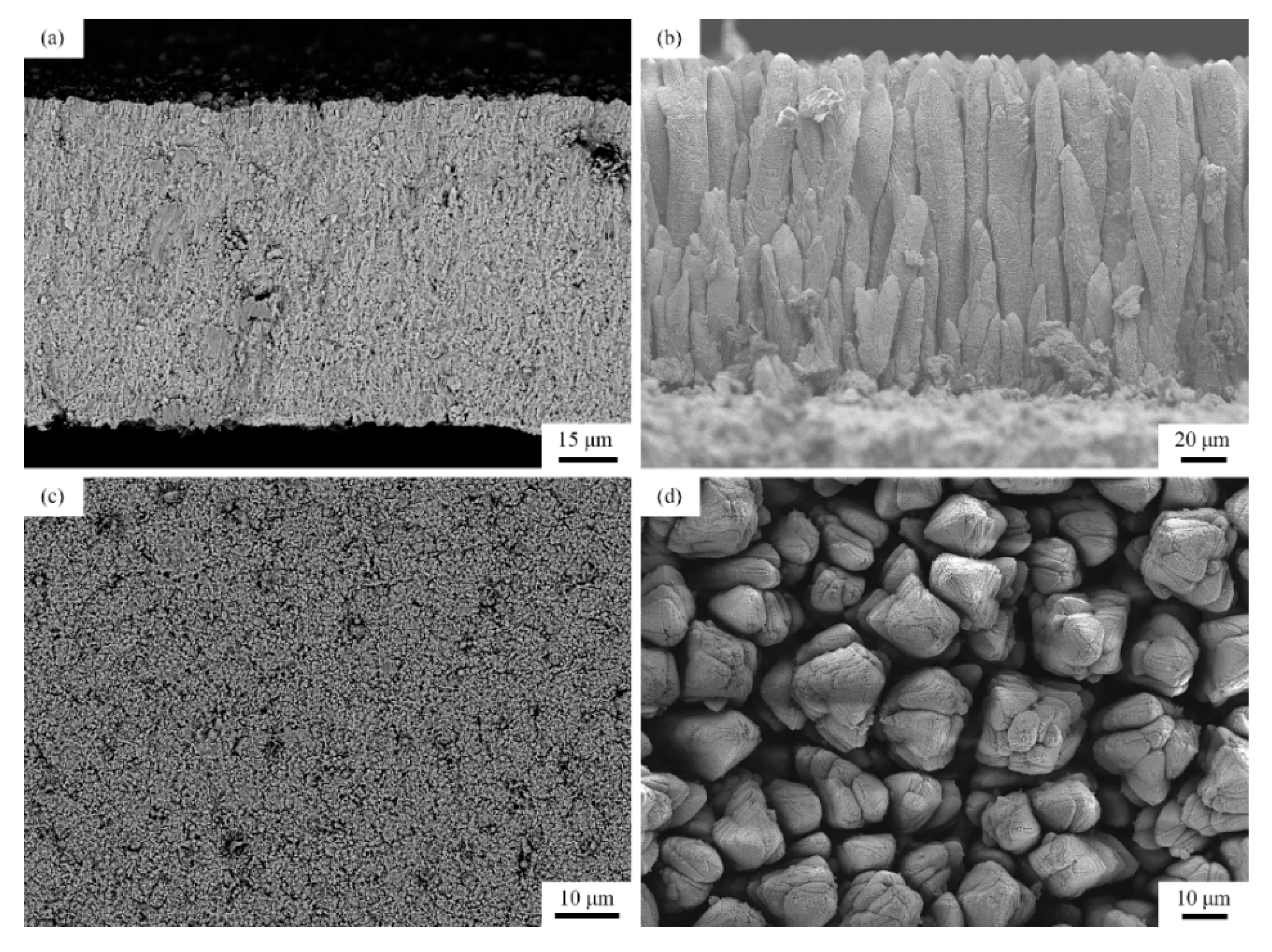

- (a)

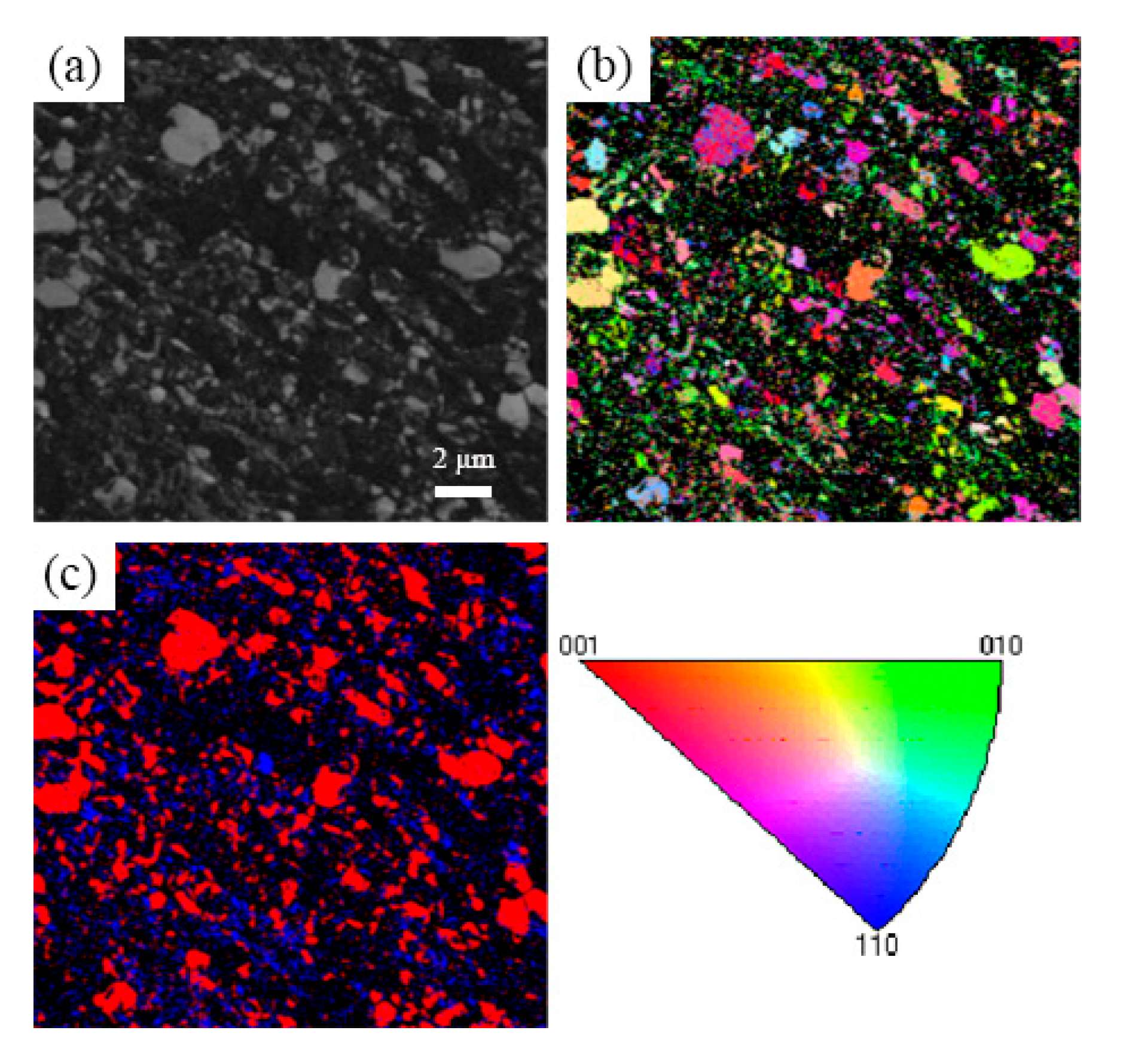

- In the process of pyramid columnar coating deposition, the quasi equiaxed grains with random orientation were deposited firstly. With the increase of coating thickness, columnar structure were formed. Single column exhibited a specific crystal orientation, but different columns had different orientations, and the coating as a whole did not show a preferred orientation. The dense layered structure coating with no preferred orientation was mainly composed of melted droplets and unmelted/semi-melted particles. In addition to droplet deposition, condensation of vapor materials was also found in the coating.

- (b)

- Compared with the dense layered coating, columnar coatings had a higher content of tetragonal phases. After heat treatment at 1550 °C for 100 h, the tetragonal phase content of the coatings decreased, the columns became smooth, the feather like structure of columnar coating disappeared, and some micro-nano grains of feather like structure also disappeared due to high temperature sintering and diffusion. The grain size of the as-sprayed dense coating was about 600 nm, and the grain size grew obviously with the extension of heat treatment time. After high temperature aging treatment, the preferred orientation of the two kinds of coatings disappeared.

Author Contributions

Funding

Conflicts of Interest

References

- Padture, N.P.; Gell, M.; Jordan, E.H. Materials science—Thermal barrier coatings for gas-turbine engine applications. Science 2002, 296, 280–284. [Google Scholar] [CrossRef] [PubMed]

- Lu, Z.; Myoung, S.W.; Jung, Y.G.; Balakrishnan, G.; Lee, J.; Paik, U. Thermal Fatigue Behavior of Air-Plasma Sprayed Thermal Barrier Coating with Bond Coat Species in Cyclic Thermal Exposure. Materials 2013, 6, 3387–3403. [Google Scholar] [CrossRef] [PubMed]

- Sadowski, T.; Golewski, P. Protective Thermal Barrier Coatings. In Loadings in Thermal Barrier Coatings of Jet Engine Turbine Blades; Springer: Singapore, 2016; pp. 5–11. [Google Scholar]

- Tian, Y.S.; Chen, C.Z.; Wang, D.Y.; Ji, Q.M. Recent developments in zirconia thermal barrier coatings. Surf. Rev. Lett. 2005, 12, 369–378. [Google Scholar] [CrossRef]

- Wolfe, D.E.; Singh, J.; Miller, R.A.; Eldridge, J.I.; Zhu, D.M. Tailored microstructure of EB-PVD 8YSZ thermal barrier coatings with low thermal conductivity and high thermal reflectivity for turbine applications. Surf. Coat. Technol. 2005, 190, 132–149. [Google Scholar] [CrossRef]

- Mauer, G.; Jarligo, M.O.; Rezanka, S.; Hospach, A.; Vaßen, R. Novel opportunities for thermal spray by PS-PVD. Surf. Coat. Technol. 2015, 268, 52–57. [Google Scholar] [CrossRef]

- Mauer, G.; Schlegel, N.; Guignard, A.; Jarligo, M.O.; Rezanka, S.; Hospach, A.; Vaßen, R. Plasma Spraying of Ceramics with Particular Difficulties in Processing. J. Therm. Spray Technol. 2014, 24, 30–37. [Google Scholar] [CrossRef]

- Gao, L.; Wei, L.; Guo, H.; Gong, S.; Xu, H. Deposition mechanisms of yttria-stabilized zirconia coatings during plasma spray physical vapor deposition. Ceram. Int. 2016, 42, 5530–5536. [Google Scholar] [CrossRef]

- Yang, J.S.; Zhao, H.Y.; Zhong, X.H.; Shao, F.; Liu, C.G.; Zhuang, Y.; Ni, J.X.; Tao, S.Y. Thermal Cycling Behavior of Quasi-Columnar YSZ Coatings Deposited by PS-PVD. J. Therm. Spray Technol. 2017, 26, 132–139. [Google Scholar] [CrossRef]

- Shao, F.; Zhao, H.; Zhong, X.; Zhuang, Y.; Cheng, Z.; Wang, L.; Tao, S. Characteristics of thick columnar YSZ coatings fabricated by plasma spray-physical vapor deposition. J. Eur. Ceram. Soc. 2018, 38, 1930–1937. [Google Scholar] [CrossRef]

- Goral, M.; Kotowski, S.; Nowotnik, A.; Pytel, M.; Drajewicz, M.; Sieniawski, J. PS-PVD deposition of thermal barrier coatings. Surf. Coat. Technol. 2013, 237, 51–55. [Google Scholar] [CrossRef]

- Mauer, G.; Vaßen, R. Plasma Spray-PVD: Plasma Characteristics and Impact on Coating Properties. In Journal of Physics: Conference Series; IOP Publishing: Bristol, UK, 2012; Volume 406, p. 012005. [Google Scholar]

- Smith, M.F.; Hall, A.C.; Fleetwood, J.D.; Meyer, P. Very Low Pressure Plasma Spray-A Review of an Emerging Technology in the Thermal Spray Community. Coatings 2011, 1, 117–132. [Google Scholar] [CrossRef]

- Yin, J.; Zhang, X.; Feng, J.; Zhang, X.; Song, J.; Liu, M.; Zeng, D.; Mao, J.; Deng, C.; Deng, C.; et al. Effect of powder composition upon plasma spray-physical vapor deposition of 8YSZ columnar coating. Ceram. Int. 2020, 46, 15867–15875. [Google Scholar] [CrossRef]

- Anwaar, A.; Wei, L.; Guo, H.; Zhang, B. Plasma–Powder Feedstock Interaction during Plasma Spray–Physical Vapor Deposition. J. Therm. Spray Technol. 2017, 26, 292–301. [Google Scholar] [CrossRef]

- Liu, M.-J.; Zhang, M.; Zhang, Q.; Yang, G.-J.; Li, C.-X.; Li, C.-J. Gaseous material capacity of open plasma jet in plasma spray-physical vapor deposition process. Appl. Surf. Sci. 2018, 428, 877–884. [Google Scholar] [CrossRef]

- Liu, M.-J.; Zhang, M.; Zhang, Q.; Yang, G.-J.; Li, C.-X.; Li, C.-J. Evaporation of Droplets in Plasma Spray–Physical Vapor Deposition Based on Energy Compensation between Self-Cooling and Plasma Heat Transfer. J. Therm. Spray Technol. 2017, 26, 1641–1650. [Google Scholar] [CrossRef]

- Zhang, Y.; Deng, C.; Mao, J.; Luo, Z.; Deng, Z.; Zhang, X.; Deng, C. Impact of cathode loss on plasma characteristics, microstructures and properties of 7YSZ coatings in PS-PVD. Ceram. Int. 2020, 46, 13307–13316. [Google Scholar] [CrossRef]

- Liu, M.-J.; Zhang, K.-J.; Zhang, Q.; Zhang, M.; Yang, G.-J.; Li, C.-X.; Li, C.-J. Thermodynamic conditions for cluster formation in supersaturated boundary layer during plasma spray-physical vapor deposition. Appl. Surf. Sci. 2019, 471, 950–959. [Google Scholar] [CrossRef]

- Mauer, G. Numerical Study on Particle–Gas Interaction Close to the Substrates in Thermal Spray Processes with High-Kinetic and Low-Pressure Conditions. J. Therm. Spray Technol. 2018, 28, 27–39. [Google Scholar] [CrossRef]

- Rezanka, S.; Mauer, G.; Vaßen, R. Improved Thermal Cycling Durability of Thermal Barrier Coatings Manufactured by PS-PVD. J. Therm. Spray Technol. 2013, 23, 182–189. [Google Scholar] [CrossRef]

- Rezanka, S.; Mack, D.E.; Mauer, G.; Sebold, D.; Guillon, O.; Vaßen, R. Investigation of the resistance of open-column-structured PS-PVD TBCs to erosive and high-temperature corrosive attack. Surf. Coat. Technol. 2017, 324, 222–235. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, M.; Li, H.; Deng, C.; Deng, C.; Deng, Z.; Niu, S.; Zhou, K. Structural evolution of Al-modified PS-PVD 7YSZ TBCs in thermal cycling. Ceram. Int. 2019, 45, 7560–7567. [Google Scholar] [CrossRef]

- He, W.; Mauer, G.; Schwedt, A.; Guillon, O.; Vaßen, R. Advanced crystallographic study of the columnar growth of YZS coatings produced by PS-PVD. J. Eur. Ceram. Soc. 2018, 38, 2449–2453. [Google Scholar] [CrossRef]

- Zhang, X.F.; Zhou, K.S.; Deng, C.M.; Liu, M.; Deng, Z.Q.; Deng, C.G.; Song, J.B. Gas-deposition mechanisms of 7YSZ coating based on plasma spray-physical vapor deposition. J. Eur. Ceram. Soc. 2016, 36, 697–703. [Google Scholar] [CrossRef]

- Gao, L.; Guo, H.; Wei, L.; Li, C.; Xu, H. Microstructure, thermal conductivity and thermal cycling behavior of thermal barrier coatings prepared by plasma spray physical vapor deposition. Surf. Coat. Technol. 2015, 276, 424–430. [Google Scholar] [CrossRef]

- Rossmann, L.; Northam, M.; Sarley, B.; Chernova, L.; Viswanathan, V.; Harder, B.; Raghavan, S. Investigation of TGO stress in thermally cycled plasma-spray physical vapor deposition and electron-beam physical vapor deposition thermal barrier coatings via photoluminescence spectroscopy. Surf. Coat. Technol. 2019, 378. [Google Scholar] [CrossRef]

- Thibblin, A.; Jonsson, S.; Olofsson, U. Influence of microstructure on thermal cycling lifetime and thermal insulation properties of yttria-stabilized zirconia thermal barrier coatings for diesel engine applications. Surf. Coat. Technol. 2018, 350, 1–11. [Google Scholar] [CrossRef]

- Mauer, G.; Vaßen, R. Coatings with Columnar Microstructures for Thermal Barrier Applications. Adv. Eng. Mater. 2019, 22. [Google Scholar] [CrossRef]

- Zhang, B.; Wei, L.; Guo, H.; Xu, H. Microstructures and deposition mechanisms of quasi-columnar structured yttria-stabilized zirconia coatings by plasma spray physical vapor deposition. Ceram. Int. 2017, 43, 12920–12929. [Google Scholar] [CrossRef]

- Deng, Z.Q.; Liu, M.; Mao, J.; Deng, C.M.; Zhang, X.F. Stage growth of columnar 7YSZ coating prepared by plasma spray-physical vapor deposition. Vacuum 2017, 145, 39–46. [Google Scholar] [CrossRef]

- Guo, S.Q.; Kagawa, Y. Effect of thermal exposure on hardness and Young’s modulus of EB-PVD yttria-partially-stabilized zirconia thermal barrier coatings. Ceram. Int. 2006, 32, 263–270. [Google Scholar] [CrossRef]

- Choi, S.R.; Zhu, D.M.; Miller, R.A. Effect of sintering on mechanical properties of plasma-sprayed zirconia-based thermal barrier coatings. J. Am. Ceram. Soc. 2005, 88, 2859–2867. [Google Scholar] [CrossRef]

- Zhu, D.M.; Miller, R.A. Sintering and creep behavior of plasma-sprayed zirconia- and hafnia-based thermal barrier coatings. Surf. Coat. Technol. 1998, 108, 114–120. [Google Scholar] [CrossRef]

- Mauer, G.; Hospach, A.; Zotov, N.; Vassen, R. Process Conditions and Microstructures of Ceramic Coatings by Gas Phase Deposition Based on Plasma Spraying. J. Therm. Spray Technol. 2013, 22, 83–89. [Google Scholar] [CrossRef]

- Shao, F.; Zhao, H.; Liu, C.; Zhong, X.; Zhuang, Y.; Ni, J.; Tao, S. Dense yttria-stabilized zirconia coatings fabricated by plasma spray-physical vapor deposition. Ceram. Int. 2017, 43, 2305–2313. [Google Scholar] [CrossRef]

- Wada, K.; Yamaguchi, N.; Matsubara, H. Crystallographic texture evolution in ZrO2-Y2O3 layers produced by electron beam physical vapor deposition. Surf. Coat. Technol. 2004, 184, 55–62. [Google Scholar] [CrossRef]

- Thornton, J.A. Influence of Apparatus Geometry and Deposition Conditions on Structure and Topography of Thick Sputtered Coatings. J. Vac. Sci. Technol. 1974, 11, 666–670. [Google Scholar] [CrossRef]

- Thornton, J.A. Influence of Substrate Temperature and Deposition Rate on Structure of Thick Sputtered Cu Coatings. J. Vac. Sci. Technol. 1975, 12, 830–835. [Google Scholar] [CrossRef]

- Singh, J.; Wolfe, D.E. Review Nano and macro-structured component fabrication by electron beam-physical vapor deposition (EB-PVD). J. Mater. Sci. Technol. 2005, 40, 1–26. [Google Scholar] [CrossRef]

| Items | Test A | Test B |

|---|---|---|

| Plasma gas flow rate (slpm) | Ar: 35, He: 60 | Ar: 35, He: 60 |

| Power (kW) | 120 | 130 |

| Current (A) | 2600 | 2700 |

| Feed rate (g/min) | 5 | 5 |

| Spray distance (mm) | 500 | 700 |

| Oxygen flow rate (splm) | 2 | 2 |

| Items | Tetragonal Phase |

|---|---|

| The as-sprayed YSZ-1 | 82.3% |

| The as-sprayed YSZ-2 | 97.9% |

| YSZ-1 after heat-treatment at 1550 °C for 100 h | 74.8% |

| YSZ-2 after heat-treatment at 1550 °C for 100 h | 78.5% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, Z.; Yang, J.; Shao, F.; Zhong, X.; Zhao, H.; Zhuang, Y.; Sheng, J.; Ni, J.; Tao, S. Thermal Stability of PS-PVD YSZ Coatings with Typical Dense Layered and Columnar Structures. Crystals 2020, 10, 826. https://doi.org/10.3390/cryst10090826

Cheng Z, Yang J, Shao F, Zhong X, Zhao H, Zhuang Y, Sheng J, Ni J, Tao S. Thermal Stability of PS-PVD YSZ Coatings with Typical Dense Layered and Columnar Structures. Crystals. 2020; 10(9):826. https://doi.org/10.3390/cryst10090826

Chicago/Turabian StyleCheng, Zefei, Jiasheng Yang, Fang Shao, Xinghua Zhong, Huayu Zhao, Yin Zhuang, Jing Sheng, Jinxing Ni, and Shunyan Tao. 2020. "Thermal Stability of PS-PVD YSZ Coatings with Typical Dense Layered and Columnar Structures" Crystals 10, no. 9: 826. https://doi.org/10.3390/cryst10090826

APA StyleCheng, Z., Yang, J., Shao, F., Zhong, X., Zhao, H., Zhuang, Y., Sheng, J., Ni, J., & Tao, S. (2020). Thermal Stability of PS-PVD YSZ Coatings with Typical Dense Layered and Columnar Structures. Crystals, 10(9), 826. https://doi.org/10.3390/cryst10090826