Deep Learning-Based Hardness Prediction of Novel Refractory High-Entropy Alloys with Experimental Validation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Computational Methods

- (a)

- The purpose of this k-fold training was to find the most generalizable set of hyperparameter configurations among the randomly chosen 500 configurations.

- (b)

- all the training data;

- (c)

- the best set of hyperparameters obtained from Step 2;

- (d)

- no cross validation. (because we had already found the hyperparameters).

2.2. Experimental Methods

3. Results and Discussions

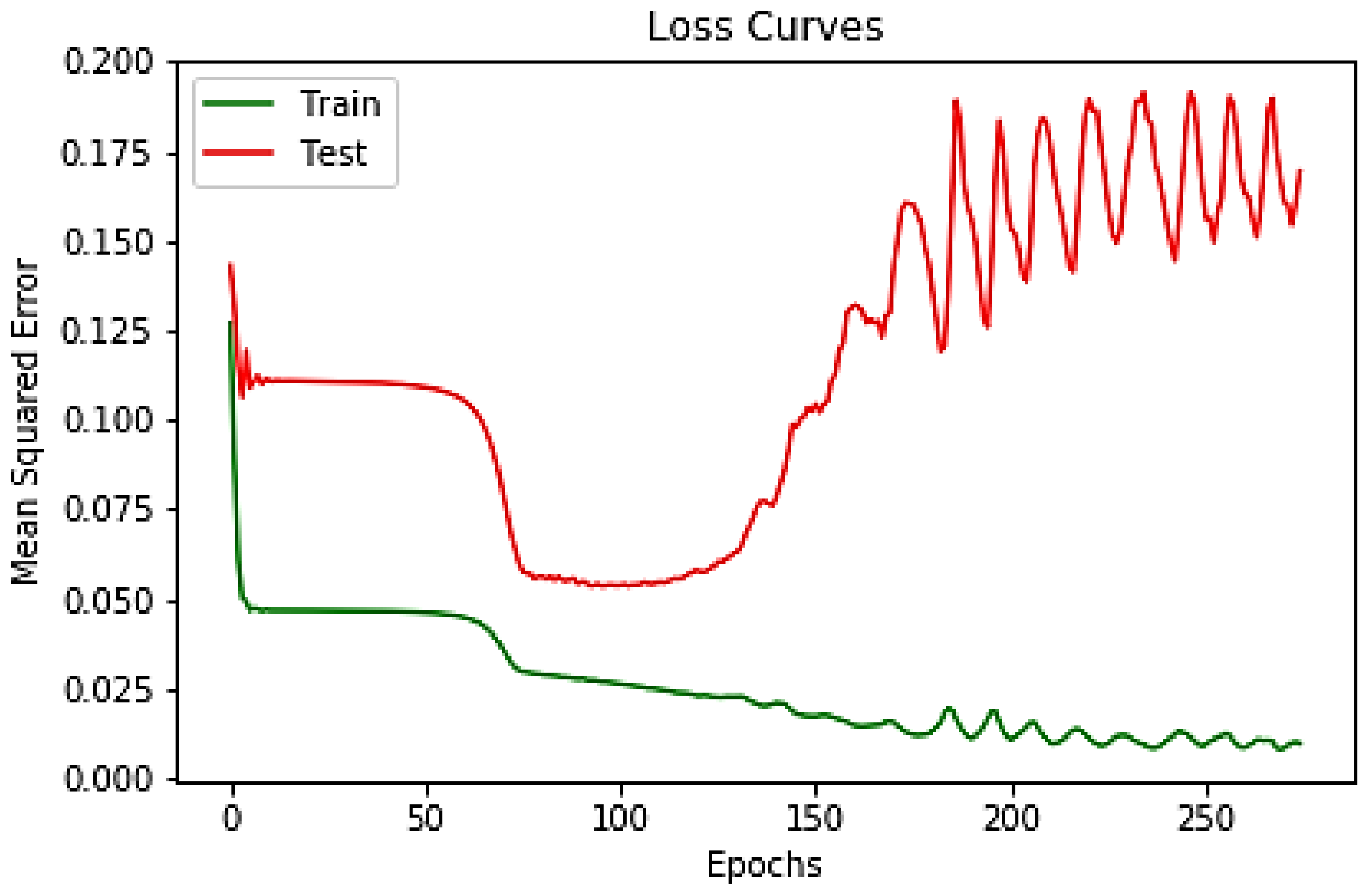

3.1. Machine Learning Results

3.2. Experimental Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Soni, V.K.; Sanyal, S.; Sinha, S.K. Phase evolution and mechanical properties of novel FeCoNiCuMox high entropy alloys. Vacuum 2020, 174, 109173. [Google Scholar] [CrossRef]

- Bhandari, U.; Zhang, C.; Yang, S. Mechanical and Thermal Properties of Low-Density Al20+XCr20-XMo20-YTi20V20+Y Alloys. Crystals 2020, 10, 278. [Google Scholar] [CrossRef] [Green Version]

- Tan, X.R.; Zhao, R.F.; Ren, B.; Zhi, Q.; Zhang, G.P.; Liu, Z.X. Effects of Hot Pressing Temperature on Microstructure, Hardness and Corrosion Resistance of Al2NbTi3V2Zr High-Entropy Alloy. Mater. Sci. Technol. 2016, 32, 1582–1591. [Google Scholar] [CrossRef]

- Senkov, O.N.; Scott, J.M.; Senkova, S.V.; Miracle, D.B.; Woodward, C.F. Microstructure and Room Temperature Properties of a High-Entropy TaNbHfZrTi Alloy. J. Alloy. Compd. 2011, 509, 6043–6048. [Google Scholar] [CrossRef]

- Wu, Y.D.; Cai, Y.H.; Chen, X.H.; Wang, T.; Si, J.J.; Wang, L.; Wang, Y.D.; Hui, X.D. Phase Composition and Solid Solution Strengthening Effect in TiZrNbMoV High-Entropy Alloys. Mater. Des. 2015, 83, 651–660. [Google Scholar] [CrossRef]

- Han, Z.D.; Chen, N.; Zhao, S.F.; Fan, L.W.; Yang, G.N.; Shao, Y.; Yao, K.F. Effect of Ti Additions on Mechanical Properties of NbMoTaW and VNbMoTaW Refractory High Entropy Alloys. Intermetallics 2017, 84, 153–157. [Google Scholar] [CrossRef]

- Qiao, D.X.; Jiang, H.; Jiao, W.N.; Lu, Y.P.; Cao, Z.Q.; Li, T.J. A Novel Series of Refractory High-Entropy Alloys Ti2ZrHf0.5VNbx with High Specific Yield Strength and Good Ductility. Acta Metall. Sin. Engl. Lett. 2019, 32, 925–931. [Google Scholar] [CrossRef] [Green Version]

- Brechtl, J.; Chen, S.Y.; Xie, X.; Ren, Y.; Qiao, J.W.; Liaw, P.K.; Zinkle, S.J. Towards a Greater Understanding of Serrated Flows in an Al-Containing High-Entropy-Based Alloy. Int. J. Plast. 2019, 115, 71–92. [Google Scholar] [CrossRef]

- Bhandari, U.; Zhang, C.; Guo, S.; Yang, S. First-Principles Study on the Mechanical and Thermodynamic Properties of MoNbTaTiW. Int. J. Miner. Metall. Mater. 2020, 27, 1398–1404. [Google Scholar] [CrossRef]

- Wang, Z.; Lu, W.; Raabe, D.; Li, Z. On the Mechanism of Extraordinary Strain Hardening in an Interstitial High-Entropy Alloy under Cryogenic Conditions. J. Alloy. Compd. 2019, 781, 734–743. [Google Scholar] [CrossRef]

- Malinovskis, P.; Fritze, S.; Riekehr, L.; von Fieandt, L.; Cedervall, J.; Rehnlund, D.; Nyholm, L.; Lewin, E.; Jansson, U. Synthesis and Characterization of Multicomponent (CrNbTaTiW) C Films for Increased Hardness and Corrosion Resistance. Mater. Des. 2018, 149, 51–62. [Google Scholar] [CrossRef]

- Zhang, H.; Hedman, D.; Feng, P.; Han, G.; Akhtar, F. A High-Entropy B4(HfMo2TaTi)C and SiC Ceramic Composite. Dalt. Trans. 2019, 48, 5161–5167. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Castle, E.; Csanádi, T.; Grasso, S.; Dusza, J.; Reece, M. Processing and Properties of High-Entropy Ultra-High Temperature Carbides. Sci. Rep. 2018, 8, 1–12. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Guo, L.; Ou, X.; Ni, S.; Liu, Y.; Song, M. Effects of Carbon on the Microstructures and Mechanical Properties of FeCoCrNiMn High Entropy Alloys. Mater. Sci. Eng. A 2019, 746, 356–362. [Google Scholar] [CrossRef]

- Huang, T.; Jiang, L.; Zhang, C.; Jiang, H.; Lu, Y.; Li, T. Effect of Carbon Addition on the Microstructure and Mechanical Properties of CoCrFeNi High Entropy Alloy. Sci. China Technol. Sci. 2018, 61, 117–123. [Google Scholar] [CrossRef]

- Seol, J.B.; Bae, J.W.; Li, Z.; Han, J.C.; Kim, J.G.; Raabe, D.; Kim, H.S. Boron doped ultrastrong and ductile high-entropy alloys. Acta Mater. 2018, 151, 366–376. [Google Scholar] [CrossRef]

- Lei, Z.; Liu, X.; Wu, Y.; Wang, H.; Jiang, S.; Wang, S.; Hui, X.; Wu, Y.; Gault, B.; Kontis, P.; et al. Enhanced strength and ductility in a high-entropy alloy via ordered oxygen complexes. Nature 2018, 563, 546–550. [Google Scholar] [CrossRef]

- Bagdasaryan, A.A.; Pshyk, A.V.; Coy, L.E.; Konarski, P.; Misnik, M.; Ivashchenko, V.I.; Kempiński, M.; Mediukh, N.R.; Pogrebnjak, A.D.; Beresnev, V.M.; et al. A new type of (TiZrNbTaHf)N/MoN nanocomposite coating: Microstructure and properties depending on energy of incident ions. Compos. Part B Eng. 2018, 146, 132–144. [Google Scholar] [CrossRef]

- Guo, N.N.; Wang, L.; Luo, L.S.; Li, X.Z.; Chen, R.R.; Su, Y.Q.; Guo, J.J.; Fu, H.Z. Microstructure and Mechanical Properties of In-Situ MC-Carbide Particulates-Reinforced Refractory High-Entropy Mo0. 5NbHf0. 5ZrTi Matrix Alloy Composite. Intermetallics 2016, 69, 74–77. [Google Scholar] [CrossRef]

- Agarwal, A.; Rao, A.K.P. Artificial Intelligence Predicts Body-Centered-Cubic and Face-Centered-Cubic Phases in High-Entropy Alloys. JOM 2019, 71, 3424–3432. [Google Scholar] [CrossRef]

- Zhang, Y.; Wen, C.; Wang, C.; Antonov, S.; Xue, D.; Bai, Y.; Su, Y. Phase Prediction in High Entropy Alloys with a Rational Selection of Materials Descriptors and Machine Learning Models. Acta Mater. 2020, 185, 528–539. [Google Scholar] [CrossRef]

- Zhou, Z.; Zhou, Y.; He, Q.; Ding, Z.; Li, F.; Yang, Y. Machine Learning Guided Appraisal and Exploration of Phase Design for High Entropy Alloys. NPJ Comput. Mater. 2019, 5, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Islam, N.; Huang, W.; Zhuang, H.L. Machine Learning for Phase Selection in Multi-Principal Element Alloys. Comput. Mater. Sci. 2018, 150, 230–235. [Google Scholar] [CrossRef]

- Wen, C.; Zhang, Y.; Wang, C.; Xue, D.; Bai, Y.; Antonov, S.; Dai, L.; Lookman, T.; Su, Y. Machine Learning Assisted Design of High Entropy Alloys with Desired Property. Acta Mater. 2019, 170, 109–117. [Google Scholar] [CrossRef] [Green Version]

- Kim, G.; Diao, H.; Lee, C.; Samaei, A.T.; Phan, T.; de Jong, M.; An, K.; Ma, D.; Liaw, P.K.; Chen, W. First-Principles and Machine Learning Predictions of Elasticity in Severely Lattice-Distorted High-Entropy Alloys with Experimental Validation. Acta Mater. 2019, 181, 124–138. [Google Scholar] [CrossRef]

- Gorsse, S.; Nguyen, M.H.; Senkov, O.N.; Miracle, D.B. Database on the Mechanical Properties of High Entropy Alloys and Complex Concentrated Alloys. Data Br. 2018, 21, 2664–2678. [Google Scholar] [CrossRef]

- Zheng, S.; Wang, S. First-Principles Design of Refractory High Entropy Alloy VMoNbTaW. Entropy 2018, 20, 965. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Zhou, Y.J.; Lin, J.P.; Chen, G.L.; Liaw, P.K. Solid-solution Phase Formation Rules for Multi-component Alloys. Adv. Eng. Mater. 2008, 10, 534–538. [Google Scholar] [CrossRef]

- Guo, S.; Ng, C.; Lu, J.; Liu, C.T. Effect of Valence Electron Concentration on Stability of Fcc or Bcc Phase in High Entropy Alloys. J. Appl. Phys. 2011, 109, 103505. [Google Scholar] [CrossRef] [Green Version]

- A Practical Guide to Dimensionality Reduction Techniques. Available online: https://www.youtube.com/watch?v=ioXKxulmwVQ&ab_channel=PyData (accessed on 12 December 2020).

- Kelleher, J.D.; Mac Namee, B.; D’arcy, A. Fundamentals of Machine Learning for Predictive Data Analytics: Algorithms, Worked Examples, and Case Studies; MIT Press: Cambridge, MA, USA, 2015. [Google Scholar]

- McKinney, W. Python for Data Analysis: Data Wrangling with Pandas, NumPy, and IPython; O’Reilly Media Inc.: Sevastopol, CA, USA, 2012. [Google Scholar]

- Maas, A.L.; Hannun, A.Y.; Ng, A.Y. Rectifier Nonlinearities Improve Neural Network Acoustic Models. Proc. ICML 2013, 30, 3. [Google Scholar]

- Juan, C.C.; Tseng, K.K.; Hsu, W.L.; Tsai, M.H.; Tsai, C.W.; Lin, C.M.; Chen, S.K.; Lin, S.J.; Yeh, J.W. Solution strengthening of ductile refractory HfMoxNbTaTiZr high-entropy alloys. Mater. Lett. 2016, 175, 284–287. [Google Scholar] [CrossRef]

- Zhang, B.; Gao, M.C.; Zhang, Y.; Guo, S.M. Senary refractory high-entropy alloy CrxMoNbTaVW. Calphad 2015, 51, 193–201. [Google Scholar] [CrossRef] [Green Version]

- Senkov, O.N.; Senkova, S.V.; Miracle, D.B.; Woodward, C. Mechanical properties of low-density, refractory multi-principal element alloys of the Cr–Nb–Ti–V–Zr system. Mater. Sci. Eng. A 2013, 565, 51–62. [Google Scholar] [CrossRef]

- Senkov, O.N.; Wilks, G.B.; Scott, J.M.; Miracle, D.B. Mechanical properties of Nb25Mo25Ta25W25 and V20Nb20Mo20Ta20W20 refractory high entropy alloys. Intermetallics 2011, 19, 698–706. [Google Scholar] [CrossRef]

- Stepanov, N.D.; Shaysultanov, D.G.; Salishchev, G.A.; Tikhonovsky, M.A.; Oleynik, E.E.; Tortika, A.S.; Senkov, O.N. Effect of V content on microstructure and mechanical properties of the CoCrFeMnNiVx high entropy alloys. J. Alloy. Compd. 2015, 628, 170–185. [Google Scholar] [CrossRef]

- Chen, S.Y.; Yang, X.; Dahmen, K.A.; Liaw, P.K.; Zhang, Y. Microstructures and crackling noise of AlxNbTiMoV high entropy alloys. Entropy 2014, 16, 870–884. [Google Scholar] [CrossRef] [Green Version]

- Zhuang, Y.X.; Liu, W.J.; Chen, Z.Y.; Xue, H.D.; He, J.C. Effect of elemental interaction on microstructure and mechanical properties of FeCoNiCuAl alloys. Mater. Sci. Eng. A 2012, 556, 395–399. [Google Scholar] [CrossRef]

- He, J.Y.; Liu, W.H.; Wang, H.; Wu, Y.; Liu, X.J.; Nieh, T.G.; Lu, Z.P. Effects of Al addition on structural evolution and tensile properties of the FeCoNiCrMn high-entropy alloy system. Acta Mater. 2014, 62, 105–113. [Google Scholar] [CrossRef]

- Cullity, B.D. Elements of X-ray Diffraction; Addison-Wesley Publishing: Boston, MA, USA, 1956. [Google Scholar]

- Trindade, V.B.; Krupp, U.; Wagenhuber, P.E.G.; Christ, H.J. Oxidation Mechanisms of Cr-Containing Steels and Ni-Base Alloys at High-Temperatures--. Part I: The Different Role of Alloy Grain Boundaries. Mater. Corros. 2005, 56, 785–790. [Google Scholar] [CrossRef]

- Tsai, S.C.; Huntz, A.M.; Dolin, C. Growth Mechanism of Cr2O3 Scales: Oxygen and Chromium Diffusion, Oxidation Kinetics and Effect of Yttrium. Mater. Sci. Eng. A 1996, 212, 6–13. [Google Scholar] [CrossRef]

- Kuhn, B.; Talik, M.; Niewolak, L.; Zurek, J.; Hattendorf, H.; Ennis, P.J.; Quadakkers, W.J.; Beck, T.; Singheiser, L. Development of High Chromium Ferritic Steels Strengthened by Intermetallic Phases. Mater. Sci. Eng. A 2014, 594, 372–380. [Google Scholar] [CrossRef]

- Alcock, C.B.; Itkin, V.P.; Horrigan, M.K. Vapour pressure equations for the metallic elements: 298–2500K. Can. Metall. Q. 1984, 23, 309–313. [Google Scholar] [CrossRef]

- Uzun, O.; Karaaslan, T.; Keskin, M. Hardness Evaluation of Al-12Si-0.5 Sb Melt-Spun Ribbons. J. Alloy. Compd. 2003, 358, 104–111. [Google Scholar] [CrossRef]

- Uzun, O.; Karaaslan, T.; Gogebakan, M.; Keskin, M. Hardness and Microstructural Characteristics of Rapidly Solidified Al-8-16 Wt.% Si Alloys. J. Alloy. Compd. 2004, 376, 149–157. [Google Scholar] [CrossRef]

- Xu, B.; Tian, Y. Ultrahardness: Measurement and Enhancement. J. Phys. Chem. C 2015, 119, 5633–5638. [Google Scholar] [CrossRef]

- Chang, Y.J.; Jui, C.Y.; Lee, W.J.; and Yeh, A.C. Prediction of the composition and hardness of high-entropy alloys by machine learning. JOM 2019, 71, 3433–3442. [Google Scholar] [CrossRef]

- Bhandari, U.; Rafi, M.R.; Zhang, C.; Yang, S. Yield strength prediction of high-entropy alloys using machine learning. Mater. Today Commun. 2020, 101871. [Google Scholar] [CrossRef]

- Zhao, Q.; Yang, H.; Liu, J.; Zhou, H.; Wang, H.; Yang, W. Machine learning-assisted discovery of strong and conductive Cu alloys: Data mining from discarded experiments and physical features. Mater. Des. 2020, 197, 109248. [Google Scholar] [CrossRef]

- Tian, Y.; Xu, B.; Zhao, Z. Microscopic theory of hardness and design of novel superhard crystals. Int. J. Refract. Met. Hard Mater. 2012, 33, 93–106. [Google Scholar] [CrossRef]

| ΔSmix | B | G | VEC | Tm | HV | |

|---|---|---|---|---|---|---|

| ΔSmix | 1 | −0.24 | −0.25 | −0.16 | −0.12 | 0.044 |

| B | −0.24 | 1 | 0.62 | 0.9 | 0.88 | 0.53 |

| G | −0.25 | 0.62 | 1 | 0.48 | 0.37 | 0.32 |

| VEC | −0.16 | 0.9 | 0.48 | 1 | 0.96 | 0.57 |

| Tm | −0.12 | 0.88 | 0.37 | 0.96 | 1 | 0.56 |

| HV | 0.044 | 0.53 | 0.32 | 0.57 | 0.56 | 1 |

| Test Samples | Name of Alloys | Experimental Hardness (HV), and Reference | ML Prediction (HV) | Error % |

|---|---|---|---|---|

| C0.1Cr3Mo11.9Nb20Re15Ta30W20 (Nominal composition) | 601 (our work) | 695 | 15.6 | |

| Cr1.6Mo8.9Nb20Re15Ta30W20 (experimental composition) | 601 | 686 | 14.1 | |

| 1 | Hf21Nb19.1Ta20.1Ti19.3V23Zr20.5 | 335 [34] | 500 | 49.2 |

| 2 | Cr20Mo20.2Nb20.4Ta20.6V13W20 | 704 [35] | 697 | 0.99 |

| 3 | Nb25Ti25V25Zr25 | 335 [36] | 481 | 43.5 |

| 4 | Mo25.6Nb22.7Ta24.4W27.3 | 454 [37] | 576 | 26.8 |

| 5 | Cr20Co19.3Fe19.6M17Ni19.52V4.6 | 151 [38] | 144 | 4.6 |

| 6 | Al14.2Mo22.2Nb22.2Ti21.5V20.95 | 517 [39] | 598 | 15.6 |

| 7 | Mo30Nb10V20Ta20W20 | 770 [27] | 686 | 10.9 |

| 8 | Mo21.7Nb20.6Ta15.6V21W21.1 | 535 [37] | 687 | 28.4 |

| 9 | Co12.9Fe10.8Ni10.8Cu40.1Al16.2Si9.2 | 682 [40] | 762 | 11.7 |

| 10 | Cr16.67Co25.81Ni25.81Fe24.58C5.92 | 207 [19] | 263 | 27 |

| 11 | Mo40Nb10V20Ta20W20 | 498 [27] | 665 | 33.5 |

| 12 | Al14.4Co16.9Cr 18.3Fe 16.8Mn 16.9Ni16.7 | 535 [41] | 628 | 17.3 |

| Element | Nb | Mo | Cr | Ta | W | Re |

|---|---|---|---|---|---|---|

| Nominal (at.%) | 20.00 | 11.90 | 3.00 | 30.00 | 20.00 | 15.00 |

| Tested (at.%) | 19.31 | 8.90 | 1.06 | 31.47 | 22.66 | 16.59 |

| Standard Deviation (at.%) | 0.71 | 0.19 | 0.15 | 0.17 | 0.51 | 0.29 |

| Load (gf) | Average Hardness (HV) | Standard Deviation (HV) |

|---|---|---|

| 2000 | 587.10 | 21.56 |

| 500 | 595.44 | 21.35 |

| 100 | 622.60 | 13.05 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bhandari, U.; Zhang, C.; Zeng, C.; Guo, S.; Adhikari, A.; Yang, S. Deep Learning-Based Hardness Prediction of Novel Refractory High-Entropy Alloys with Experimental Validation. Crystals 2021, 11, 46. https://doi.org/10.3390/cryst11010046

Bhandari U, Zhang C, Zeng C, Guo S, Adhikari A, Yang S. Deep Learning-Based Hardness Prediction of Novel Refractory High-Entropy Alloys with Experimental Validation. Crystals. 2021; 11(1):46. https://doi.org/10.3390/cryst11010046

Chicago/Turabian StyleBhandari, Uttam, Congyan Zhang, Congyuan Zeng, Shengmin Guo, Aashish Adhikari, and Shizhong Yang. 2021. "Deep Learning-Based Hardness Prediction of Novel Refractory High-Entropy Alloys with Experimental Validation" Crystals 11, no. 1: 46. https://doi.org/10.3390/cryst11010046

APA StyleBhandari, U., Zhang, C., Zeng, C., Guo, S., Adhikari, A., & Yang, S. (2021). Deep Learning-Based Hardness Prediction of Novel Refractory High-Entropy Alloys with Experimental Validation. Crystals, 11(1), 46. https://doi.org/10.3390/cryst11010046