Analysis of Microstructure and Mechanical Properties in As-Built/As-Cast and Heat-Treated Conditions for IN718 Alloy Obtained by Selective Laser Melting and Investment Casting Processes

Abstract

:1. Introduction

2. Materials and Methods

3. Results

3.1. Powder Characterization

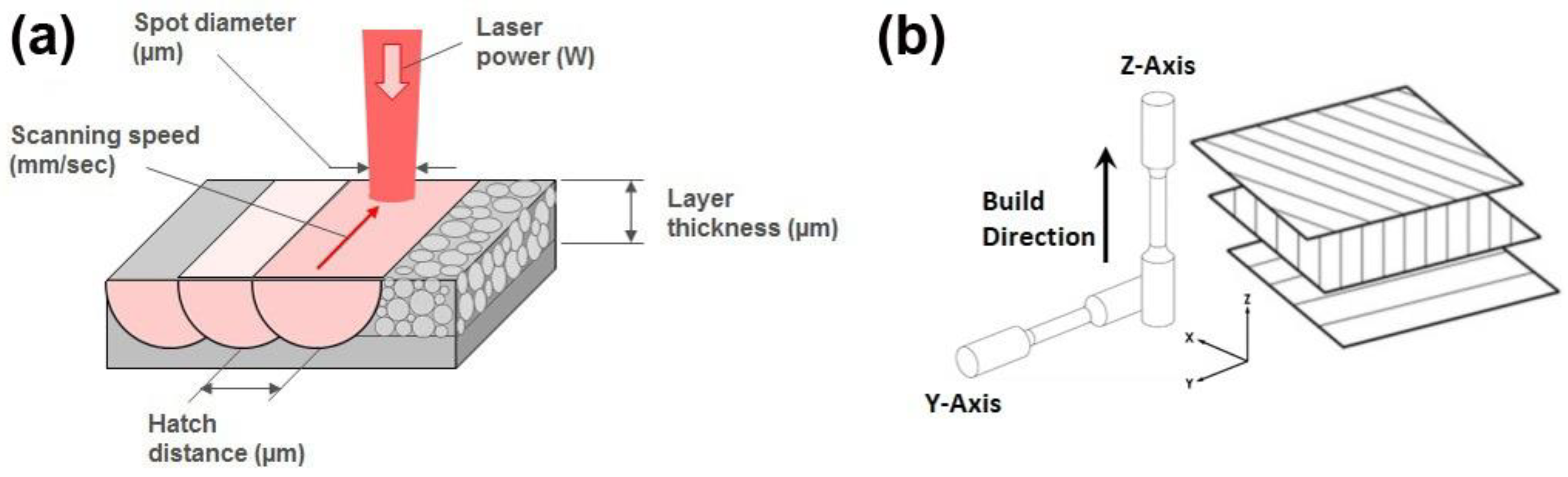

3.2. Selective Laser Melting Process

3.3. Investment Casting Process

- For primary coatings, a slurry made of colloidal silica binder and zircon flour was used. Then, the mould was stuccoed with zircon sand.

- For secondary coatings, a slurry made of colloidal silica binder and silica flour was used. Then, the mould was stuccoed with silica sand.

4. Discussion

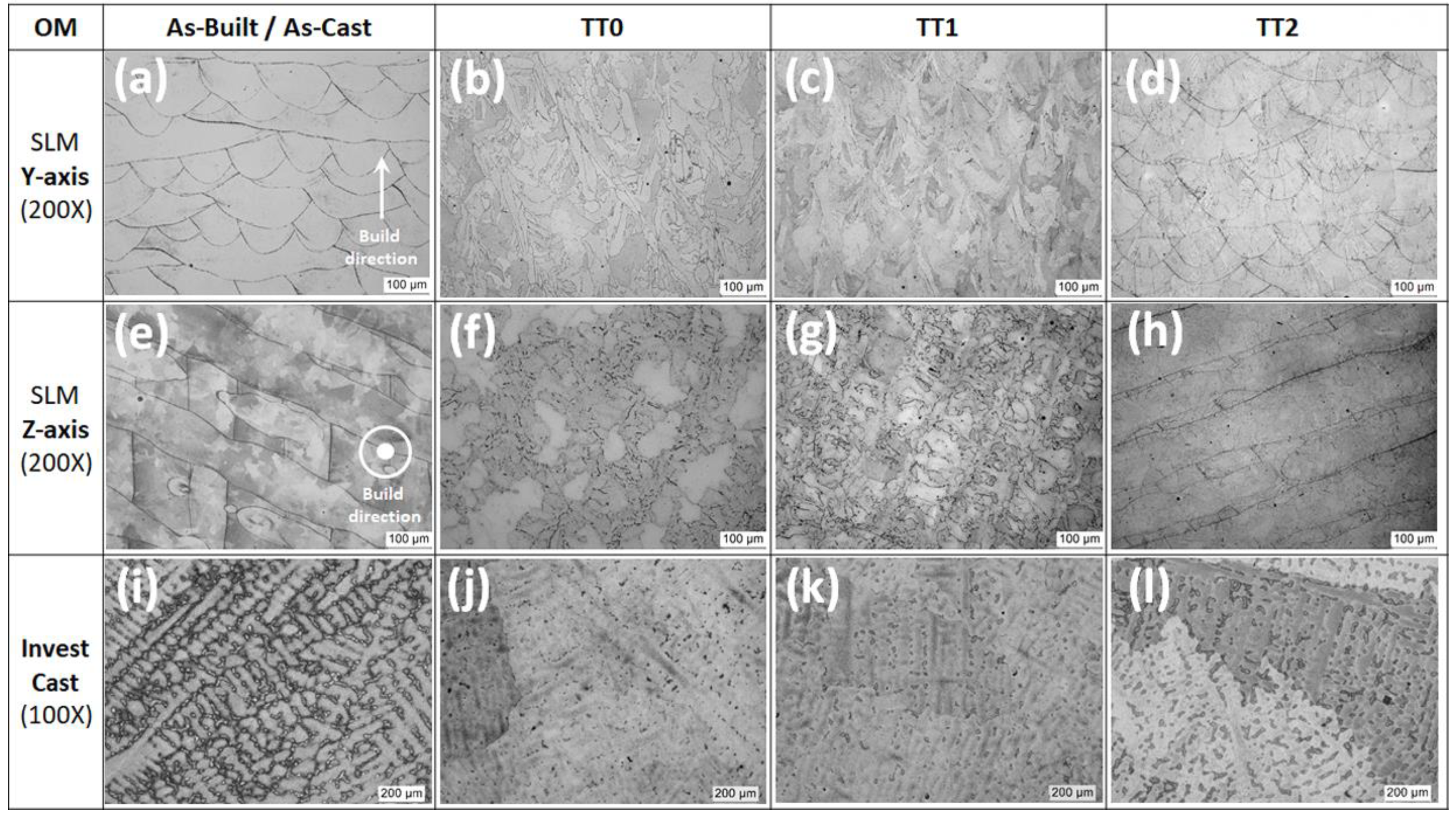

4.1. Comparison of Microstructures

4.2. Phase Identification and Evolution—XRD Analysis

4.3. Comparison of Mechanical Properties

5. Conclusions

- Due to the differences in cooling rates between investment casting and SLM process, the microstructures generated are completely different. While the one obtained by investment casting is composed mainly by a dendritic structure, the one obtained by SLM is characterized by columnar and cellular structures with a very thin cells microstructure.

- The employment of the homogenization stage in the thermal treatment allows to achieve the solubilization of undesired phases, which is not the case with the solution stage.

- The double aging treatment at stepped temperatures carried out in the present work assures the precipitation of γ′ and γ″ to improve the mechanical properties obtained in as-built/as-cast conditions for the IN718 alloy.

- The dispersion of γ′/γ″ particles (solid solution) in the γ-Ni matrix and the presence of a small quantity of delta phases in the interdendritic regions, which allows to improve the mechanical properties of the material after its SLM processing.

- Due to the fine and relative homogeneous microstructure obtained from SLM processing of IN718 alloy, it is not necessary to apply homogenization and solution stages as in the standard heat treatment used for this type of alloy obtained by casting or wrought. The pre-heating and process parameters selected, in combination with direct-stepped aging heat treatment (at 720 °C/620 °C), provides the material obtained by SLM with its best mechanical properties.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sun, S.-H.; Koizumi, Y.; Saito, T.; Yamanaka, K.; Li, Y.-P.; Cui, Y.; Chiba, A. Electron beam additive manufacturing of Inconel 718 alloy rods: Impact of build direction on microstructure and high-temperature tensile properties. Addit. Manuf. 2018, 23, 457–470. [Google Scholar] [CrossRef]

- Hosseini, E.; Popovich, V.A. A review of mechanical properties of additively manufactured Inconel 718. Addit. Manuf. 2019, 30, 100877. [Google Scholar] [CrossRef]

- Ghiban, B.; Elefterie, C.F.; Guragata, C.; Bran, D. Requirements of Inconel 718 alloy for aeronautical applications. AIP Conf. Proc. 2018, 1932, 30016. [Google Scholar] [CrossRef]

- Zhang, B.; Wang, P.; Chew, Y.; Wen, Y.; Zhang, M.; Wang, P.; Bi, G.; Wei, J. Mechanical properties and microstructure evolution of selective laser melting Inconel 718 along building direction and sectional dimension. Mater. Sci. Eng. A 2020, 794, 139941. [Google Scholar] [CrossRef]

- Godec, M.; Malej, S.; Feizpour, D.; Donik, Č.; Balažic, M.; Klobčar, D.; Pambaguian, L.; Conradi, M.; Kocijan, A. Hybrid additive manufacturing of Inconel 718 for future space applications. Mater. Charact. 2021, 172, 110842. [Google Scholar] [CrossRef]

- AM-Motion. A Strategic Approach to increasing Europe’s Value Proposition forAdditive Manufacturing Technologies and Capabilities. 2018. Available online: https://ec.europa.eu/research/participants/documents/downloadPublic?documentIds=080166e5bf8b8d98&appId=PPGMS (accessed on 7 June 2021).

- McCue, T. Significant 3D Printing Forecast Surges to $35.6 Billion. Available online: https://www.forbes.com/sites/tjmccue/2019/03/27/wohlers-report-2019-forecasts-35-6-billion-in-3d-printing-industry-growth-by-2024/ (accessed on 25 September 2019).

- Wang, P.; Song, J.; Nai, M.L.S.; Wei, J. Experimental analysis of additively manufactured component and design guidelines for lightweight structures: A case study using electron beam melting. Addit. Manuf. 2020, 33, 101088. [Google Scholar] [CrossRef]

- Wang, P.; Li, X.; Luo, S.; Nai, M.L.S.; Ding, J.; Wei, J. Additively manufactured heterogeneously porous metallic bone with biostructural functions and bone-like mechanical properties. J. Mater. Sci. Technol. 2021, 62, 173–179. [Google Scholar] [CrossRef]

- Zhang, D.; Feng, Z.; Wang, C.; Wang, W.; Liu, Z.; Niu, W. Comparison of microstructures and mechanical properties of Inconel 718 alloy processed by selective laser melting and casting. Mater. Sci. Eng. A 2018, 724, 357–367. [Google Scholar] [CrossRef]

- Schröder, J.; Mishurova, T.; Fritsch, T.; Serrano-Munoz, I.; Evans, A.; Sprengel, M.; Klaus, M.; Genzel, C.; Schneider, J.; Bruno, G. On the influence of heat treatment on microstructure and mechanical behavior of laser powder bed fused inconel 718. Mater. Sci. Eng. A 2020, 805, 140555. [Google Scholar] [CrossRef]

- Tucho, W.M.; Cuvillier, P.; Sjolyst-Kverneland, A.; Hansen, V. Microstructure and hardness studies of Inconel 718 manufactured by selective laser melting before and after solution heat treatment. Mater. Sci. Eng. A 2017, 689, 220–232. [Google Scholar] [CrossRef]

- Pollock, T.M.; Tin, S. Nickel-based superalloys for advanced turbine engines: Chemistry, microstructure and properties. J. Propuls. Power 2006, 22, 361–374. [Google Scholar] [CrossRef]

- AMS2774F Standard. Heat Treatment Nickel Alloy and Cobalt Alloy Parts. 2020. Available online: https://www.sae.org/standards/content/ams2774f/ (accessed on 2 October 2021).

- AMS5383F Standard. Nickel Alloy, Corrosion and Heat-Resistant, Investment Castings 52.5Ni–19Cr–3.0Mo–5.1Cb(Nb)–0.90Ti–0.60Al–18Fe Vacuum Melted Homogenization and Solution Heat Treated. 2018. Available online: https://www.sae.org/standards/content/ams5383f/ (accessed on 2 October 2021).

- Huang, W.; Yang, J.; Yang, H.; Jing, G.; Wang, Z.; Zeng, X. Heat treatment of Inconel 718 produced by selective laser melting: Microstructure and mechanical properties. Mater. Sci. Eng. A 2019, 750, 98–107. [Google Scholar] [CrossRef]

- ASTM B213-17 Standard. Test Methods for Flow Rate of Metal Powders Using the Hall Flowmeter Funnel. 2017. Available online: https://www.astm.org/Standards/B213.htm (accessed on 2 October 2021).

- Moussaoui, K.; Rubio, W.; Mousseigne, M.; Sultan, T.; Rezai, F. Effects of Selective Laser Melting additive manufacturing parameters of Inconel 718 on porosity, microstructure and mechanical properties. Mater. Sci. Eng. A 2018, 735, 182–190. [Google Scholar] [CrossRef] [Green Version]

- Lesyk, D.A.; Martinez, S.; Mordyuk, B.N.; Dzhemelinskyi, V.V.; Lamikiz, A.; Prokopenko, G.I. Post-processing of the Inconel 718 alloy parts fabricated by selective laser melting: Effects of mechanical surface treatments on surface topography, porosity, hardness and residual stress. Surf. Coat. Technol. 2020, 381, 125136. [Google Scholar] [CrossRef]

- Xia, M.; Gu, D.; Yu, G.; Dai, D.; Chen, H.; Shi, Q. Porosity evolution and its thermodynamic mechanism of randomly packed powder-bed during selective laser melting of Inconel 718 alloy. Int. J. Mach. Tools Manuf. 2017, 116, 96–106. [Google Scholar] [CrossRef]

- Mancisidor, A.M.; Gil, E.; Iturrioz, A.; Garciandia, F.; San Sebastian, M. The Effect of Maraging Steel 300 Powder Characteristics in Cracking Susceptibility of Parts Manufactured by SLM. In Proceedings of the Euro PM 2017, International Powder Metallurgy Congress and Exhibition; (EPMA), European Powder Metallurgy Association, Milan, Italy, 1–5 October 2017. [Google Scholar]

- Zhao, Y.; Li, K.; Gargani, M.; Xiong, W. A comparative analysis of Inconel 718 made by additive manufacturing and suction casting: Microstructure evolution in homogenization. Addit. Manuf. 2020, 36, 101404. [Google Scholar] [CrossRef]

- Yi, J.H.; Kang, J.W.; Wang, T.J.; Wang, X.; Hu, Y.Y.; Feng, T.; Feng, Y.L.; Wu, P.Y. Effect of laser energy density on the microstructure, mechanical properties, and deformation of Inconel 718 samples fabricated by selective laser melting. J. Alloys Compd. 2019, 786, 481–488. [Google Scholar] [CrossRef]

- Choi, J.-P.; Shin, G.-H.; Yang, S.; Yang, D.-Y.; Lee, J.-S.; Brochu, M.; Yu, J.-H. Densification and microstructural investigation of Inconel 718 parts fabricated by selective laser melting. Powder Technol. 2017, 310, 60–66. [Google Scholar] [CrossRef]

- Hakeem, A.S.; Patel, F.; Minhas, N.; Malkawi, A.; Aleid, Z.; Ehsan, M.A.; Sharrofna, H.; Al Ghanim, A. Comparative evaluation of thermal and mechanical properties of nickel alloy 718 prepared using selective laser melting, spark plasma sintering, and casting methods. J. Mater. Res. Technol. 2021, 12, 870–881. [Google Scholar] [CrossRef]

- Wang, Z.; Guan, K.; Gao, M.; Li, X.; Chen, X.; Zeng, X. The microstructure and mechanical properties of deposited-IN718 by selective laser melting. J. Alloys Compd. 2012, 513, 518–523. [Google Scholar] [CrossRef]

- Deng, D.; Peng, R.L.; Brodin, H.; Moverare, J. Microstructure and mechanical properties of Inconel 718 produced by selective laser melting: Sample orientation dependence and effects of post heat treatments. Mater. Sci. Eng. A 2018, 713, 294–306. [Google Scholar] [CrossRef]

- Popovich, A.A.; Sufiiarov, V.S.; Polozov, I.A.; Borisov, E. Microstructure and mechanical properties of inconel 718 produced by SLM and subsequent heat treatment. In Proceedings of the Material Forming ESAFORM 2015, Graz, Austria, 15–17 April 2015; Trans Tech Publications Ltd.: New York, NY, USA, 2015; Volume 651, pp. 665–670. [Google Scholar]

- Tucho, W.M.; Hansen, V. Characterization of SLM-fabricated Inconel 718 after solid solution and precipitation hardening heat treatments. J. Mater. Sci. 2019, 54, 823–839. [Google Scholar] [CrossRef]

- Zhang, D.; Niu, W.; Cao, X.; Liu, Z. Effect of standard heat treatment on the microstructure and mechanical properties of selective laser melting manufactured Inconel 718 superalloy. Mater. Sci. Eng. A 2015, 644, 32–40. [Google Scholar] [CrossRef]

- Anderson, M.; Thielin, A.-L.; Bridier, F.; Bocher, P.; Savoie, J. δ Phase precipitation in Inconel 718 and associated mechanical properties. Mater. Sci. Eng. A 2017, 679, 48–55. [Google Scholar] [CrossRef]

- Li, X.; Shi, J.J.; Wang, C.H.; Cao, G.H.; Russell, A.M.; Zhou, Z.J.; Li, C.P.; Chen, G.F. Effect of heat treatment on microstructure evolution of Inconel 718 alloy fabricated by selective laser melting. J. Alloys Compd. 2018, 764, 639–649. [Google Scholar] [CrossRef]

- Álvarez, P.; Cobos, A.; Vázquez, L.; Ruiz, N.; Rodríguez, P.P.; Magaña, A.; Niklas, A.; Santos, F. Weldability Evaluation of Alloy 718 Investment Castings with Different Si Contents and Thermal Stories and Hot Cracking Mechanism in Their Laser Beam Welds. Metals 2021, 11, 402. [Google Scholar] [CrossRef]

- Helmink, R.C. The Golden Age of Cast Structural Superalloys. In Proceedings of the 8th International Symposium on Superalloy 718 and Derivatives, Pittsburgh, PA, USA, 28 September–1 October 2014; John Wiley & Sons Ltd.: London, UK, 2014; pp. 169–180, ISBN 9781119016854. [Google Scholar]

- Michaelsen, C. On the structure and homogeneity of solid solutions: The limits of conventional X-ray diffraction. Philos. Mag. A 1995, 72, 813–828. [Google Scholar] [CrossRef]

- Huang, L.; Cao, Y.; Li, G.; Wang, Y. Microstructure characteristics and mechanical behaviour of a selective laser melted Inconel 718 alloy. J. Mater. Res. Technol. 2020, 9, 2440–2454. [Google Scholar] [CrossRef]

- Li, X.; Shi, J.J.; Cao, G.H.; Russell, A.M.; Zhou, Z.J.; Li, C.P.; Chen, G.F. Improved plasticity of Inconel 718 superalloy fabricated by selective laser melting through a novel heat treatment process. Mater. Des. 2019, 180, 107915. [Google Scholar] [CrossRef]

- Trosch, T.; Strößner, J.; Völkl, R.; Glatzel, U. Microstructure and mechanical properties of selective laser melted Inconel 718 compared to forging and casting. Mater. Lett. 2016, 164, 428–431. [Google Scholar] [CrossRef]

- Gao, Y.; Zhang, D.; Cao, M.; Chen, R.; Feng, Z.; Poprawe, R.; Schleifenbaum, J.H.; Ziegler, S. Effect of δ phase on high temperature mechanical performances of Inconel 718 fabricated with SLM process. Mater. Sci. Eng. A 2019, 767, 138327. [Google Scholar] [CrossRef]

- Chen, M.-S.; Zou, Z.-H.; Lin, Y.C.; Li, H.-B.; Wang, G.-Q.; Ma, Y.-Y. Microstructural evolution and grain refinement mechanisms of a Ni-based superalloy during a two-stage annealing treatment. Mater. Charact. 2019, 151, 445–456. [Google Scholar] [CrossRef]

- Teng, Q.; Li, S.; Wei, Q.; Shi, Y. Investigation on the influence of heat treatment on Inconel 718 fabricated by selective laser melting: Microstructure and high temperature tensile property. J. Manuf. Process. 2021, 61, 35–45. [Google Scholar] [CrossRef]

| Elements and Chemical Composition Range (wt.%) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Cr | Fe | Nb + Ta | Al | Ti | Si | Mo | Co | C | O | Ni |

| 19.30 | 18.24 | 4.93 | 0.49 | 0.96 | 0.03 | 3.00 | 0.04 | 0.03 | 0.02 | 52.96 |

| Sample | Elements and Chemical Composition Measured (wt.%) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Cr | Fe | Nb + Ta | Al | Ti | Si | Mo | Co | C * | O | Ni | |

| Ingot | 17.78 | 19.91 | 5.30 | 0.60 | 0.92 | 0.070 | 3.00 | 0.30 | 0.050 | 0.03 | 52.03 |

| Invest Cast | 18.10 | 19.98 | 4.80 | 0.57 | 0.94 | 0.120 | 2.83 | 0.13 | 0.054 | 0.03 | 52.50 |

| Powder | 19.20 | 17.90 | 4.96 | 0.47 | 0.96 | 0.062 | 2.99 | 0.12 | 0.036 | 0.02 | 53.30 |

| SLM Y-axis | 19.20 | 17.80 | 5.00 | 0.46 | 0.96 | 0.058 | 3.01 | 0.13 | 0.035 | 0.02 | 53.40 |

| SLM Z-axis | 19.40 | 18.00 | 4.94 | 0.47 | 0.95 | 0.042 | 2.99 | 0.10 | 0.032 | 0.02 | 53.20 |

| Stage | Cooling Condition | Standard (TT0) | Modified HT 1 (TT1) | Direct Aging (TT2) | |||

|---|---|---|---|---|---|---|---|

| Temp (°C) | Time (h) | Temp (°C) | Time (h) | Temp (°C) | Time (h) | ||

| Homogenization | 1093 to 482 °C <45 min, then air cooling | 1093 ± 10 | 2 | --- | --- | --- | --- |

| Solution | Air cooling | 954 ± 10 | 1 | 980 ± 10 | 1.5 | --- | --- |

| Double aging | Cool down to 620 °C at 55 ± 8 °C/h | 720 ± 10 | 8 | 720 ± 10 | 8 | 720 ± 10 | 8 |

| Air cooled in static air | 620 ± 10 | 8 | 620 ± 10 | 8 | 620 ± 10 | 8 | |

| Process | SLM Y Axis | SLM Z Axis | SLM Y Axis | SLM Z Axis | SLM Y Axis | SLM Z Axis | SLM Y Axis | SLM Z Axis |

|---|---|---|---|---|---|---|---|---|

| Condition | As-Built | TT0 | TT1 | TT2 | ||||

| σy (MPa) | 756.1 ± 2.7 | 638.9 ± 2.0 | 1243.1 ± 10.6 | 1235.6 ± 19.7 | 1300.1 ± 4.9 | 1236.7 ± 10.7 | 1420.1 ± 42.3 | 1267.6 ± 8.2 |

| UTS (MPa) | 1054.5 ± 1.9 | 1001.5 ± 4.3 | 1445.9 ± 2.7 | 1414.9 ± 6.5 | 1508.2 ± 4.2 | 1447.6 ± 9.5 | 1567.4 ± 40.5 | 1464.9 ± 4.2 |

| E (GPa) | 201.0 ± 2.7 | 185.9 ± 2.0 | 211.1 ± 4.1 | 208.2 ± 6.5 | 207.3 ± 4.9 | 204.5 ± 6.6 | 212.3 ± 1.7 | 207.5 ± 5.8 |

| ε (%) | 30.1 ± 0.2 | 31.1 ± 0.6 | 18.9 ± 0.4 | 17.6 ± 2.2 | 17.9 ± 0.5 | 18.0 ± 0.1 | 15.7 ± 0.3 | 19.1 ± 1.2 |

| Reference | Mechanical Properties | SLM As Built | + Homogenization + Solution + Double Aging | + Solution + Double Aging | + Double Aging |

|---|---|---|---|---|---|

| This work | σy (MPa) | 756.1 ± 2.7 | 1243.1 ± 10.6 | 1300.1 ± 4.9 | 1420.1 ± 42.3 |

| UTS (MPa) | 1054.5 ± 1.9 | 1445.9 ± 2.7 | 1508.2 ± 4.2 | 1567.4 ± 40.5 | |

| Ɛ(%) | 30.1 ± 0.2 | 18.9 ± 0.4 | 17.9 ± 0.5 | 15.7 ± 0.3 | |

| Li et al. [37] | σy (MPa) | 590 ± 5 | - | - | - |

| UTS (MPa) | 935 ± 16 | - | - | - | |

| Ɛ(%) | 30 ± 3 | - | - | - | |

| Zhang et al. [30] | σy (MPa) | 849 | 1046 | 1084 | - |

| UTS (MPa) | 1126 | 1371 | 1371 | - | |

| Ɛ(%) | 22.8 | 12.3 | 10.1 | - | |

| Trosch et al. [38] | σy (MPa) | - | - | 1185 | - |

| UTS (MPa) | - | - | 1430 | - | |

| Ɛ(%) | - | - | 18.6 | - | |

| Hosseini et al. [2] | σy (MPa) | 700 | 1200 | - | - |

| UTS (MPa) | 1000 | 1400 | - | - | |

| Ɛ(%) | 22 | 20 | - | - |

| Investment Casting | ||||

|---|---|---|---|---|

| Property | As-Cast | TT0 | TT1 | TT2 |

| σy (MPa) | 434.20 ± 4.05 | 854.61 ± 42.47 | 757.76 ± 18.27 | 769.64 ± 29.95 |

| UTS (MPa) | 764.83 ± 39.19 | 1036.06 ± 25.62 | 995.79 ± 4.56 | 1032.78 ± 45.99 |

| E (GPa) | 61.78 ± 2.81 | 167.94 ± 6.00 | 170.89 ± 2.83 | 172.96 ± 4.84 |

| ε (%) | 28.47 ± 6.87 | 15.69 ± 3.66 | 10.02 ± 2.50 | 15.42 ± 5.37 |

| Process/Condition | As-Built/As-Cast | TT0 | TT1 | TT2 |

|---|---|---|---|---|

| SLM Y axis | 338.8 ± 15.9 | 504.8 ± 16.8 | 518.4 ± 13.5 | 535.1 ± 17.0 |

| SLM Z axis | 329.0 ± 5.8 | 503.4 ± 16.9 | 508.4 ± 10.3 | 532.2 ± 17.8 |

| Investment casting | 264.0 ± 47.7 | 423.8 ± 40.1 | 408.6 ± 24.2 | 420.4 ± 28.9 |

| Condition | This work | Zhang et al. [30] | Huang et al. [16] | Tucho et al. [29] | Li et al. [37] |

|---|---|---|---|---|---|

| As-Built | 34 | 32.5 | - | - | 30 |

| + Homogeneization + Solution + Double + Aging | 49 | 42.5 | - | - | - |

| + Solution + Double Aging | 50 | 43 | 50 | 45 | 44 |

| + Double Aging | 51 | - | - | - | 38 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pereira, J.C.; Aranzabe, J.; Taboada, M.C.; Ruiz, N.; Rodriguez, P.P. Analysis of Microstructure and Mechanical Properties in As-Built/As-Cast and Heat-Treated Conditions for IN718 Alloy Obtained by Selective Laser Melting and Investment Casting Processes. Crystals 2021, 11, 1196. https://doi.org/10.3390/cryst11101196

Pereira JC, Aranzabe J, Taboada MC, Ruiz N, Rodriguez PP. Analysis of Microstructure and Mechanical Properties in As-Built/As-Cast and Heat-Treated Conditions for IN718 Alloy Obtained by Selective Laser Melting and Investment Casting Processes. Crystals. 2021; 11(10):1196. https://doi.org/10.3390/cryst11101196

Chicago/Turabian StylePereira, Juan Carlos, Jon Aranzabe, Mari Carmen Taboada, Noelia Ruiz, and Pedro Pablo Rodriguez. 2021. "Analysis of Microstructure and Mechanical Properties in As-Built/As-Cast and Heat-Treated Conditions for IN718 Alloy Obtained by Selective Laser Melting and Investment Casting Processes" Crystals 11, no. 10: 1196. https://doi.org/10.3390/cryst11101196

APA StylePereira, J. C., Aranzabe, J., Taboada, M. C., Ruiz, N., & Rodriguez, P. P. (2021). Analysis of Microstructure and Mechanical Properties in As-Built/As-Cast and Heat-Treated Conditions for IN718 Alloy Obtained by Selective Laser Melting and Investment Casting Processes. Crystals, 11(10), 1196. https://doi.org/10.3390/cryst11101196