Microstructural Evolution and Tensile Testing of a Bi–Sn (57/43) Alloy Processed by Tube High-Pressure Shearing

Abstract

:1. Introduction

2. Experimental Material and Procedures

3. Experimental Results

4. Discussion

5. Summary and Conclusions

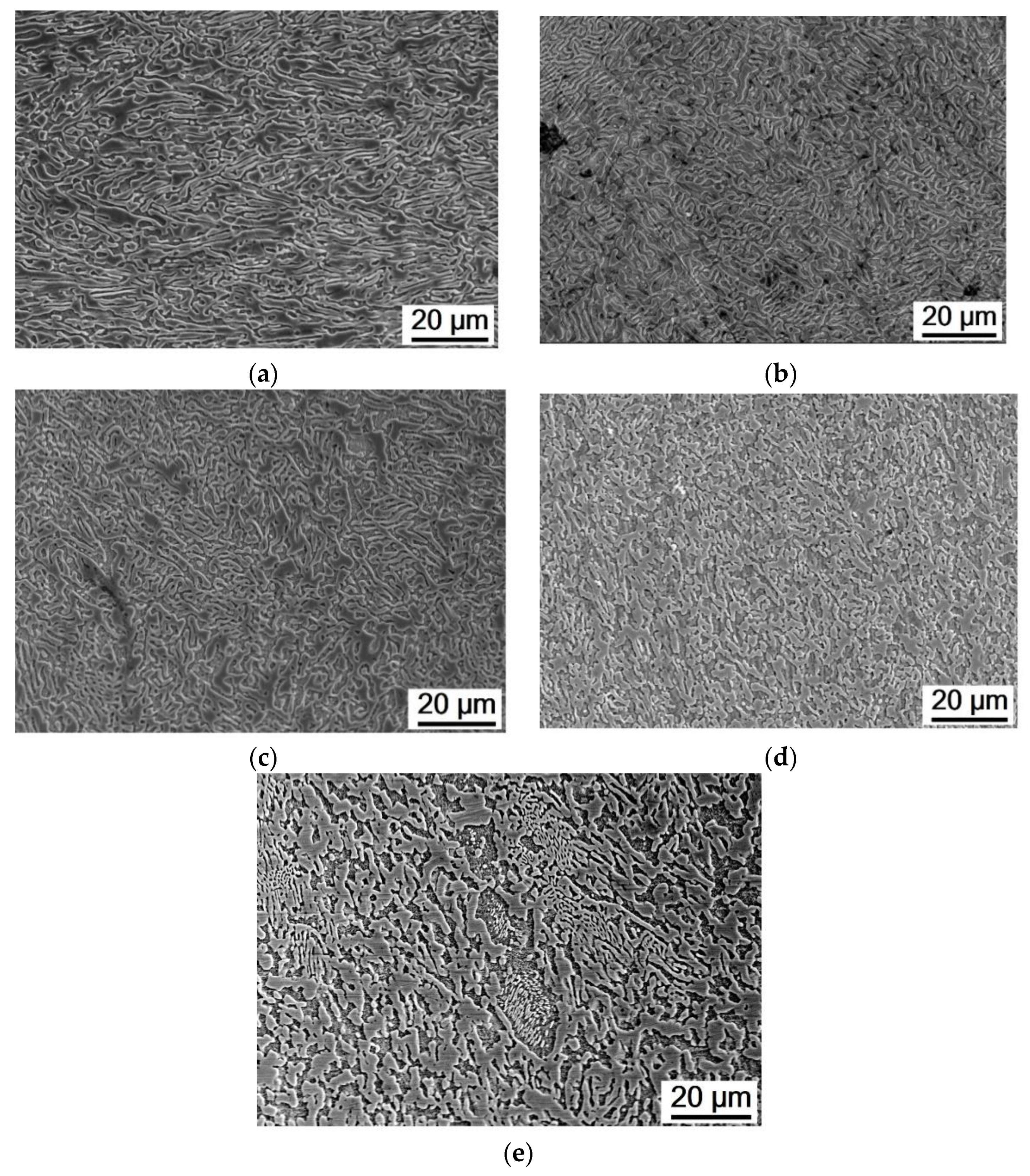

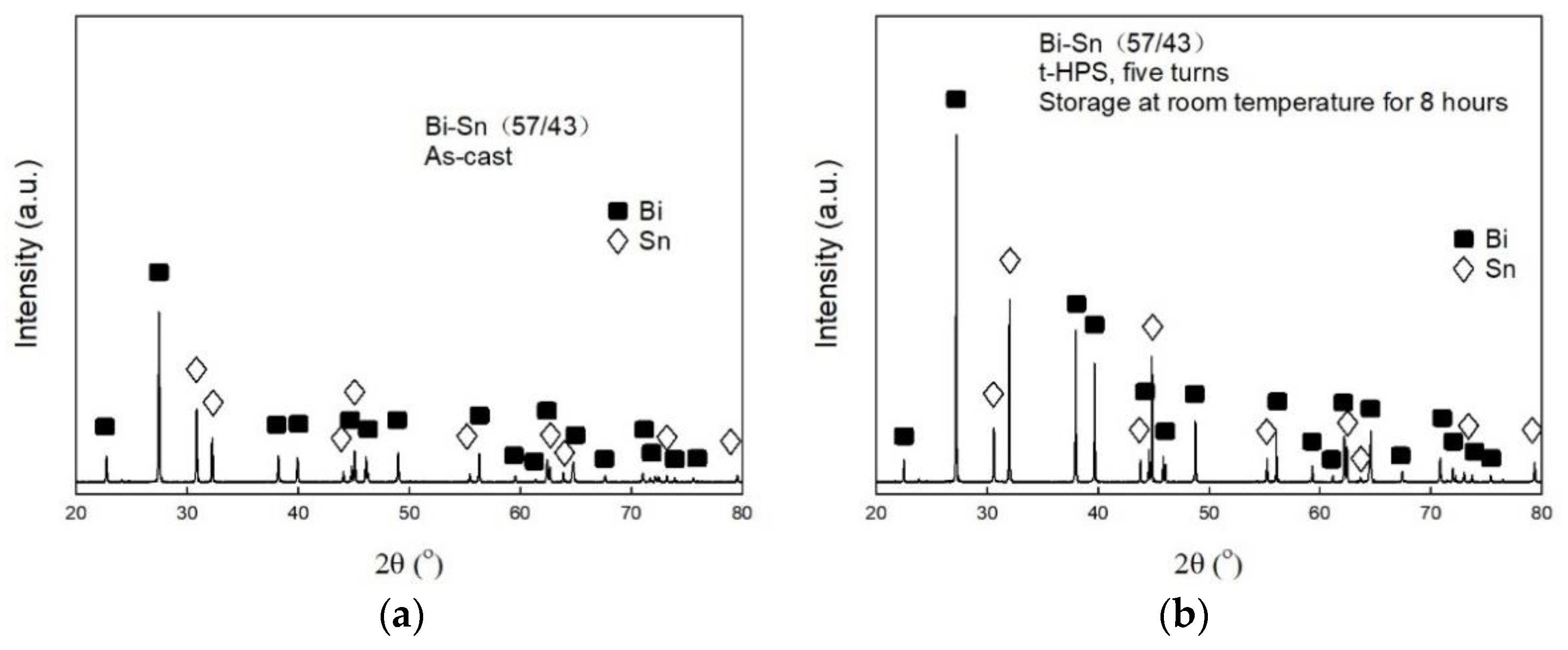

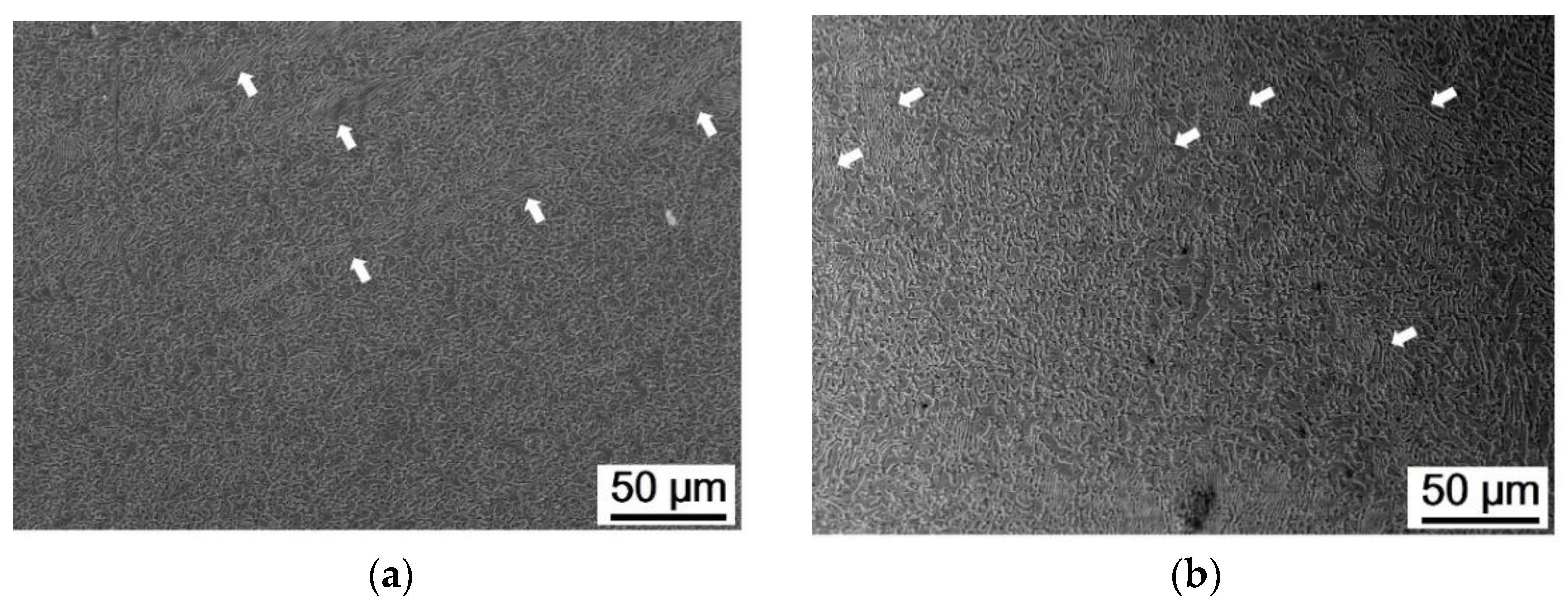

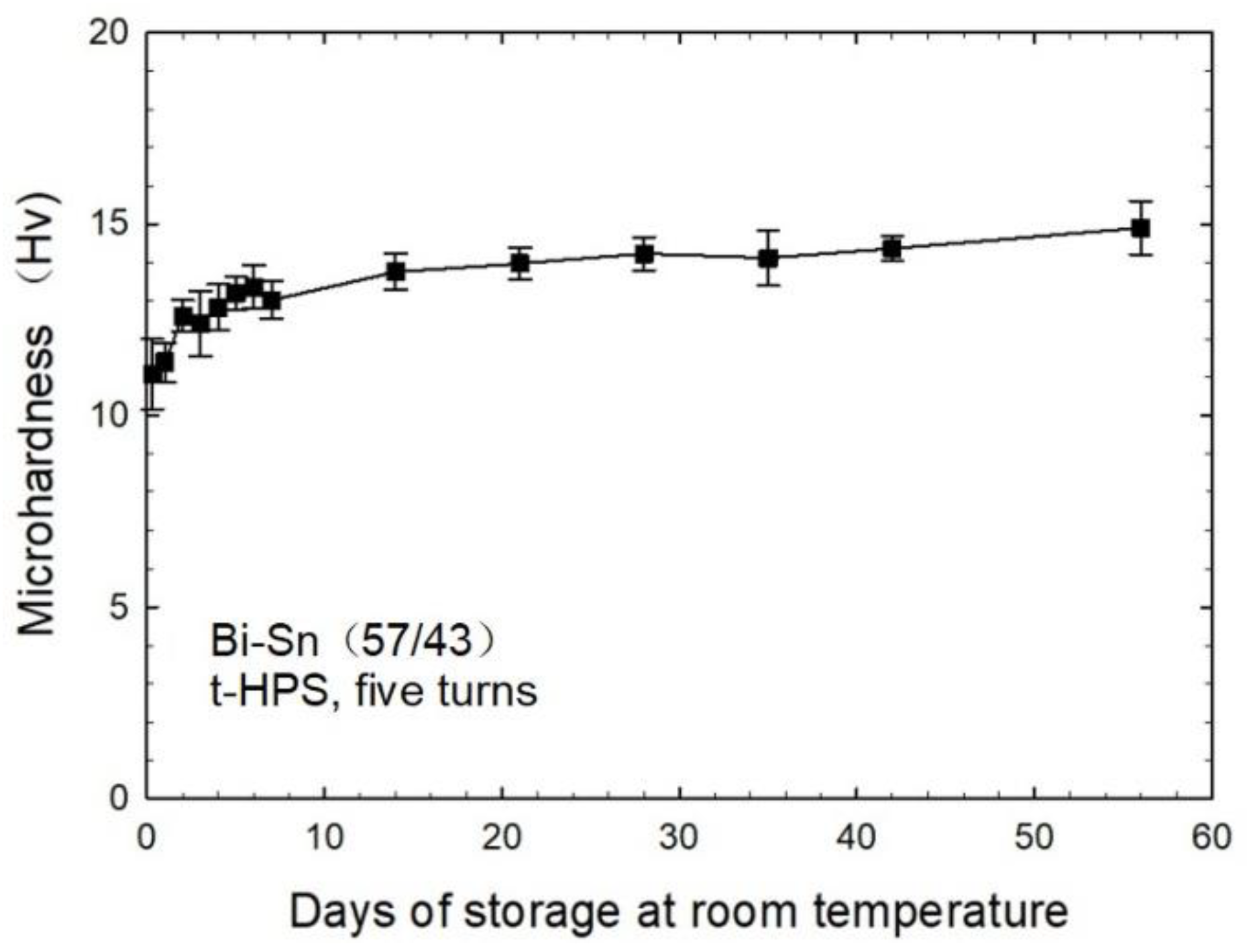

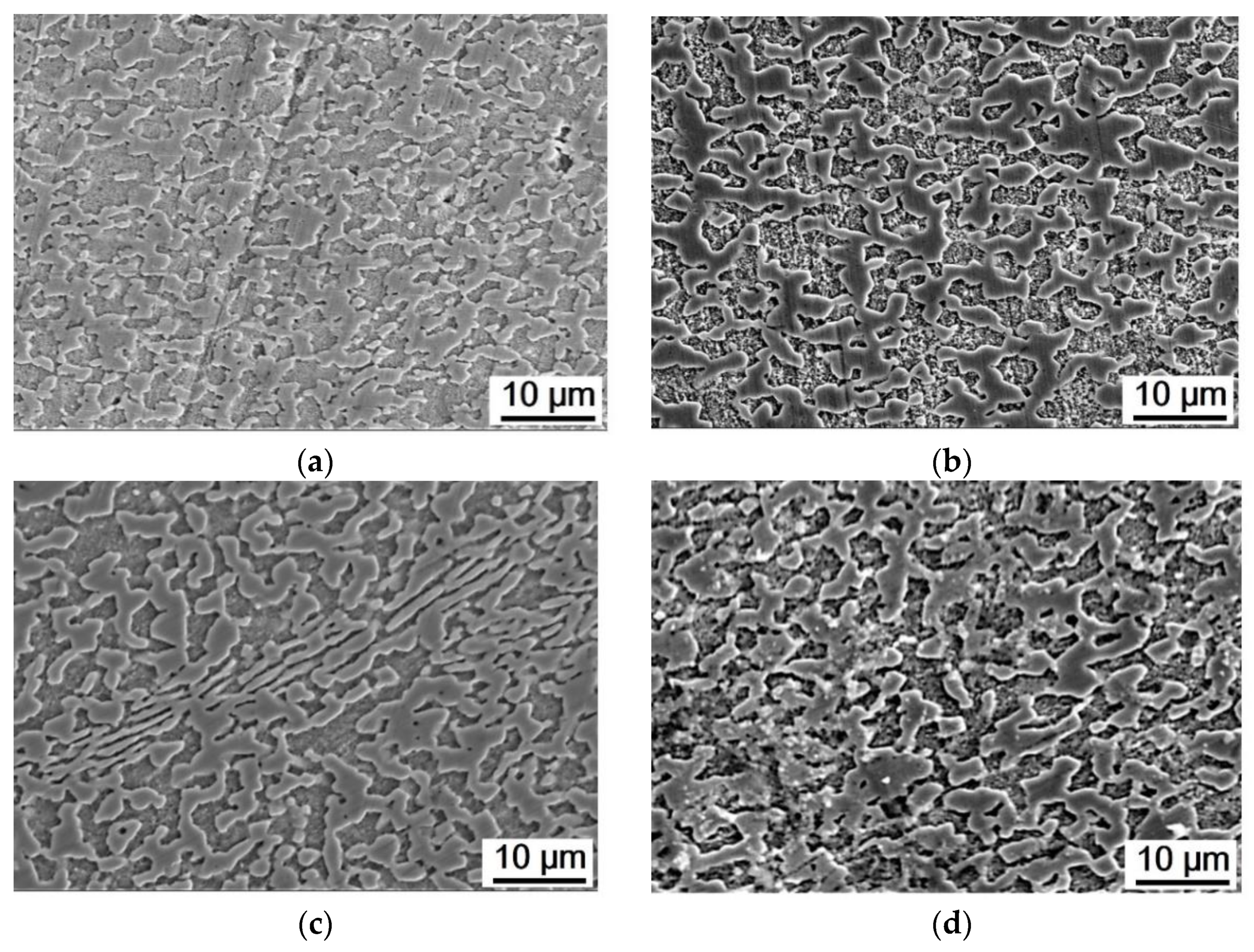

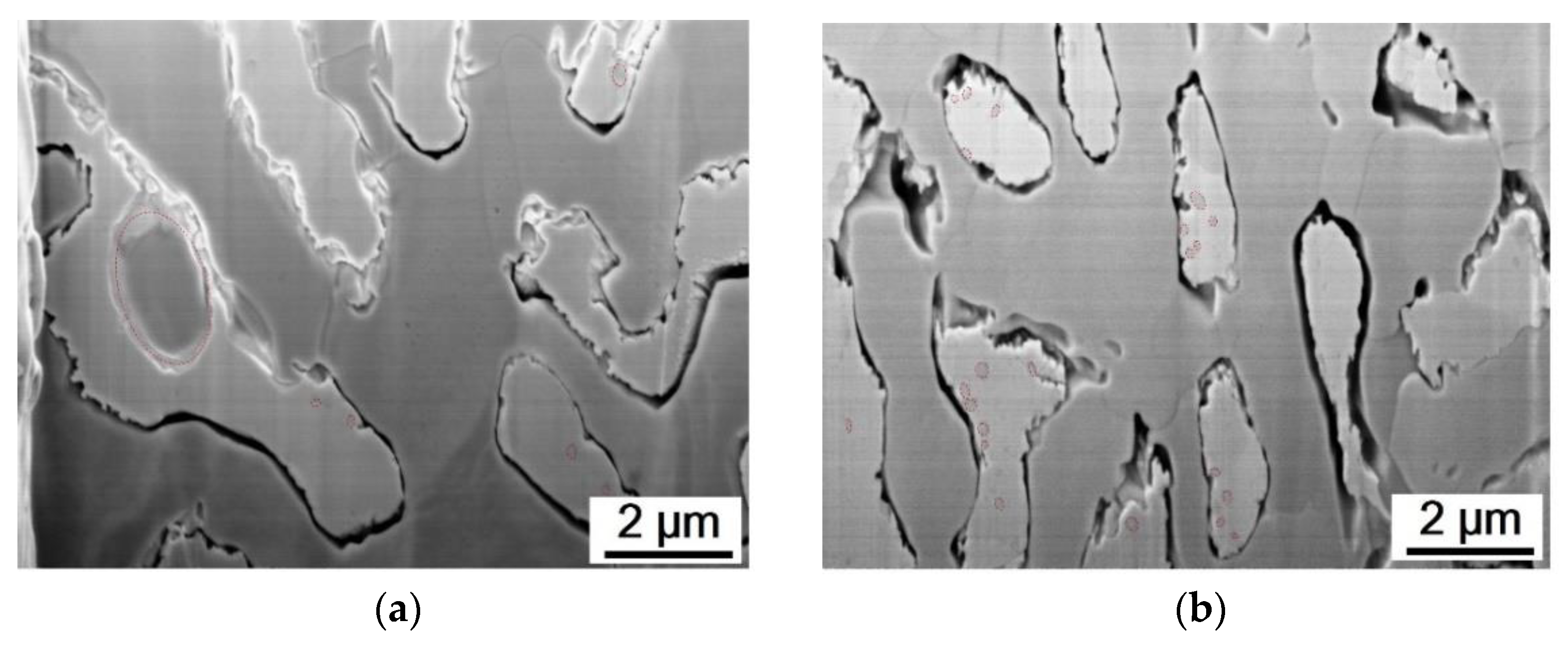

- Experiments on a Bi–Sn (57/43) eutectic alloy showed that t-HPS processing gradually refined the microstructure and led to decreasing microhardness.

- Shear localization of the eutectic structure during t-HPS processing was observed, but some preserved dense lamellar bands were visible even after t-HPS processing for 20 turns.

- The Bi–Sn (57/43) alloy processed by t-HPS showed significantly enhanced superplasticity, with elongations up to >1000%. This is attributed to the breaking of the lamellar structure and the presence of a refined grain size.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Valiev, R.Z.; Estrin, Y.; Horita, Z.; Langdon, T.G.; Zehetbauer, M.J.; Zhu, Y.T. Producing bulk ultrafine-grained materials by severe plastic deformation. JOM 2006, 58, 33–39. [Google Scholar] [CrossRef] [Green Version]

- Barnes, A.J. Superplastic forming 40 years and still growing. J. Mater. Eng. Perform. 2007, 16, 440–454. [Google Scholar] [CrossRef]

- Langdon, T.G. Twenty-five years of ultrafine-grained materials: Achieving exceptional properties through grain refinement. Acta Mater. 2013, 61, 7035–7059. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Langdon, T.G. Principles of equal-channel angular pressing as a processing tool for gain refinement. Prog. Mater. Sci. 2006, 51, 881–981. [Google Scholar] [CrossRef]

- Zhilyaev, A.P.; Langdon, T.G. Using high-pressure tosrion for metal processing: Fundamentals and applications. Prog. Mater. Sci. 2008, 53, 893–979. [Google Scholar] [CrossRef]

- Zhilyaev, A.P.; Kim, B.K.; Nurislamova, G.V.; Baró, M.D.; Szpunar, J.A.; Langdon, T.G. Orientation imaging microscopy of ultrafine-grained nickel. Scripta Mater. 2002, 46, 575–580. [Google Scholar] [CrossRef]

- Zhilyaev, A.P.; Nurislamova, G.V.; Kim, B.K.; Baró, M.D.; Szpunar, J.A.; Langdon, T.G. Experimental parameters influencing grain refinement and microstructural evolution during high-pressure torsion. Acta Mater. 2003, 51, 753–765. [Google Scholar] [CrossRef]

- Wongsa-Ngam, J.; Kawasaki, M.; Langdon, T.G. A comparison of microstructures and mechanical properties in a Cu-Zr alloy processed using different SPD techniques. J. Mater. Sci. 2013, 48, 4653–4660. [Google Scholar] [CrossRef]

- Brodova, I.; Rasposienko, D.; Shirinkina, I.; Petrova, A.; Akopyan, T.; Bobruk, E. Effect of severe plastic deformation on structure refinement and mechanical properties of the Al-Zn-Mg-Fe-Ni Alloy. Metals 2021, 11, 296. [Google Scholar] [CrossRef]

- Edalati, K.; Li, H.-W.; Kilmametov, A.; Floriano, R.; Borchers, C. High-Pressure Torsion for Synthesis of High-Entropy Alloys. Metals 2021, 11, 1263. [Google Scholar] [CrossRef]

- Nocivin, A.; Raducanu, D.; Vasile, B.; Trisca-Rusu, C.; Cojocaru, E.; Dan, A.; Irimescu, R.; Cojocaru, V. Tailoring a Low Young Modulus for a Beta Titanium Alloy by Combining Severe Plastic Deformation with Solution Treatment. Materials 2021, 14, 3467. [Google Scholar] [CrossRef]

- Svirid, A.; Pushin, V.; Kuranova, N.; Makarov, V.; Ustyugov, Y. Structural and Phase Transformations and Physical and Mechanical Properties of Cu-Al-Ni Shape Memory Alloys Subjected to Severe Plastic Deformation and Annealing. Materials 2021, 14, 4394. [Google Scholar] [CrossRef]

- Wang, J.T.; Li, Z.; Wang, J.; Langdon, T.G. Principles of severe plastic deformation using tube high-pressure shearing. Scr. Mater. 2012, 67, 810–813. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, P.F.; Yuan, H.; Lin, K.; Liu, Y.; Yin, D.L.; Wang, J.T.; Langdon, T.G. Principle of one-step synthesis for multilayered structures using tube high-pressure shearing. Mater. Sci. Eng. A 2016, 658, 367–375. [Google Scholar] [CrossRef]

- Meng, J.J.; Li, Z.; Liu, Y.; Bin Zhu, Y.; Wang, S.; Lin, K.; Tao, J.Q.; Wang, J.T. Investigation on the Strain Distribution in Tube High-Pressure Shearing. Metals 2019, 9, 1117. [Google Scholar] [CrossRef] [Green Version]

- Wang, C.T.; He, Y.; Langdon, T.G. The significance of strain weakening and self-annealing in a superplastic Bi–Sn eutectic alloy processed by high-pressure torsion. Acta Mater. 2019, 185, 245–256. [Google Scholar] [CrossRef] [Green Version]

- Wang, C.T.; Langdon, T.G. An examination of strain weakening and self-annealing in a Bi-Sn alloy processed by high-pressure torsion. Mater. Lett. 2021, 301, 130321. [Google Scholar] [CrossRef]

- Pearson, C.E. The viscous properties of extruded eutectic alloys of lead-tin and bismuth-tin. J. Inst. Met. 1934, 54, 111–124. [Google Scholar]

- Kawasaki, M.; Ahn, B.; Langdon, T.G. Microstructural evolution in a two-phase alloy processed by high-pressure torsion. Acta Mater. 2009, 58, 919–930. [Google Scholar] [CrossRef]

- Zhang, N.X.; Kawasaki, M.; Huang, Y.; Langdon, T.G. Microstructural evolution in two-phase alloys processed by high-pressure torsion. J. Mater. Sci. 2012, 48, 4582–4591. [Google Scholar] [CrossRef]

- Zhang, N.X.; Chinh, N.Q.; Kawasaki, M.; Huang, Y.; Langdon, T.G. Self-annealing in a two-phase Pb-Sn alloy after processing by high-pressure torsion. Mater. Sci. Eng. A 2016, 666, 350–359. [Google Scholar] [CrossRef] [Green Version]

- Zhang, N.X.; Kawasaki, M.; Huang, Y.; Langdon, T.G. An examination of microstructural evolution in a Pb–Sn eutectic alloy processed by high-pressure torsion and subsequent self-annealing. Mater. Sci. Eng. A 2020, 802, 140653. [Google Scholar] [CrossRef]

- Wang, J.; Kang, S.-B.; Kim, H. Microstructure transformation from lamellar to equiaxed microduplex through equal-channel angular pressing in an Al-33 pct Cu eutectic alloy. Met. Mater. Trans. A 2004, 35, 279–286. [Google Scholar] [CrossRef]

- Wang, J.; Kang, S.-B.; Kim, H. Shear features during equal channel angular pressing of a lamellae eutectic alloy. Mater. Sci. Eng. A 2004, 383, 356–361. [Google Scholar] [CrossRef]

- Massalski, T.B. Binary Alloy. Phase Diagrams, 2nd ed.; ASM International: Materials Park, OH, USA, 1990; pp. 794–796. [Google Scholar]

- Ren, G.; Collins, M.N. Improved Reliability and Mechanical Performance of Ag Microalloyed Sn58Bi Solder Alloys. Metals 2019, 9, 462. [Google Scholar] [CrossRef] [Green Version]

- Wang, K.; Wang, F.; Huang, Y.; Qi, K. Comprehensive Properties of a Novel Quaternary Sn-Bi-Sb-Ag Solder: Wettability, Interfacial Structure and Mechanical Properties. Metals 2019, 9, 791. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Tu, K.N. Low melting point solders based on Sn, Bi, and In elements. Mater. Today Adv. 2020, 8, 100115. [Google Scholar] [CrossRef]

- Kang, H.; Rajendran, S.H.; Jung, J.P. Low melting temperature Sn-Bi solder: Effect of alloying and nanoparticle addition on the microstructural, thermal, interfacial bonding, and mechanical characteristics. Metals 2021, 11, 364. [Google Scholar] [CrossRef]

- Langdon, T.G. A unified approach to grain boundary sliding in creep and superplasticity. Acta Metall. Mater. 1994, 42, 2437–2443. [Google Scholar] [CrossRef]

- Hu, X.; Li, K.; Ai, F. Research on lamellar structure and micro-hardness of directionally solidified Sn-58Bi eutectic alloy. China Foundry 2012, 9, 360–365. [Google Scholar]

- Lee, H.B.; Kim, Y.W.; Kim, S.H.; Park, S.H.; Choi, J.-P.; Aranas, C., Jr. A Modular Solder System with Hierarchical Morphology and Backward Compatibility. Small 2018, 14, e1801349. [Google Scholar] [CrossRef]

- Kim, S.H.; Yeon, S.-M.; Kim, J.H.; Park, S.J.; Lee, J.E.; Park, S.-H.; Choi, J.-P.; Aranas, C.J.; Son, Y. Fine Microstructured In–Sn–Bi Solder for Adhesion on a Flexible PET Substrate: Its Effect on Superplasticity and Toughness. ACS Appl. Mater. Interfaces 2019, 11, 17090–17099. [Google Scholar] [CrossRef] [PubMed]

- Xu, K.-K.; Zhang, L.; Gao, L.-L.; Jiang, N.; Zhang, L.; Zhong, S.-J. Review of microstructure and properties of low temperature lead-free solder in electronic packaging. Sci. Technol. Adv. Mater. 2020, 21, 689–711. [Google Scholar] [CrossRef] [PubMed]

- Langdon, T.G. Seventy-five years of superplasticity: Historic developments and new opportunities. J. Mater. Sci. 2009, 44, 5998–6010. [Google Scholar] [CrossRef]

| Strain Rate | 1.0 × 10−2 s−1 | 1.0 × 10−3 s−1 | 1.0 × 10−4 s−1 | |||

|---|---|---|---|---|---|---|

| UTS, MPa | Elongation | UTS, MPa | Elongation | UTS, MPa | Elongation | |

| As-cast | 70 | ~40% | 60 | ~80% | 53 | ~130% |

| 0.25 turns | 69 | ~80% | 48 | ~280% | 33 | ~430% |

| 1 turn | 69 | ~100% | 49 | ~270% | 31 | ~490% |

| 5 turns | / | / | 42 | ~1170% | 23 | ~1530% |

| 20 turns | / | / | 26 | ~1060% | 12 | ~1820% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, C.-T.; Li, Z.; He, Y.; Wang, J.-T.; Langdon, T.G. Microstructural Evolution and Tensile Testing of a Bi–Sn (57/43) Alloy Processed by Tube High-Pressure Shearing. Crystals 2021, 11, 1229. https://doi.org/10.3390/cryst11101229

Wang C-T, Li Z, He Y, Wang J-T, Langdon TG. Microstructural Evolution and Tensile Testing of a Bi–Sn (57/43) Alloy Processed by Tube High-Pressure Shearing. Crystals. 2021; 11(10):1229. https://doi.org/10.3390/cryst11101229

Chicago/Turabian StyleWang, Chuan-Ting, Zheng Li, Yong He, Jing-Tao Wang, and Terence G. Langdon. 2021. "Microstructural Evolution and Tensile Testing of a Bi–Sn (57/43) Alloy Processed by Tube High-Pressure Shearing" Crystals 11, no. 10: 1229. https://doi.org/10.3390/cryst11101229