Investigation on Optimal Ta/Cr Ratio of a Single Crystal Ni-Base Superalloy in View of the Isothermal Oxidation Behavior

Abstract

:1. Introduction

2. Materials and Methods

3. Results

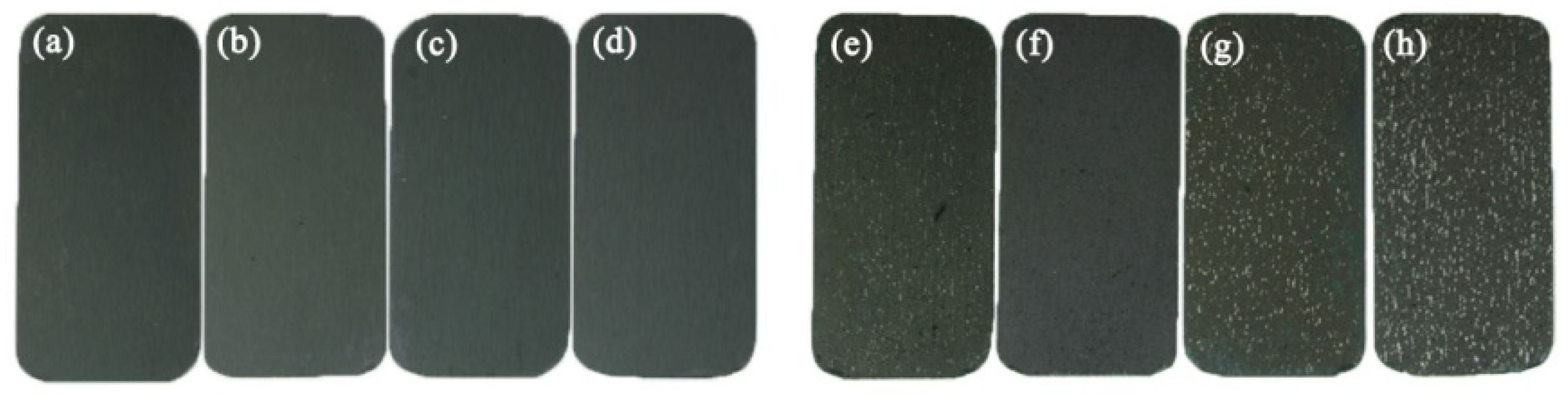

3.1. Macroscopic Morphologies

3.2. Oxidation Kinetics

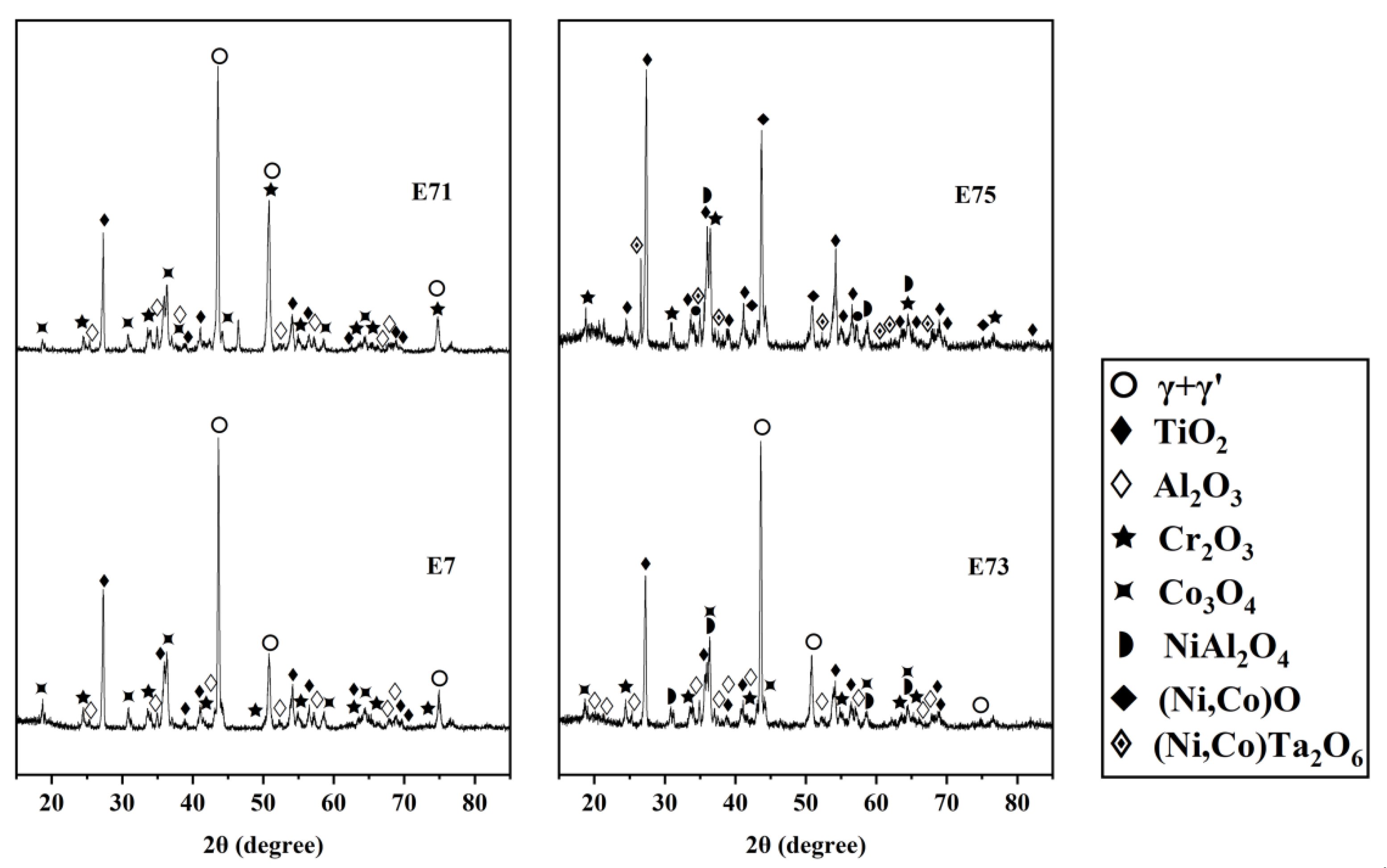

3.3. XRD Results

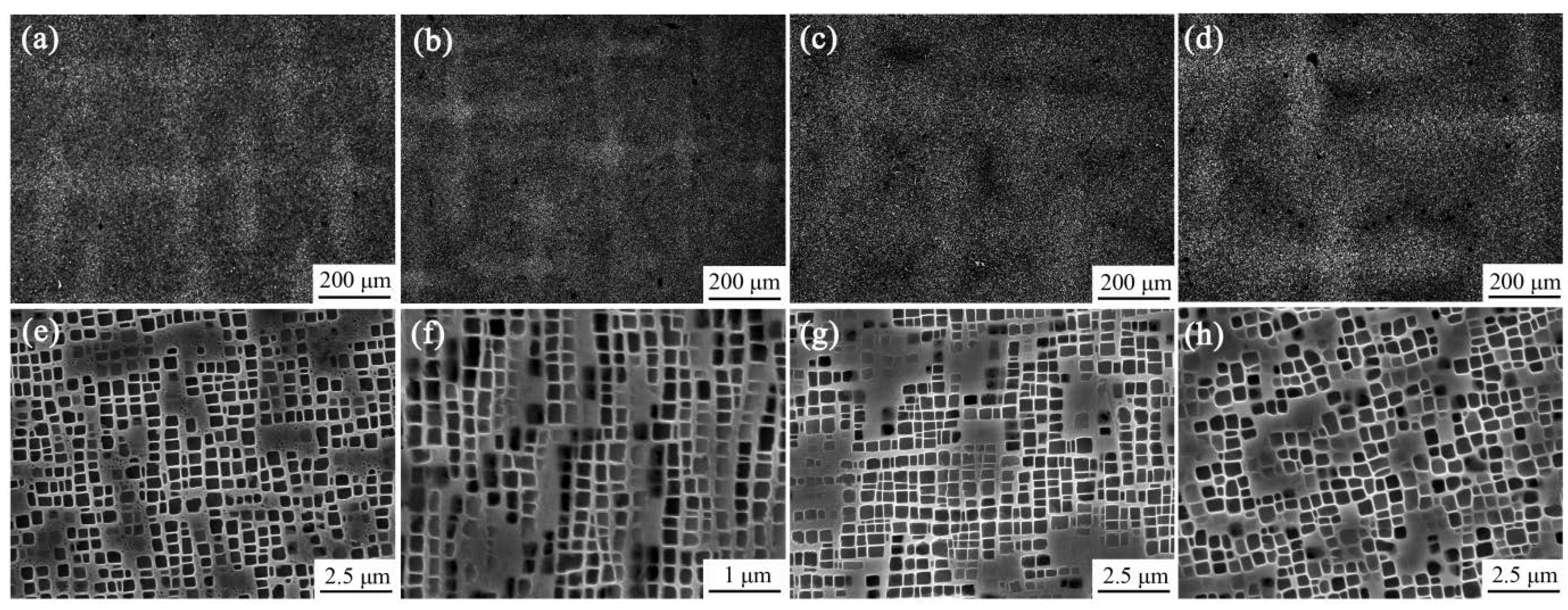

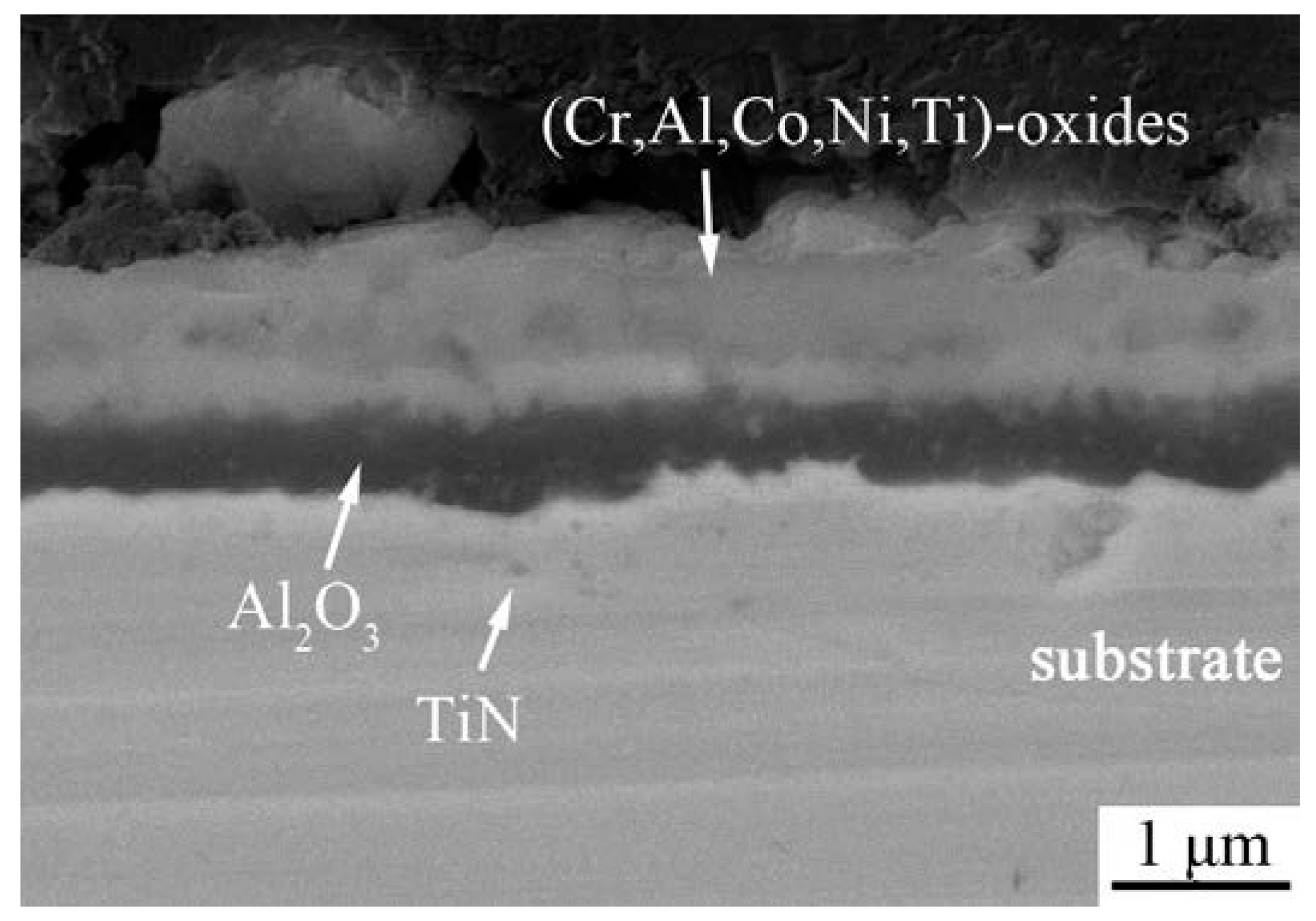

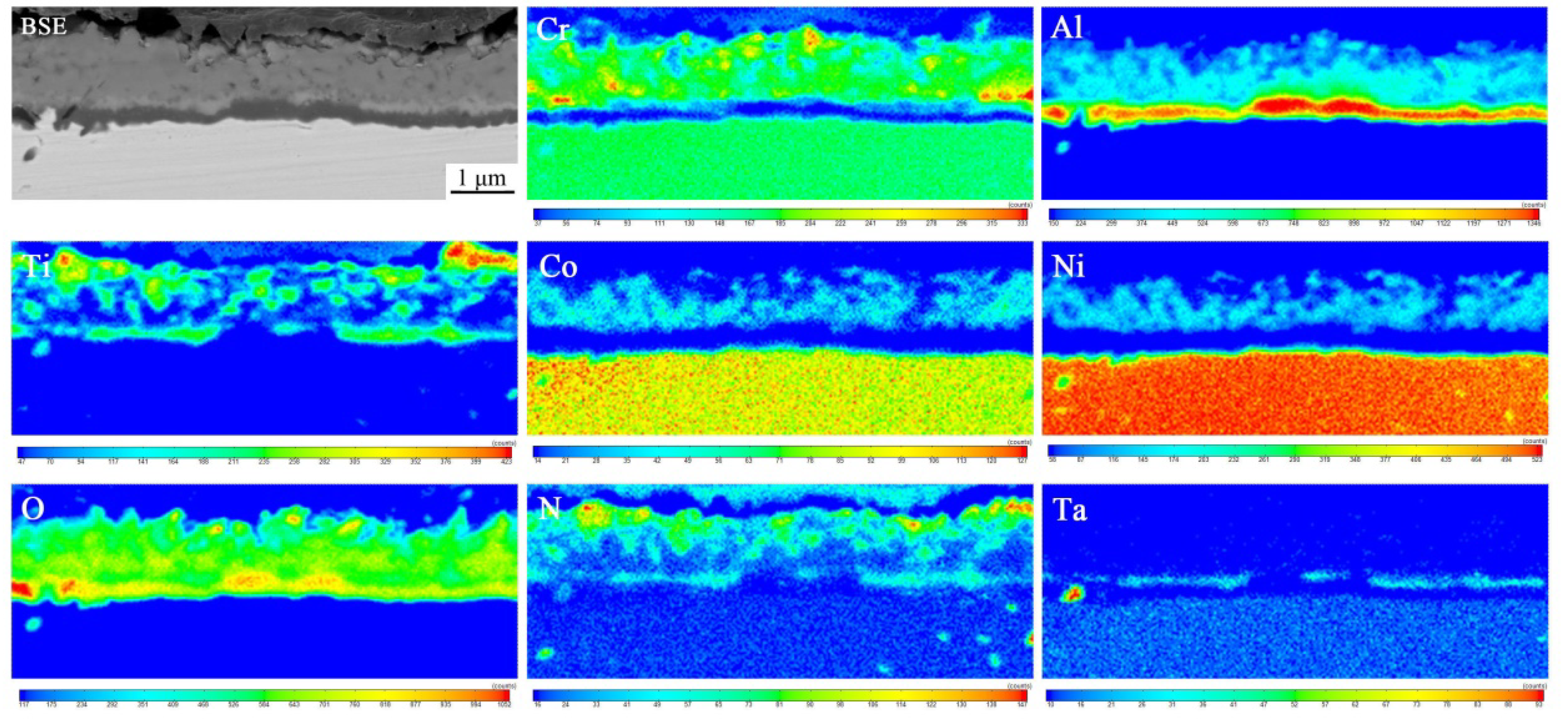

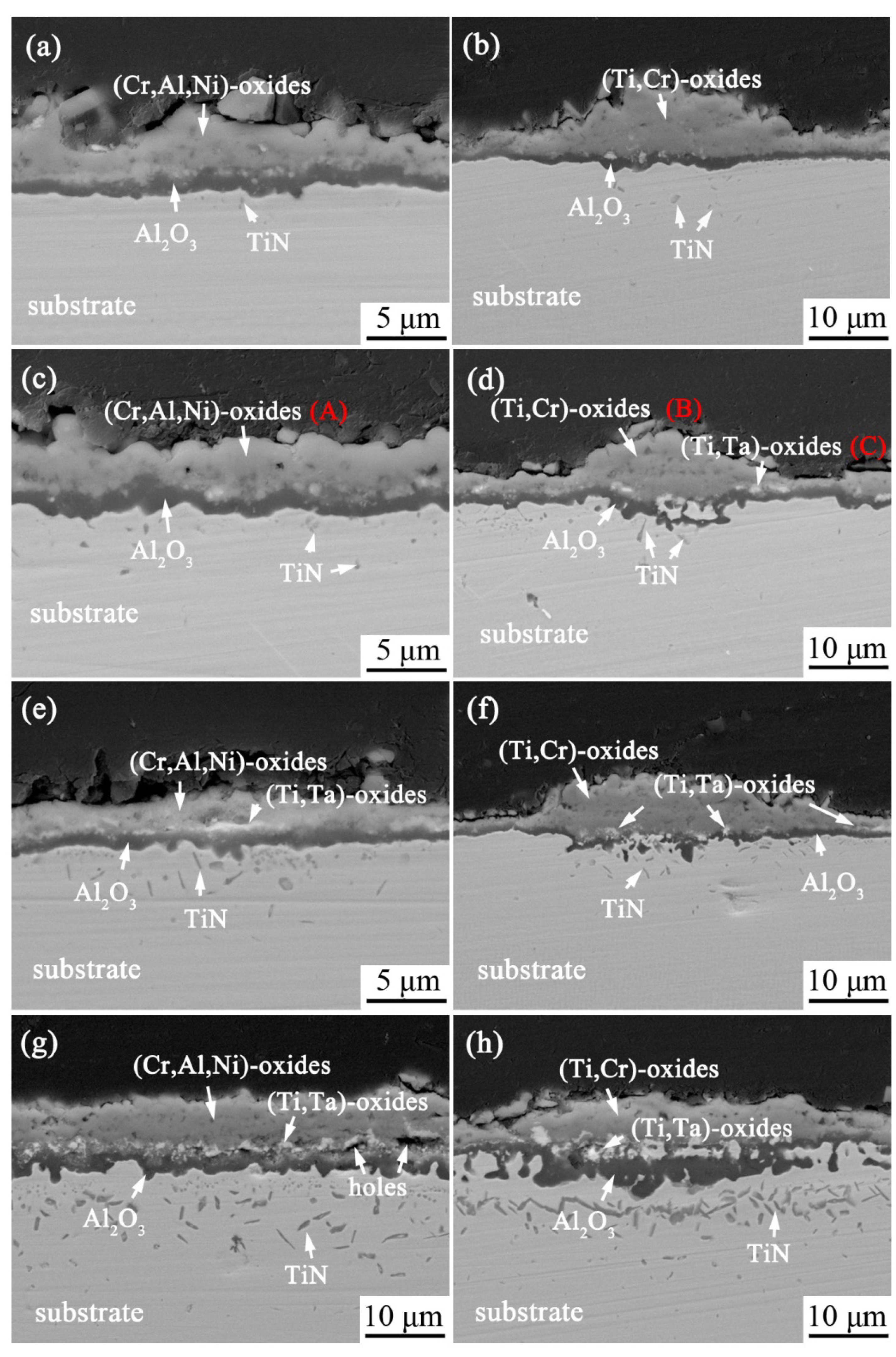

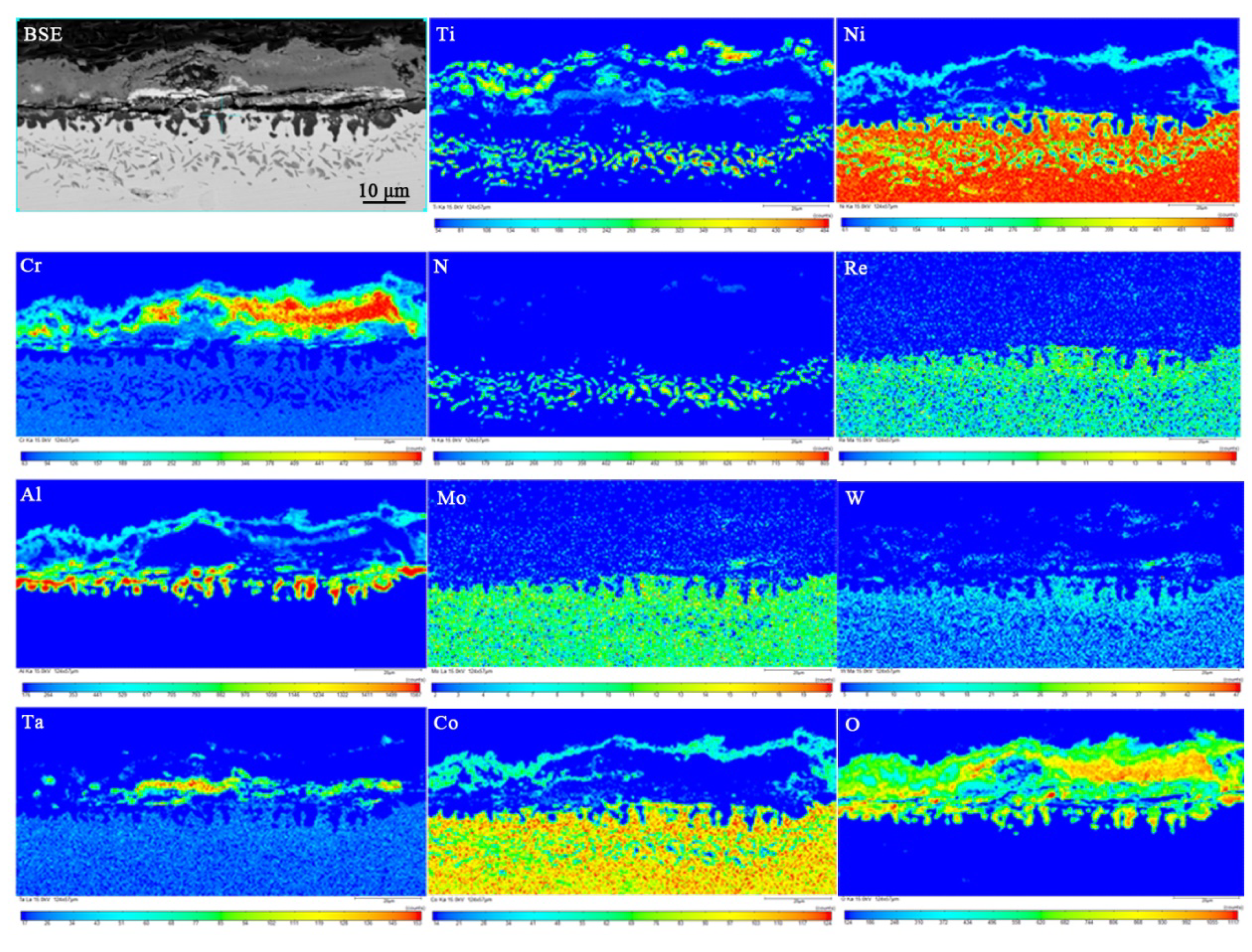

3.4. Surface and Cross-Section Morphology

4. Discussion

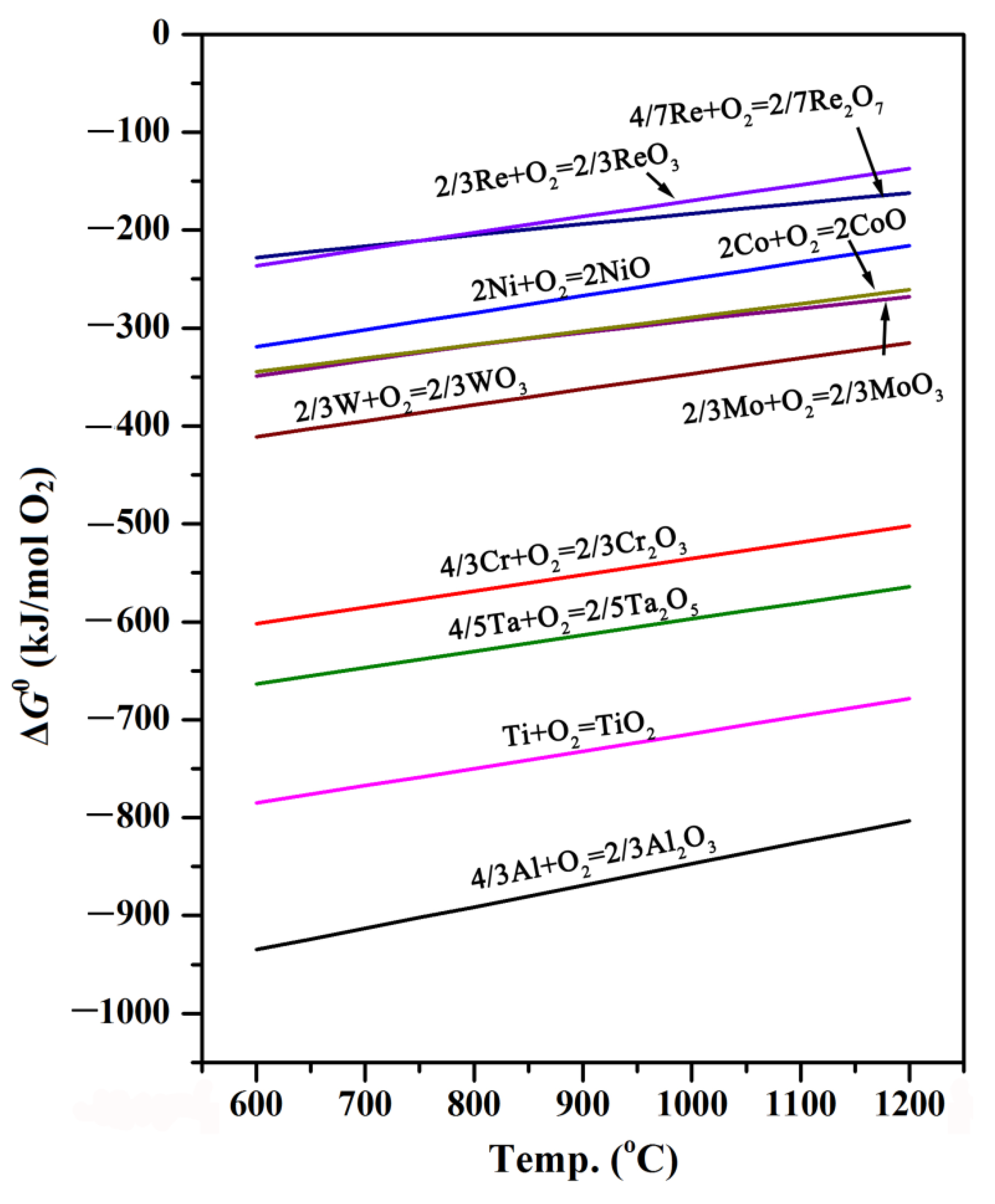

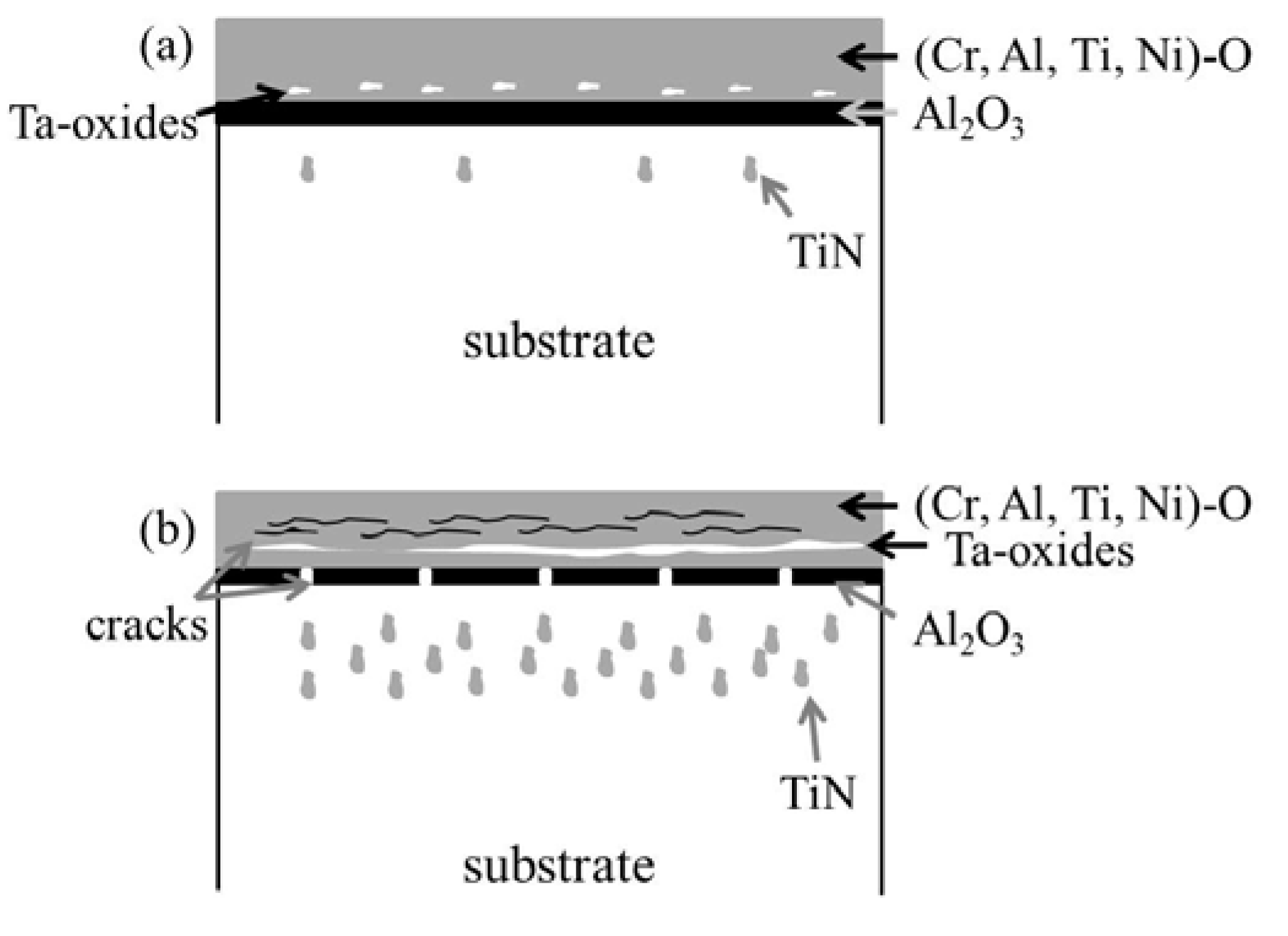

4.1. Oxidation Process

4.2. Interaction of Ta and Cr

5. Conclusions

- (1)

- If Ta/Cr ≤ 0.5, Ta improved the growth rate of Cr2O3 and promoted the selective oxidation of Al. The oxidation resistance of the alloy was excellent. The mechanism was the doping effect induced by Ta cation.

- (2)

- If Ta/Cr > 0.5, Ta reduced the growth rate of Cr2O3 and suppressed the formation of Al2O3. The oxidation property of the alloy deteriorated. The mechanism was the competitive growth of Ta2O5 and Cr2O3.

- (3)

- A good oxidation performance can be expected with the value Ta/Cr ≤ 0.5.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Oskarsson, H. Material challenges in industrial gas turbines. J. Iron Steel Res. Int. 2007, 14, 11–14. [Google Scholar] [CrossRef]

- Pettit, F.S.; Meier, G.H. Oxidation and hot corrosion of superalloys. In Superalloys 1984; TMS: Warrendale, PA, USA, 2012; pp. 651–687. [Google Scholar]

- Chang, J.X.; Wang, D.; Liu, T.; Zhang, G.; Lou, L.H.; Zhang, J. Role of tantalum in the hot corrosion of a Ni-base single crystal superalloy. Corros. Sci. 2015, 98, 585–591. [Google Scholar] [CrossRef]

- Bai, M.; Chen, Y.; Xiao, P. Investigations on the diffusion of platinum between CMSX-4 superalloy and platinum-enriched bond Coat. Coatings 2021, 11, 441. [Google Scholar] [CrossRef]

- Giamei, A.F.; Anton, D.L. Rhenium additions to a Ni-base superalloy—Effects on microstructure. Metall. Trans. A 1985, 16, 1997–2005. [Google Scholar] [CrossRef]

- Gurrappa, I.; Wilson, A.; Du, H.L.; Burnell-Gray, J.; Datta, P.K. Hot corrosion behavior of newly developed nickel based superalloy and comparison with other alloys. ECS Trans. 2008, 24, 105–115. [Google Scholar]

- Reed, R.C.; Moverare, J.J.; Sato, A.; Karlsson, F.; Hasselqvist, M. A new single crystal superalloy for power generation applications. In Superalloys 2012; TMS: Warrendale, PA, USA, 2012; pp. 197–204. [Google Scholar]

- Chang, J.X.; Wang, D.; Liu, X.G.; Lou, L.H.; Zhang, J. Effect of rhenium addition on hot corrosion resistance of Ni-based single crystal superalloys. Metall. Mater. Trans. A 2018, 4, 4343–4352. [Google Scholar] [CrossRef]

- Chang, J.X.; Wang, D.; Dong, J.S.; Wang, D.; Wu, H.C.; Zhang, G.; Lou, L.H. Effect of rhenium addition on isothermal oxidation behavior of a nickel-base single crystal superalloy. Chin. J. Mater. Res. 2017, 31, 695–702. [Google Scholar]

- Chang, J.X.; Wang, D.; Zhang, G.; Lou, L.H.; Zhang, J. Interaction of Ta and Cr on Type-I hot corrosion resistance of single crystal Ni-base superalloys. Corros. Sci. 2017, 117, 35–42. [Google Scholar] [CrossRef]

- Yang, S.W. Effect of Ti and Ta on the oxidation of a complex superalloy. Oxid. Met. 1981, 15, 375–397. [Google Scholar] [CrossRef]

- Barrett, C.A.; Miner, R.V.; Hull, D.R. The effects of Cr, Al, Ti, Mo, W, Ta and Cb on the cyclic oxidation behavior of cast Ni-base superalloys at 1100 and 1150 °C. Oxid. Met. 1983, 20, 255–278. [Google Scholar] [CrossRef]

- Wu, F.; Murakami, H.; Suzuki, A. Development of an iridium–tantalum modified aluminide coating as a diffusion barrier on nickel-base single crystal superalloy TMS-75. Surf. Coat. Technol. 2003, 168, 62–69. [Google Scholar] [CrossRef]

- Kuppusami, P.; Murakami, H. Effect of Ta on microstructure and phase distribution in cyclic oxidized Ir-Ta modified aluminide coatings on nickel base single crystal superalloy. Mater. Sci. Eng. A 2007, 452, 254–261. [Google Scholar] [CrossRef]

- Giggins, C.S.; Pettit, F.S. Oxidation of Ni-Cr-Al alloys between 1000 degrees and 1200 degrees C. J. Electrochem. Soc. 1971, 118, 1782–1790. [Google Scholar] [CrossRef]

- Li, Y.; Li, S.; Zhang, C.; Xu, N.; Bao, Z. Oxidation behavior and oxide transformation of a Pt-modified aluminide coating at moderate high temperature. Crystals 2021, 11, 972. [Google Scholar] [CrossRef]

- Campbell, C.E.; Boettinger, W.J.; Kattner, U.R. Development of a diffusion mobility database for Ni-base superalloys. Acta Mater. 2002, 50, 775–792. [Google Scholar] [CrossRef]

- Han, S.; Young, D.J. Simultaneous internal oxidation and nitridation of Ni-Cr-Al alloys. Oxid. Met. 2001, 55, 223–242. [Google Scholar] [CrossRef]

- Birks, N.; Meier, G.H.; Pettit, F.S. Introduce to the High-Temperature Oxidation of Metals, 2nd ed.; Cambridge University Press: Cambridge, UK, 2006; p. 16. [Google Scholar]

- Huang, L.; Sun, X.F.; Guan, H.R.; Hu, Z.Q. Oxidation behavior of the single-crystal Ni-base superalloy DD32 in Air at 900, 1000, and 1100 °C. Oxid. Met. 2006, 65, 391–408. [Google Scholar] [CrossRef]

- Pfennig, A.; Fedelich, B. Oxidation of single crystal PWA 1483 at 950 degrees C in flowing air. Corros. Sci. 2008, 50, 2484–2492. [Google Scholar] [CrossRef]

- Wagner, C.; Zimens, K.E. *Die oxydationsgeschwindigkeit von nickel bei kleinen zusatzen von chrom und mangan—Beitrag zur theorie des anlaufvorganges. Acta Chem. Scand. 1947, 1, 547–565. [Google Scholar] [CrossRef]

- Bornstein, N.S.; Decresce, M.A. Role of sodium in accelerated oxidation phenomenon termed sulfidation. Metall. Trans. 1971, 2, 2875–2883. [Google Scholar] [CrossRef]

- Bornstei, N.S.; Decresce, M.A.; Roth, H.A. Relationship between relative oxide ion content of Na2SO4, presence of liquid-metal oxides and sulfidation attack. Metall. Trans. 1973, 4, 1799–1810. [Google Scholar] [CrossRef]

- Goebel, J.A.; Pettit, F.S.; Goward, G.W. Mechanisms for the hot corrosion of nickel-base alloys. Metall. Trans. 1973, 4, 261–278. [Google Scholar] [CrossRef]

- Otsuka, N.; Rapp, R.A. Effects of chromate and vanadate anions on the hot corrosion of preoxidized Ni by a thin fused Na2SO4 film at 900-degreeS-C. J. Electrochem. Soc. 1990, 137, 53–60. [Google Scholar] [CrossRef]

- Han, F.F.; Chang, J.X.; Li, H.; Lou, L.H.; Zhang, J. Influence of Ta content on hot corrosion behaviour of a directionally solidified nickel base superalloy. J. Alloys Compd. 2015, 619, 102–108. [Google Scholar] [CrossRef]

| Alloys | Cr | Ta | Re | Mo | W | Ti | Al | Co | C | Ni | Ta/Cr |

|---|---|---|---|---|---|---|---|---|---|---|---|

| E7 | 12.00 | 4.09 | 1.97 | 1.91 | 4.00 | 3.99 | 3.41 | 9.02 | 0.05 | Bal. | 0.34 |

| E71 | 12.00 | 6.15 | 2.03 | 1.93 | 4.01 | 3.94 | 3.39 | 9.04 | 0.04 | Bal. | 0.51 |

| E73 | 9.84 | 6.04 | 2.04 | 2.01 | 3.99 | 3.94 | 3.30 | 9.01 | 0.04 | Bal. | 0.61 |

| E75 | 9.89 | 6.87 | 2.00 | 1.03 | 3.82 | 3.96 | 3.46 | 8.94 | 0.06 | Bal. | 0.69 |

| Time | Alloys | Phase Constituents |

|---|---|---|

| 100 h | E7 | TiO2, Co3O4, Al2O3, Cr2O3, γ + γ′ |

| E71 | TiO2, Co3O4, Al2O3, Cr2O3, γ + γ′ | |

| E73 | TiO2, Co3O4, Al2O3, Cr2O3, NiAl2O4, γ + γ′ | |

| E75 | TiO2, NiAl2O4, (Ni,Co)Ta2O6, Cr2O3, (Ni,Co)O, γ + γ′ | |

| 500 h | E7 | TiO2, Co3O4, Cr2O3, Al2O3, NiCr2O4, γ + γ′ |

| E71 | TiO2, Co3O4, Cr2O3, Al2O3, NiCr2O4, γ + γ′ | |

| E73 | TiO2, Co3O4, Cr2O3, γ + γ′ | |

| E75 | TiO2, NiAl2O4, (Ni,Co)Ta2O6, Cr2O3, (Ni,Co)O, γ + γ′ |

| Al | Cr | Ti | Ni | Ta | O | |

|---|---|---|---|---|---|---|

| A | 6.31 | 28.26 | 3.59 | 1.07 | - | 60.76 |

| B | 2.53 | 3.87 | 23.22 | 0.36 | - | 69.45 |

| C | - | 1.15 | 20.73 | 2.36 | 13.11 | 62.65 |

| Al | Cr | Ti | Ni | Ta | Co | O | |

|---|---|---|---|---|---|---|---|

| A | 9.71 | 19.63 | 5.22 | 3.85 | - | 0.62 | 60.97 |

| B | - | 9.56 | 7.99 | 4.54 | 11.94 | 0.63 | 65.33 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, J.; Feng, W.; Zhao, W.; Jia, H.; Liu, Y.; Luo, S.; Wang, D.; Dong, J. Investigation on Optimal Ta/Cr Ratio of a Single Crystal Ni-Base Superalloy in View of the Isothermal Oxidation Behavior. Crystals 2021, 11, 1421. https://doi.org/10.3390/cryst11111421

Chang J, Feng W, Zhao W, Jia H, Liu Y, Luo S, Wang D, Dong J. Investigation on Optimal Ta/Cr Ratio of a Single Crystal Ni-Base Superalloy in View of the Isothermal Oxidation Behavior. Crystals. 2021; 11(11):1421. https://doi.org/10.3390/cryst11111421

Chicago/Turabian StyleChang, Jianxiu, Wenhao Feng, Wenwen Zhao, Hongmin Jia, Yanming Liu, Sheji Luo, Dong Wang, and Jiasheng Dong. 2021. "Investigation on Optimal Ta/Cr Ratio of a Single Crystal Ni-Base Superalloy in View of the Isothermal Oxidation Behavior" Crystals 11, no. 11: 1421. https://doi.org/10.3390/cryst11111421

APA StyleChang, J., Feng, W., Zhao, W., Jia, H., Liu, Y., Luo, S., Wang, D., & Dong, J. (2021). Investigation on Optimal Ta/Cr Ratio of a Single Crystal Ni-Base Superalloy in View of the Isothermal Oxidation Behavior. Crystals, 11(11), 1421. https://doi.org/10.3390/cryst11111421