Research and Progress of Transparent, Flexible Tin Oxide Ultraviolet Photodetector

Abstract

:1. Introduction

2. The Parameters and Structures of Photodetectors

2.1. Parameters

2.1.1. Dark Current

2.1.2. Responsivity

2.1.3. Detectivity

2.1.4. Response Time

2.1.5. Gain

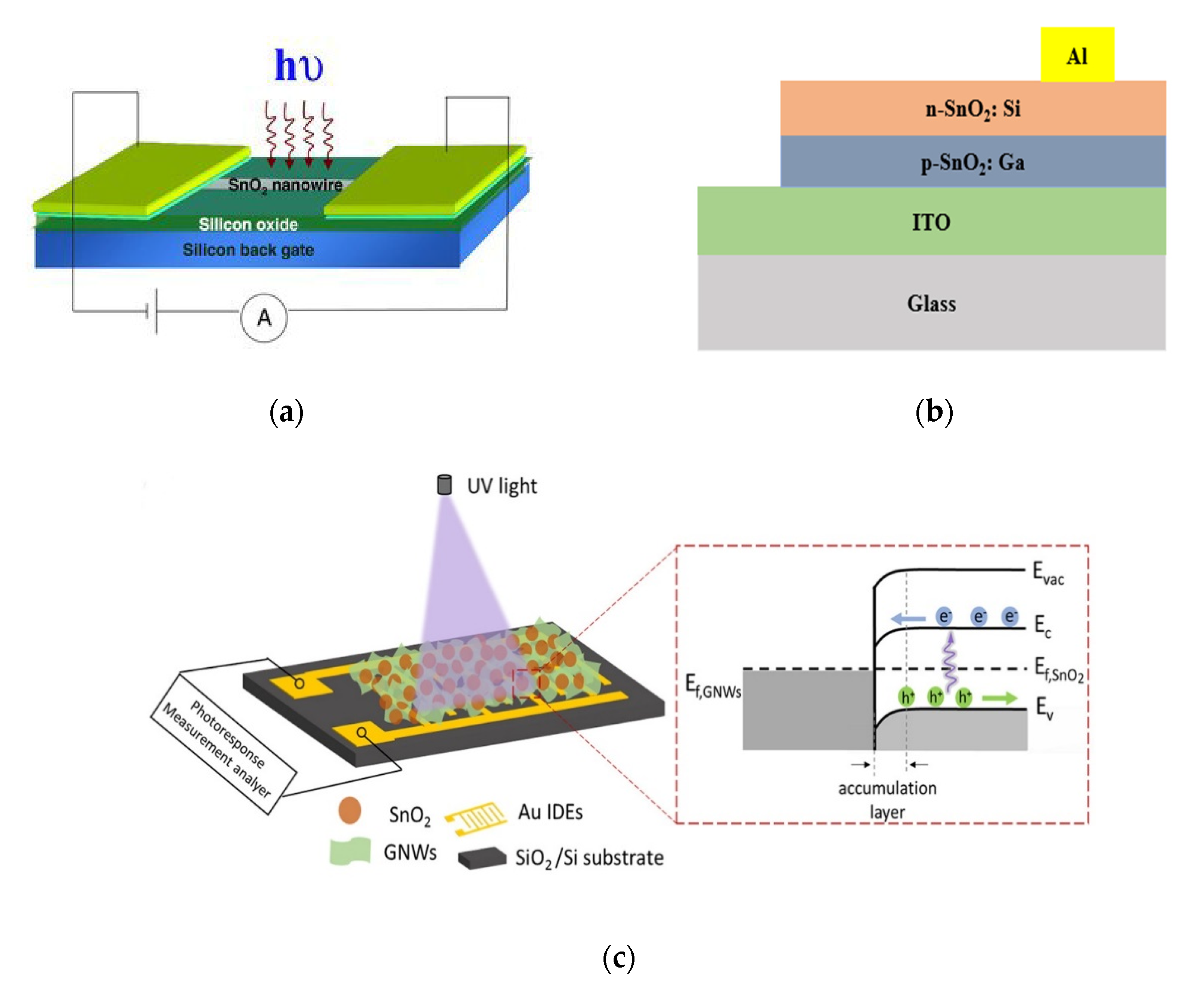

2.2. Device Structures

3. Transparent SnO2 UV Photodetector

4. Flexible SnO2 UV Photodetector

5. Optimization

6. Summary

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Game, O.; Singh, U.; Kumari, T.; Banpurkar, A.; Ogale, S. ZnO(N)–Spiro-MeOTAD hybrid photodiode: An efficient self-powered fast-response UV (visible) photosensor. Nanoscale 2014, 6, 503–513. [Google Scholar] [CrossRef]

- Fu, Q.; Peng, J.; Yao, Z.; Zhao, H.; Ma, Z.; Tao, H.; Tu, Y.; Tian, Y.; Zhou, D.; Han, Y. Highly sensitive ultraviolet photodetectors based on ZnO/SnO2 core-shell nanorod arrays. Appl. Surf. Sci. 2020, 527, 146923. [Google Scholar] [CrossRef]

- Mohammadi, S.; Zavvari, M. High performance n-ZnO/p-metal-oxides UV detector grown in low-temperature aqueous solution bath. Thin Solid Films 2017, 626, 173–177. [Google Scholar] [CrossRef]

- Bie, Y.; Liao, Z.; Zhang, H.; Li, G.; Ye, Y.; Zhou, Y.; Xu, J.; Qin, Z.; Dai, L.; Yu, D. Self-Powered, Ultrafast, Visible-Blind UV Detection and Optical Logical Operation based on ZnO/GaN Nanoscale p-n Junctions. Adv. Mater. 2011, 23, 649–653. [Google Scholar] [CrossRef] [PubMed]

- Xie, C.; Nie, B.; Zeng, L.; Liang, F.; Wang, M.; Luo, L.; Feng, M.; Yu, Y.; Wu, C.; Wu, Y.; et al. Core–Shell Heterojunction of Silicon Nanowire Arrays and Carbon Quantum Dots for Photovoltaic Devices and Self-Driven Photodetectors. ACS Nano 2014, 8, 4015–4022. [Google Scholar] [CrossRef] [PubMed]

- Zhai, T.; Li, L.; Wang, X.; Fang, X.; Bando, Y.; Golberg, D. Recent Developments in One-Dimensional Inorganic Nanostructures for Photodetectors. Adv. Funct. Mater. 2010, 20, 4233–4248. [Google Scholar] [CrossRef]

- Han, S.; Peng, H.; Sun, Q.; Venkatesh, S.; Chung, K.; Lau, S.C.; Zhou, Y.; Roy, V.A.L. An Overview of the Development of Flexible Sensors. Adv. Mater. 2017, 29, 1700375. [Google Scholar] [CrossRef]

- Xu, Y.; Lin, Q. Photodetectors based on solution-processable semiconductors: Recent advances and perspectives. Appl. Phys. Rev. 2020, 7, 11315. [Google Scholar] [CrossRef]

- Zou, Y.; Zhang, Y.; Hu, Y.; Gu, H. Ultraviolet Detectors Based on Wide Bandgap Semiconductor Nanowire: A Review. Sensors 2018, 18, 2072. [Google Scholar] [CrossRef] [Green Version]

- Nasiri, N.; Jin, D.; Tricoli, A. Nanoarchitechtonics of Visible-Blind Ultraviolet Photodetector Materials: Critical Features and Nano-Microfabrication. Adv. Opt. Mater. 2019, 7, 1800580. [Google Scholar] [CrossRef] [Green Version]

- Shieh, J.; Lai, Y.; Ni, W.; Kuo, H.; Fang, C.; Huang, J.Y.; Pan, C. Enhanced photoresponse of a metal-oxide-semiconductor photodetector with silicon nanocrystals embedded in the oxide layer. Appl. Phys. Lett. 2007, 90, 51105. [Google Scholar] [CrossRef]

- Patel, M.; Kim, H.; Kim, J. All Transparent Metal Oxide Ultraviolet Photodetector. Adv. Electron. Mater. 2015, 1, 1500232. [Google Scholar] [CrossRef]

- Fang, Y.K.; Hwang, S.B.; Chen, K.H.; Liu, C.R.; Tsai, M.J.; Kuo, L.C. An amorphous SiC/Si heterojunction p-i-n diode for low-noise and high-sensitivity UV detector. IEEE Trans. Electron. Dev. 1992, 39, 292–296. [Google Scholar] [CrossRef]

- Chen, X.; Zhu, H.; Cai, J.; Wu, Z. High-performance 4H-SiC-based ultraviolet p-i-n photodetector. J. Appl. Phys. 2007, 102, 24505. [Google Scholar] [CrossRef]

- Luo, J.; Li, S.; Wu, H.; Zhou, Y.; Li, Y.; Liu, J.; Li, J.; Li, K.; Yi, F.; Niu, G.; et al. Cs2AgInCl6 Double Perovskite Single Crystals: Parity Forbidden Transitions and Their Application For Sensitive and Fast UV Photodetectors. ACS Photonics 2018, 5, 398–405. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, Y.; Xu, Z.; Ye, H.; Li, Q.; Hu, M.; Yang, Z.; Liu, S.F. Two-dimensional (PEA)2PbBr4 perovskite single crystals for a high performance UV-detector. J. Mater. Chem. C Mater. Opt. Electron. Devices 2019, 7, 1584–1591. [Google Scholar] [CrossRef]

- Bo, R.; Nasiri, N.; Chen, H.; Caputo, D.; Fu, L.; Tricoli, A. Low-Voltage High-Performance UV Photodetectors: An Interplay between Grain Boundaries and Debye Length. ACS Appl. Mater. Interfaces 2017, 9, 2606–2615. [Google Scholar] [CrossRef]

- Zhao, B.; Wang, F.; Chen, H.; Zheng, L.; Su, L.; Zhao, D.; Fang, X. An Ultrahigh Responsivity (9.7 mA W−1) Self-Powered Solar-Blind Photodetector Based on Individual ZnO–Ga2O3 Heterostructures. Adv. Funct Mater. 2017, 27, 1700264. [Google Scholar] [CrossRef]

- Nasiri, N.; Bo, R.; Fu, L.; Tricoli, A. Three-dimensional nano-heterojunction networks: A highly performing structure for fast visible-blind UV photodetectors. Nanoscale 2017, 9, 2059–2067. [Google Scholar] [CrossRef]

- Li, P.; Shi, H.; Chen, K.; Guo, D.; Cui, W.; Zhi, Y.; Wang, S.; Wu, Z.; Chen, Z.; Tang, W. Construction of GaN/Ga2O3 p-n junction for an extremely high responsivity self-powered UV photodetector. J. Mater. Chem. C Mater. Opt. Electron. Devices 2017, 5, 1157–1562. [Google Scholar] [CrossRef]

- Pargoletti, E.; Hossain, U.H.; Di Bernardo, I.; Chen, H.; Tran-Phu, T.; Chiarello, G.L.; Lipton-Duffin, J.; Pifferi, V.; Tricoli, A.; Cappelletti, G. Engineering of SnO2–Graphene Oxide Nanoheterojunctions for Selective Room-Temperature Chemical Sensing and Optoelectronic Devices. ACS Appl. Mater. Interfaces 2020, 12, 39549–39560. [Google Scholar] [CrossRef]

- Pargoletti, E.; Hossain, U.H.; Di Bernardo, I.; Chen, H.; Tran-Phu, T.; Lipton-Duffin, J.; Cappelletti, G.; Tricoli, A. Room-temperature photodetectors and VOC sensors based on graphene oxide–ZnO nano-heterojunctions. Nanoscale 2019, 11, 22932–22945. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S.; Pratiyush, A.S.; Dolmanan, S.B.; Tripathy, S.; Muralidharan, R.; Nath, D.N. UV detector based on InAlN/GaN-on-Si HEMT stack with photo-to-dark current ratio > 107. Appl. Phys. Lett. 2017, 111, 251103. [Google Scholar] [CrossRef] [Green Version]

- Dang, V.Q.; Trung, T.Q.; Duy, L.T.; Kim, B.; Siddiqui, S.; Lee, W.; Lee, N. High-Performance Flexible Ultraviolet (UV) Phototransistor Using Hybrid Channel of Vertical ZnO Nanorods and Graphene. ACS Appl. Mater. Interfaces 2015, 7, 11032–11040. [Google Scholar] [CrossRef] [PubMed]

- Lu, M.; Weng, T.; Chen, J.; Chen, Y. Ultrahigh-gain single SnO2 nanowire photodetectors made with ferromagnetic nickel electrodes. Npg Asia Mater. 2012, 4, e26. [Google Scholar] [CrossRef]

- Sheng Pan, S.; Fung Yu, S.; Xia Zhang, Y.; Yuan Luo, Y.; Wang, S.; Min Xu, J.; Hai Li, G. Crystallite size-modulated exciton emission in SnO2 nanocrystalline films grown by sputtering. J. Appl. Phys. 2013, 113, 143104. [Google Scholar] [CrossRef] [Green Version]

- Xu, S.; Zhao, H.; Xu, Y.; Xu, R.; Lei, Y. Carrier Mobility-Dominated Gas Sensing: A Room-Temperature Gas-Sensing Mode for SnO2 Nanorod Array Sensors. ACS Appl. Mater. Interfaces 2018, 10, 13895–13902. [Google Scholar] [CrossRef]

- Yang, H.Y.; Yu, S.F.; Liang, H.K.; Lau, S.P.; Pramana, S.S.; Ferraris, C.; Cheng, C.W.; Fan, H.J. Ultraviolet Electroluminescence from Randomly Assembledn -SnO2 Nanowiresp-GaN: Mg Heterojunction. ACS Appl. Mater. Interfaces 2010, 2, 1191–1194. [Google Scholar] [CrossRef]

- Liu, R.; Chen, Y.; Wang, F.; Cao, L.; Pan, A.; Yang, G.; Wang, T.; Zou, B. Stimulated emission from trapped excitons in SnO2 nanowires. Phys. E Low-Dimens. Syst. Nanostruct. 2007, 39, 223–229. [Google Scholar] [CrossRef]

- Lin, C.; Chen, R.; Chen, T.; Chen, H.; Chen, Y.; Chen, K.; Chen, L. High photocurrent gain in SnO2 nanowires. Appl. Phys. Lett. 2008, 93, 112115. [Google Scholar] [CrossRef]

- Das Mahapatra, A.; Basak, D. Investigation on sub-band gap defects aided UV to NIR broad-band low-intensity photodetection by SnO2 thin film. Sens. Actuators A Phys. 2020, 312, 112168. [Google Scholar] [CrossRef]

- Bouznit, Y.; Henni, A. Characterization of Sb doped SnO2 films prepared by spray technique and their application to photocurrent generation. Mater. Chem. Phys. 2019, 233, 242–248. [Google Scholar] [CrossRef]

- Wu, J.; Kuo, C. Ultraviolet photodetectors made from SnO2 nanowires. Thin Solid Films 2009, 517, 3870–3873. [Google Scholar] [CrossRef]

- Lou, Z.; Yang, X.; Chen, H.; Liang, Z. Flexible ultraviolet photodetectors based on ZnO–SnO2 heterojunction nanowire arrays. J. Semicond. 2018, 39, 24002. [Google Scholar] [CrossRef]

- Chen, Y.; Zhu, C.; Cao, M.; Wang, T. Photoresponse of SnO2 nanobelts grown in situ on interdigital electrodes. Nanotechnology 2007, 18, 285502. [Google Scholar] [CrossRef]

- Kaur, D.; Kumar, M. A Strategic Review on Gallium Oxide Based Deep-Ultraviolet Photodetectors: Recent Progress and Future Prospects. Adv. Opt. Mater. 2021, 9, 2002160. [Google Scholar] [CrossRef]

- Huang, C.; Li, W.; Hsiao, Y.; Gao, W.; Chen, C. Trap-assisted photomultiplication in a-IGZO/p-Si heterojunction ultraviolet photodiodes. Smart Mater. Struct. 2020, 29, 115019. [Google Scholar] [CrossRef]

- Creeden, J.A.; Madaras, S.E.; Beringer, D.B.; Novikova, I.; Lukaszew, R.A. Growth and Characterization of Vanadium Dioxide/Niobium Doped Titanium Dioxide Heterostructures for Ultraviolet Detection. Adv. Opt. Mater. 2019, 7, 1901143. [Google Scholar] [CrossRef]

- Teng, F.; Hu, K.; Ouyang, W.; Fang, X. Photoelectric Detectors Based on Inorganic p-Type Semiconductor Materials. Adv. Mater. 2018, 30, 1706262. [Google Scholar] [CrossRef]

- Konstantatos, G.; Badioli, M.; Gaudreau, L.; Osmond, J.; Bernechea, M.; de Arquer FP, G.; Gatti, F.; Koppens, F.H.L. Hybrid graphene–quantum dot phototransistors with ultrahigh gain. Nat. Nanotechnol. 2012, 7, 363–368. [Google Scholar] [CrossRef]

- McIntyre, R.J. Recent developments in silicon avalanche photodiodes. Measurement 1985, 3, 146–152. [Google Scholar] [CrossRef]

- Zhai, T.; Fang, X.; Liao, M.; Xu, X.; Zeng, H.; Yoshio, B.; Golberg, D. A Comprehensive Review of One-Dimensional Metal-Oxide Nanostructure Photodetectors. Sensors 2009, 9, 6504–6529. [Google Scholar] [CrossRef] [PubMed]

- Kim, W.; Chu, K.S. ZnO nanowire field-effect transistor as a UV photodetector; optimization for maximum sensitivity. Phys. Status Solidi A 2009, 206, 179–182. [Google Scholar] [CrossRef]

- Lien, D.H.; Retamal, J.R.; Ke, J.J.; Kang, C.F.; He, J.H. Surface effects in metal oxide-based nanodevices. Nanoscale 2015, 7, 19874–19884. [Google Scholar] [CrossRef]

- Zheng, J.; Cheng, B.; Wu, F.; Su, X.; Xiao, Y.; Guo, R.; Lei, S. Modulation of Surface Trap Induced Resistive Switching by Electrode Annealing in Individual PbS Micro/Nanowire-Based Devices for Resistance Random Access Memory. ACS Appl. Mater. Interfaces 2014, 6, 20812–20818. [Google Scholar] [CrossRef]

- Özer, M.; Yıldız, D.E.; Altındal, Ş.; Bülbül, M.M. Temperature dependence of characteristic parameters of the Au/SnO2/n-Si (MIS) Schottky diodes. Solid-State Electron. 2007, 51, 941–949. [Google Scholar] [CrossRef]

- Hu, L.; Yan, J.; Liao, M.; Wu, L.; Fang, X. Ultrahigh External Quantum Efficiency from Thin SnO2 Nanowire Ultraviolet Photodetectors. Small 2011, 7, 1012–1017. [Google Scholar] [CrossRef] [PubMed]

- Lan, G.; Nong, J.; Jin, W.; Zhu, R.; Luo, P.; Jiang, H.; Wei, W. Enhanced UV photoresponse employing 3D graphene nanowalls/SnO2 nanocomposite film. Surf. Coat. Technol. 2019, 359, 90–96. [Google Scholar] [CrossRef]

- Tian, W.; Zhai, T.; Zhang, C.; Li, S.; Wang, X.; Liu, F.; Liu, D.; Cai, X.; Tsukagoshi, K.; Golberg, D.; et al. Low-Cost Fully Transparent Ultraviolet Photodetectors Based on Electrospun ZnO-SnO2 Heterojunction Nanofibers. Adv. Mater. 2013, 25, 4625–4630. [Google Scholar] [CrossRef]

- Hsu, C.; Lu, Y. Fabrication of a transparent ultraviolet detector by using n-type Ga2O3 and p-type Ga-doped SnO2 core-shell nanowires. Nanoscale 2012, 4, 571–5717. [Google Scholar] [CrossRef]

- Huang, S.; Wu, H.; Matsubara, K.; Cheng, J.; Pan, W. Facile assembly of n-SnO2 nanobelts–p-NiO heterojunctions with enhanced ultraviolet photoresponse. Chem. Commun. 2014, 50, 2847–2850. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Long, Z.; Xu, X.; Yang, W.; Hu, M.; Shtansky, D.V.; Golberg, D.; Fang, X. Cross-Bar SnO2-NiO Nanofiber-Array-Based Transparent Photodetectors with High Detectivity. Adv. Electron. Mater. 2020, 6, 1901048. [Google Scholar] [CrossRef]

- Zhang, W.; Chuu, C.; Huang, J.; Chen, C.; Tsai, M.; Chang, Y.; Liang, C.; Chen, Y.; Chueh, Y.; He, J.; et al. Ultrahigh-Gain Photodetectors Based on Atomically Thin Graphene-MoS2 Heterostructures. Sci. Rep. 2014, 4, 1–8. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kilic, C.; Zunger, A. Origins of coexistence of conductivity and transparency in SnO2. Phys. Rev. Lett. 2002, 88, 95501. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Samson, S.; Fonstad, C.G. Defect structure and electronic donor levels in stannic oxide crystals. J. Appl. Phys. 1973, 44, 4618–4621. [Google Scholar] [CrossRef]

- Gao, C.; Li, X.; Zhu, X.; Chen, L.; Wang, Y.; Teng, F.; Zhang, Z.; Duan, H.; Xie, E. High performance, self-powered UV-photodetector based on ultrathin, transparent, SnO2–TiO2 core–shell electrodes. J. Alloys Compd. 2014, 616, 510–515. [Google Scholar] [CrossRef]

- Hatch, S.M.; Briscoe, J.; Dunn, S. A Self-Powered ZnO-Nanorod/CuSCN UV Photodetector Exhibiting Rapid Response. Adv. Mater. 2013, 25, 867–871. [Google Scholar] [CrossRef]

- Qiao, H.; Huang, Z.; Ren, X.; Liu, S.; Zhang, Y.; Qi, X.; Zhang, H. Self-Powered Photodetectors Based on 2D Materials. Adv. Opt. Mater. 2020, 8, 1900765. [Google Scholar] [CrossRef]

- Su, L.; Yang, W.; Cai, J.; Chen, H.; Fang, X. Self-Powered Ultraviolet Photodetectors Driven by Built-In Electric Field. Small 2017, 13, 1701687. [Google Scholar] [CrossRef] [Green Version]

- Li, X.; Gao, C.; Duan, H.; Lu, B.; Pan, X.; Xie, E. Nanocrystalline TiO2 film based photoelectrochemical cell as self-powered UV-photodetector. Nano Energy 2012, 1, 640–645. [Google Scholar] [CrossRef]

- Gao, C.; Li, X.; Wang, Y.; Chen, L.; Pan, X.; Zhang, Z.; Xie, E. Titanium dioxide coated zinc oxide nanostrawberry aggregates for dye-sensitized solar cell and self-powered UV-photodetector. J. Power Sources 2013, 239, 458–465. [Google Scholar] [CrossRef]

- Mahapatra, A.D.; Basak, D. Augmented performance towards ultraviolet and visible dual-band photodetection by polyvinyl butyral coated SnO2 nanorod array film. Surf. Interfaces 2021, 26, 101342. [Google Scholar] [CrossRef]

- Kumar, A.; Rout, L.; Dhaka, R.S.; Samal, S.L.; Dash, P. Design of a graphene oxide-SnO2 nanocomposite with superior catalytic efficiency for the synthesis of β-enaminones and β-enaminoesters. Rsc Adv. 2015, 5, 39193–39204. [Google Scholar] [CrossRef]

- Bonaccorso, F.; Sun, Z.; Hasan, T.; Ferrari, A.C. Graphene photonics and optoelectronics. Nat. Photonics 2010, 4, 611–622. [Google Scholar] [CrossRef] [Green Version]

- Park, J.; Ahn, Y.H.; Ruiz-Vargas, C. Imaging of Photocurrent Generation and Collection in Single-Layer Graphene. Nano Lett. 2009, 9, 1742–1746. [Google Scholar] [CrossRef]

- Shen, H.; Zhao, X.; Duan, L.; Liu, R.; Wu, H.; Hou, T.; Jiang, X.; Gao, H. Influence of interface combination of RGO-photosensitized SnO2@RGO core-shell structures on their photocatalytic performance. Appl. Surf. Sci. 2017, 391, 627–634. [Google Scholar] [CrossRef]

- Singh, M.K.; Pandey, R.K.; Prakash, R. High-performance photo detector based on hydrothermally grown SnO2 nanowire/reduced graphene oxide (rGO) hybrid material. Org. Electron. 2017, 50, 359–366. [Google Scholar] [CrossRef]

- Nong, J.; Wei, W.; Song, X.; Tang, L.; Yang, J.; Sun, T.; Yu, L.; Luo, W.; Li, C.; Wei, D. Direct growth of graphene nanowalls on silica for high-performance photo-electrochemical anode. Surf. Coat. Technol. 2017, 320, 579–583. [Google Scholar] [CrossRef]

- Tang, W.; Wang, J.; Qiao, Q.; Liu, Z.; Li, X. Mechanism for acetone sensing property of Pd-loaded SnO2 nanofibers prepared by electrospinning: Fermi-level effects. J. Mater. Sci. 2015, 50, 2605–2615. [Google Scholar] [CrossRef]

- Fan, Z.; Ho, J.C.; Jacobson, Z.A.; Yerushalmi, R.; Alley, R.L.; Razavi, H.; Javey, A. Wafer-Scale Assembly of Highly Ordered Semiconductor Nanowire Arrays by Contact Printing. Nano Lett. 2008, 8, 20–25. [Google Scholar] [CrossRef] [Green Version]

- Park, J.; Kim, Y.; Kim, G.; Ha, J.S. Facile Fabrication of SWCNT/SnO2 Nanowire Heterojunction Devices on Flexible Polyimide Substrate. Adv. Funct. Mater. 2011, 21, 4159–4165. [Google Scholar] [CrossRef]

- Deng, K.; Lu, H.; Shi, Z.; Liu, Q.; Li, L. Flexible Three-Dimensional SnO2 Nanowire Arrays: Atomic Layer Deposition-Assisted Synthesis, Excellent Photodetectors, and Field Emitters. ACS Appl. Mater. Interfaces 2013, 5, 7845–7851. [Google Scholar] [CrossRef]

- Li, Y.; Huang, W.; Liu, H.; Wang, J.; Tian, L.; Zhang, S. UV photodetector based on polycrystalline SnO2 nanotubes by electrospinning with enhanced performance. J. Nanopart. Res. 2018, 20, 1–2. [Google Scholar] [CrossRef]

- Jiang, J.; Heck, F.; Hofmann, D.M.; Eickhoff, M. Synthesis of SnO2 Nanowires Using SnI2 as Precursor and Their Application as High-Performance Self-Powered Ultraviolet Photodetectors. Phys. Status Solidi B 2018, 255, 1700426. [Google Scholar] [CrossRef]

- Wang, S.; Zhao, J.; Tong, T.; Cheng, B.; Xiao, Y.; Lei, S. Bias-Controlled Tunable Electronic Transport with Memory Characteristics in an Individual ZnO Nanowire for Realization of a Self-Driven UV Photodetector with Two Symmetrical Electrodes. ACS Appl. Mater. Interfaces 2019, 11, 14932–14943. [Google Scholar] [CrossRef]

- Gupta, A.A.; Arunachalam, S.; Cloutier, S.G.; Izquierdo, R. Fully Aerosol-Jet Printed, High-Performance Nanoporous ZnO Ultraviolet Photodetectors. ACS Photonics 2018, 5, 3923–3929. [Google Scholar] [CrossRef]

- Li, L.; Zhang, Y.; Fang, X.; Zhai, T.; Liao, M.; Sun, X.; Koide, Y.; Bando, Y.; Golberg, D. WO3 nanowires on carbon papers: Electronic transport, improved ultraviolet-light photodetectors and excellent field emitters. J. Mater. Chem. 2011, 21, 6525. [Google Scholar] [CrossRef]

- Kim, D.; Shin, G.; Yoon, J.; Jang, D.; Lee, S.; Zi, G.; Ha, J.S. High performance stretchable UV sensor arrays of SnO2 nanowires. Nanotechnology 2013, 24, 315502. [Google Scholar] [CrossRef] [PubMed]

- Huang, S.; Guo, C.F.; Zhang, X.; Pan, W.; Luo, X.; Zhao, C.; Gong, J.; Li, X.; Ren, Z.F.; Wu, H. Buckled Tin Oxide Nanobelt Webs as Highly Stretchable and Transparent Photosensors. Small 2015, 11, 5712–5718. [Google Scholar] [CrossRef]

- Mallick, H.K.; Zhang, Y.; Pradhan, J.; Sahoo MP, K.; Pattanaik, A.K. Influence of particle size and defects on the optical, magnetic and electronic properties of Al doped SnO2 nanoparticles. J. Alloys Compd. 2021, 854, 156067. [Google Scholar] [CrossRef]

- Shahid, M.; Wang, Y.; Yang, J.; Li, T.; Xing, Y.; Cheng, J.; Zhang, M.; Wan, C.; Pan, W. Indium-doped SnO2 nanobelts for high-performance transparent and flexible photosensors by a facile assembly. Nanotechnology 2017, 28, 335705. [Google Scholar] [CrossRef]

- Ogawa, H.; Nishikawa, M.; Abe, A. Hall measurement studies and an electrical conduction model of tin oxide ultrafine particle films. J. Appl. Phys. 1982, 53, 4448–4455. [Google Scholar] [CrossRef]

- Mathur, S.; Barth, S.; Shen, H.; Pyun, J.; Werner, U. Size-Dependent Photoconductance in SnO2 Nanowires. Small 2005, 1, 713–717. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Liu, X.; Ning, H.; Yuan, W.; Deng, Y.; Zhang, X.; Wang, S.; Wang, J.; Yao, R.; Peng, J. Characterization studies of the structure and properties of Zr-doped SnO2 thin films by spin-coating technique. Superlattices Microstruct. 2018, 123, 330–337. [Google Scholar] [CrossRef]

- Tiwari, N.; Nirmal, A.; Kulkarni, M.R.; John, R.A.; Mathews, N. Enabling high performance n-type metal oxide semiconductors at low temperatures for thin film transistors. Inorg. Chem. Front. 2020, 7, 1822–1844. [Google Scholar] [CrossRef]

- Zhang, Y. Electronegativities of elements in valence states and their applications. 1. Electronegativities of elements in valence states. Inorg. Chem. 1982, 21, 3886–3889. [Google Scholar] [CrossRef]

- Chetri, P.; Dhar, J.C. Self-powered UV detection using SnO2 nanowire arrays with Au Schottky contact. Mater. Sci. Semicond. Process. 2019, 100, 123–129. [Google Scholar] [CrossRef]

- Li, S.; Wang, S.; Liu, K.; Zhang, N.; Zhong, Z.; Long, H.; Fang, G. Self-powered blue-sensitive photodetector based on PEDOT: PSS/SnO2 microwires organic/inorganic p–n heterojunction. Appl. Phys. A 2015, 119, 1561–1566. [Google Scholar] [CrossRef]

- Chen, H.; Hu, L.; Fang, X.; Wu, L. General Fabrication of Monolayer SnO2 Nanonets for High-Performance Ultraviolet Photodetectors. Adv. Funct. Mater. 2012, 22, 1229–1235. [Google Scholar] [CrossRef]

- Wu, Y.; Sun, X.; Jia, Y.; Li, D. Review of improved spectral response of ultraviolet photodetectors by surface plasmon. Chin. Phys. B 2018, 27, 126101. [Google Scholar] [CrossRef]

- Huang, Y.; Lin, J.; Li, L.; Xu, L.; Wang, W.; Zhang, J.; Xu, X.; Zou, J.; Tang, C. High performance UV light photodetectors based on Sn-nanodot-embedded SnO2 nanobelts. J. Mater. Chem. C 2015, 3, 5253–5258. [Google Scholar] [CrossRef]

- Rieu, M.; Camara, M.; Tournier, G.; Viricelle, J.; Pijolat, C.; de Rooij, N.F.; Briand, D. Fully inkjet printed SnO2 gas sensor on plastic substrate. Sens. Actuators B Chem. 2016, 236, 1091–1097. [Google Scholar] [CrossRef] [Green Version]

- Devabharathi, N.; Umarji, A.M.; Dasgupta, S. Fully Inkjet-Printed Mesoporous SnO2-Based Ultrasensitive Gas Sensors for Trace Amount NO2 Detection. ACS Appl. Mater. Interfaces 2020, 12, 57207–57217. [Google Scholar] [CrossRef]

- Shen, W. Properties of SnO2 based gas-sensing thin films prepared by ink-jet printing. Sens. Actuators B Chem. 2012, 166–167, 110–116. [Google Scholar] [CrossRef]

- Huang, S.; Matsubara, K.; Cheng, J.; Li, H.; Pan, W. Highly enhanced ultraviolet photosensitivity and recovery speed in electrospun Ni-doped SnO2 nanobelts. Appl. Phys. Lett. 2013, 103, 141108. [Google Scholar] [CrossRef]

- Yuan, W.; Liu, X.; Fang, Z.; Ning, H.; Zhang, X.; Deng, Y.; Deng, P.; Liang, Z.; Yao, R.; Peng, J. The effect of different annealing temperature on transparent conductive SnO2 thin film by solution process. Mol. Cryst. Liq. Cryst. 2018, 676, 44–49. [Google Scholar] [CrossRef]

- Park, J.W.; Kang, B.H.; Kim, H.J. A Review of Low-Temperature Solution-Processed Metal Oxide Thin-Film Transistors for Flexible Electronics. Adv. Funct. Mater. 2020, 30, 1904632. [Google Scholar] [CrossRef]

| Structure | Material | Bias (V) | Dark Current | Detectivity (Jones) | Responsivity (A/W) | Response Time (s) | Ref. |

|---|---|---|---|---|---|---|---|

| p-i-n | SiC/Si | — | 10−11 A/cm2 | — | 0.28 | — | [13] |

| p-i-n | 4H-SiC | 5 | 2.5 pA/mm2 | — | 0.13 | — | [14] |

| MSM | Cs2AgInCl6 | 5 | 10 pA | ~1012 | ∼0.013 | 0.8 ms/1 ms | [15] |

| MSM | (PEA)2PbBr4 | 10 | ~0.25 pA | 1.55 × 1013 | ~0.031 | 0.41 ms/0.37 ms | [16] |

| MSM | ZnO | 2 × 10−4 | 1.32 pA | 1.45 × 1015 | 0.014 | 250 s/150 s | [17] |

| pn junction | ZnO–Ga2O3 | 0 | ~1 nA | 6.29 × 1012 | 9.7 × 10−3 | 0.1 ns/0.9 ns | [18] |

| 3D nano- herojunction | NiO/ZnO | 1 | 18 pA | — | 13 | 5 s/9 s | [19] |

| pn junction | GaN/Ga2O3 | 0 | — | 1.23 × 1011 | 5.443 × 10−3 | 0.1 s/0.08 s | [20] |

| herojunction | SnO2/GO | 1 | 100 nA | 1.4 × 1015 | 395 | 120 s/100 s | [21] |

| herojunction | ZnO/GO | 1 | 0.18 μA | 2.6 × 1012 | ~0.3 | 160 s/190 s | [22] |

| HEMTstack | InAlN/GaN | 5 | < 32 pA | — | 32.9 | 3.6 ms/4.2 ms | [23] |

| FET | ZnO NRs | 5 | — | — | 2.5 × 106 | — | [24] |

| Material | Transparency (380–780 nm) | Flexible/Substrate | Dark Current | Responsivity (A/W) | Response Time | Ref. |

|---|---|---|---|---|---|---|

| ZnO/SnO2 NFs | >80% | — | 1.7 pA | — | 32.2 s/7.8 s | [49] |

| SnO2 NBs/NiO | >60% | — | — | — | 17 s/9 s | [51] |

| SnO2-NiO NFs | >85% | — | — | 8.67 | 8 s/— | [52] |

| SnO2 NS-TiO2 | >60% | — | — | 0.6 | 20 ms/4 ms | [56] |

| SnO2 NW/rGO | >30% | — | 2 nA | — | — | [67] |

| SWCNT/SnO2 NW | — | PI substrate | — | — | — | [71] |

| SnO2 NWAs | — | carbon cloth | 2.3 pA | — | < 0.3 s | [72] |

| SnO2 NW device array | — | 23% pre-strain | 2 pA | — | 40 s/10 s | [78] |

| SnO2 nanowebs | >70% | 160% tensile strain | — | — | 12 s/18 s | [79] |

| In-SnO2 NB | — | 0.83% strain | 4.7 nA | — | —/<0.175 s | [81] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ye, Q.; Zhang, X.; Yao, R.; Luo, D.; Liu, X.; Zou, W.; Guo, C.; Xu, Z.; Ning, H.; Peng, J. Research and Progress of Transparent, Flexible Tin Oxide Ultraviolet Photodetector. Crystals 2021, 11, 1479. https://doi.org/10.3390/cryst11121479

Ye Q, Zhang X, Yao R, Luo D, Liu X, Zou W, Guo C, Xu Z, Ning H, Peng J. Research and Progress of Transparent, Flexible Tin Oxide Ultraviolet Photodetector. Crystals. 2021; 11(12):1479. https://doi.org/10.3390/cryst11121479

Chicago/Turabian StyleYe, Qiannan, Xu Zhang, Rihui Yao, Dongxiang Luo, Xianzhe Liu, Wenxin Zou, Chenxiao Guo, Zhuohui Xu, Honglong Ning, and Junbiao Peng. 2021. "Research and Progress of Transparent, Flexible Tin Oxide Ultraviolet Photodetector" Crystals 11, no. 12: 1479. https://doi.org/10.3390/cryst11121479