High Anisotropic Thermal Conductivity, Long Durability Form-Stable Phase Change Composite Enhanced by a Carbon Fiber Network Structure

Abstract

:1. Introduction

2. Experimental

2.1. Materials

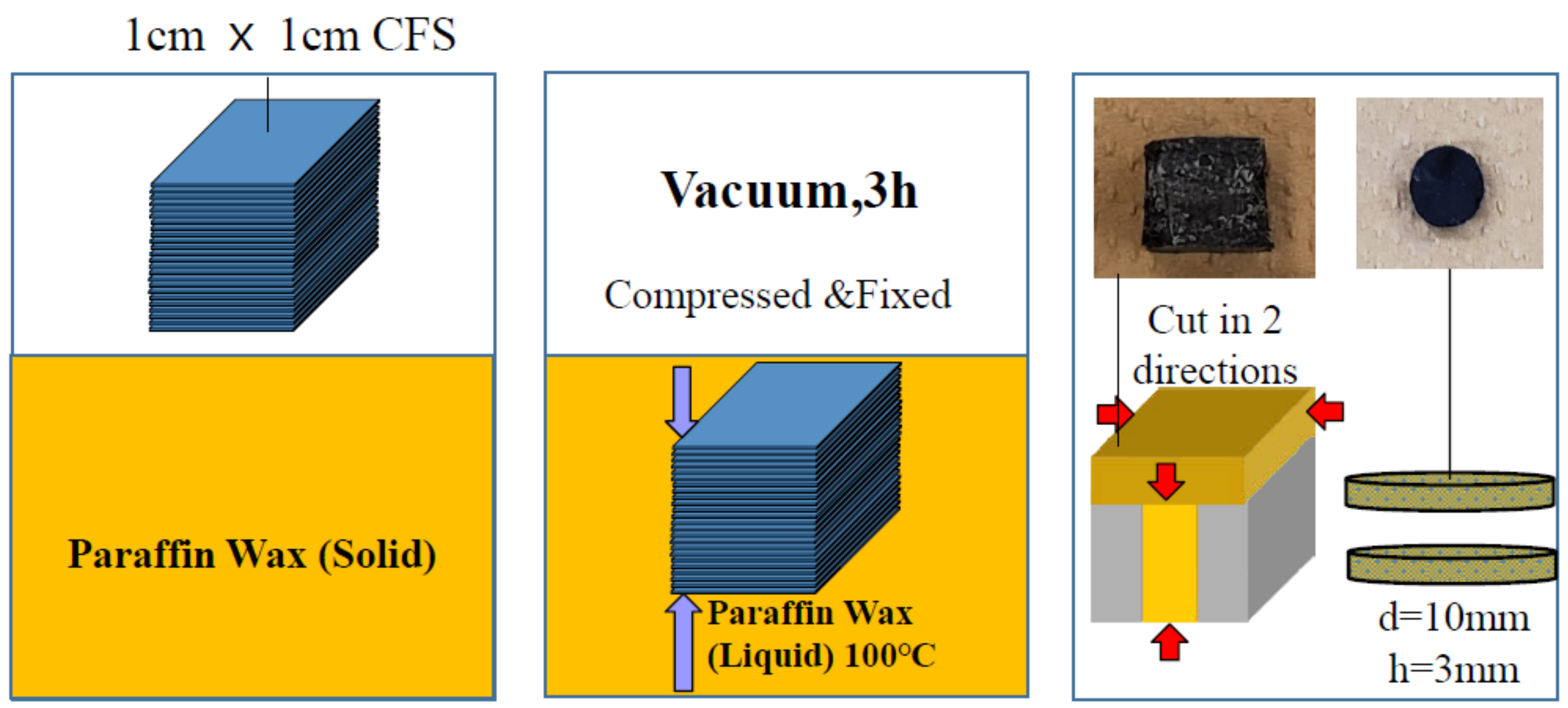

2.2. Experimental Method

2.3. Characterization

3. Results and Discussion

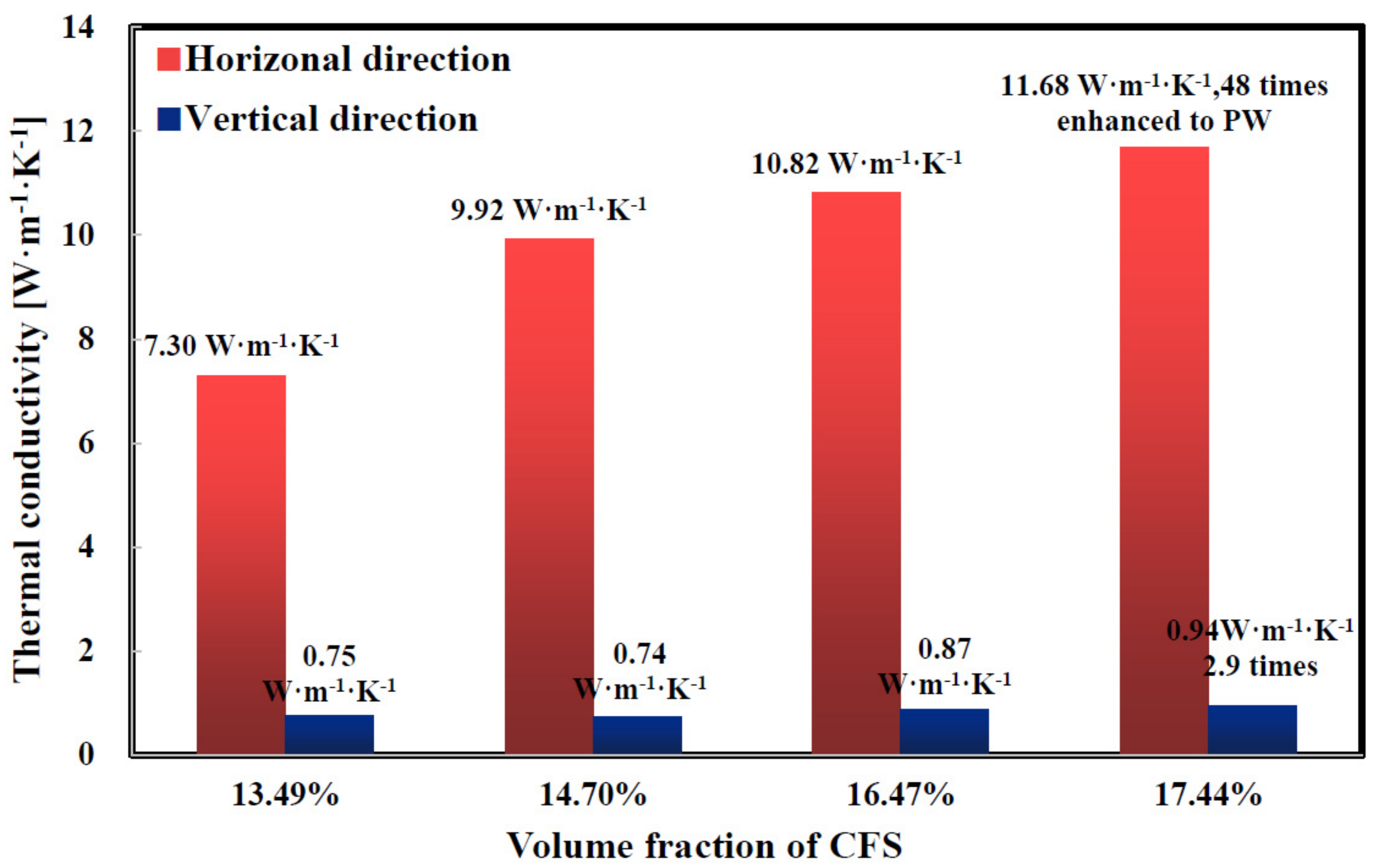

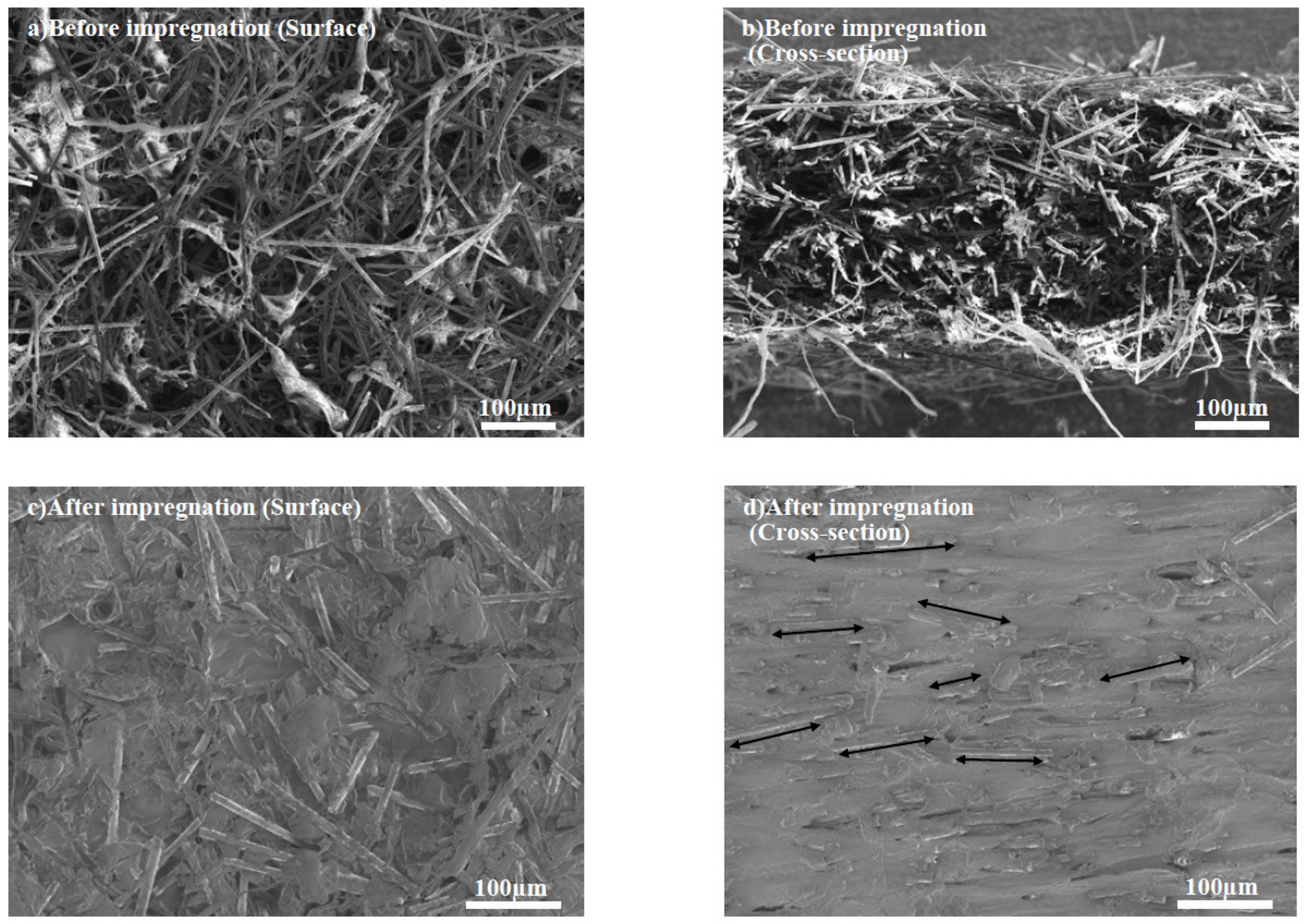

3.1. Effective Thermal Conductivity of the PCC

3.2. Durability and Form Stability of the PCC

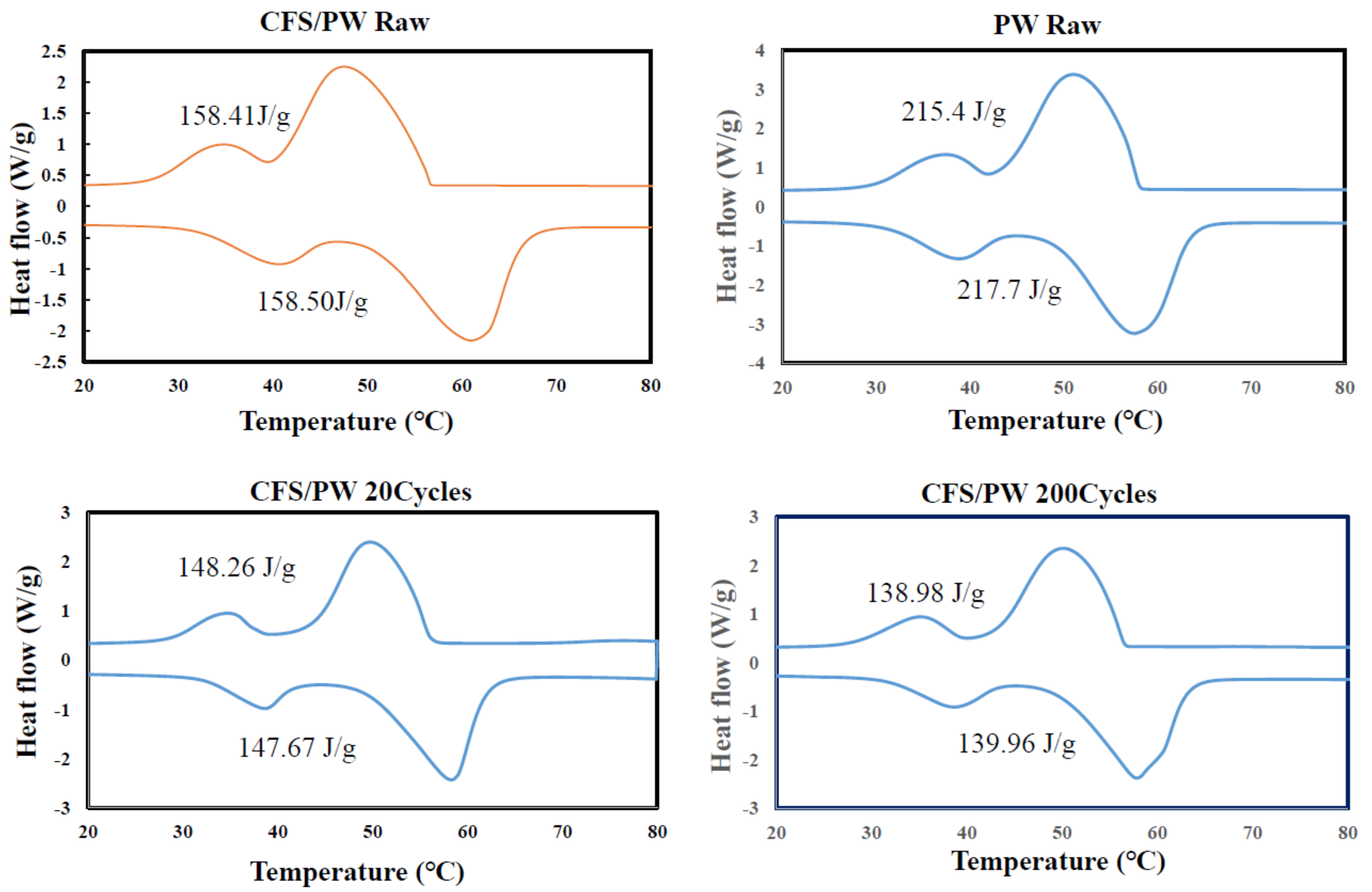

3.3. Thermal Properties of the PCC

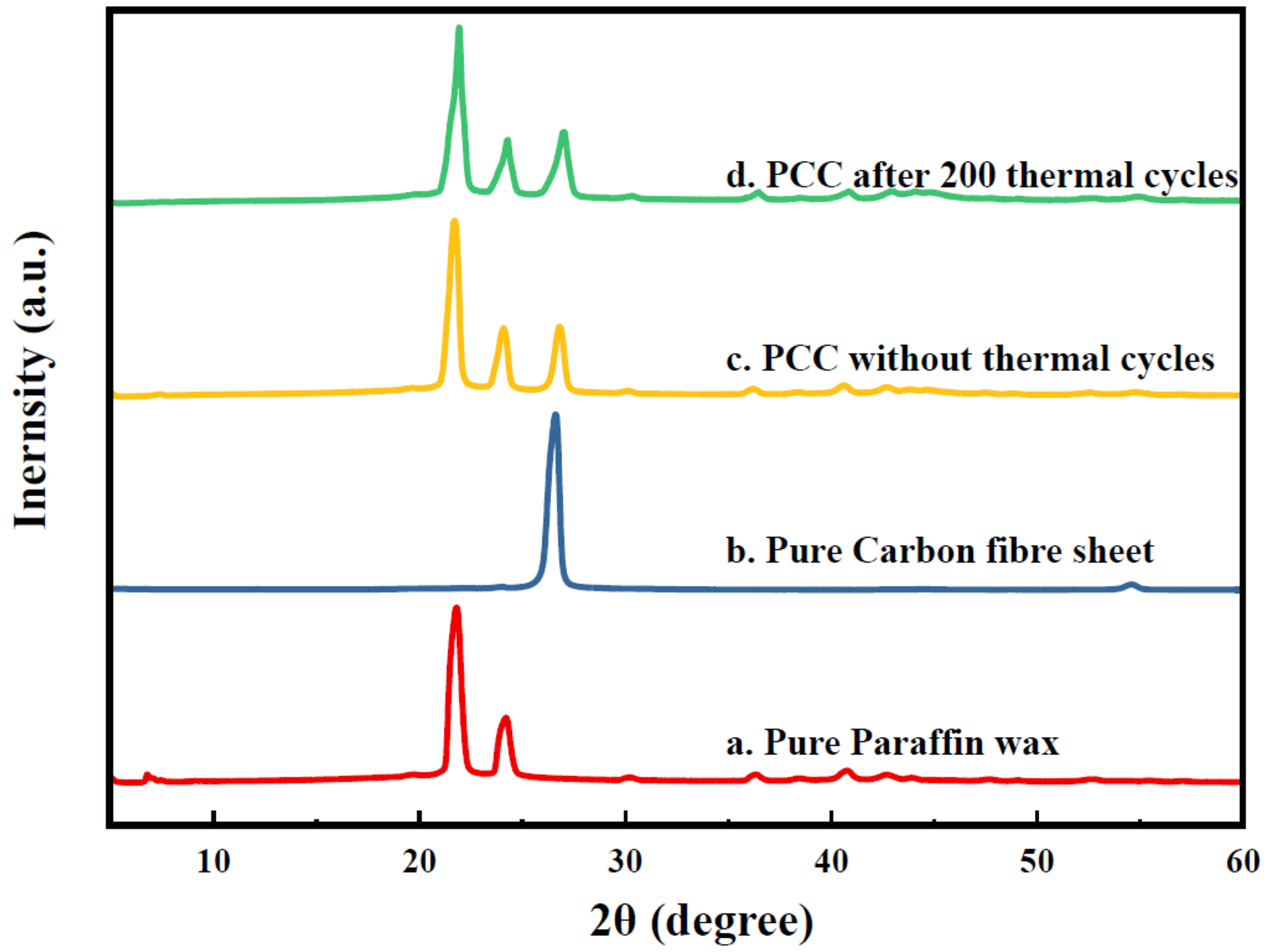

3.4. Chemical Stability of the PCC

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gökgöz, F.; Güvercin, M.T. Energy security and renewable energy efficiency in EU. Renew. Sustain. Energy Rev. 2018, 96, 226–239. [Google Scholar] [CrossRef]

- Hasnain, S.M. Review on sustainable thermal energy storage technologies, Part I: Heat storage materials and techniques. Energy Convers. Manag. 1998, 39, 1127–1138. [Google Scholar] [CrossRef]

- Sarı, A.; Bicer, A.; Al-Ahmed, A.; Al-Sulaiman, F.A.; Zahir, M.H.; Mohamed, S.A. Silica fume/capric acid-palmitic acid composite phase change material doped with CNTs for thermal energy storage. Sol. Energy Mater. Sol. Cells 2018, 179, 353–361. [Google Scholar] [CrossRef]

- Fukai, J.; Hamada, Y.; Morozumi, Y.; Miyatake, O. Effect of carbon-fiber brushes on conductive heat transfer in phase change materials. Int. J. Heat Mass Transf. 2002, 45, 4781–4792. [Google Scholar] [CrossRef]

- Xu, T.; Chen, Q.; Huang, G.; Zhang, Z.; Gao, X.; Lu, S. Preparation and thermal energy storage properties of d-Mannitol/expanded graphite composite phase change material. Sol. Energy Mater. Sol. Cells 2016, 155, 141–146. [Google Scholar] [CrossRef]

- Zheng, H.; Wang, C.; Liu, Q.; Tian, Z.; Fan, X. Thermal performance of copper foam/paraffin composite phase change material. Energy Convers. Manag. 2018, 157, 372–381. [Google Scholar] [CrossRef]

- Oya, T.; Nomura, T.; Tsubota, M.; Okinaka, N.; Akiyama, T. Thermal conductivity enhancement of erythritol as PCM by using graphite and nickel particles. Appl. Therm. Eng. 2013, 61, 825–828. [Google Scholar] [CrossRef]

- Sheng, N.; Dong, K.; Zhu, C.; Akiyama, T.; Nomura, T. Thermal conductivity enhancement of erythritol phase change material with percolated aluminum filler. Mater. Chem. Phys. 2019, 229, 87–91. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, Z.; Jia, L.; Yang, L. Paraffin and paraffin/aluminum foam composite phase change material heat storage experimental study based on thermal management of Li-ion battery. Appl. Therm. Eng. 2015, 78, 428–436. [Google Scholar] [CrossRef]

- Fang, X.; Fan, L.W.; Ding, Q.; Yao, X.L.; Wu, Y.Y.; Hou, J.F.; Wang, X.; Yu, Z.T.; Cheng, G.H.; Hu, Y.C. Thermal energy storage performance of paraffin-based composite phase change materials filled with hexagonal boron nitride nanosheets. Energy Convers. Manag. 2014, 80, 103–109. [Google Scholar] [CrossRef]

- Mohamed, N.H.; Soliman, F.S.; El Maghraby, H.; Moustfa, Y.M. Thermal conductivity enhancement of treated petroleum waxes, as phase change material, by α nano alumina: Energy storage. Renew. Sustain. Energy Rev. 2017, 70, 1052–1058. [Google Scholar] [CrossRef]

- Chung, O.; Jeong, S.G.; Yu, S.; Kim, S. Thermal performance of organic PCMs/micronized silica composite for latent heat thermal energy storage. Energy Build. 2014, 70, 180–185. [Google Scholar] [CrossRef]

- Burger, N.; Laachachi, A.; Ferriol, M.; Lutz, M.; Toniazzo, V.; Ruch, D. Review of thermal conductivity in composites: Mechanisms, parameters and theory. Prog. Polym. Sci. 2016, 61, 1–28. [Google Scholar] [CrossRef]

- Park, J.G.; Cheng, Q.; Lu, J.; Bao, J.; Li, S.; Tian, Y.; Liang, Z.; Zhang, C.; Wang, B. Thermal conductivity of MWCNT/epoxy composites: The effects of length, alignment and functionalization. Carbon 2012, 50, 2083–2090. [Google Scholar] [CrossRef]

- Nomura, T.; Tabuchi, K.; Zhu, C.; Sheng, N.; Wang, S.; Akiyama, T. High thermal conductivity phase change composite with percolating carbon fiber network. Appl. Energy 2015, 154, 678–685. [Google Scholar] [CrossRef] [Green Version]

- Yang, J.; Tang, L.S.; Bao, R.Y.; Bai, L.; Liu, Z.Y.; Xie, B.H.; Yang, M.B.; Yang, W. Hybrid network structure of boron nitride and graphene oxide in shape-stabilized composite phase change materials with enhanced thermal conductivity and light-to-electric energy conversion capability. Sol. Energy Mater. Sol. Cells 2018, 174, 56–64. [Google Scholar] [CrossRef]

- Wang, T.; Wang, S.; Geng, L.; Fang, Y. Enhancement on thermal properties of paraffin/calcium carbonate phase change microcapsules with carbon network. Appl. Energy 2016, 179, 601–608. [Google Scholar] [CrossRef]

- Heu, C.S.; Kim, S.W.; Lee, K.S.; Kim, D.R. Fabrication of three-dimensional metal-graphene network phase change composite for high thermal conductivity and suppressed subcooling phenomena. Energy Convers. Manag. 2017, 149, 608–615. [Google Scholar] [CrossRef]

- Jiang, Z.; Ouyang, T.; Yang, Y.; Chen, L.; Fan, X.; Chen, Y.; Li, W.; Fei, Y. Thermal conductivity enhancement of phase change materials with form-stable carbon bonded carbon fiber network. Mater. Des. 2018, 143, 177–184. [Google Scholar] [CrossRef]

- Sheng, N.; Zhu, R.; Dong, K.; Nomura, T.; Zhu, C.; Aoki, Y.; Habazaki, H.; Akiyama, T. Vertically aligned carbon fibers as supporting scaffolds for phase change composites with anisotropic thermal conductivity and good shape stability. J. Mater. Chem. A 2019, 7, 4394–4940. [Google Scholar] [CrossRef]

- Qiu, J.; Fan, X.; Shi, Y.; Zhang, S.; Jin, X.; Wang, W.; Tang, B. PEG/3D graphene oxide network form-stable phase change materials with ultrahigh filler content. J. Mater. Chem. A 2019, 7, 21371–21377. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, Y. Form-stable phase change material based on Na2CO3·10H2O-Na2HPO4·12H2O eutectic hydrated salt/expanded graphite oxide composite: The influence of chemical structures of expanded graphite oxide. Renew. Energy 2018, 115, 734–740. [Google Scholar] [CrossRef]

| Material | Density [kg·m−3] | Latent Heat [kJ·kg−1] | Specific Heat [kJ·kg−1·K−1] | Thermal Conductivity [W·m−1·K−1] |

|---|---|---|---|---|

| Paraffin wax | 0.90 | 220 | 2.259 | 0.24 |

| Carbon fiber sheet | 2.09 | - | 0.72 | > 900 |

| Specimen | Melting Point (peak) [°C] | Latent Heat (m)[kJ·kg−1] | Solidification Point (peak) [°C] | Latent Heat (s) [kJ·kg−1] |

|---|---|---|---|---|

| PCM | 57.35 | 217.70 | 50.96 | 215.40 |

| PCC | 60.54 | 158.50 | 47.24 | 158.41 |

| PCC 20 cycles | 59.90 | 147.67 | 49.46 | 148.26 |

| PCC 200 cycles | 57.58 | 139.96 | 50.09 | 138.98 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, K.; Sheng, N.; Zou, D.; Wang, C.; Yi, X.; Nomura, T. High Anisotropic Thermal Conductivity, Long Durability Form-Stable Phase Change Composite Enhanced by a Carbon Fiber Network Structure. Crystals 2021, 11, 230. https://doi.org/10.3390/cryst11030230

Dong K, Sheng N, Zou D, Wang C, Yi X, Nomura T. High Anisotropic Thermal Conductivity, Long Durability Form-Stable Phase Change Composite Enhanced by a Carbon Fiber Network Structure. Crystals. 2021; 11(3):230. https://doi.org/10.3390/cryst11030230

Chicago/Turabian StyleDong, Kaixin, Nan Sheng, Deqiu Zou, Cheng Wang, Xuemei Yi, and Takahiro Nomura. 2021. "High Anisotropic Thermal Conductivity, Long Durability Form-Stable Phase Change Composite Enhanced by a Carbon Fiber Network Structure" Crystals 11, no. 3: 230. https://doi.org/10.3390/cryst11030230

APA StyleDong, K., Sheng, N., Zou, D., Wang, C., Yi, X., & Nomura, T. (2021). High Anisotropic Thermal Conductivity, Long Durability Form-Stable Phase Change Composite Enhanced by a Carbon Fiber Network Structure. Crystals, 11(3), 230. https://doi.org/10.3390/cryst11030230