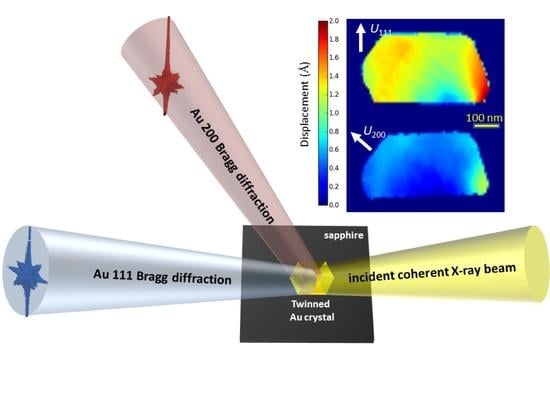

Simultaneous Multi-Bragg Peak Coherent X-ray Diffraction Imaging

Abstract

:1. Introduction

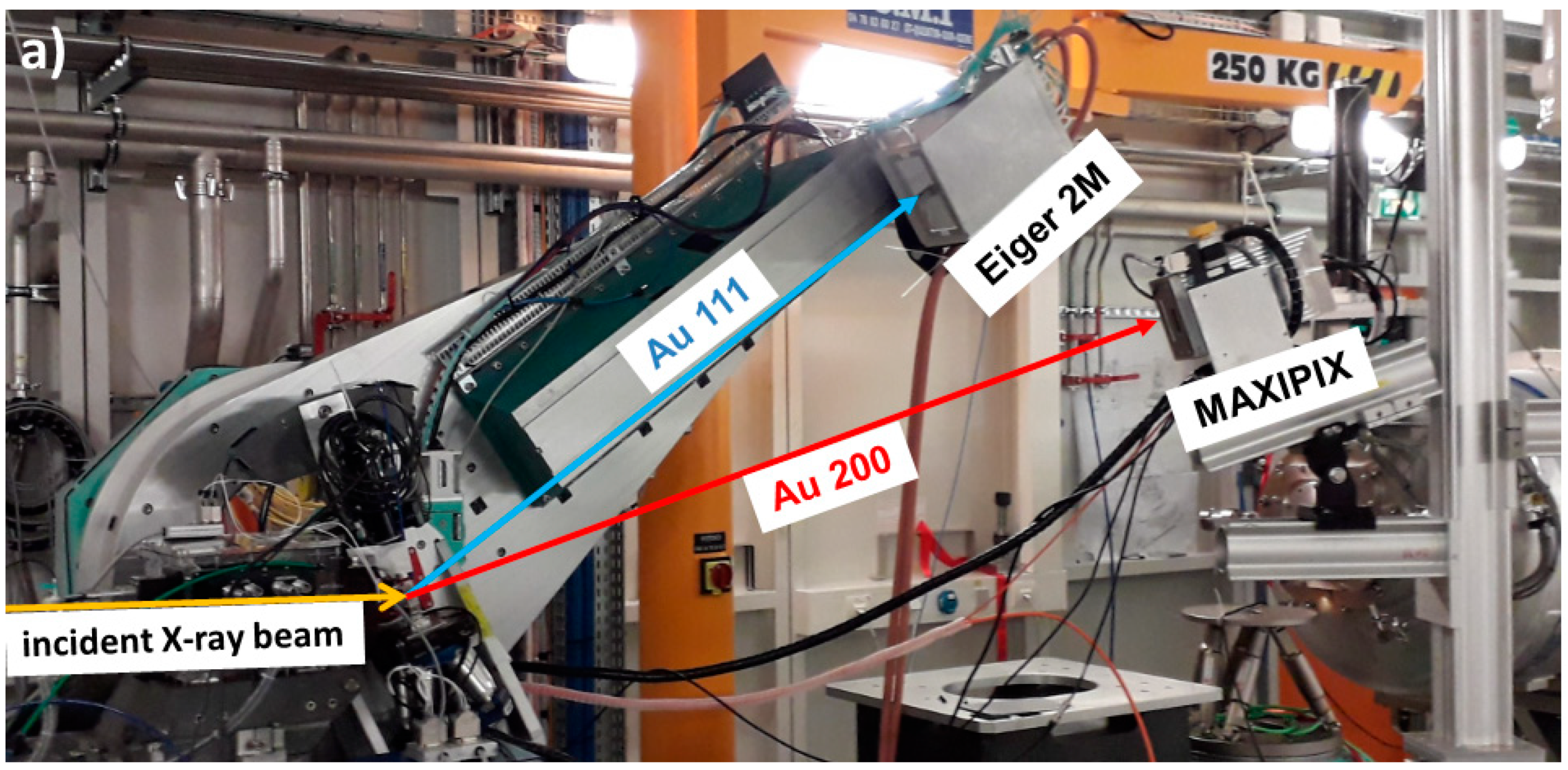

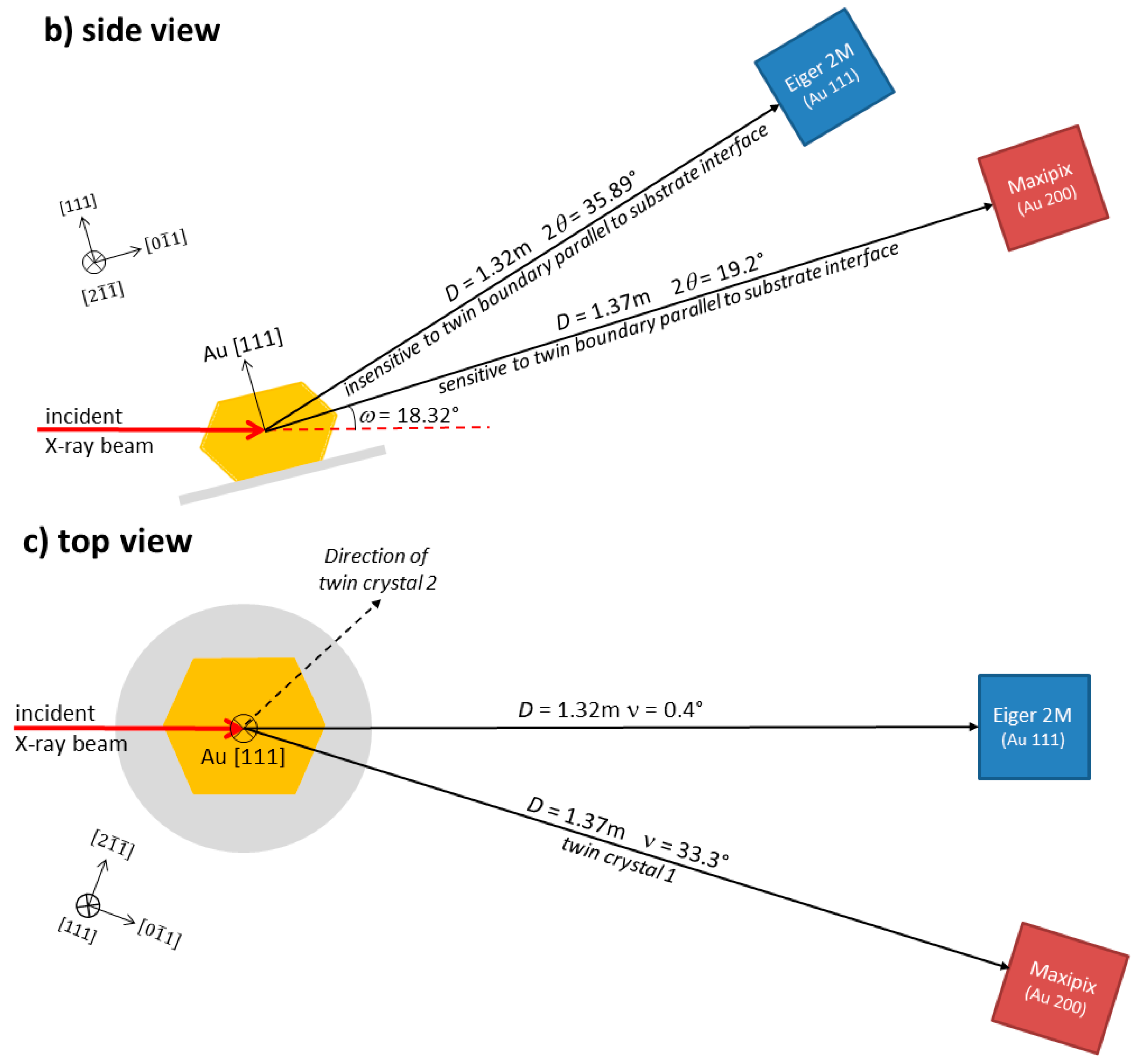

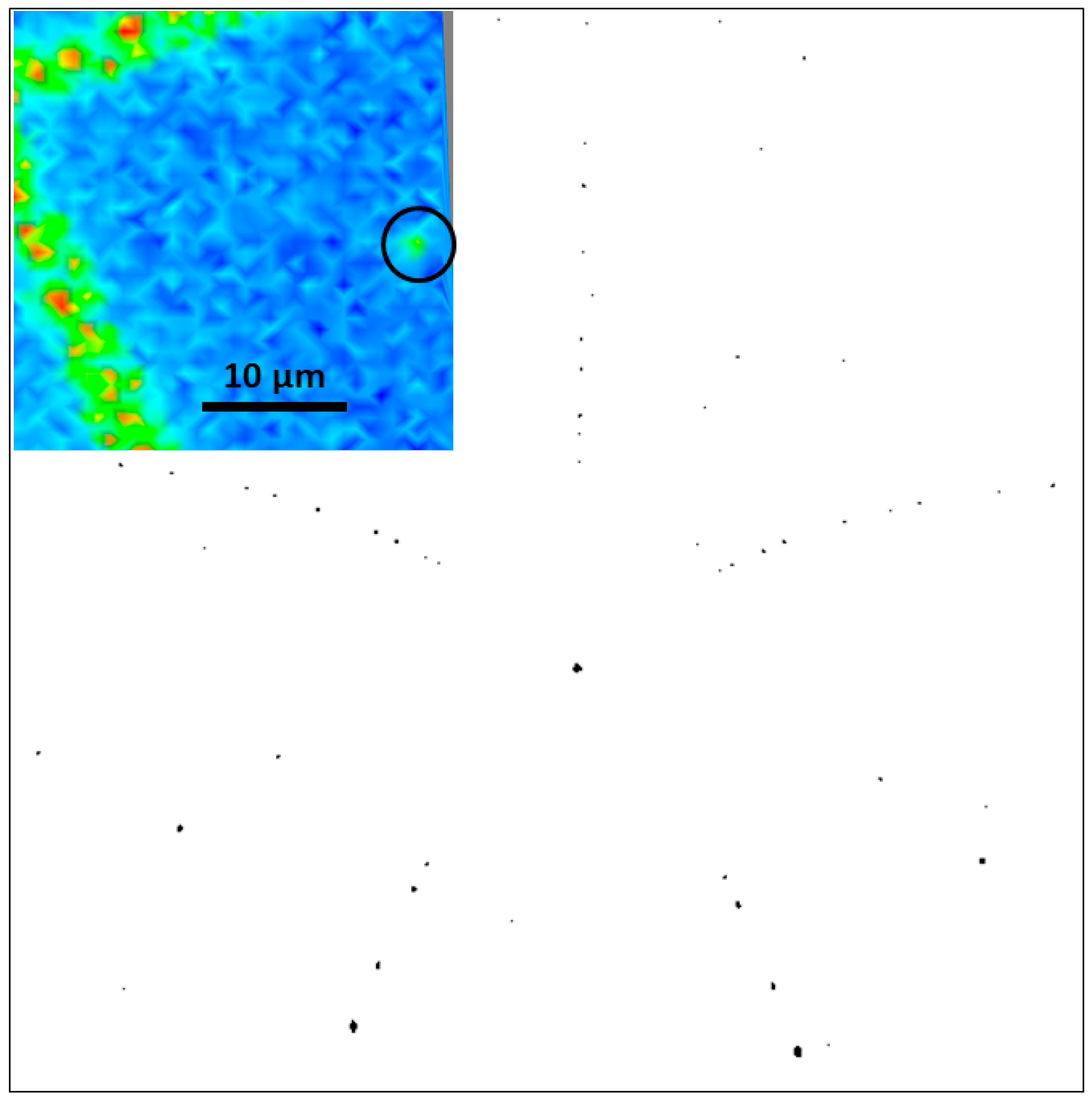

2. Materials and Methods

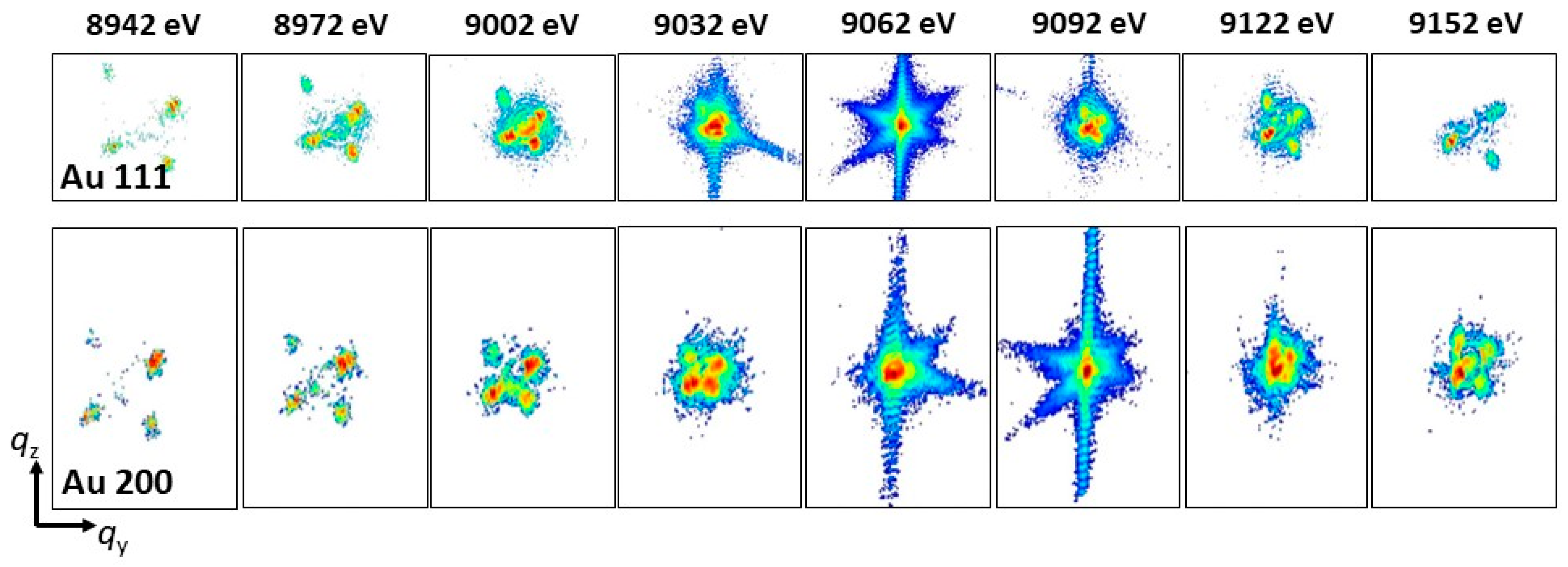

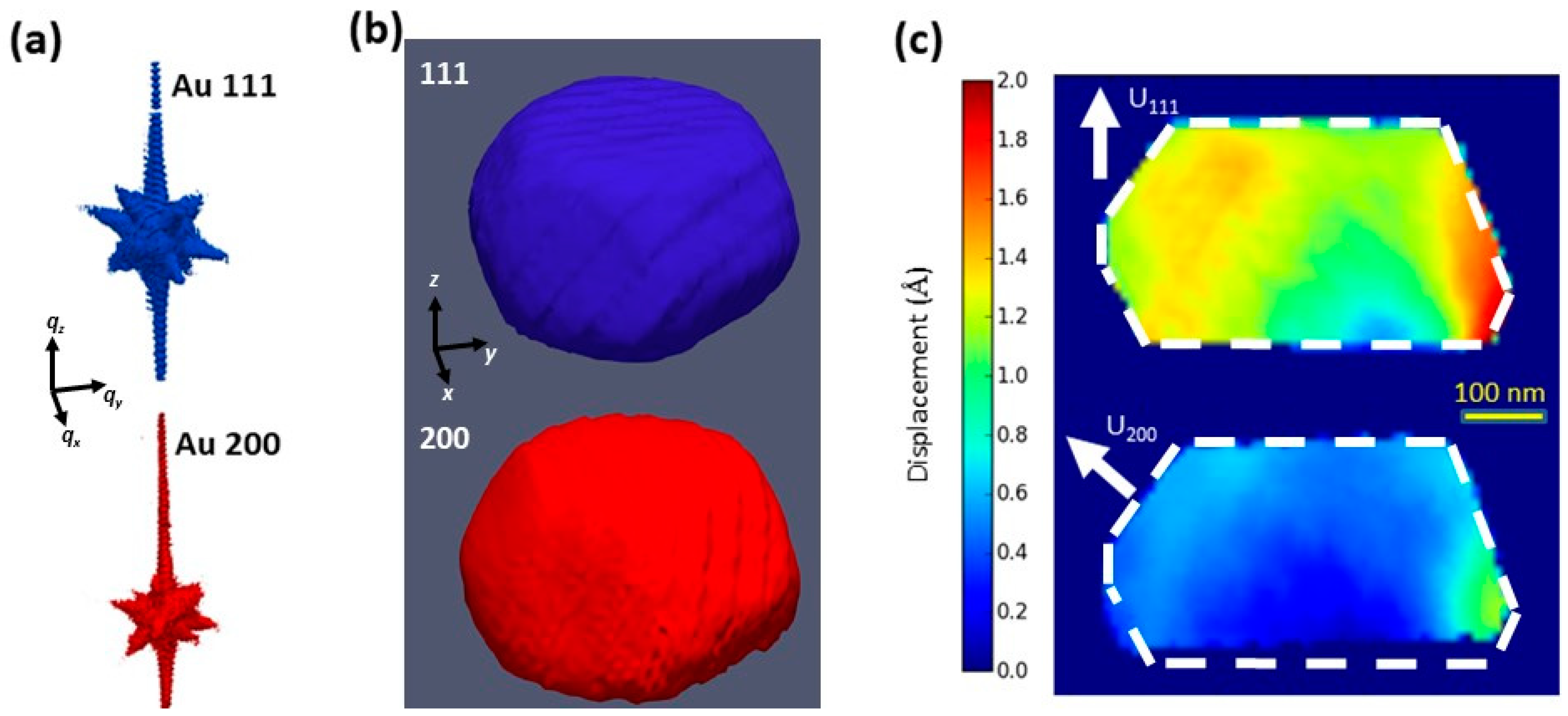

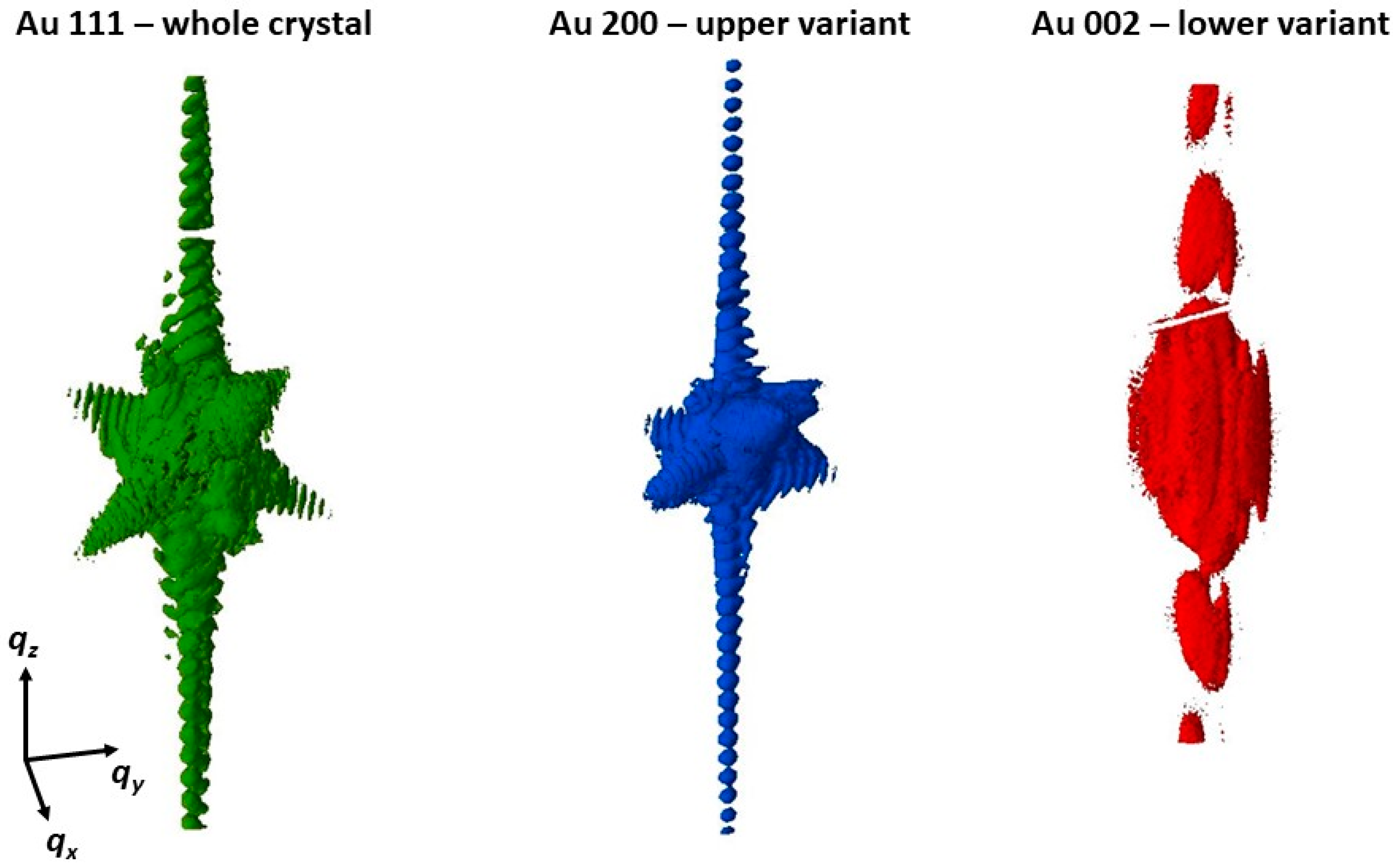

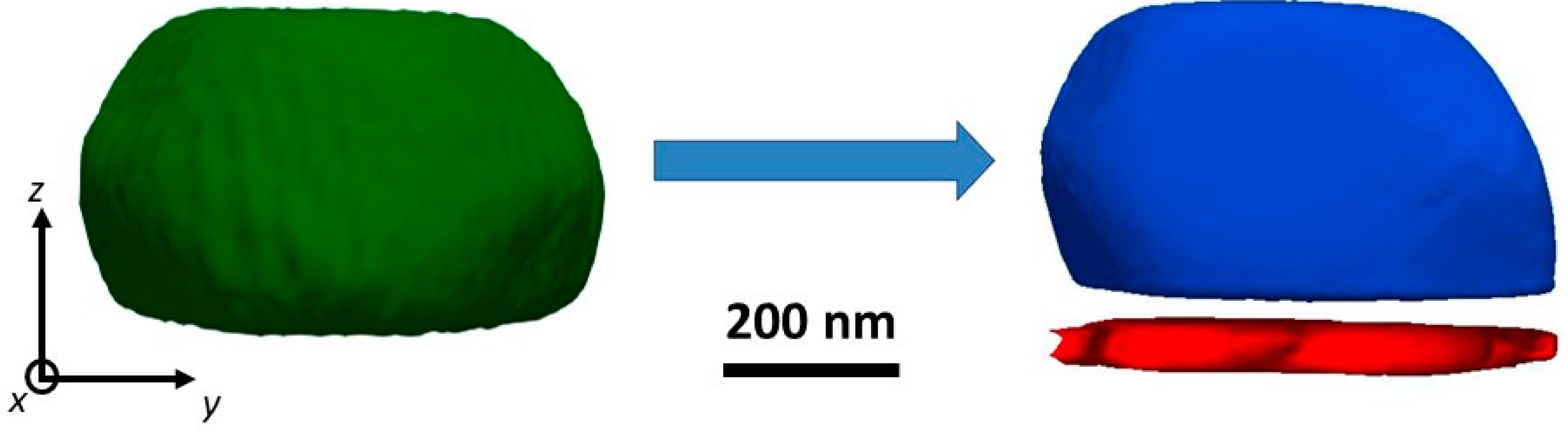

3. Results

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Fienup, J.R. Reconstruction of an object from the modulus of its Fourier transform. Opt. Lett. 1978, 3, 27–29. [Google Scholar] [CrossRef] [PubMed]

- Fienup, J.R. Phase retrieval algorithms: A comparison. Appl. Opt. 1982, 21, 2758–2769. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Marchesini, S.; He, H.; Chapman, H.N.; Hau-Riege, S.P.; Noy, A.; Howells, M.R.; Weierstall, U.; Spence, J.C.H. X-ray image reconstruction from a diffraction pattern alone. Phys. Rev. B 2003, 68, 140101. [Google Scholar] [CrossRef] [Green Version]

- Newton, M.C.; Leake, S.J.; Harder, R.; Robinson, I.K. Three-dimensional imaging of strain in a single ZnO nanorod. Nat. Mater. 2010, 9, 120–124. [Google Scholar] [CrossRef] [PubMed]

- Labat, S.; Richard, M.-I.; Dupraz, M.; Gailhanou, M.; Beutier, G.; Verdier, M.; Mastropietro, F.; Cornelius, T.W.; Schülli, T.U.; Eymery, J.; et al. Inversion domain boundaries in GaN nanowires revealed by coherent Bragg imaging. ACS Nano 2015, 9, 9210–9216. [Google Scholar] [CrossRef] [PubMed]

- Hofmann, F.; Tarleton, E.; Harder, R.J.; Philips, N.W.; Ma, P.-W.; Clark, J.N.; Abbey, B.; Liu, W.; Beck, C.E. 3D lattice distortions and defect structures in ion-implanted nano-crystals. Sci. Rep. 2017, 7, 45993. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Choi, S.; Chung, M.; Kim, D.; Kim, S.; Yun, K.; Cha, W.; Harder, R.; Kawaguchi, T.; Liu, Y.; Ulvestad, A.; et al. In situ strain evolution on Pt nanoparticles during hydrogen peroxide decomposition. Nano Lett. 2020, 20, 8541–8548. [Google Scholar] [CrossRef] [PubMed]

- Certified Scientific Software. Available online: https://certif.com/ (accessed on 20 March 2021).

- Cha, W.; Ulvestad, A.; Allain, M.; Chamard, V.; Harder, R.; Leake, S.J.; Maser, J.; Fuoss, P.H.; Hruszekewycz, S.O. Three-dimensional variable-wavelength X-ray Bragg coherent diffraction imaging. Phys. Rev. Lett. 2016, 117, 225501. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lauraux, F.; Cornelius, T.W.; Labat, S.; Richard, M.-I.; Leake, S.; Zhou, T.; Kovalenko, O.; Rabkin, E.; Schülli, T.U.; Thomas, O. Multi-wavelength Bragg coherent X-ray diffraction imaging of Au particles. J. Appl. Cryst. 2020, 53, 170–177. [Google Scholar] [CrossRef] [Green Version]

- Micha, J.-S. LaueTools: Open Source Python Packages for X-ray MicroLaue Diffraction Analysis. 2014. Available online: https://gitlab.esrf.fr/micha/lauetools (accessed on 20 March 2021).

- Pfeiffer, F. X-ray ptychography. Nat. Photonics 2018, 12, 9–17. [Google Scholar] [CrossRef]

- Leake, S.J.; Favre-Nicolin, V.; Zatterin, E.; Richard, M.-I.; Fernandez, S.; Chahine, G.; Zhou, T.; Boesecke, P.; Djazouli, H.; Schülli, T.U. Coherent nanoscale X-ray probe for crystal interrogation at ID01, ESRF—The European Synchrotron. Mater. Des. 2017, 119, 470–471. [Google Scholar] [CrossRef]

- Mandula, O.; Aizarna, M.E.; Eymery, J.; Burghammer, M.; Favre-Nicolin, V. PyNX.Ptycho: A computing library for X-ray coherent diffraction imaging of nanostructures. J. Appl. Cryst. 2016, 49, 1842. [Google Scholar] [CrossRef]

- Cornelius, T.W.; Davydok, A.; Jacques, V.L.R.; Grifone, R.; Schülli, T.; Richard, M.-I.; Beutier, G.; Verdier, M.; Metzger, T.H.; Pietsch, U.; et al. In situ 3D reciprocal space mapping during mechanical deformation. J. Synchrotron Radiat. 2012, 19, 688–694. [Google Scholar] [CrossRef] [PubMed]

- Amram, D.; Klinger, L.; Rabkin, E. Anisotropic hole growth during solid-state dewetting of single crystal Au-Fe thin films on sapphire. Acta Mater. 2012, 60, 3047–3056. [Google Scholar] [CrossRef]

- Mordehai, D.; Lee, S.-W.; Backes, B.; Srolovitz, D.J.; Nix, W.D.; Rabkin, E. Size effect in compression of single-crystal gold microparticles. Acta Mater. 2011, 59, 5202–5215. [Google Scholar] [CrossRef]

- Flanagan, T.J.; Kovalenko, O.; Rabkin, E.; Lee, S.-W. The effect of defects on strength of gold microparticles. Scr. Mater. 2019, 171, 83–86. [Google Scholar] [CrossRef]

- Casillas, G.; Palomares-Báez, J.P.; Rodríguez-López, J.L.; Luo, J.; Ponce, A.; Esparza, R.; Velázquez-Salazar, J.J.; Hurtado-Macias, A.; González-Hernández, J.; José-Yacaman, M. In situ TEM study of mechanical behaviour of twinned nanoparticles. Philos. Mag. 2012, 92, 4437–4453. [Google Scholar] [CrossRef]

- Hyde, B.; Espinosa, H.D.; Farkas, D. An atomistic investigation of elastic and plastic properties of Au nanowires. JOM 2005, 57, 62–66. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lauraux, F.; Labat, S.; Yehya, S.; Richard, M.-I.; Leake, S.J.; Zhou, T.; Micha, J.-S.; Robach, O.; Kovalenko, O.; Rabkin, E.; et al. Simultaneous Multi-Bragg Peak Coherent X-ray Diffraction Imaging. Crystals 2021, 11, 312. https://doi.org/10.3390/cryst11030312

Lauraux F, Labat S, Yehya S, Richard M-I, Leake SJ, Zhou T, Micha J-S, Robach O, Kovalenko O, Rabkin E, et al. Simultaneous Multi-Bragg Peak Coherent X-ray Diffraction Imaging. Crystals. 2021; 11(3):312. https://doi.org/10.3390/cryst11030312

Chicago/Turabian StyleLauraux, Florian, Stéphane Labat, Sarah Yehya, Marie-Ingrid Richard, Steven J. Leake, Tao Zhou, Jean-Sébastien Micha, Odile Robach, Oleg Kovalenko, Eugen Rabkin, and et al. 2021. "Simultaneous Multi-Bragg Peak Coherent X-ray Diffraction Imaging" Crystals 11, no. 3: 312. https://doi.org/10.3390/cryst11030312

APA StyleLauraux, F., Labat, S., Yehya, S., Richard, M.-I., Leake, S. J., Zhou, T., Micha, J.-S., Robach, O., Kovalenko, O., Rabkin, E., Schülli, T. U., Thomas, O., & Cornelius, T. W. (2021). Simultaneous Multi-Bragg Peak Coherent X-ray Diffraction Imaging. Crystals, 11(3), 312. https://doi.org/10.3390/cryst11030312