Reduced Statistical Representation of Crystallographic Textures Based on Symmetry-Invariant Clustering of Lattice Orientations

Abstract

:1. Introduction

2. Preliminaries

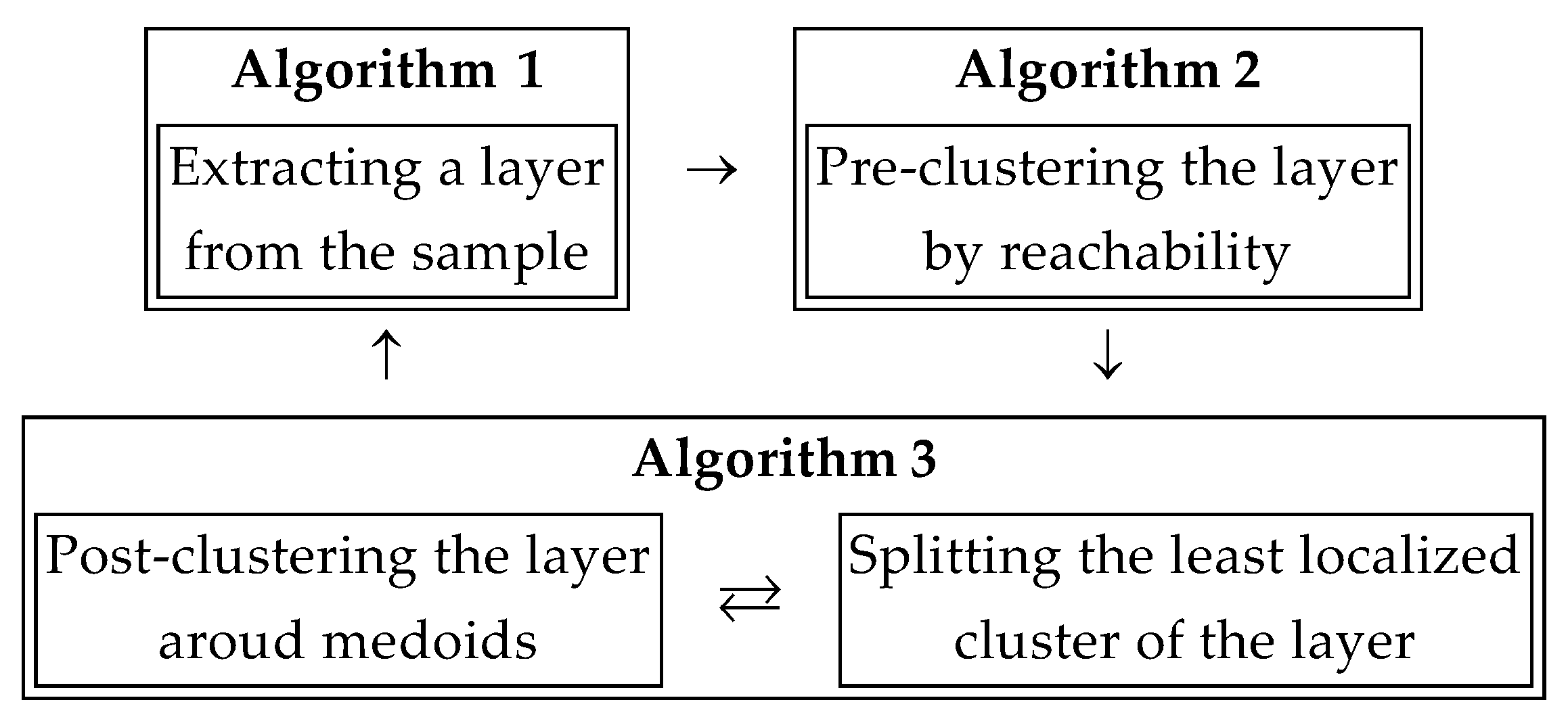

3. Crystallographic Texture Clustering

| Algorithm 1. Extracting a layer from a sample. | |

| Parameters: | |

| • , the index set defining the sample of orientations; | |

| • , the radius of pseudometric neighborhoods used in mollifying; | |

| • , the total fraction of the sample orientations in a neighborhood above which its content should be included in the layer. | |

| 1. For each sample orientation, add the indexes of other sample orientations within its neighborhood to a set: | |

| . | (16) |

| 2. For each sample orientation, calculate its weight, i.e., the total fraction of the sample orientations within its neighborhood: | |

| . | (17) |

| 3. Add the indexes of the sample orientations within sufficiently dense neighborhoods to a set: | |

| (18) | |

| Algorithm 2. Pre-clustering a layer by reachability. |

| Parameters: |

| • , the pseudometric distance between two orientations equal or below which they are considered as adjacent ones. |

| 1. Add the index pairs for close orientations within the layer to a set (of edges): (20) |

| 2. Divide the graph into the maximal connected subgraphs . |

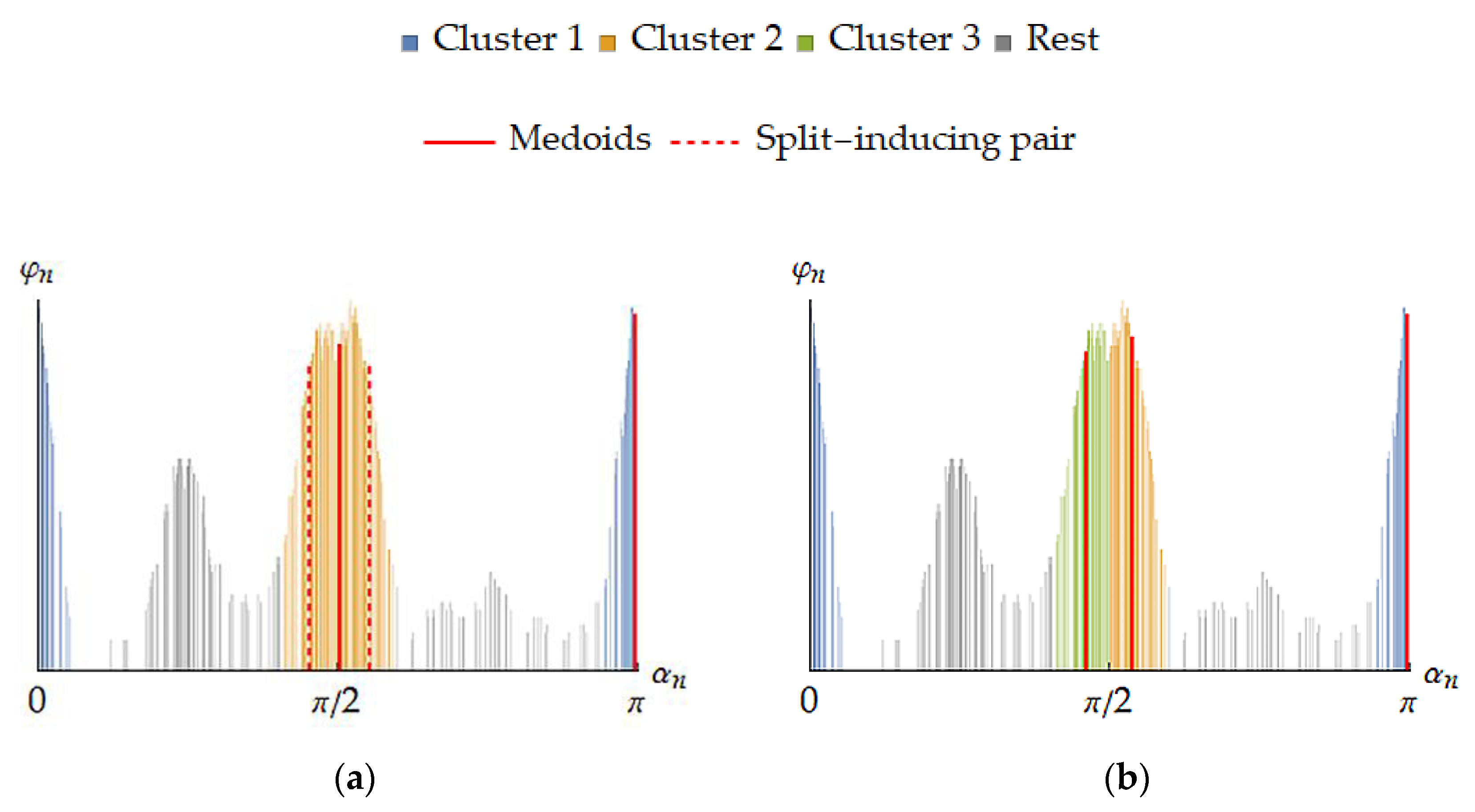

| Algorithm 3. Post-clustering a layer around medoids and splitting the least localized clusters. | |

| • δ, the mean pseudometric deviation of cluster orientations from the medoid equal or above which the cluster should be split. | |

| 1. For each initial cluster, find its medoid: | |

| (25) | |

| 2. For each current medoid, update the corresponding cluster by reassigning orientations to which this medoid is the closest one (among other medoids): | |

| (26) | |

| 3. For each current cluster, update its medoid: | |

| (27) | |

| 4. If at least one of is changed at Step 3, go to Step 2. | |

| 5. Find the cluster with the largest fraction-weighted mean pseudometric deviation of its orientations from the medoid: | |

| (28) | |

| 6. If the cluster determined by Step 5 is not well enough localized, i.e., | |

| (29) | |

| 6.1. Replace its medoid by the pair of orientations with the largest weighted distance (with the amount of clusters increased by one): | |

| (30) | |

| (31) | |

| 6.2. Go to Step 2. | |

| Algorithm 4. Clustering the whole sample. |

| 1. . |

| 2. . |

| 3. Set and an execute Algorithm 1. |

| 4. . |

| 5. . |

| 6. Set and execute Algorithm 2. |

| 7. Set and execute Algorithm 3. |

| 8. . |

| 9. . |

| 10. If then go to Step 3. |

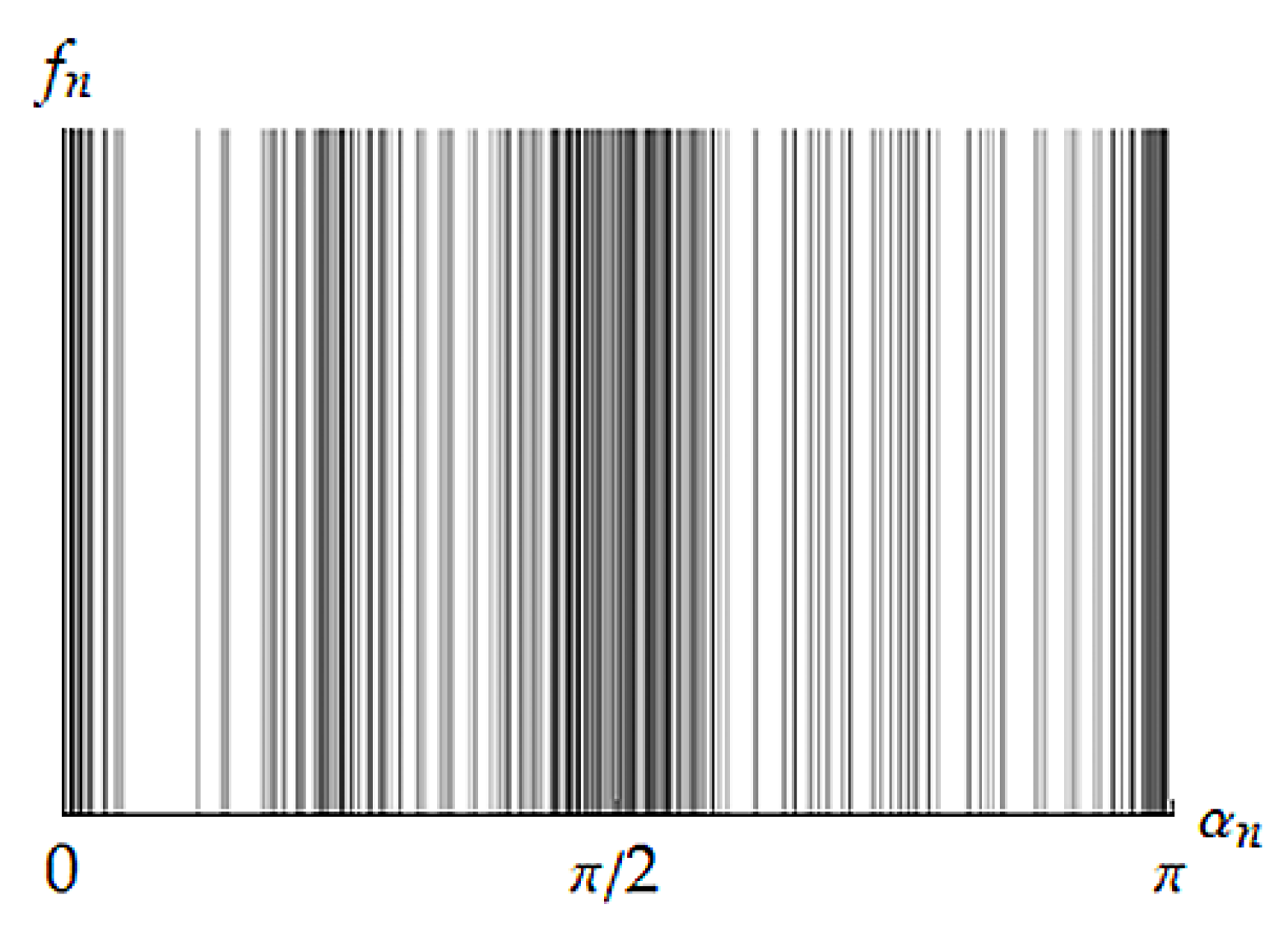

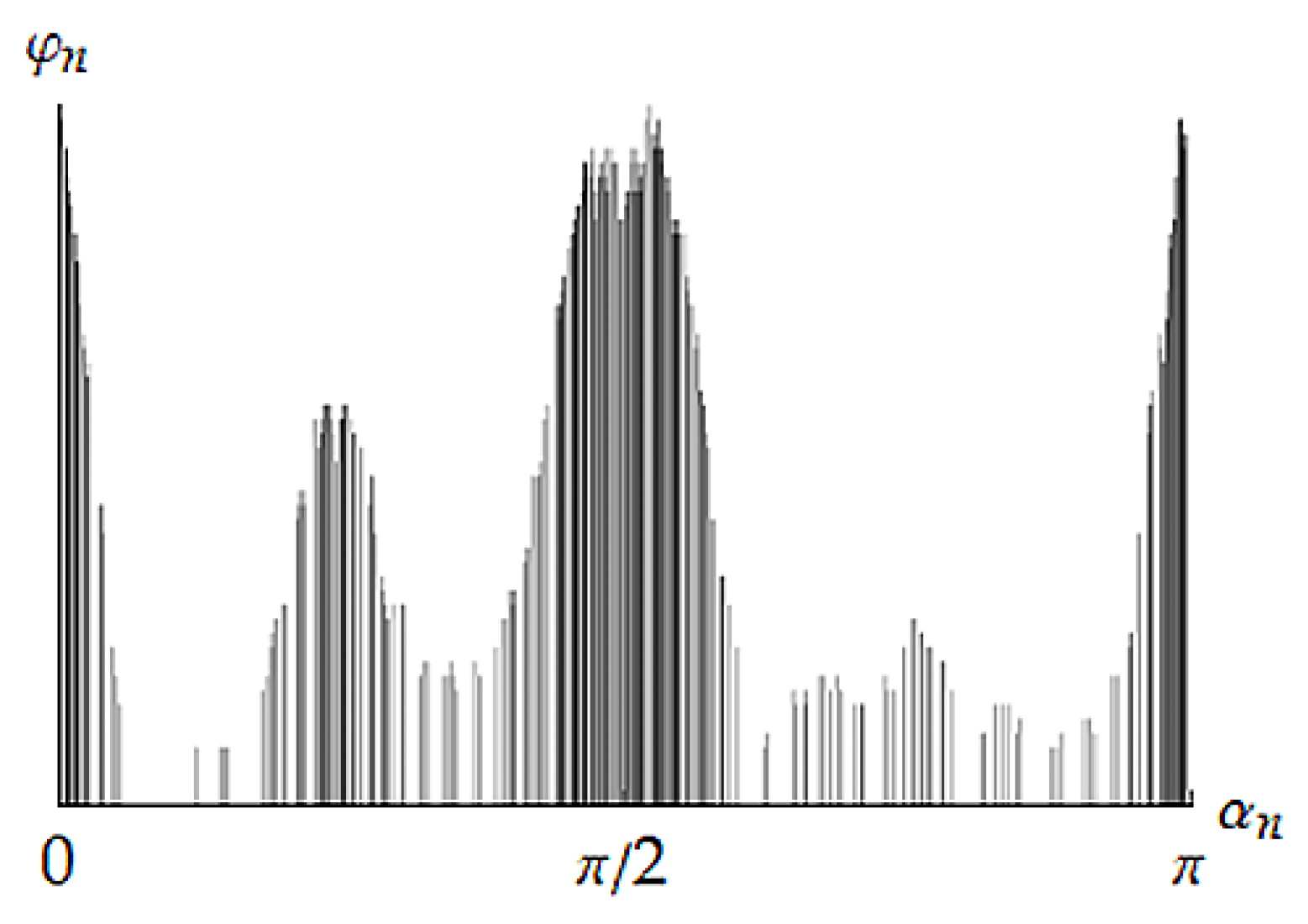

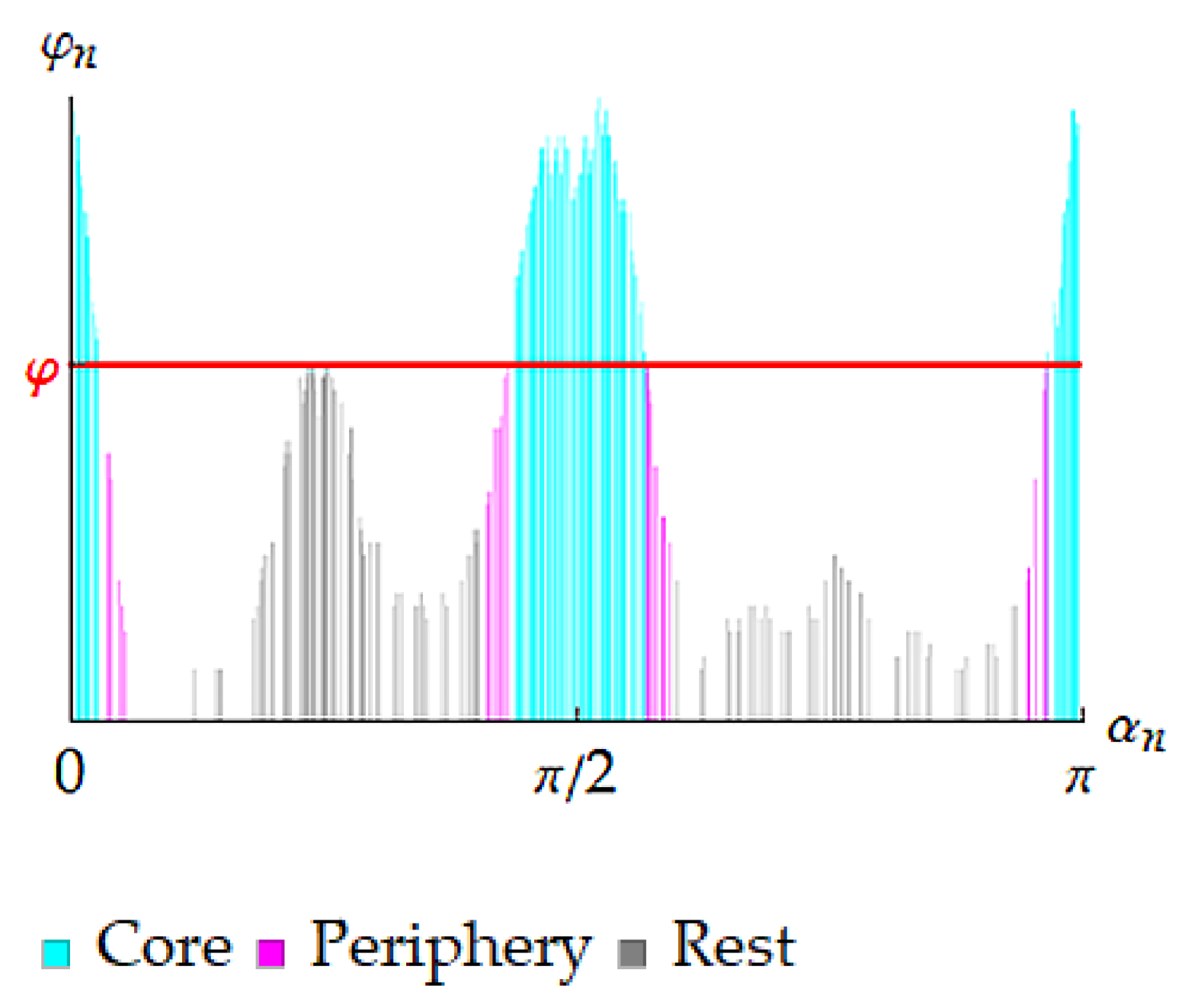

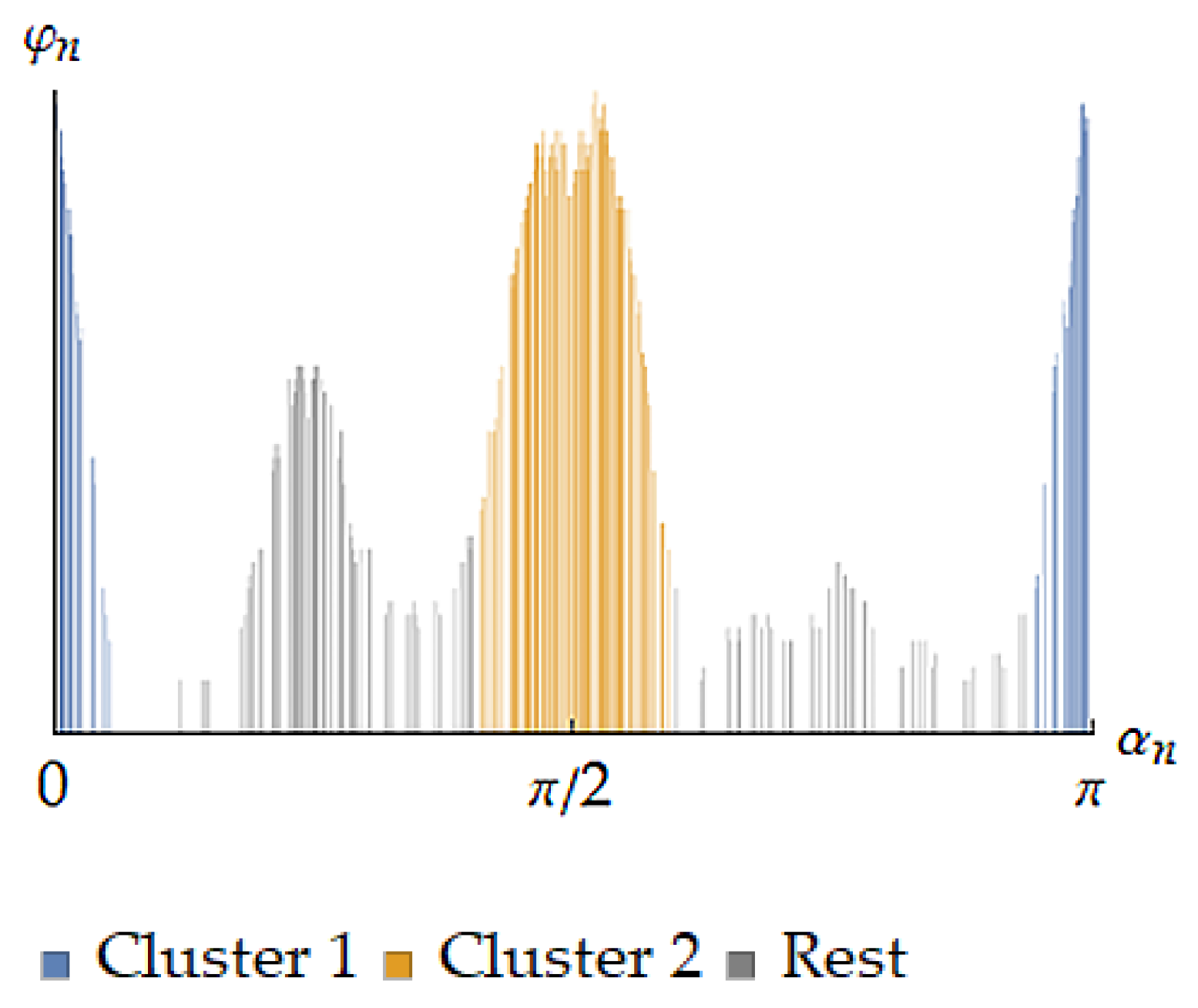

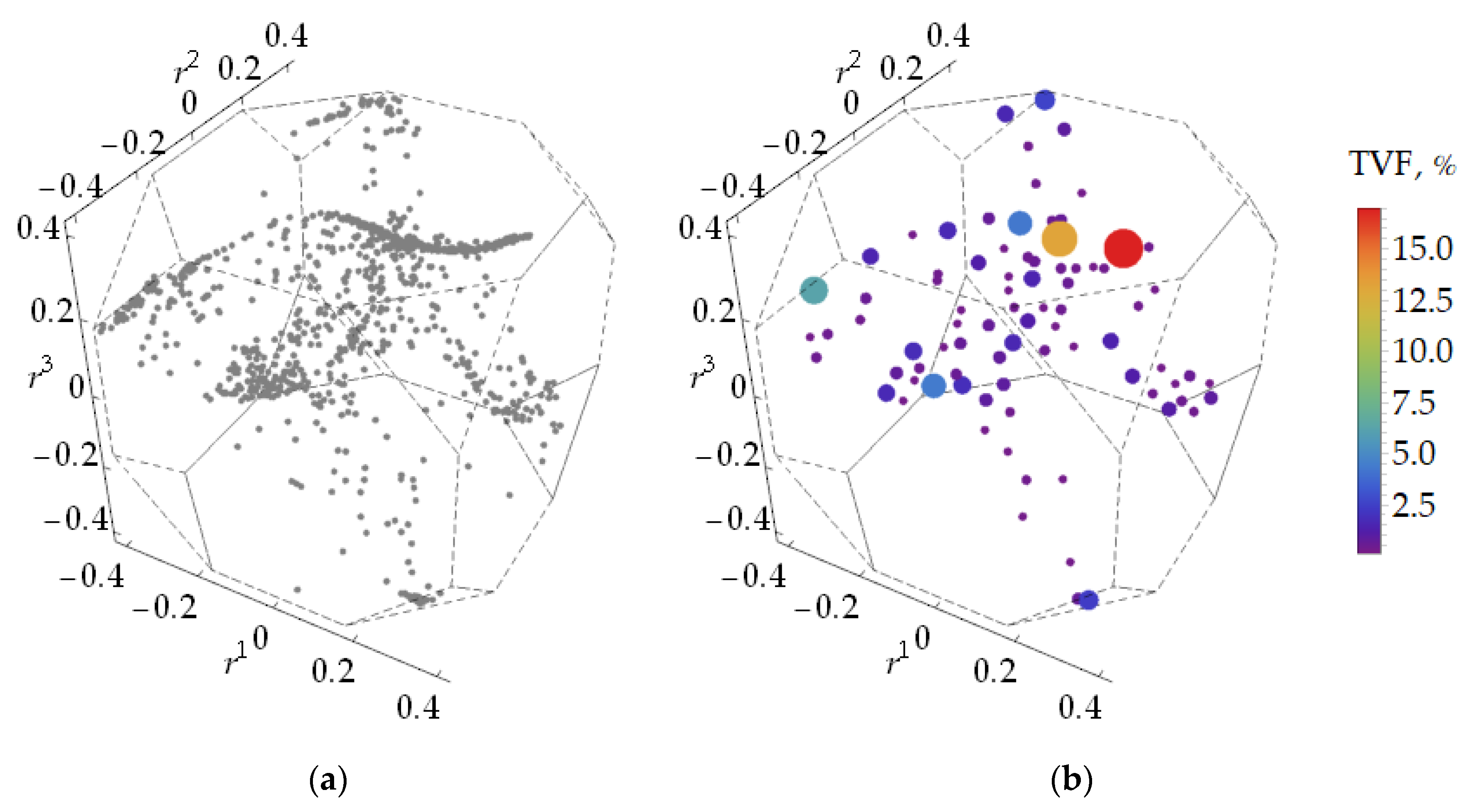

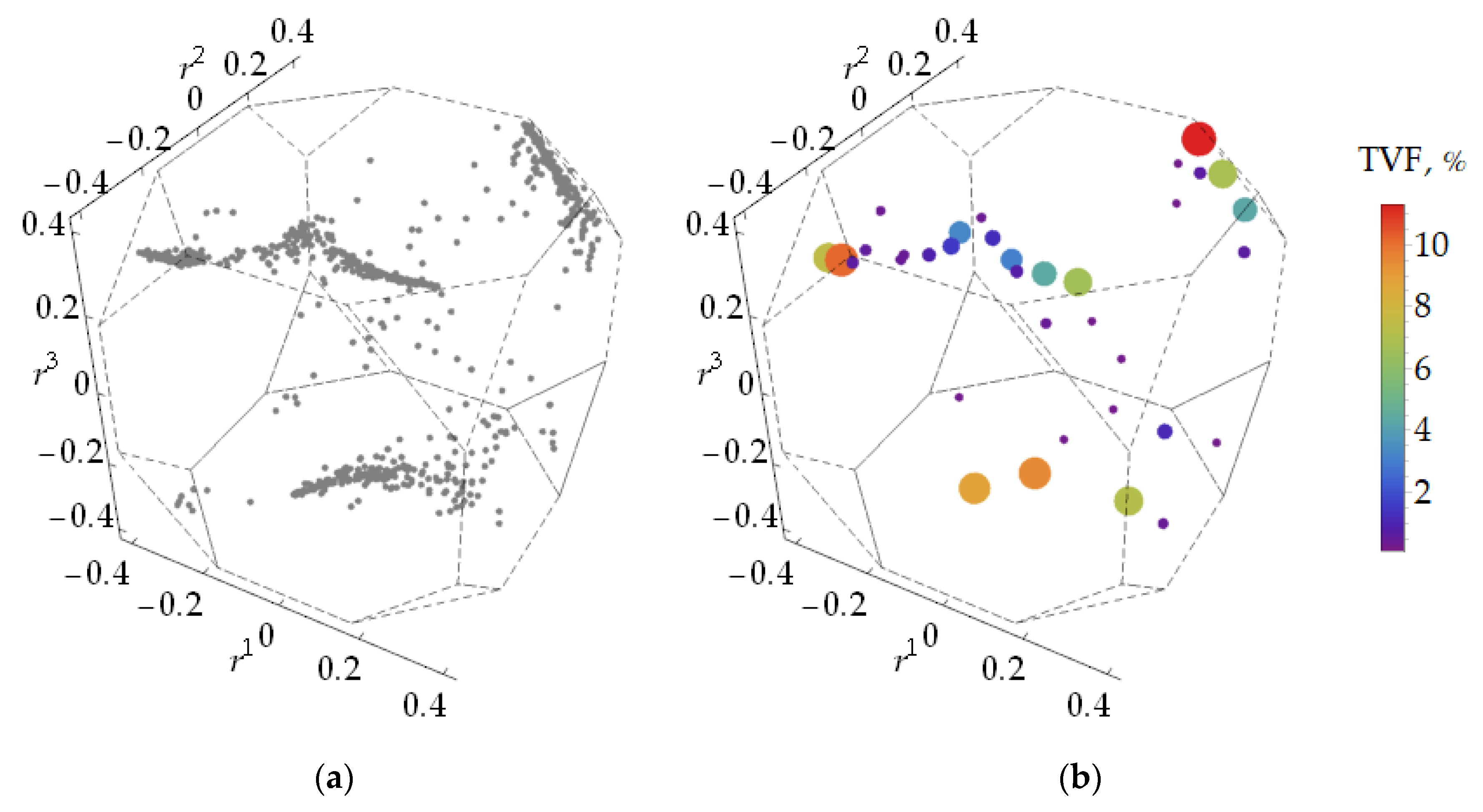

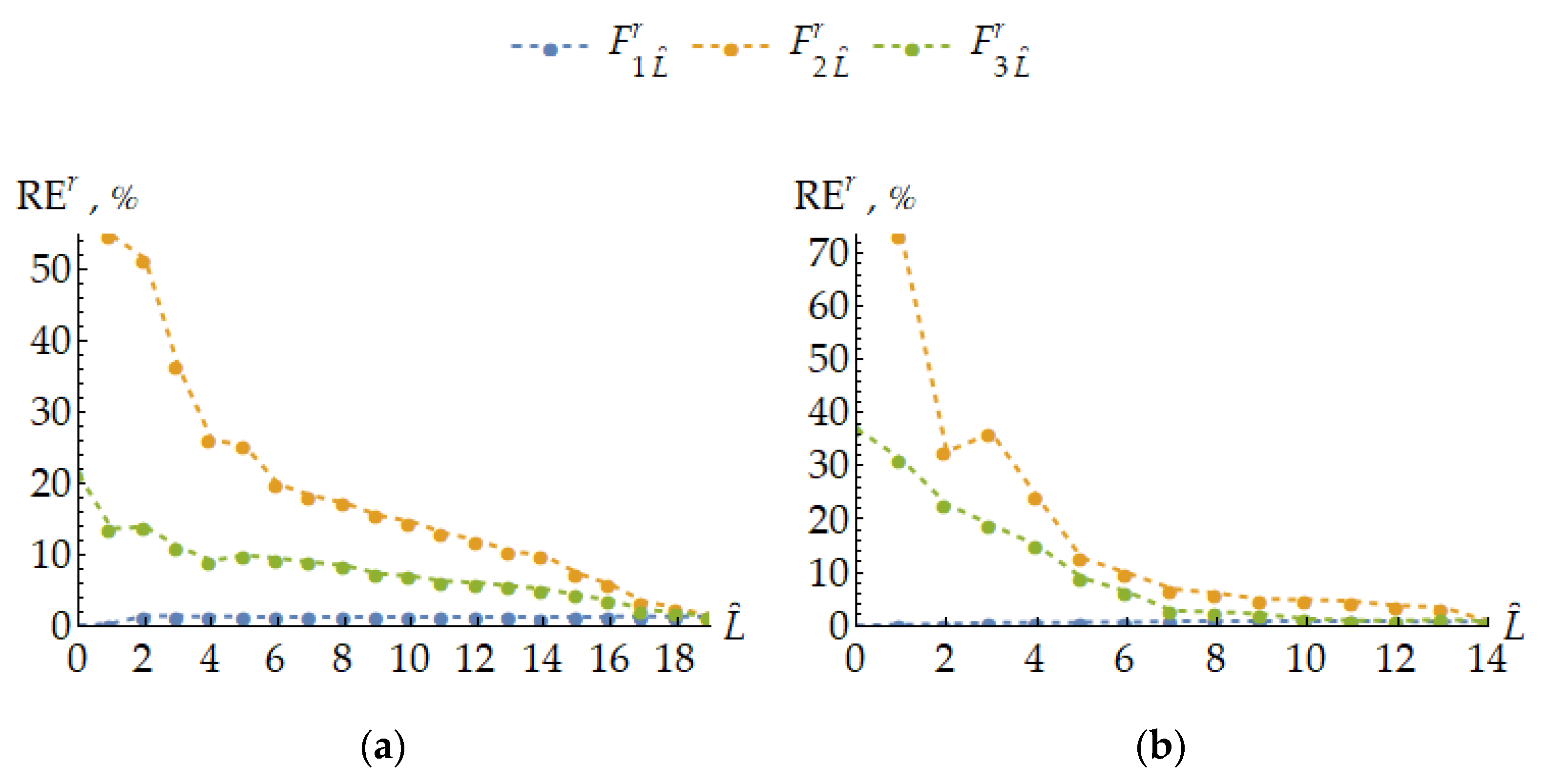

4. Some Numerical Results

5. Discussion

5.1. Adequacy Estimations

- Orientations of the rest layers are taken into consideration without any data reductions, i.e., just like in a PA-induced ODM. In such a way, these reduced ODMs arise:

- The rest layers are simply excluded from consideration. In this case, total volume fraction of crystallites corresponded to the remaining orientations requires renormalization so the reduced ODMs are:

- Orientations of the rest layers are taken as uniformly distributed ones providing the following reduced ODMs:

5.2. An Application to Approximating Orientation Distribution Functions for Generating Textured Polycrystalline Aggregates

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A. Elements of Tensor Algebra

Appendix B. The Special Orthogonal Group as a (Pseudo-) Metric Space

References

- Taylor, G.I.; Elam, C.F. The distortion of an aluminium crystal during a tensile test. Proc. Roy. Soc. Ser. A 1923, 102, 643–647. [Google Scholar]

- Taylor, G.I.; Elam, C.F. The plastic extension and fracture of aluminium crystals. Proc. Roy. Soc. Ser. A 1925, 108, 28–51. [Google Scholar]

- Sachs, G.O. Zur Ableitungeiner Fliessbedingung. Z. Ver. Deut. Ing. 1928, 72, 734–736. [Google Scholar]

- Masimo, M.; Sachs, G.O. Mechanische Eigenschaften von Messingkristallen. Z. Phys. 1928, 50, 161–186. [Google Scholar] [CrossRef]

- Taylor, G.I. Plastic strain in metals. J. Inst. Met. 1938, 62, 307–324. [Google Scholar]

- Bishop, J.F.W.; Hill, R. A theory of the plastic distortion of a polycrystalline aggregate under combined stresses. Phil. Mag. Ser. 7 1951, 42, 414–427. [Google Scholar] [CrossRef]

- Bishop, J.F.W.; Hill, R. A theoretical derivation of the plastic properties of a polycrystalline face-centred metal. Phil. Mag. Ser. 7 1951, 42, 1298–1307. [Google Scholar] [CrossRef]

- Lin, T.H. Analysis of elastic and plastic strains of a face-centered cubic crystal. J. Mech. Phys. Solids 1957, 5, 143–149. [Google Scholar] [CrossRef]

- Anand, L. Single-crystal elasto-viscoplasticity: Application to texture evolution in polycrystalline metals at large strains. Comput. Methods Appl. Mech. Eng. 2004, 193, 5359–5383. [Google Scholar] [CrossRef]

- McDowell, D.L.; Olson, G.B. Concurrent design of hierarchical materials and structures. In Lecture Notes in Computational Science and Engineering; Springer: Berlin/Heidelberg, Germany, 2008; Volume 68, pp. 207–240. ISBN 9781402097409. [Google Scholar]

- Van Houtte, P. Crystal plasticity based modelling of deformation textures. In Microstructure and Texture in Steels; Haldar, A., Suwas, S., Bhattacharjee, D., Eds.; Springer: Berlin/Heidelberg, Germany, 2009; pp. 209–224. ISBN 978-1-84882-454-6. [Google Scholar]

- Roters, F.; Eisenlohr, P.; Hantcherli, L.; Tjahjanto, D.D.; Bieler, T.R.; Raabe, D. Overview of constitutive laws, kinematics, homogenization and multiscale methods in crystal plasticity finite-element modeling: Theory, experiments, applications. Acta Mater. 2010, 58, 1152–1211. [Google Scholar] [CrossRef]

- Trusov, P.V.; Shveykin, A.I. Multilevel crystal plasticity models of single- and polycrystals. Statistical Models. Phys. Mesomech. 2013, 16, 23–33. [Google Scholar] [CrossRef]

- Trusov, P.V.; Shveykin, A.I. Multilevel crystal plasticity models of single- and polycrystals. Direct models. Phys. Mesomech. 2013, 16, 99–124. [Google Scholar] [CrossRef]

- Trusov, P.V.; Shveykin, A.I. Multilevel Models of Mono- and Polycrystalline Materials: Theory, Algorithms, Application Examples; SO RAN: Novosibirsk, Russia, 2019; ISBN 978-5-7692-1661-9. [Google Scholar]

- Busso, E.P. Multiscale Approaches: From the Nanomechanics to the Micromechanics. In Computational and Experimental Mechanics of Advanced Materials; Silberschmidt, V.V., Ed.; Springer: Berlin/Heidelberg, Germany, 2006; pp. 141–165. [Google Scholar]

- Luscher, D.J.; McDowell, D.L. An extended multiscale principle of virtual velocities approach for evolving microstructure. Procedia Eng. 2009, 1, 117–121. [Google Scholar] [CrossRef] [Green Version]

- Luscher, D.J.; McDowell, D.L.; Bronkhorst, C.A. A second gradient theoretical framework for hierarchical multiscale modeling of materials. Int. J. Plast. 2010, 26, 1248–1275. [Google Scholar] [CrossRef]

- Clement, A. Prediction of deformation texture using a physical principle of conservatiol. Mater. Sci. Eng. 1982, 55, 203–210. [Google Scholar] [CrossRef]

- Kumar, A.; Dawson, P.R. The simulation of texture evolution with finite elements over orientation space II. Application to planar crystals. Comput. Methods Appl. Mech. Eng. 1996, 130, 247–261. [Google Scholar] [CrossRef]

- Kumar, A.; Dawson, P.R. The simulation of texture evolution with finite elements over orientation space I. Development. Comput. Methods Appl. Mech. Eng. 1996, 130, 227–246. [Google Scholar] [CrossRef]

- Kumar, A.; Dawson, P.R. Modeling crystallographic texture evolution with finite elements over neo-Eulerian orientation spaces. Comput. Methods Appl. Mech. Eng. 1998, 153, 259–302. [Google Scholar] [CrossRef]

- Acharjee, S.; Zabaras, N. A proper orthogonal decomposition approach to microstructure model reduction in Rodrigues space with applications to optimal control of microstructure-sensitive properties. Acta Mater. 2003, 51, 5627–5646. [Google Scholar] [CrossRef]

- Ganapathysubramanian, S.; Zabaras, N. Modeling the thermoelastic-viscoplastic response of polycrystals using a continuum representation over the orientation space. Int. J. Plast. 2005, 21, 119–144. [Google Scholar] [CrossRef]

- Lebensohn, R.A. N-site modeling of a 3D viscoplastic polycrystal using Fast Fourier Transform. Acta Mater. 2001, 49, 2723–2737. [Google Scholar] [CrossRef]

- Hu, L.; Rollet, A.D.; Iadicola, M.; Foecke, T.; Banovic, S. Constitutive Relations for AA 5754 Based on Crystal Plasticity. Met. Mater. Trans. A 2012, 43, 854–869. [Google Scholar] [CrossRef]

- Bunge, H.-J. Texture Analysis in Materials Science. Mathematical Methods; Elsevier Ltd.: Amsterdam, The Netherlands, 1969; ISBN 978-0-408-10642-9. [Google Scholar]

- Sam, D.; Onat, E.; Etingof, P.; Adams, B. Coordinate free tensorial representation of the orientation distribution function with harmonic polynomials. Textures Microstruct. 1993, 21, 233–250. [Google Scholar] [CrossRef] [Green Version]

- Ganapathysubramanian, S.; Zabaras, N. Design across length scales: A reduced-order model of polycrystal plasticity for the control of microstructure-sensitive material properties. Comput. Methods Appl. Mech. Eng. 2004, 193, 5017–5034. [Google Scholar] [CrossRef]

- Sundararaghavan, V.; Zabaras, N. On the synergy between texture classification and deformation process sequence selection for the control of texture-dependent properties. Acta Mater. 2005, 53, 1015–1027. [Google Scholar] [CrossRef]

- Holmes, P.; Lumley, J.L.; Berkooz, G.; Rowley, C.W. Proper orthogonal decomposition. In Turbulence, Coherent Structures, Dynamical Systems and Symmetry; Cambridge University Press: Cambridge, UK, 2012; pp. 68–105. [Google Scholar]

- Sirovich, L. Turbulence and the dynamics of coherent structures. I. Coherent structures. Qarterly Appl. Math. 1987, 45, 561–571. [Google Scholar] [CrossRef] [Green Version]

- Ruer, D.; Baro, R. Vectorial method of texture analysis of cubic lattice polycrystalline material. J. Appl. Cryst. 1977, 10, 458–464. [Google Scholar] [CrossRef]

- Matthies, S. The ODF-Spectrum a New and Comprehensive Characterization of the Degree of Anisotropy of Orientation Distributions. Mater. Sci. Forum 2005, 495–497, 331–338. [Google Scholar] [CrossRef]

- Matthies, S. Form effects in the description of the orientation distribution function (ODF) of texturized materials by model components. Phys. Status Solidi 1982, 112, 705–716. [Google Scholar] [CrossRef]

- Luecke, K.; Jura, J.; Pospiech, J.; Hirsch, J.R. On the presentation of orientation distribution functions by model functions. Z. Met. 1986, 77, 312–321. [Google Scholar]

- Helming, K.; Eschner, T. A new approach to texture analysis of multiphase materials using a texture component model. Cryst. Res. Technol. 1990, 25, 203–208. [Google Scholar] [CrossRef]

- Helming, K.; Schwarzer, R.A.; Rauschenbach, B.; Geier, S.; Leiss, B.; Heinitz, J. Texture estimates by means of components. Z. Met. 1994, 85, 545–553. [Google Scholar]

- Eschner, T.; Fundenberger, J.-J. Application of anisotropic texture components. Textures Microstruct. 1997, 28, 181–195. [Google Scholar] [CrossRef] [Green Version]

- Raabe, D.; Roters, F. Using texture components in crystal plasticity finite element simulations. Int. J. Plast. 2004, 20, 339–361. [Google Scholar] [CrossRef]

- Ivanova, T.M.; Savyolova, T.I.; Sypchenko, M.V. The modified component method for calculation of orientation distribution function from pole figures. Inverse Probl. Sci. Eng. 2010, 18, 163–171. [Google Scholar] [CrossRef]

- Chateigner, D. Quantitative Texture Analysis. In Combined Analysis; ISTE Ltd.: London, UK, 2013; pp. 95–190. ISBN 9781118622506. [Google Scholar]

- Suwas, S.; Ray, R.K. Crystallographic Texture of Materials; Springer: London, UK, 2014; ISBN 978-1-4471-6314-5. [Google Scholar]

- Mokrova, S.M.; Petrov, R.P.; Milich, V.N. Determination of the texture of polycrystalline materials using an algorithm of object-vector representation of reflection planes and visualization of the results in Rodrigues space. Vestn. Udmurt. Univ. Mat. Mekh. Komp. Nauk. 2016, 26, 336–344. [Google Scholar] [CrossRef] [Green Version]

- Ostapovich, K.V.; Trusov, P.V.; Yanz, A.Y. An algorithm for identifying texture components in the framework of statistical crystal plasticity models. IOP Conf. Ser. Mater. Sci. Eng. 2019, 581, 12014. [Google Scholar] [CrossRef]

- Ostapovich, K.V.; Trusov, P.V. Investigation of crystallographic textures in multi-level models for polycrystalline deformation using clustering techniques. Comput. Contin. Mech. 2019, 12, 67–79. [Google Scholar] [CrossRef] [Green Version]

- Ostapovich, K.V.; Trusov, P.V. An application of clustering techniques to reducing crystallographic texture data. AIP Conf. Proc. 2020, 2216, 70003. [Google Scholar]

- Trusov, P.V.; Dudar’, O.I.; Keller, I.E. Tensor Algebra and Analysis; Perm State Technical University: Perm, Russia, 1998; ISBN 5-88151-148-4. [Google Scholar]

- Bertram, A. Mathematical Preparation. In Elasticity and Plasticity of Large Deformations: An Introduction; Springer: Berlin/Heidelberg, Germany, 2012; pp. 3–90. ISBN 978-3-642-24615-9. [Google Scholar]

- Weyl, H. The Classical Groups: Their Invariants and Representations, 2nd ed.; Princeton University Press: Princeton, NJ, USA, 1966; ISBN 9780691057569. [Google Scholar]

- Halmos, P.R. Measure Theory; Springer: New York, NY, USA, 1974. [Google Scholar]

- Reed, M.; Simon, B. Methods of Modern Mathematical Physics. I: Functional Analysis, 1st ed.; Academic Press: Cambridge, MA, USA, 1980; ISBN 978-0157850505. [Google Scholar]

- Morawiec, A. Orientations and Rotations; Springer: Berlin/Heidelberg, Germany, 2004; ISBN 978-3-662-09156-2. [Google Scholar]

- Arnold, R.; Jupp, P.E.; Schaeben, H. Statistics of ambiguous rotations. J. Multivar. Anal. 2017, 165, 73–85. [Google Scholar] [CrossRef] [Green Version]

- Altmann, S.L. Rotations, Quaternions, and Double Groups; Dover Publications: Mineola, NY, USA, 2013; ISBN 9780486317731. [Google Scholar]

- Heinz, A.; Neumann, P. Representation of Orientation and Disorientation Data for Cubic, Hexagonal, Tetragonal and Orthorhombic Crystals. Acta Cryst. 1991, A47, 780–789. [Google Scholar] [CrossRef]

- Pospiech, J. Die Parameter der Drehung und die Orientierungsverteilungsfunktion (OVF). Kristall und Technik 1972, 7, 1057–1072. [Google Scholar] [CrossRef]

- Hastie, T.; Tibshirani, R.; Friedman, J. The Elements of Statistical Learning: Data Mining, Inference, and Prediction, 2nd ed.; Springer: New York, NY, USA, 2009; ISBN 9780387848570. [Google Scholar]

- Kriegel, H.-P.; Kröger, P.; Jörg, S.; Arthur, Z. Density-based clustering. Wiley Interdiscip. Rev. Data Min. Knowl. Discov. 2011, 1, 231–240. [Google Scholar] [CrossRef]

- Ester, M.; Kriegel, H.-P.; Jörg, S.; Xu, X. A density-based algorithm for discovering clusters in large spatial databases with noise. In Proceedings of the 2nd ACM International Conference on Knowledge Discovery and Data Mining (KDD), Portland, Oregon, 2–4 August 1996; pp. 226–231. [Google Scholar]

- Kaufman, L.; Rousseeuw, P. Finding Groups in Data: An Introduction to Cluster Analysis; John Wiley & Sons: Hoboken, NJ, USA, 1990; ISBN 0-471-73578-7. [Google Scholar]

- Massart, D.L.; Plastria, F.; Kaufman, L. Non-hierarchical clustering with MASLOC. Pattern Recognit. 1983, 16, 507–516. [Google Scholar] [CrossRef]

- Trusov, P.V.; Shveykin, A.I. Motion decomposition, frame-indifferent derivatives, and constitutive relations at large displacement gradients from the viewpoint of multilevel modeling. Phys. Mesomech. 2017, 20, 357–376. [Google Scholar] [CrossRef]

- Trusov, P.V.; Ostapovich, K.V. On Elastic Symmetry Identification for Polycrystalline Materials. Symmetry 2017, 9, 240. [Google Scholar] [CrossRef] [Green Version]

- Park, F.C. Distance metrics on the rigid-body motions with applications to mechanism design. ASME J. Mech. Des. 1995, 117, 48–54. [Google Scholar] [CrossRef]

- Park, F.C.; Ravani, B. Smooth invariant interpolation of rotations. ACM Trans. Graph. 1997, 16, 277–295. [Google Scholar] [CrossRef]

- Huynh, D.Q. Metrics for 3D Rotations: Comparison and Analysis. J. Math. Imaging Vis. 2009, 155–164. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ostapovich, K.V.; Trusov, P.V. Reduced Statistical Representation of Crystallographic Textures Based on Symmetry-Invariant Clustering of Lattice Orientations. Crystals 2021, 11, 336. https://doi.org/10.3390/cryst11040336

Ostapovich KV, Trusov PV. Reduced Statistical Representation of Crystallographic Textures Based on Symmetry-Invariant Clustering of Lattice Orientations. Crystals. 2021; 11(4):336. https://doi.org/10.3390/cryst11040336

Chicago/Turabian StyleOstapovich, Kirill V., and Peter V. Trusov. 2021. "Reduced Statistical Representation of Crystallographic Textures Based on Symmetry-Invariant Clustering of Lattice Orientations" Crystals 11, no. 4: 336. https://doi.org/10.3390/cryst11040336