Sol–Gel Ceramics for SEIRAS and SERS Substrates

Abstract

:1. Introduction

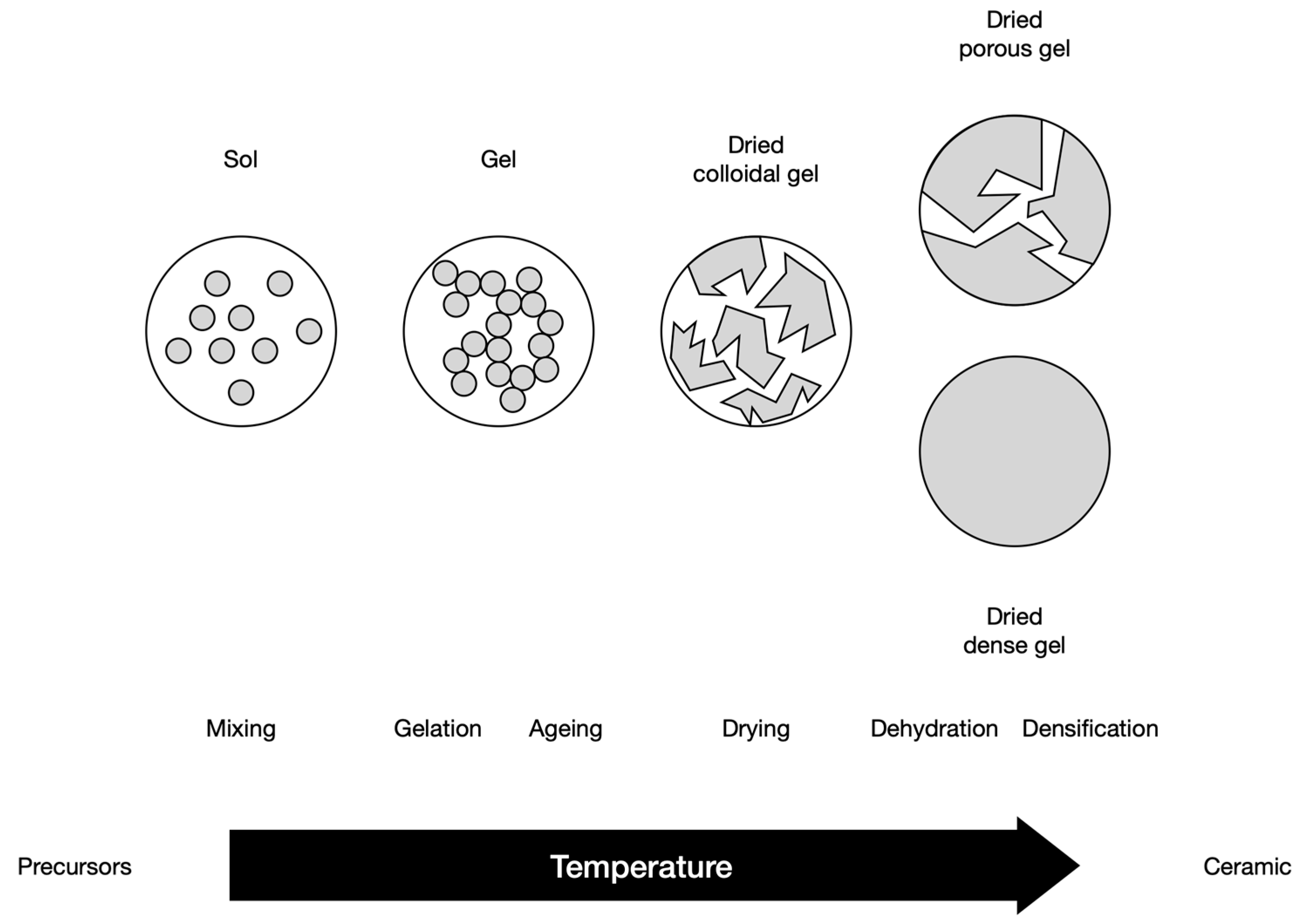

2. The Sol–Gel Method

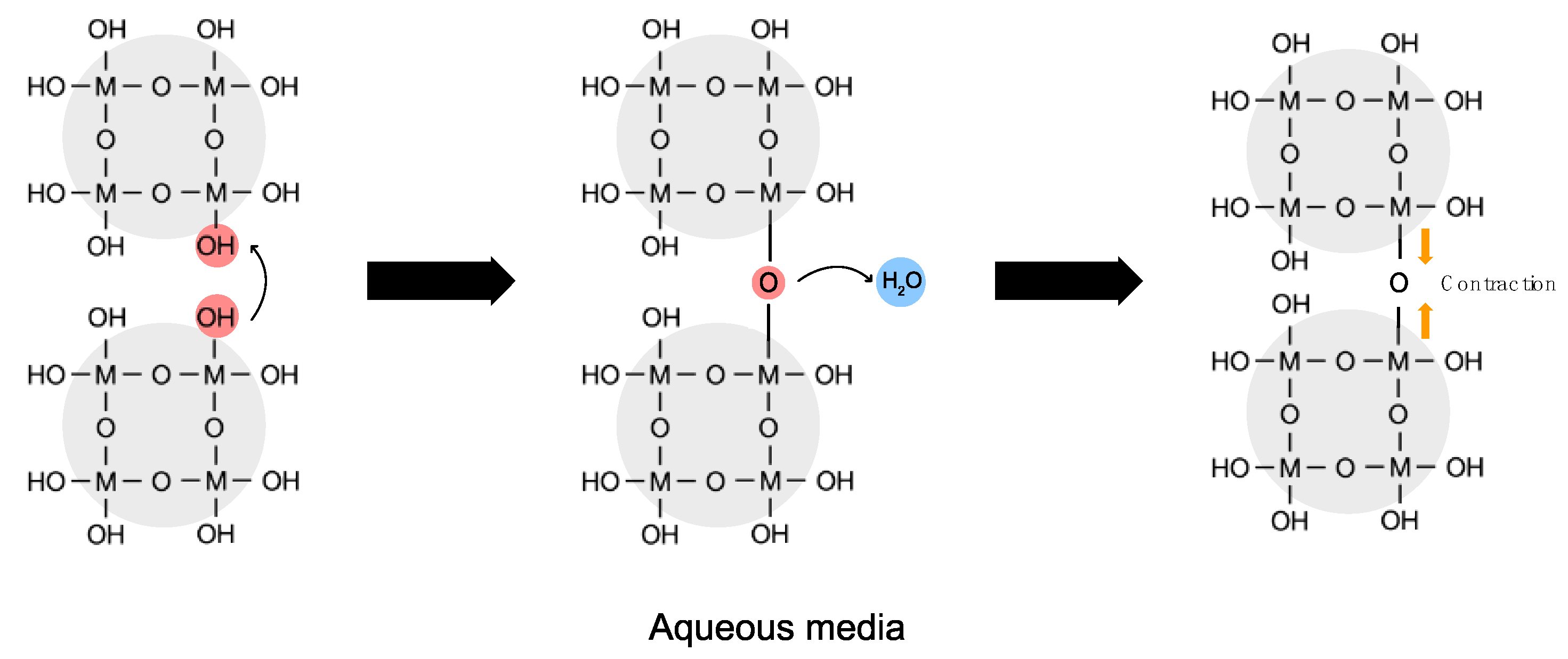

2.1. Hydrolysis and Condensation

2.2. Gelation

2.3. Aging and Drying

2.4. Sintering or Densification and Consolidation of the Material

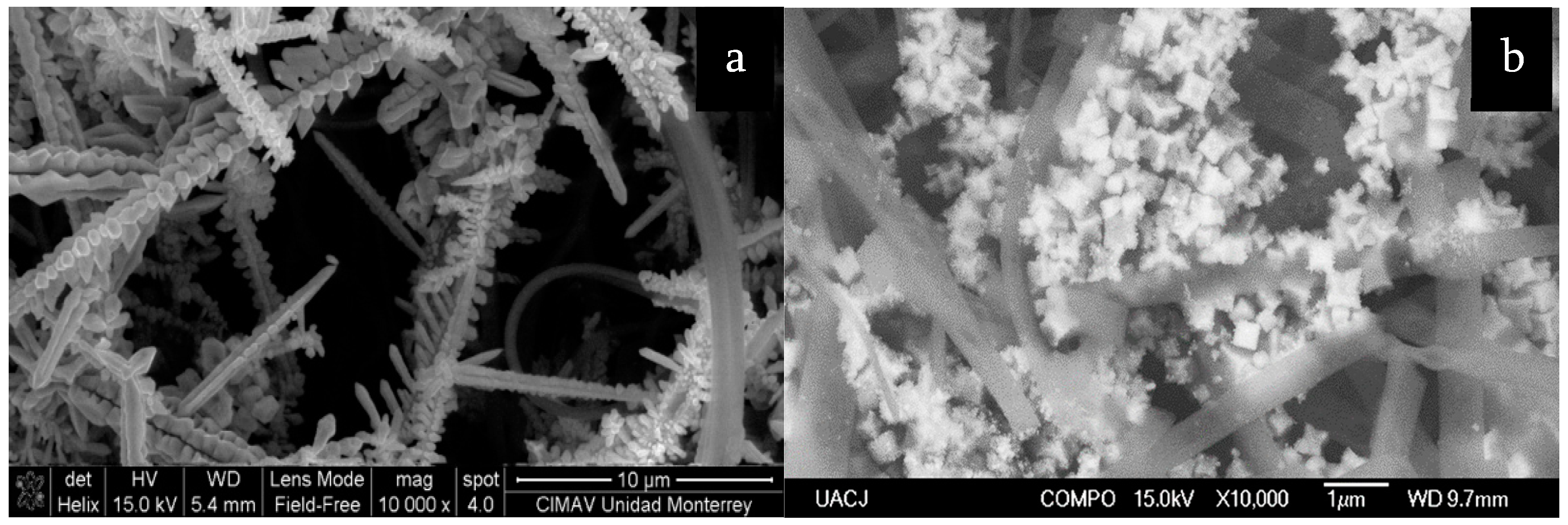

3. Electrospinning of Sol–Gel Ceramic Precursors

4. Sol-Gel Ceramics for SEIRAS and SERS

5. Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- van der Put, P.J. Solid State Reactions. In The Inorganic Chemistry of Materials; Springer: Boston, MA, USA, 1998; pp. 87–110. [Google Scholar]

- Subasri, R.; Raju, K.S. Multifunctional Sol-Gel Nanocomposite Coatings for Aerospace, Energy, and Strategic Applications: Challenges and Perspectives. In Handbook of Advanced Ceramics and Composites: Defense, Security, Aerospace and Energy Applications; Springer: Cham, Switzerland, 2020; pp. 1413–1442. [Google Scholar]

- Cavalheiro, A.A.; Cabeza, N.A.; Anjos, A.D.; Rodrigues, D.C.M. Synthesis of Silver Embedded Nanoparticles Immobilized within Silica Alumina Porous Matrix to Sensor Applications. In Proceedings of the Brazilian SBPMat meeting, João Pessoa, Brazil, 28 September–2 October 2014. [Google Scholar]

- Sakka, S.; Kamiya, K. The sol-gel transition in the hydrolysis of metal alkoxides in relation to the formation of glass fibers and films. J. Non-Cryst. Solids 1982, 48, 31–46. [Google Scholar] [CrossRef]

- Sinha, A.K.; Seelan, S.; Okumura, M.; Akita, T.; Tsubota, S.; Haruta, M. Three-dimensional mesoporous titanosilicates prepared by modified sol− gel method: Ideal gold catalyst supports for enhanced propene epoxidation. J. Phys. Chem. B 2005, 109, 3956–3965. [Google Scholar] [CrossRef]

- Aguilar, G.V.; Fonseca, M.R.J.; Ramírez, Á.M.; Gracia, A.G.J. Photoluminescence studies on ZnO thin films obtained by sol-gel method. Recent Appl. Sol.-Gel Synth. 2017, 195. [Google Scholar] [CrossRef] [Green Version]

- Sun, M.; Zhao, T.; Ma, Z.; Li, Z. Facile preparation of macro-mesoporous zirconium titanate monoliths via a sol–gel reaction accompanied by phase separation. J. Mater. Res. 2019, 34, 4066–4075. [Google Scholar] [CrossRef]

- Ashrafi-Shahri, S.M.; Ravari, F.; Seifzadeh, D. Smart organic/inorganic sol-gel nanocomposite containing func-tionalized mesoporous silica for corrosion protection. Prog. Org. Coat. 2019, 133, 44–54. [Google Scholar] [CrossRef]

- Kayani, Z.N.; Riaz, S.; Naseem, S. Magnetic and antibacterial studies of sol-gel dip coated Ce doped TiO2 thin films: Influence of Ce contents. Ceram. Int. 2020, 46, 381–390. [Google Scholar] [CrossRef]

- Sharifianjazi, F.; Parvin, N.; Tahriri, M. Synthesis and characteristics of sol-gel bioactive SiO2-P2O5-CaO-Ag2O glasses. J. Non-Cryst. Solids 2017, 476, 108–113. [Google Scholar] [CrossRef]

- Singh, J.; Palsaniya, S.; Soni, R. Mesoporous dark brown TiO2 spheres for pollutant removal and energy storage applications. Appl. Surf. Sci. 2020, 527, 146796. [Google Scholar] [CrossRef]

- Pant, B.; Park, M.; Park, S.J. Recent advances in TiO2 films prepared by sol-gel methods for photocatalytic degradation of organic pollutants and antibacterial activities. Coatings 2019, 9, 613. [Google Scholar] [CrossRef] [Green Version]

- Zhu, H.; Jing, Y.; Pal, M.; Liu, Y.; Liu, Y.; Wang, J.; Zhao, D. Mesoporous TiO2@ N-doped carbon composite nan-ospheres synthesized by the direct carbonization of surfactants after sol–gel process for superior lithium storage. Nanoscale 2017, 9, 1539–1546. [Google Scholar] [CrossRef]

- Kumar, A. Sol gel synthesis of zinc oxide nanoparticles and their application as nano-composite electrode material for supercapacitor. J. Mol. Struct. 2020, 1220, 128654. [Google Scholar] [CrossRef]

- Sonia, M.M.L.; Anand, S.; Vinosel, V.M.; Janifer, M.A.; Pauline, S.; Manikandan, A. Effect of lattice strain on structure, morphology and magneto-dielectric properties of spinel NiGdxFe2−xO4 ferrite nano-crystallites synthesized by sol-gel route. J. Magn. Magn. Mater. 2018, 466, 238–251. [Google Scholar] [CrossRef]

- Zhang, Z.; Yu, J.; Ma, L.; Sun, Y.; Wang, P.; Wang, T.; Peng, S. Preparation of the plasmonic Ag/AgBr/ZnO film sub-strate for reusable SERS detection: Implication to the Z-scheme photocatalytic mechanism. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2020, 224, 117381. [Google Scholar] [CrossRef]

- Wan, M.; Zhao, H.; Peng, L.; Zou, X.; Zhao, Y.; Sun, L. Loading of Au/Ag Bimetallic Nanoparticles within and Out-side of the Flexible SiO2 Electrospun Nanofibers as Highly Sensitive, Stable, Repeatable Substrates for Versatile and Trace SERS Detection. Polymers 2020, 12, 3008. [Google Scholar] [CrossRef]

- Shamitha, C.; Senthil, T.; Wu, L.; Kumar, B.S.; Anandhan, S. Sol–gel electrospun mesoporous ZnMn2O4 nano-fibers with superior specific surface area. J. Mater. Sci. Mater. Electron. 2017, 28, 15846–15860. [Google Scholar] [CrossRef]

- Zhang, W.; Liu, W.; Liu, Y.; Wang, C. Tribological behaviors of single and dual sol–gel ceramic films on Ti–6Al–4V. Ceram. Int. 2009, 35, 1513–1520. [Google Scholar] [CrossRef]

- Brinker, C.J.; Scherer, G.W. Sol.-Gel Science: The Physics and Chemistry of Sol-Gel Processing; Academic Press: Cambridge, MA, USA, 2013. [Google Scholar]

- Hench, L.L.; West, J.K. The sol-gel process. Chem. Rev. 1990, 90, 33–72. [Google Scholar] [CrossRef]

- Corriu, R.; Nguyên, T.A. Molecular Chemistry of Sol-Gel Derived Nanomaterials; Wiley: New York, NY, USA, 2009. [Google Scholar]

- Hench, L.L. Sol-Gel Silica: Properties, Processing and Technology Transfer; William Andrew: Chichester, UK, 1998. [Google Scholar]

- Komarneni, S.; Lee, B.; Komarneni, S. (Eds.) Nanocomposite materials. In Chemical Processing of Ceramics; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Sakka, S.; Kozuka, H. (Eds.) Handbook of Sol-Gel Science and Technology. 1. Sol-Gel Processing; Springer Science & Business Media: Chem, Switzerland, 2005; Volume 1. [Google Scholar]

- Zamboulis, A.; Dautel, O.; Moreau, J.J. Synthetic self-assembly strategies and methods. In The Sol-Gel Handbook; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2015. [Google Scholar]

- Wright, J.D.; Sommerdijk, N.A. Sol-Gel Materials: Chemistry and Applications; CRC Press: Boca Raton, FL, USA, 2000; Volume 4. [Google Scholar]

- Li, R.; Clark, A.E.; Hench, L.L. An investigation of bioactive glass powders by sol-gel processing. J. Appl. Biomater. 1991, 2, 231–239. [Google Scholar] [CrossRef]

- Bois, L.; Bonhommé, A.; Ribes, A.; Pais, B.; Raffin, G.; Tessier, F. Functionalized silica for heavy metal ions adsorption. Colloids Surf. A Physicochem. Eng. Asp. 2003, 221, 221–230. [Google Scholar] [CrossRef]

- Lawal, S.; Kanezashi, M.; Nagasawa, H.; Tsuru, T. Development of an acetylacetonate-modified silica-zirconia composite membrane applicable to gas separation. J. Membr. Sci. 2020, 599, 117844. [Google Scholar] [CrossRef]

- Charoenchai, M.; Tangbunsuk, S.; Keawwattana, W. Silica-graphene oxide nanohybrids as reinforcing filler for natural rubber. J. Polym. Res. 2020, 27, 1–16. [Google Scholar] [CrossRef]

- Shah, S.H.; Mirza, R.; Butt, T.A.; Bilal, M.; Yasser, M.; Ali, A.; Ali, M.A.; Baig, A.; Shah, R.Z.; Shah, M.H.; et al. Nano-Porous Zirconia Membranes for Separation of Hydrogen from Carbon Dioxide. Pol. J. Environ. Stud. 2021. [Google Scholar] [CrossRef]

- Ayanwale, A.P.; Ruíz-Baltazar, A.D.J.; Espinoza-Cristóbal, L.; Reyes-López, S.Y. Bactericidal Activity Study of ZrO2-Ag2O Nanoparticles. Dose-Response 2020, 18, 1559325820941374. [Google Scholar] [CrossRef]

- Sharma, D.; Kumari, M.; Dhayal, V. Fabrication and characterization of cellulose/PVA/TiO2 nanocomposite thin film as a photocatalyst. Mater. Today Proc. 2021. [Google Scholar] [CrossRef]

- Alotaibi, A.M.; Promdet, P.; Hwang, G.B.; Li, J.; Nair, S.P.; Sathasivam, S.; Kafizas, A.; Carmalt, C.J.; Parkin, I.P. Zn and N Codoped TiO2 Thin Films: Photocatalytic and Bactericidal Activity. ACS Appl. Mater. Interfaces 2021, 13, 10480–10489. [Google Scholar] [CrossRef]

- Silva-Holguín, P.N.; Reyes-López, S.Y. Synthesis of Hydroxyapatite-Ag Composite as Antimicrobial Agent. Dose-Response 2020, 18, 1559325820951342. [Google Scholar] [CrossRef] [PubMed]

- Monrreal-Rodríguez, A.K.; Garibay-Alvarado, J.; Vargas-Requena, C.L.; Reyes-López., S.Y. In vitro evaluation of poly-ε-caprolactone-hydroxypatite-alumina electrospun fibers on the fibroblast’s proliferation. Results Mater. 2020, 6, 100091. [Google Scholar] [CrossRef]

- Fakhri, M.A.; Salim, E.T.; Wahid, M.H.A.; Salim, Z.T.; Hashim, U. A novel parameter effects on optical properties of the LiNbO3 films using sol-gel method. AIP Conf. Proc. 2020, 2213, 020242. [Google Scholar]

- Zhukov, R.N.; Kushnerev, K.; Kiselev, D.A.; Ilina, T.S.; Kubasov, I.V.; Kislyuk, A.M.; Malinkovich, M.D.; Parkhomenko, Y.N. Enhancement of piezoelectric properties of lithium niobate thin films by different annealing parameters. Mod. Electron. Mater. 2020, 6, 47–52. [Google Scholar] [CrossRef]

- Ranjeh, M.; Beshkar, F.; Amiri, O.; Salavati-Niasari, M.; Moayedi, H. Pechini sol-gel synthesis of Cu2O/Li3BO3 and CuO/Li3BO3 nanocomposites for visible light-driven photocatalytic degradation of dye pollutant. J. Alloy. Compd. 2020, 815, 152451. [Google Scholar] [CrossRef]

- Kurajica, S.; Mali, G.; Mandić, V.; Simčić, I.; Matijašić, G.; Mužina, K. Tailoring microstructural, textural and thermal properties of γ-alumina by modifying aluminum sec-butoxide with ethyl acetoacetate within a sol–gel synthesis. J. Phys. Chem. Solids 2021, 148, 109783. [Google Scholar] [CrossRef]

- Yi, H.; Wan, Y.; Zhang, Y.; Wang, Y.; Fei, W.; Luo, G. Controllable preparation of highly uniform γ-alumina microspheres via the sol–gel route for alkoxide in a coaxial microchannel. J. Sol.-Gel Sci. Technol. 2020, 93, 391–401. [Google Scholar] [CrossRef]

- Grishina, E.P.; Kudryakova, N.O.; Ramenskaya, L.M. Characterization of the properties of thin Al2O3 fi lms formed on structural steel by the sol-gel method. Kondens. Sredy Mezhfaznye Granitsy Condens. Matter Interphases 2020, 22. [Google Scholar] [CrossRef]

- Jastrzębska, A.M.; Jureczko, J.; Karcz, J.; Kunicki, A.; Ziemkowska, W.; Olszyna, A. Controlled synthesis of gra-phene oxide/alumina nanocomposites using a new dry sol–gel method of synthesis. Chem. Pap. 2017, 71, 579–595. [Google Scholar] [CrossRef]

- Yoldas, B.E. Hydrolysis of aluminium alkoxides and bayerite conversion. J. Appl. Chem. Biotechnol. 2007, 23, 803–809. [Google Scholar] [CrossRef]

- Yoldas, B.E.; BE, Y. Alumina Sol Preparation from Alkoxides. Amer Ceram Bull. 1975, 54, 289–290. [Google Scholar]

- Cova, F.; Moretti, F.; Fasoli, M.; Chiodini, N.; Pauwels, K.; Auffray, E.; Lucchini, M.T.; Baccaro, S.; Cemmi, A.; Bártová, H.; et al. Radiation hardness of Ce-doped sol-gel silica fibers for high energy physics applications. Opt. Lett. 2018, 43, 903–906. [Google Scholar] [CrossRef] [Green Version]

- Mota, T.L.R.; De Oliveira, A.P.M.; Nunes, E.H.M.; Houmard, M. Simple process for preparing mesoporous sol-gel silica adsorbents with high water adsorption capacities. Microporous Mesoporous Mater. 2017, 253, 177–182. [Google Scholar] [CrossRef]

- Ji, X.; Wang, C.; Harumoto, T.; Zhang, S.; Tu, R.; Shen, Q.; Shi, J. Structure and electrical properties of BCZT ceramics derived from microwave-assisted sol–gel-hydrothermal synthesized powders. Sci. Rep. 2020, 10, 1–8. [Google Scholar] [CrossRef]

- Bhuiyan, A.H.; Nagakawa, T.; Nakane, K. Polyvinyl butyral-zirconia hybrid hollow fibers prepared by air gap spinning. J. Appl. Polym. Sci. 2021, 138, 50164. [Google Scholar] [CrossRef]

- Yazid, S.A.; Rosli, Z.M.; Juoi, J.M. Effect of titanium (IV) isopropoxide molarity on the crystallinity and photo-catalytic activity of titanium dioxide thin film deposited via green sol–gel route. J. Mater. Res. Technol. 2019, 8, 1434–1439. [Google Scholar] [CrossRef]

- Wiranwetchayan, O.; Promnopas, S.; Thongtem, T.; Chaipanich, A.; Thongtem, S. Effect of alcohol solvents on TiO2 films prepared by sol–gel method. Surf. Coatings Technol. 2017, 326, 310–315. [Google Scholar] [CrossRef]

- Tsai, S.W.; Huang, S.S.; Yu, W.X.; Hsu, Y.W.; Hsu, F.Y. Fabrication and characteristics of porous hydroxyap-atite-CaO composite nanofibers for biomedical applications. Nanomaterials 2018, 8, 570. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Baskaran, P.; Udduttula, A.; Uthirapathy, V. Development and characterisation of novel Ce-doped hydroxyapatite–Fe3O4 nanocomposites and their in vitro biological evaluations for biomedical applications. IET Nanobiotechnology 2018, 12, 138–146. [Google Scholar] [CrossRef]

- Wang, L.H.; Yuan, D.R.; Duan, X.L.; Wang, X.Q.; Yu, F.P. Synthesis and characterization of fine lithium niobate powders by sol- gel method. Cryst. Res. Technol. 2007, 42, 321–324. [Google Scholar] [CrossRef]

- Fakhri, M.A.; Al-Douri, Y.; Hashim, U.; Salim, E.T. Optical investigations of photonics lithium niobate. Sol. Energy 2015, 120, 381–388. [Google Scholar] [CrossRef]

- Claude, V.; Mahy, J.G.; Micheli, F.; Geens, J.; Lambert, S.D. Sol-gel Ni/γ-Al2O3 material as secondary catalyst for toluene reforming: Tailoring the γ-Al2O3 substrate with stearic acid. Microporous Mesoporous Mater. 2020, 291, 109681. [Google Scholar] [CrossRef]

- Krishnan, S.V.; Palanivelu, S.; Ambalam, M.M.M.; Venkatesan, R.; Arivalagan, M.; Pearce, J.M.; Mayandi, J. Chemical Synthesis and Characterization of Nano Alumina, Nano Composite of Carbon–Alumina and Their Comparative Studies. Z. Phys. Chem. 2018, 232, 1827–1842. [Google Scholar] [CrossRef]

- Thomas, I.M.; Klein, L.C. (Eds.) Multicomponent Glasses from the Sol-Gel Process. In Sol-Gel Technology for Thin Films, Fibers, Preforms, Electronics and Specialty Shapes; Noyes Publications: Park Ridge, NJ, USA, 1988. [Google Scholar]

- Nishio, K.; Tsuchiya, T.; Klein, L.; Aparicio, M.; Jitianu, A. (Eds.) Sol-Gel Processing of Thin Films with Metal Salts. In Handbook of Sol-Gel Science and Technology; Springer International Publishing: New York, NY, USA, 2016. [Google Scholar]

- Thiruchitrambalam, M.; Palkar, V.; Gopinathan, V. Hydrolysis of aluminium metal and sol–gel processing of nano alumina. Mater. Lett. 2004, 58, 3063–3066. [Google Scholar] [CrossRef]

- Behera, P.S.; Bhattacharyya, S.; Sarkar, R. Effect of citrate to nitrate ratio on the sol-gel synthesis of nanosized α-Al2O3 powder. Ceram. Int. 2017, 43, 15221–15226. [Google Scholar] [CrossRef]

- Raj, S.V.; Rajkumar, M.; Sundaram, N.M.; Kandaswamy, A. Synthesis and characterization of hydroxyapatite/alumina ceramic nanocomposites for biomedical applications. Bull. Mater. Sci. 2018, 41, 93. [Google Scholar] [CrossRef] [Green Version]

- Tabesh, S.; Davar, F.; Loghman-Estarki, M.R. Preparation of γ-Al2O3 nanoparticles using modified sol-gel method and its use for the adsorption of lead and cadmium ions. J. Alloy. Compd. 2018, 730, 441–449. [Google Scholar] [CrossRef]

- Abdellah, W.; Abdelfattah, E.; Diab, H.; Saad, E.A. Removal of Chromium from Liquid Waste by Gamma Alumi-num Oxide (γ-Al2O3) Nanoparticles Synthesized using Citrate Sol–gel Method. Arab J. Nucl. Sci. Appl. 2018, 51, 126–134. [Google Scholar]

- Nayar, P.; Waghmare, S.; Singh, P.; Najar, M.; Puttewar, S.; Agnihotri, A. Comparative study of phase transfor-mation of Al2O3 nanoparticles prepared by chemical precipitation and sol-gel auto combustion methods. Mater. Today Proc. 2020, 26, 122–125. [Google Scholar] [CrossRef]

- Brito, J.V.; Gaponenko, N.V.; Sukalin, K.S.; Raichenok, T.F.; Tikhomorov, S.A.; Wang, X.; Kargin, N.I. Euro-pium luminescence from amorphous yttrium alumina films on fused silica substrates. IOP Conf. Ser. Mater. Sci. Eng. 2019, 475, 012019. [Google Scholar] [CrossRef]

- Brinker, C.; Keefer, K.; Schaefer, D.; Assink, R.; Kay, B.; Ashley, C. Sol-gel transition in simple silicates II. J. Non-Cryst. Solids 1984, 63, 45–59. [Google Scholar] [CrossRef]

- Buckley, A.M.; Greenblatt, M. The Sol-Gel Preparation of Silica Gels. J. Chem. Educ. 1994, 71, 599. [Google Scholar] [CrossRef]

- Tognonvi, M.T.; LeComte, A.; Rossignol, S.; Bonnet, J.-P. Ripening of Na-silicate gels in basic media: Identification of involved chemical species. J. Non-Cryst. Solids 2019, 522, 119482. [Google Scholar] [CrossRef]

- Kobayashi, M.; Kato, H.; Kakihana, M. Water-dispersed silicates and water-soluble phosphates, and their use in sol-gel synthesis of silicate-and phosphate-based materials. In Handbook of Sol-Gel Science and Technology: Processing, Characterization and Applications; Springer International Publishing: Cham, Switzerlland, 2018; pp. 205–231. [Google Scholar]

- Brinker, C.J.; Scherer, G.W. Sol→ gel→ glass: I. Gelation and gel structure. J. Non-Cryst. Solids 1985, 70, 301–322. [Google Scholar] [CrossRef]

- S Scherer, G.W. Sol-Gel Technology for Thin Films, Fibers, Preforms, Electronics, and Specialty Shapes, Edited by Lisa C. Klein (Noyes Publications, 1988). MRS Bull. 1989, 14, 73. [Google Scholar]

- Schubert, U.; Levy, D.; Zayat, M. (Eds.) Chemistry and Fundamentals of the Sol–Gel Process. In The Sol-Gel Hand-book, 3 Volume Set: Synthesis, Characterization, and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2015; Volume 1. [Google Scholar]

- Pierre, A.C. Introduction to Sol-Gel Processing; Springer Nature: Weinheim, Germany, 2020. [Google Scholar]

- Azarian, M.H.; Mahmood, W.A.K. In-situ sol–gel synthesis of zirconia networks in flexible and conductive composite films. J. Appl. Polym. Sci. 2020, 137, 49506. [Google Scholar] [CrossRef]

- Guo, Y.J.; Cheng, W.; Liu, P.S. Porous ceramic foam loading titanium dioxide for photocatalytic degradation of the me-thyl orange solution. Multidiscip. Model. Mater. Struct. 2019, 15, 1366–1378. [Google Scholar] [CrossRef]

- Popescu, R.A.; Magyari, K.; Taulescu, M.; Vulpoi, A.; Berce, C.; Bogdan, S.; Lelescu, C.; Dreancă, A.; Tudoran, O.; Papuc, I.; et al. New alginate-pullulan-bioactive glass composites with copper oxide for bone tissue regeneration trials. J. Tissue Eng. Regen. Med. 2018, 12, 2112–2121. [Google Scholar] [CrossRef]

- Jmal, N.; Bouaziz, J. Synthesis, characterization and bioactivity of a calcium-phosphate glass-ceramics obtained by the sol-gel processing method. Mater. Sci. Eng. C 2017, 71, 279–288. [Google Scholar] [CrossRef]

- Xie, Y.-T.; Chen, J.-R.; Chen, Y.-T.; Jiang, B.-C.; Sie, Z.-H.; Hsu, H.-Y.; Chen, T.-L.; Chiang, Y.-Y.; Hsueh, H.-Y. Sol–gel-derived hierarchically wrinkled mesoporous ceramics for enhancement of cell alignment. Chem. Eng. J. 2021, 405, 126572. [Google Scholar] [CrossRef]

- Wilhelm, S.; Kind, M. Influence of pH, temperature and sample size on natural and enforced syneresis of precipitated silica. Polymers 2015, 7, 2504–2521. [Google Scholar] [CrossRef] [Green Version]

- Aiken, B.A.R.; Hsu, W.P.; Matijević, E. Preparation and properties of monodispersed colloidal particles of lan-thanide compounds: III, yttrium (III) and mixed yttrium (III)/cerium (III) systems. J. Am. Ceram. Soc. 1988, 71, 845–853. [Google Scholar] [CrossRef]

- LaCourse, W.C. Continuous filament fibers by the sol-gel process. Sol-Gel Technol. Thin Film. Fibres Preforms Electron. Spec. Shapes 1988, 184–187. [Google Scholar] [CrossRef]

- Reisfeld, R. Lasers based on sol-gel technology. J. Lumin. 1997, 72, 7–8. [Google Scholar] [CrossRef]

- Rabinovich, E.M. Sol Gel Processing—General Principles. In Sol-Gel Optics; Springer: Boston, MA, USA, 1994. [Google Scholar]

- Speaks, D.T. Effect of concentration, aging, and annealing on sol gel ZnO and Al-doped ZnO thin films. Int. J. Mech. Mater. Eng. 2020, 15, 1–14. [Google Scholar] [CrossRef]

- Ben-Arfa, B.A.E.; Salvado, I.M.M.; Ferreira, J.M.F.; Pullar, R.C. A hundred times faster: Novel, rapid sol-gel synthesis of bio-glass nanopowders (Si-Na-Ca-P system, Ca:P = 1.67) without aging. Int. J. Appl. Glass Sci. 2016, 8, 337–343. [Google Scholar] [CrossRef]

- Depardieu, M.; Kinadjian, N.; Portehault, D.; Backov, R.; Sanchez, C. Integrative Sol-Gel Chemistry. Sol-Gel Handb. 3 Vol. Set Synth. Charact. Appl. 2015, 2, 4–6. [Google Scholar] [CrossRef]

- Oleg, A.Y.; Igor, M.D.; Alexandr, A.A.; Mykhaylo, Y.L.; Andriy, V.K.; Anatoliy, O.P. Photoluminescence from Silver Nanoparticles Enhanced by Surface Plasmon Resonance. MRS Online Proc. Libr. 2009, 1208, 1–5. [Google Scholar]

- Yeshchenko, O.A.; Bondarchuk, I.S.; Losytskyy, M.Y.; Alexeenko, A.A. Temperature dependence of photolumi-nescence from silver nanoparticles. Plasmonics 2014, 9, 93–101. [Google Scholar] [CrossRef]

- Feng, G.; Jiang, W.; Liu, J.; Zhang, Q.; Wu, Q.; Miao, L. A novel green nonaqueous sol-gel process for preparation of partially stabilized zirconia nanopowder. Process. Appl. Ceram. 2017, 11, 220–224. [Google Scholar] [CrossRef]

- Fu, L.; Engqvist, H.; Xia, W. Highly translucent and strong ZrO2-SiO2 nanocrystalline glass ceramic prepared by sol-gel method and spark plasma sintering with fine 3D microstructure for dental restoration. J. Eur. Ceram. Soc. 2017, 37, 4067–4081. [Google Scholar] [CrossRef]

- Lee, H.G.; Gopalan, A.I.; Sai-Anand, G.; Lee, B.C.; Kang, S.W.; Lee, K.P. Facile synthesis of functionalized gra-phene-palladium nanoparticle incorporated multicomponent TiO2 composite nanofibers. Mater. Chem. Phys. 2015, 154, 125–136. [Google Scholar] [CrossRef]

- Nakamura, R.; Ueda, K.; Sato, S. In Situ Observation of the Photoenhanced Adsorption of Water on TiO2Films by Surface-Enhanced IR Absorption Spectroscopy. Langmuir 2001, 17, 2298–2300. [Google Scholar] [CrossRef]

- Phatai, P.; Futalan, C.M.; Utara, S.; Khemthong, P.; Kamonwannasit, S. Structural characterization of cerium-doped hydroxyapatite nanoparticles synthesized by an ultrasonic-assisted sol-gel technique. Results Phys. 2018, 10, 956–963. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, L.; Li, Y.; Hua, Y.; Li, Y.; Li, W.; Li, W. Template-assisted, sol-gel fabrication of biocompatible, hierarchically porous hydroxyapatite scaffolds. Materials 2019, 12, 1274. [Google Scholar] [CrossRef] [Green Version]

- Taleb, S.M.; Fakhri, M.A.; Adnan, S.A. Optical Investigations of Nanophotonic LiNbO3 Films Deposited by Pulsed Laser Deposition Method. Defect Diffus. Forum 2020, 398, 16–22. [Google Scholar] [CrossRef]

- Xu, Y.; Lu, F.; Liu, K.; Ma, C. Direct Graphene Synthesis on Lithium Niobate Substrate by Carbon Ion Implantation. Front. Mater. 2020, 7, 327. [Google Scholar] [CrossRef]

- Taromi, A.A.; Kaliaguine, S. Hydrodeoxygenation of triglycerides over reduced mesostructured Ni/γ-alumina catalysts prepared via one-pot sol-gel route for green diesel production. Appl. Catal. A Gen. 2018, 558, 140–149. [Google Scholar] [CrossRef]

- Khodadadi, A.; Farahmandjou, M.; Yaghoubi, M. Investigation on synthesis and characterization of Fe-doped Al2O3 nanocrystals by new sol–gel precursors. Mater. Res. Express 2018, 6, 025029. [Google Scholar] [CrossRef]

- Ding, Y.; Li, W.; Correia, A.; Yang, Y.; Zheng, K.; Liu, D.; Roether, J.A. Electrospun polyhydroxybutyrate/poly (ε-caprolactone)/Sol–gel-derived silica hybrid scaffolds with drug releasing function for bone tissue engineering applications. ACS Appl. Mater. Interfaces 2018, 10, 14540–14548. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- La Monaca, A.; Paolella, A.; Guerfi, A.; Rosei, F.; Zaghib, K. Electrospun ceramic nanofibers as 1D solid electrolytes for lithium batteries. Electrochem. Commun. 2019, 104, 106483. [Google Scholar] [CrossRef]

- Cho, Y.-S.; Roh, S.H. Sol–gel synthesis of porous titania fibers by electro-spinning for water purification. J. Dispers. Sci. Technol. 2017, 39, 33–44. [Google Scholar] [CrossRef]

- Methaapanon, R.; Chutchakul, K.; Pavarajarn, V. Photocatalytic zinc oxide on flexible polyacrylonitrile nanofibers via sol–gel coaxial electrospinning. Ceram. Int. 2020, 46, 8287–8292. [Google Scholar] [CrossRef]

- Ansari, M.A.; Albetran, H.M.; Alheshibri, M.H.; Timoumi, A.; Algarou, N.A.; Akhtar, S.; Slimani, Y.; Almessiere, M.A.; AlAhmari, F.S.; Baykal, A.; et al. Synthesis of Electrospun TiO2 Nanofibers and Characterization of Their Antibacterial and Antibiofilm Potential against Gram-Positive and Gram-Negative Bacteria. Antibiotics 2020, 9, 572. [Google Scholar] [CrossRef]

- Yuan, K.; Jin, X.; Xu, C.; Wang, X. Manipulation of electrospun mesoporous zirconia nanofiber with enhanced surface area and catalytic property. Ceram. Int. 2019, 45, 13414–13421. [Google Scholar] [CrossRef]

- Nagrath, M.; Alhalawani, A.; Yazdi, A.R.; Towler, M.R. Bioactive glass fiber fabrication via a combination of sol-gel process with electro-spinning technique. Mater. Sci. Eng. C 2019, 101, 521–538. [Google Scholar] [CrossRef]

- Ávila-Martínez, A.K.; Roque-Ruiz, J.H.; Torres-Pérez, J.; Medellín-Castillo, N.A.; Reyes-López, S.Y. Allura Red dye sorption onto electrospun zirconia nanofibers. Environ. Technol. Innov. 2020, 18, 100760. [Google Scholar] [CrossRef]

- Koo, J.Y.; Lim, Y.; Kim, Y.B.; Byun, D.; Lee, W.-Y. Electrospun yttria-stabilized zirconia nanofibers for low-temperature solid oxide fuel cells. Int. J. Hydrog. Energy 2017, 42, 15903–15907. [Google Scholar] [CrossRef]

- Pescador-Rojas, J.A.; Jiménez-Pérez, J.L.; Sánchez-Ramírez, J.F.; Gutiérrez-Fuentes, R.; Correa-Pacheco, Z.N.; Zúñiga-Zarco, J.P.; Orozco-Flores, L.D. Synthesis of Electrospun Titania Nanofibers for Thermal Lens Study in Heat Transport Applications. Mater. Sci. Forum 2018, 936, 58–62. [Google Scholar] [CrossRef]

- De Dicastillo, C.L.; Patiño, C.; Galotto, M.J.; Palma, J.L.; Alburquenque, D.; Escrig, J. Novel Antimicrobial Titanium Dioxide Nanotubes Obtained through a Combination of Atomic Layer Deposition and Electrospinning Technologies. Nanomaterials 2018, 8, 128. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Garibay-Alvarado, J.A.; Espinosa-Cristóbal, L.F.; Reyes-López, S.Y. FIBROUS SILICA-HYDROXYAPATITE COMPOSITE BY ELECTROSPINNING. Int. J. Res. Granthaalayah 2017, 5, 39–47. [Google Scholar] [CrossRef]

- Roque-Ruiz, J.H.; Garibay-Alvarado, J.A.; Medellín-Castillo, N.A.; Reyes-López, S.Y. Preparation of Electrospun Hydroxyapatite-Glass Fibers for Removal of Cadmium (Cd+2) and Lead (Pb+2) from Aqueous Media. Water Air Soil Pollut. 2020, 231, 1–13. [Google Scholar] [CrossRef]

- Garibay-Alvarado, J.A.; Farías, R.; Reyes-López, S.Y. Sol-Gel and Electrospinning Synthesis of Lithium Niobate-Silica Nanofibers. Coatings 2019, 9, 212. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Li, W.; Xia, Y.; Jiao, X.; Chen, D. Electrospun flexible self-standing γ-alumina fibrous membranes and their potential as high-efficiency fine particulate filtration media. J. Mater. Chem. A 2014, 2, 15124–15131. [Google Scholar] [CrossRef]

- Choi, Y.S.; Oh, K.; Koh, H.-L. Electrospun Alumina-Nanofiber-Supported Pt–Sn Catalyst for Propane Dehydrogenation. J. Nanosci. Nanotechnol. 2020, 20, 6897–6903. [Google Scholar] [CrossRef] [PubMed]

- Xie, Y.; Jin, Y.; Zhou, Y.; Wang, Y. SERS activity of self-cleaning silver/titania nano-array. Appl. Surf. Sci. 2014, 313, 549–557. [Google Scholar] [CrossRef]

- Xie, Y.; Meng, Y. SERS performance of graphene oxide decorated silver nanoparticle/titania nanotube array. RSC Adv. 2014, 4, 41734–41743. [Google Scholar] [CrossRef]

- Roque-Ruiz, J.H.; Martínez-Máynez, H.; Zalapa-Garibay, M.A.; Arizmendi-Moraquecho, A.; Farias, R.; Reyes-López, S.Y. Surface enhanced Raman spectroscopy in nanofibers mats of SiO2-TiO2-Ag. Results Phys. 2017, 7, 2520–2527. [Google Scholar] [CrossRef]

- Singh, J.; Manna, A.K.; Soni, R.K. Bifunctional Au–TiO2 thin films with enhanced photocatalytic activity and SERS based multiplexed detection of organic pollutant. J. Mater. Sci. Mater. Electron. 2019, 30, 16478–16493. [Google Scholar] [CrossRef]

- Prakashan, V.; Gejo, G.; Sanu, M.; Sajna, M.; Subin, T.; Biju, P.; Cyriac, J.; Unnikrishnan, N. Novel SPR based fiber optic sensor for vitamin A using Au@Ag core-shell nanoparticles doped SiO2-TiO2-ZrO2 ternary matrix. Appl. Surf. Sci. 2019, 484, 219–227. [Google Scholar] [CrossRef]

- Prakashan, V.; Georgeab, G.; Sanu, M.S.; Sajnaac, M.S.; Saritha, A.; Sudarsanakumar, C.; Biju, P.; Josepha, C.; Unnikrishnan, N. Investigations on SPR induced Cu@Ag core shell doped SiO2-TiO2-ZrO2 fiber optic sensor for mercury detection. Appl. Surf. Sci. 2020, 507, 144957. [Google Scholar] [CrossRef]

- Hareesh, S.; Simon, S.M.; Jose, T.A.; Gopinath, M.; Saritha, A.; Joseph, C.; Biju, P.; Unnikrishnan, N. Highly sensitive and stable Ag nanoparticles decorated TiO2-ZrO2 composite SERS substrates for Rhodamine 6G detection. Mater. Today Proc. 2020, 33, 1396–1401. [Google Scholar] [CrossRef]

- Ji, P.; Wang, Z.; Shang, X.; Zhang, Y.; Liu, Y.; Mao, Z.; Shi, X. Direct Observation of Enhanced Raman Scattering on Nano-Sized ZrO2 Substrate: Charge-Transfer Contribution. Front. Chem. 2019, 7, 245. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hu, Y.; Wang, X.; Zhang, M.; Wang, S.; Li, S.; Chen, G. A Hierarchical Anodic Aluminum Oxide Template. Nano Lett. 2021, 21, 250–257. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Zhao, A.; Wang, D.; Guo, H.; Sun, H.; He, Q. Fabrication of cube-like Fe3O4@SiO2@Ag nanocomposites with high SERS activity and their application in pesticide detection. J. Nanoparticle Res. 2016, 18, 178. [Google Scholar] [CrossRef]

- Shi, T.; Tang, Z.; Liang, P.; Zhang, X.; Zhang, D.; Shao, Q.; Chen, H. ZrO2@ Ag@ SiO2 Sandwich Structure with High SERS Enhancement Effect and Stability. J. Phys. Chem. C 2020, 124, 25967–25974. [Google Scholar] [CrossRef]

- Soto-Nieto, F.; Farías, R.; Reyes-López, S.Y. Sol–Gel and Electrospinning Synthesis of Silica–Hydroxyapatite–Silver Nanofibers for SEIRAS and SERS. Coatings 2020, 10, 910. [Google Scholar] [CrossRef]

| Ceramic | Precursor | Reference |

|---|---|---|

| Silica | Tetramethyl orthosilicate | [47] |

| Silica | Tetraethyl orthosilicate | [48] |

| Zirconia | Zirconium butoxide | [49] |

| Zirconia | Zirconium butoxide | [50] |

| Titania | Titanium isopropoxide | [51] |

| Titania | Titanium isopropoxide | [52] |

| Hydroxyapatite | Triethyl phosphite | [53] |

| Hydroxyapatite | Triethyl phosphite | [54] |

| Lithium niobate | Dihydrate lithium acetate and niobium chloride | [55] |

| Lithium niobate | Lithium carbonate and niobium pentoxide | [56] |

| Alumina | Aluminum nitrate | [57] |

| Alumina | Aluminum nitrate | [58] |

| Ceramic | Sintering Temperature (°C) | Material | Reference |

|---|---|---|---|

| Silica | 600 and 1200 | Silica matrix | [90] |

| Silica | 600 and 1200 | Glass | [91] |

| Zirconia | 700 | Film | [92] |

| Zirconia | 366, 900, and 1150 | Thin film | [93] |

| Titania | 500 | Fibers | [94] |

| Titania | 500 | Films | [95] |

| Hydroxyapatite | 600 | Nanoparticles | [96] |

| Hydroxyapatite | 800 | Porous scaffold | [97] |

| Lithium niobate | 1000 | Film | [98] |

| Lithium niobate | 900 | Substrate | [99] |

| Alumina | 700 | Catalyst | [100] |

| Alumina | 1000 | Nanocrystals | [101] |

| Ceramic | Diameter (nm) | Use | Reference |

|---|---|---|---|

| Silica | ≈500 | Beryllium uptake | [108] |

| Zirconia | ≈360 | Dye sorption | [109] |

| Zirconia | ≤200 | Fuel cells | [110] |

| Titania | ≤80 | Heat transport | [111] |

| Titania | ≈160 | Antimicrobial activity | [112] |

| Hydroxyapatite | ≤330 | Bioactive behavior | [113] |

| Hydroxyapatite | ≈150 | Metal adsorption | [114] |

| Lithium niobate | ≈190 | Piezoelectric behavior | [115] |

| Alumina | ≤250 | Filtration device | [116] |

| Alumina | ≤250 | Catalyst support | [117] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Garibay’Alvarado, J.A.; Reyes-López, S.Y. Sol–Gel Ceramics for SEIRAS and SERS Substrates. Crystals 2021, 11, 439. https://doi.org/10.3390/cryst11040439

Garibay’Alvarado JA, Reyes-López SY. Sol–Gel Ceramics for SEIRAS and SERS Substrates. Crystals. 2021; 11(4):439. https://doi.org/10.3390/cryst11040439

Chicago/Turabian StyleGaribay’Alvarado, Jesús Alberto, and Simón Yobanny Reyes-López. 2021. "Sol–Gel Ceramics for SEIRAS and SERS Substrates" Crystals 11, no. 4: 439. https://doi.org/10.3390/cryst11040439