High Thermal Stability of κ-Ga2O3 Grown by MOCVD

Abstract

1. Introduction

2. Materials and Methods

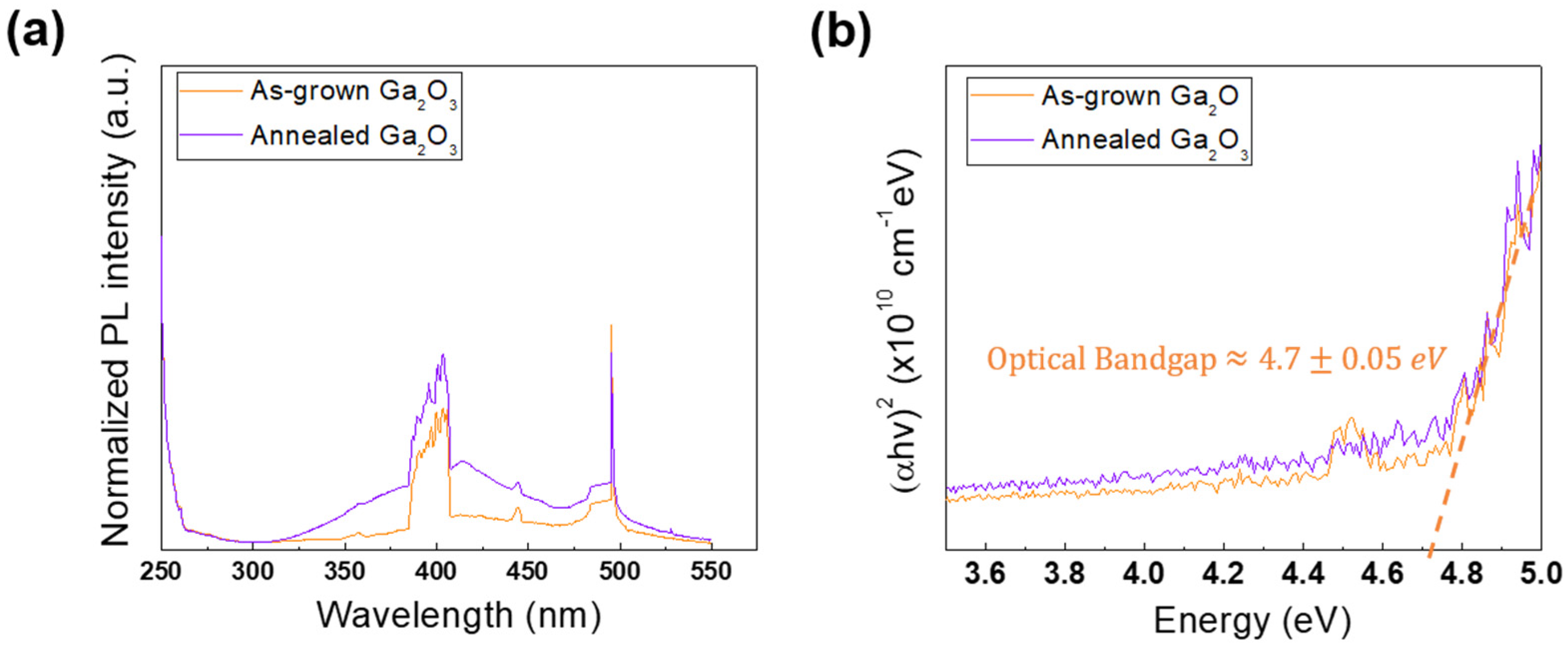

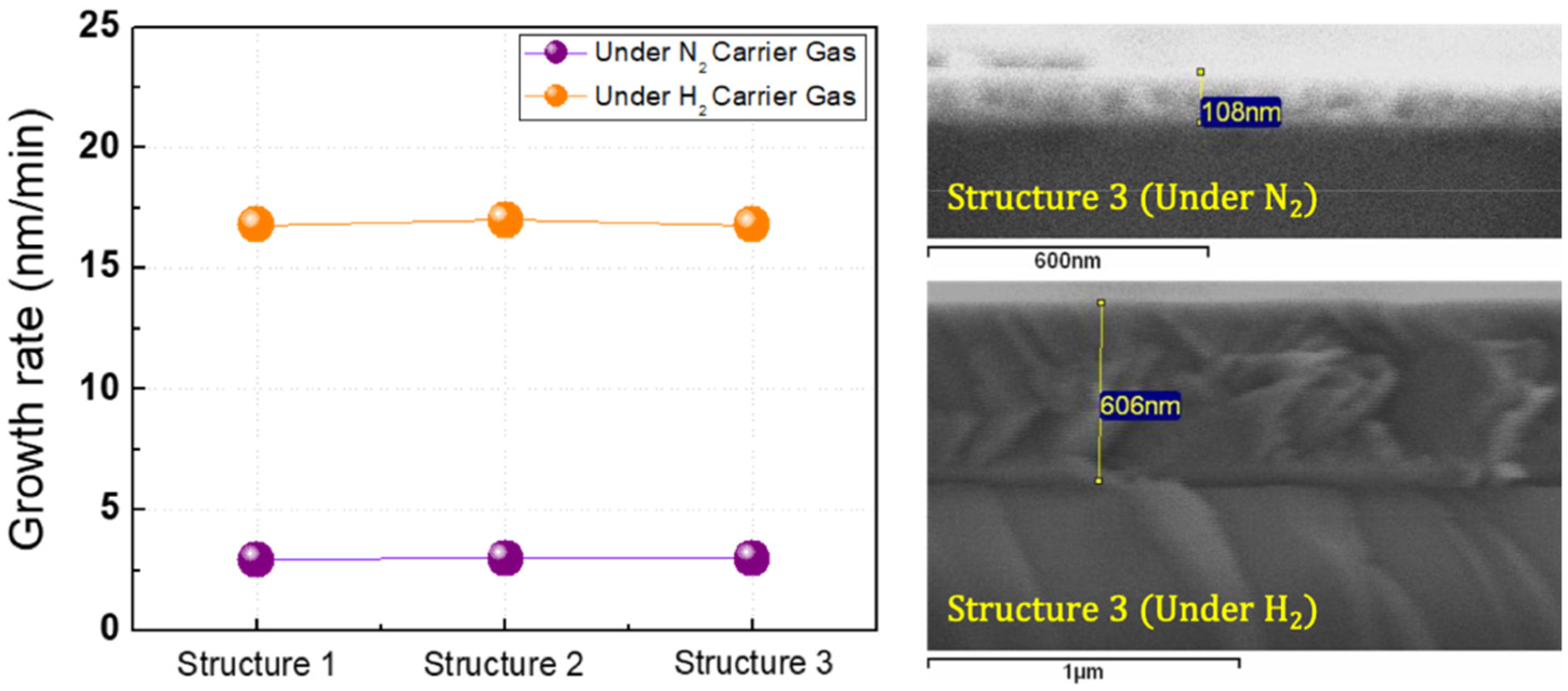

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Roy, R.; Hill, V.G.; Osborn, E.F. Polymorphism of Ga2O3 and the System Ga2O3—H2O. J. Am. Chem. Soc. 1952, 74, 719–722. [Google Scholar] [CrossRef]

- Razeghi, M.; Park, J.H.; McClintock, R.; Pavlidis, D.; Teherani, F.H.; Rogers, D.J.; Magill, B.A.; Khodaparast, G.A.; Xu, Y.; Wu, J.; et al. A Review of the Growth, Doping, and Applications of β-Ga2O3 Thin Films. Proc. SPIE 2018, 10533, 105330R1-24. [Google Scholar]

- Zhou, H.; Zhang, J.; Zhang, C.; Feng, Q.; Zhao, S.; Ma, P.; Hao, Y. A review of the most recent progresses of state-of-art gallium oxide power devices. J. Semicond. 2019, 40, 011803. [Google Scholar] [CrossRef]

- Cora, I.; Mezzadri, F.; Boschi, F.; Bosi, M.; Čaplovičová, M.; Calestani, G.; Dódony, I.; Pécz, B.; Fornari, R. The real structure of ε-Ga2O3 and its relation to κ-phase. CrystEngComm 2017, 19, 1509–1516. [Google Scholar] [CrossRef]

- Nikolaev, V.; Stepanov, S.; Pechnikov, A.V.; Shapenkov, S.; Scheglov, M.; Chikiryaka, A.; Vyvenko, O.F. HVPE Growth and Characterization of ε-Ga2O3 Films on Various Substrates. ECS J. Solid State Sci. Technol. 2020, 9, 045014. [Google Scholar] [CrossRef]

- Anhar Uddin Bhuiyan, A.F.M.; Feng, Z.; Johnson, J.M.; Huang, H.L.; Hwang, J.; Zhao, H. MOCVD Epitaxy of ultrawide bandgap β-(AlxGa1−x)2O3 with high-Al composition on (100) β-Ga2O3 substrates. Cryst. Growth Des. 2020, 20, 6722–6730. [Google Scholar] [CrossRef]

- Hatipoglu, I.; Mukhopadhyay, P.; Alema, F.; Sakthivel, T.S.; Seal, S.; Osinsky, A.; Schoenfeld, W.V. Tuning the responsivity of monoclinic solar-blind photodetectors grown by metal organic chemical vapor deposition. J. Phys. D Appl. Phys. 2020, 53, 454001. [Google Scholar] [CrossRef]

- Bi, X.; Wu, Z.; Huang, Y.; Tang, W. Stabilization and enhanced energy gap by Mg doping in ε-phase Ga2O3 thin films. AIP Adv. 2018, 8, 025008. [Google Scholar] [CrossRef]

- Maccioni, M.B.; Fiorentini, V. Phase diagram and polarization of stable phases of (Ga1−xInx)2O3. Appl. Phys. Express 2016, 9, 041102. [Google Scholar] [CrossRef]

- Nishinaka, H.; Miyauchi, N.; Tahara, D.; Morimoto, S.; Yoshimoto, M. Incorporation of indium into ε-gallium oxide epitaxial thin films grown via mist chemical vapour deposition for bandgap engineering. CrystEngComm 2018, 20, 1882–1888. [Google Scholar] [CrossRef]

- Lee, J.; Kim, H.; Gautam, L.; He, K.; Hu, X.; Dravid, V.; Razeghi, M. Study of Phase Transition in MOCVD Grown Ga2O3 from κ to β Phase by Ex Situ and In Situ Annealing. Photonics 2021, 8, 17. [Google Scholar] [CrossRef]

- Lee, J.; Kim, H.; Gautam, L.; Razeghi, M. Highly Conductive Co-Doped Ga2O3:Si-In Grown by MOCVD. Coatings 2021, 11, 287. [Google Scholar] [CrossRef]

- Chen, Q.; Dapkus, P.D. On the Thermal Decomposition of Trimethylgallium—A Molecular Beam Sampling Mass Spectroscopy Study. J. Electrochem. Soc. 1991, 138, 2821. [Google Scholar] [CrossRef]

| Structure | Components | TMGa | TMIn | H2O | SiH4 |

|---|---|---|---|---|---|

| Structure 1 | Ga2O3 [Reference] | 5 sccm (N2) | 0 sccm (N2) | 1600 sccm (N2) | 20 sccm (N2) |

| Structure 2 | Superlattice [Ga2O3 (30 s)/In2O3 (1 min)] | 5 sccm (N2) | 70 sccm (N2) | 1600 sccm (N2) | 0 |

| Structure 3 | Superlattice [Ga2O3 (30 s)/In2O3 (1 min)] | 5 sccm (N2) | 70 sccm (N2) | 1600 sccm (N2) | 20 sccm (N2) |

| Before Annealing | After Annealing | |||

|---|---|---|---|---|

| Hall Mobility | Carrier Concentration | Hall Mobility | Carrier Concentration | |

| Structure 1 | Highly resistive | Highly resistive | Highly resistive | Highly resistive |

| Structure 2 | Highly resistive | Highly resistive | Highly resistive | Highly resistive |

| Structure 3 | 2 cm2/V·s | 2 × 1017 cm−3 | 4 cm2/V·s | 4 × 1018 cm−3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, J.; Kim, H.; Gautam, L.; Razeghi, M. High Thermal Stability of κ-Ga2O3 Grown by MOCVD. Crystals 2021, 11, 446. https://doi.org/10.3390/cryst11040446

Lee J, Kim H, Gautam L, Razeghi M. High Thermal Stability of κ-Ga2O3 Grown by MOCVD. Crystals. 2021; 11(4):446. https://doi.org/10.3390/cryst11040446

Chicago/Turabian StyleLee, Junhee, Honghyuk Kim, Lakshay Gautam, and Manijeh Razeghi. 2021. "High Thermal Stability of κ-Ga2O3 Grown by MOCVD" Crystals 11, no. 4: 446. https://doi.org/10.3390/cryst11040446

APA StyleLee, J., Kim, H., Gautam, L., & Razeghi, M. (2021). High Thermal Stability of κ-Ga2O3 Grown by MOCVD. Crystals, 11(4), 446. https://doi.org/10.3390/cryst11040446