Experimental Research on Interfacial Bonding Strength between Vertical Cast-In-Situ Joint and Precast Concrete Walls

Abstract

1. Introduction

2. Experimental Work

2.1. Preparation of Concretes

2.2. Mechanical Properties of Concretes

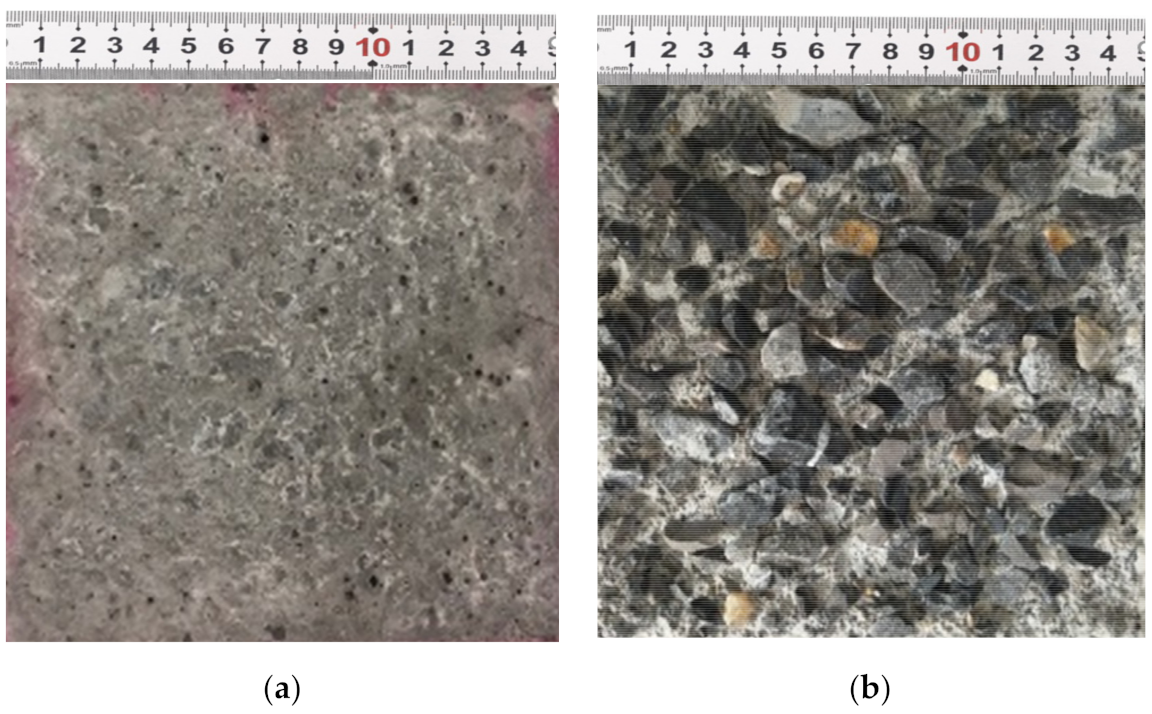

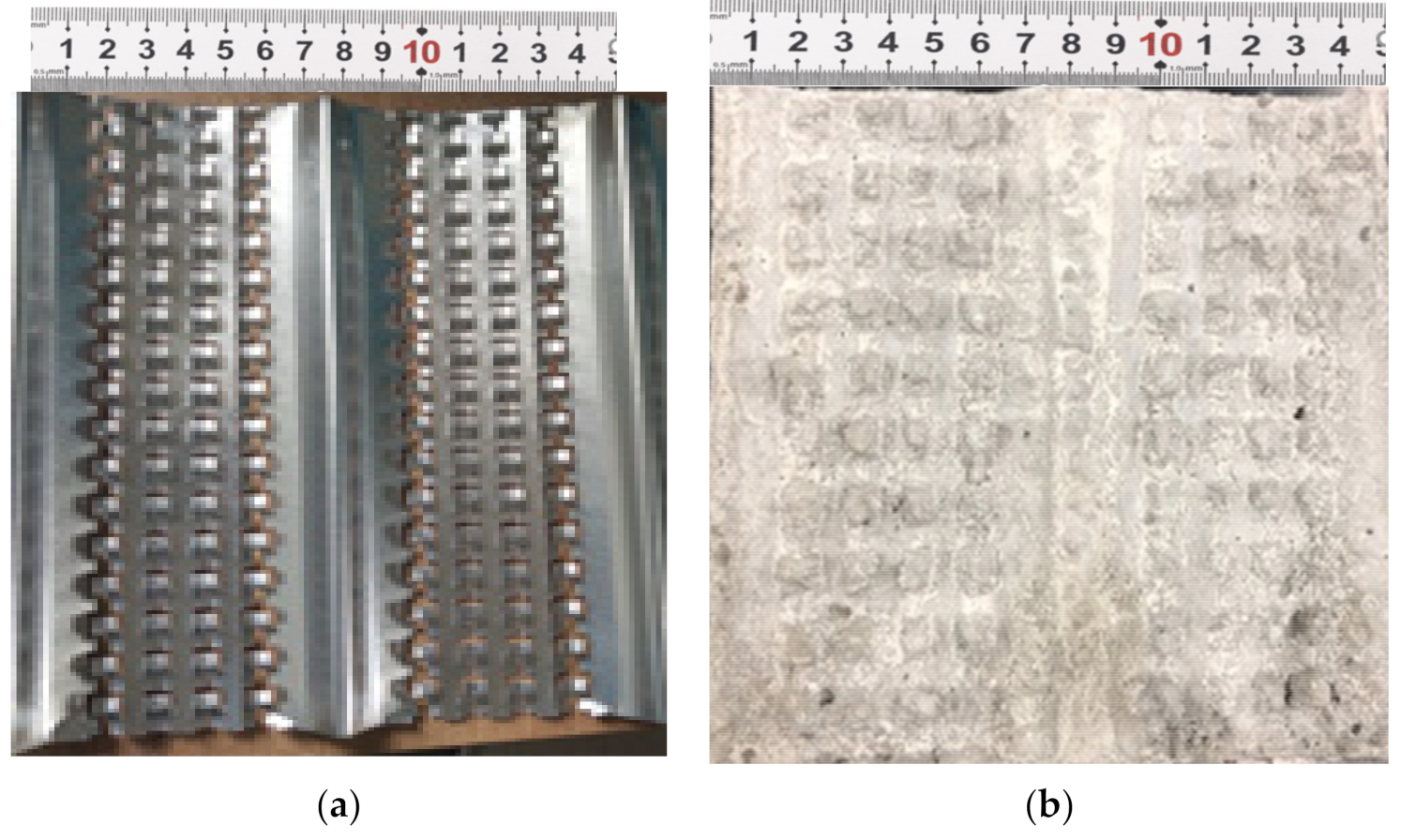

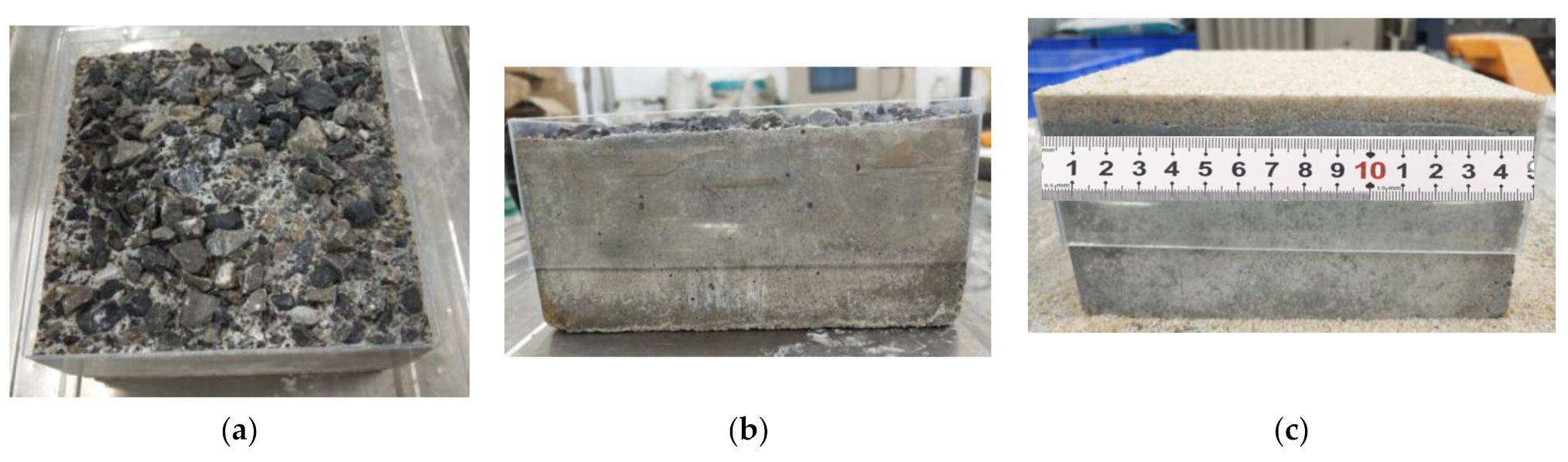

2.3. Formation of Interface

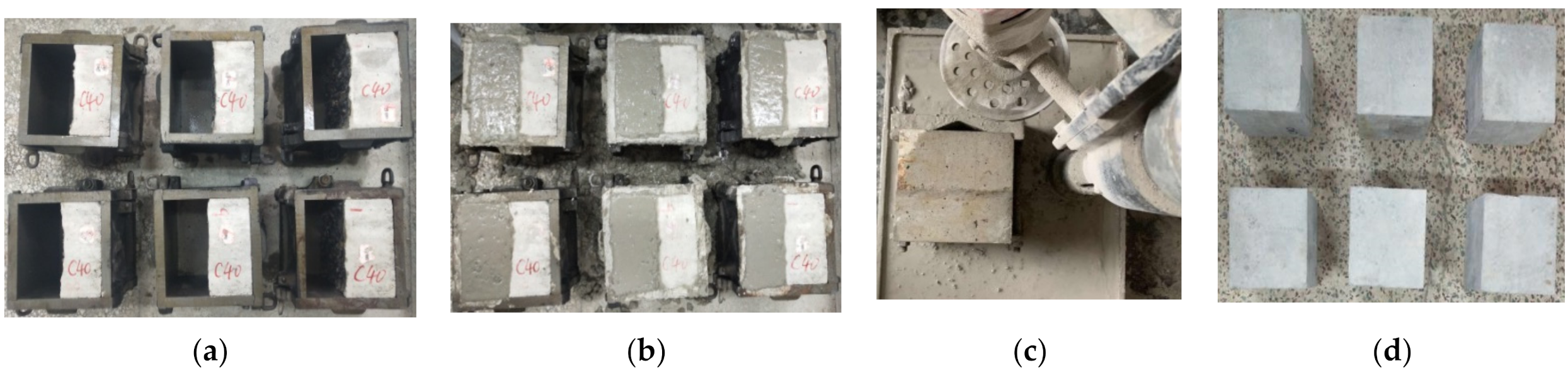

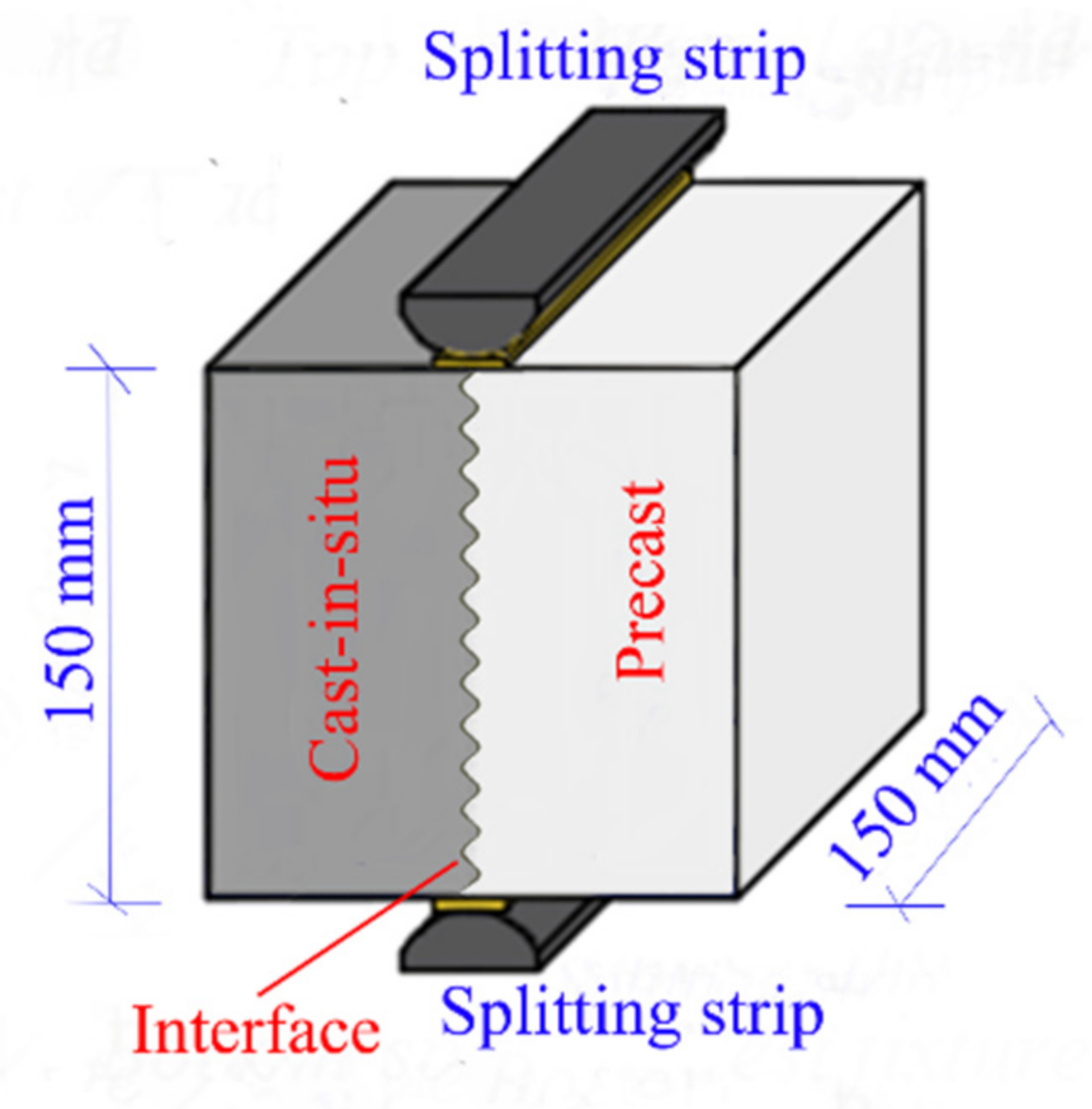

2.4. Preparation of Bond Specimens and Test Method

3. Analyses of Test Results

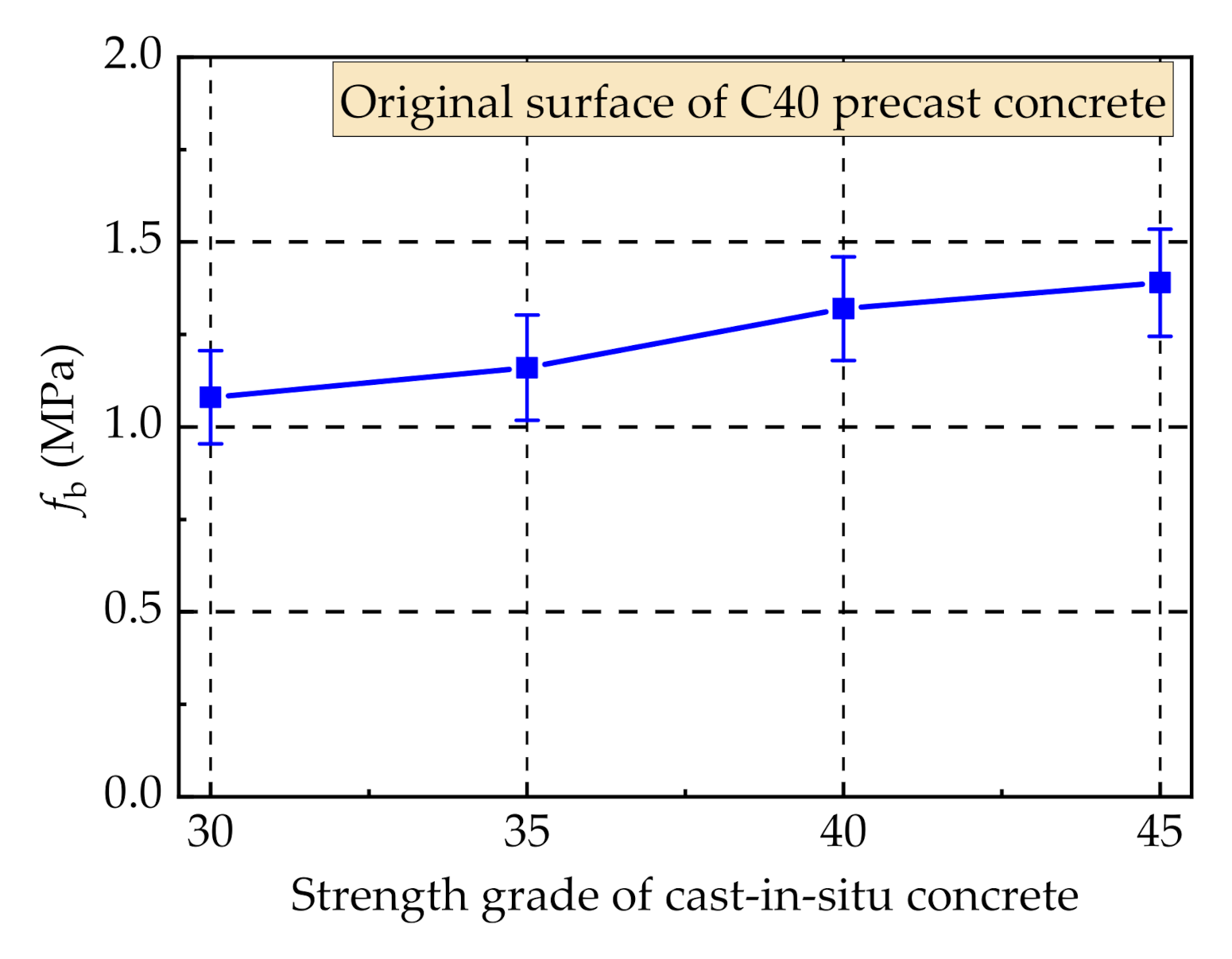

3.1. Effect of Cast-In-Situ Concrete Strength

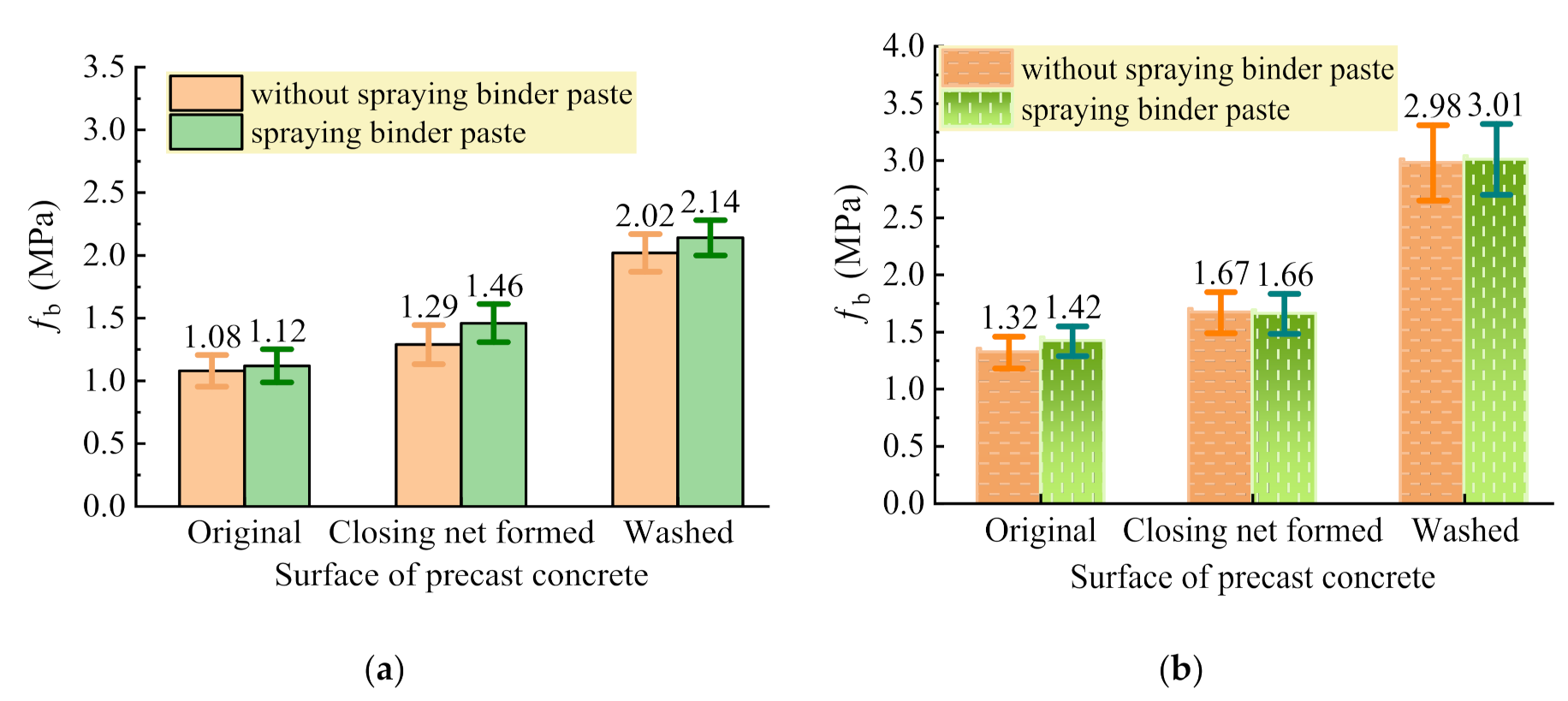

3.2. Effect of Interface of Precast Concrete

3.3. Effect of Interface Adhesion Agent

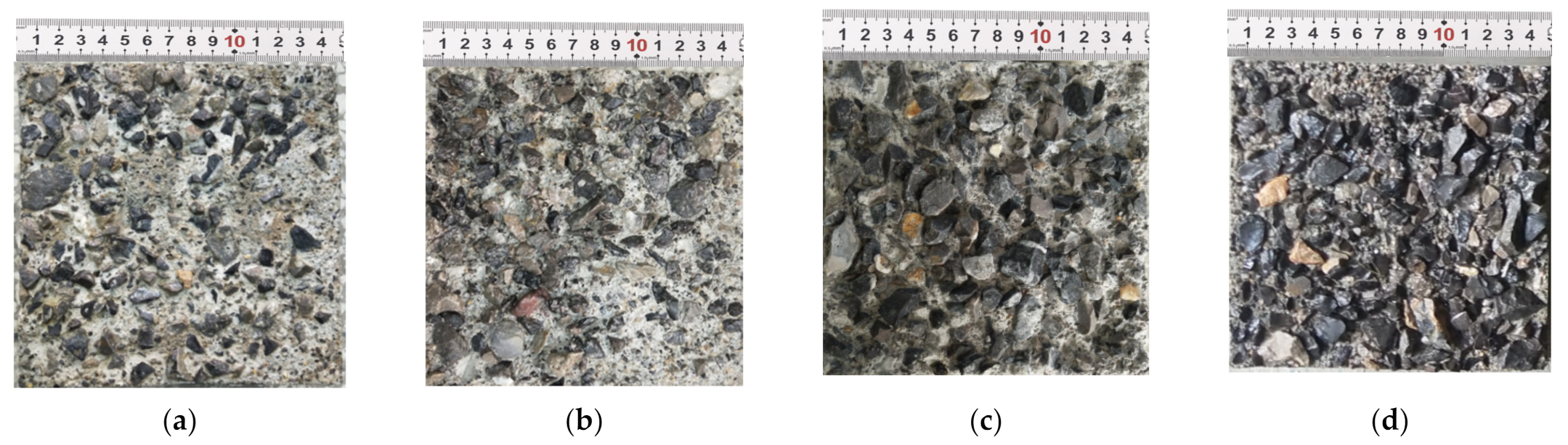

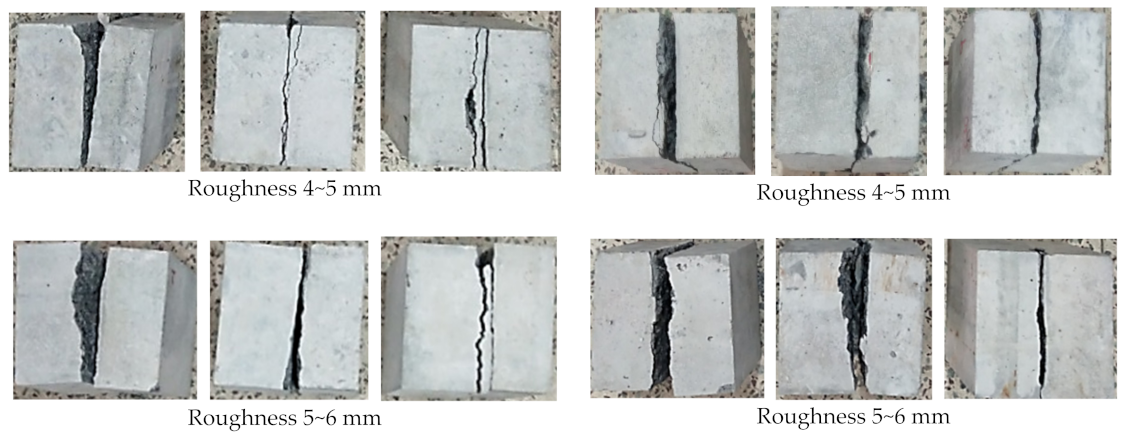

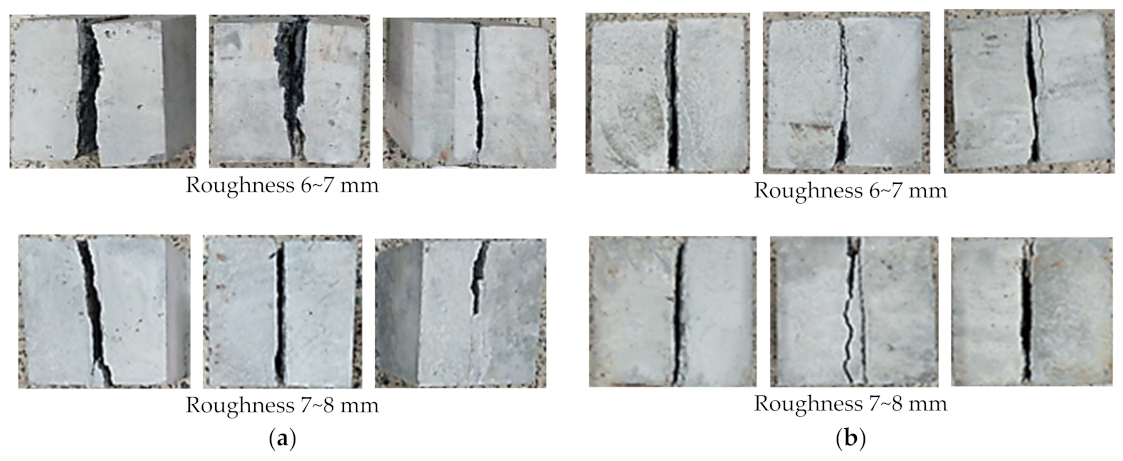

3.4. Effect of Roughness of Washing Exposed Aggregates

3.5. Effect of Storage Time of Precast Concrete

4. Conclusions

- (1)

- With the premise of higher strength grade of cast-in-situ concrete than precast concrete, the interfacial bonding strength increased with the increasing strength of cast-in-situ concrete. In practice, the cast-in-situ concrete is better one strength grade higher than precast concrete.

- (2)

- The interfacial bonding strength increased with sequence of original interface, closing net formed interface and washed rough interface of precast concrete. The washed rough interface of precast concrete is a good choice in practice to ensure the interfacial bonding strength. When the roughness was over 6 mm that is about one-third of exposed aggregates with maximum particle size of 20 mm, the interfacial bonding strength can reach the tensile strength of precast concrete.

- (3)

- Spraying binder paste on surface of precast concrete has beneficial effect on the bond of interface. This can be considered as a choice for the quality promotion of joints in practice.

- (4)

- The interfacial bonding strength decreased with the increasing storage time of precast concrete. The bonding strength could be equivalent to the tensile strength of precast concrete when the casting age of precast concrete was not over than 28 days. In practice, the production and installation cycle of precast concrete components should limit within 28 days.

- (5)

- The research of this paper has limitations only in macroscopic phenomena and index of bonding strength. Due to the complexity of interfacial bonding performance influenced by multi factors, further systematical researches should be carried out combined the macroscopic with the microscopic indices to revel the truth and accumulate research results.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Technical Standard for Assembled Buildings with Concrete Structure; GB/T 51231-2016; China Building Industry Press: Beijing, China, 2016.

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Standard for Design of Assembled Housing; JGJ/T398-2017; China Building Industry Press: Beijing, China, 2017.

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Technical Specification for Precast Concrete Structures; JGJ 1-2014; China Building Industry Press: Beijing, China, 2014.

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Technical Specification for Grout Sleeve Splicing of Rebars; JGJ 355-2015; China Building Industry Press: Beijing, China, 2015.

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Technical Standard for Precast Reinforced Concrete Shear Wall Structure Assembled by Anchoring Closed Loop Reinforcement; JGJ/T430-2018; China Building Industry Press: Beijing, China, 2018.

- Kang, P.; Xu, D.W.; Li, N.J. Key construction techniques of monolithic precast concrete shear-wall structure. Shanghai Build. Technol. 2018, 3, 62–64. [Google Scholar]

- Yin, B.Q.; Wu, Y. Research and application of construction technology for prefabricated component rough surface. J. New Ind. 2018, 8, 109–112. [Google Scholar]

- Huang, X.M.; Zhang, X.J.; Liu, H.; Zhang, N. Split tensile test of prefabricated component laminated surface. Build. Sci. 2019, 35, 70–76. [Google Scholar] [CrossRef]

- Cao, H.; Ma, Q.Y.; Zhang, R.R.; Wang, Y. Experimental study on adhesive splitting tensile performance of post pouring concrete on precast concrete. Bull. China Ceram. Soc. 2016, 35, 2926–2929. [Google Scholar]

- Xie, H.C.; Li, G.Y.; Xiong, G.J. The mechanism formed the bonding force between new and old concrete. Bull. China Ceram. Soc. 2003, 24, 7–10. [Google Scholar] [CrossRef]

- Dong, S.S.; Feng, K.C.; Shi, W.Z. New agent based on different interface tensile strength of old concrete. Concrete 2011, 2, 14–16. [Google Scholar] [CrossRef]

- Hu, L.M.; Ma, C.M.; Xu, C.G.; Cao, H.L. Effect of interface agent on splitting tensile strength of old and new concrete in second age. Water Power 2017, 43, 53–55. [Google Scholar]

- Gao, D.Y.; Cheng, H.Q.; Zhu, H.T. Splitting tensile bonding strength of steel fiber reinforced concrete to old concrete. J. Build. Mater. 2007, 10, 505–509. [Google Scholar]

- Santos, P.M.D.; Julio, E.N.B.S. Factors affecting bond between new and old concrete. ACI Mater. J. 2011, 108, 449–456. [Google Scholar]

- Diab, A.M.; Elmoaty, A.E.M.A.; Eldin, M.R.T. Slant shear bond strength between self compacting concrete and old concrete. Constr. Build. Mater. 2017, 130, 73–82. [Google Scholar] [CrossRef]

- Gadri, K.; Guettala, A. Evaluation of bond strength between sand concrete as new repair material and ordinary concrete substrate (The surface roughness effect). Constr. Build. Mater. 2017, 157, 1133–1144. [Google Scholar] [CrossRef]

- He, Y.; Zhang, X.; Hooton, R.D.; Zhang, X.W. Effects of interface roughness and interface adhesion on new-to-old concrete bonding. Constr. Build. Mater. 2017, 151, 582–590. [Google Scholar] [CrossRef]

- British Standards Institution. Design of Concrete Structures: Part 1-1: General Rules and Rules for Buildings; Eurocode 2; British Standards Institution: London, UK, 2004. [Google Scholar]

- MC2010. Fib Model Code for Concrete Structures; Ernst & Sohn Publishing House: Hoboken, NJ, USA, 2013. [Google Scholar]

- ACI Committee 318. Building Code Requirements for Structural Concrete; ACI 318-14; ACI: Farmington Hill, MI, USA, 2014. [Google Scholar]

- Bentz, D.P.; De la Varga, I.; Munoz, J.F.; Spragg, R.P.; Graybeal, B.A.; Hussey, D.S.; Jacobson, D.L.; Jones, S.Z.; LaManna, J.M. Influence of substrate moisture state and roughness on interface microstructure and bond strength: Slant shear vs. pull-off testing. Cem. Concr. Compos. 2018, 87, 63–72. [Google Scholar] [CrossRef]

- Zhao, Z.F.; Zhao, G.F. Experimental research on treating interface of young on old concrete with high-pressure water-jet method. J. Dalian Univ. Tech. 1999, 39, 559–561. [Google Scholar]

- Zhao, Z.F.; Zhao, G.F.; Liu, J.; Yu, Y.H. Experimental study on adhesive tensile performance of young on old concrete. J. Build. Struct. 2001, 22, 51–55. [Google Scholar]

- Fan, J.; Wu, L.; Zhang, B. Influence of old concrete age, interface roughness and freeze-thawing attack on new-to-old concrete structure. Materials 2021, 14, 1057. [Google Scholar] [CrossRef]

- Zhang, M.J.; Chu, L.S.; Zhao, J.F.; Liu, X.H. Experimental study on splitting strength of new-to-old concrete in short age. Sichuan Build. Sci. 2018, 44, 106–108. [Google Scholar]

- Shi, C.C.; Wang, D.H.; Yuan, Q.; Cao, H.L.; Ma, Y. Study of splitting tensile strength for bond of new to old concrete in short age. China Concr. Cem. Prod. 2015, 5, 15–18. [Google Scholar] [CrossRef]

- General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. Common Portland Cement; GB 175-2007; China Standard Press: Beijing, China, 2007. [Google Scholar]

- General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. Fly Ash Used for Cement and Concrete; GB/T 1596-2017; China Standard Press: Beijing, China, 2017. [Google Scholar]

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Technical Specification for Application of Ground Limestone in Concrete; JGJ/T 318-2014; China Building Industry Press: Beijing, China, 2014.

- Ministry of housing and urban rural development of the people’s Republic of China. Specification for Mix Proportion Design of Ordinary Concrete; JGJ 55-2011; China Building Industry Press: Beijing, China, 2011.

- Ministry of Housing and Urban-Rural Construction of the People’s Republic of China. Technical Specification for Application of Self-Compacting Concrete; JGJ/T 283-2012; China Building Industry Press: Beijing, China, 2002.

- Zhao, M.L.; Ding, X.X.; Li, J.; Law, D. Numerical analysis of mix proportion of self-compacting concrete compared to ordinary concrete. Key Eng. Mater. 2018, 789, 69–75. [Google Scholar] [CrossRef]

- Ding, X.X.; Zhao, M.L.; Zhou, S.Y.; Fu, Y.; Li, C.Y. Statistical analysis and preliminary study on the mix proportion design of self-compacting steel fiber reinforced concrete. Materials 2019, 12, 637. [Google Scholar] [CrossRef]

- Li, C.Y.; Shang, P.R.; Li, F.L.; Feng, M.; Zhao, S.B. Shrinkage and mechanical properties of self-compacting SFRC with calcium sulfoaluminate expansive agent. Materials 2020, 13, 588. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.M.; Zhu, M.M.; Ding, X.X.; Ren, Z.G.; Zhao, S.B.; Zhao, M.S.; Dang, J.T. High-durability concrete with supplementary cementitious admixtures used at severe environment. Crystals 2021, 11, 196. [Google Scholar] [CrossRef]

- Ministry of Construction of the People’s Republic of China. Standard for Test Methods on Mechanical Properties of Ordinary Concrete; GB/T 50081-2002; China Building Industry Press: Beijing, China, 2002.

- Santos, P.M.D.; Julio, E.N.B.S. Comparison of methods for texture assessment of concrete surfaces. ACI Mater. J. 2010, 107, 433–440. [Google Scholar]

- Espeche, A.D.; Leon, J. Estimation of bond strength envelopes for old-to-new concrete interfaces based on a cylinder splitting test. Constr. Build. Mater. 2011, 25, 1222–1235. [Google Scholar] [CrossRef]

- Ma, J.T.; Wang, D.G.; Zhao, S.B.; Duan, P.; Yang, S.T. Influence of particle morphology of ground fly ash on the fluidity and strength of cement paste. Materials 2021, 14, 283. [Google Scholar] [CrossRef]

- Zhang, Y.; Jiang, L.; Zhang, W.; Qu, W. Durability of Concrete Structures; Shanghai Science and Technology Press: Shanghai, China, 2003. [Google Scholar]

- Zhao, S.B.; Liang, N.; Ma, X.L.; Yang, S. Experiment of carbonization for wet-sieving fine aggregate concrete made from ordinary concrete. Adv. Mater. Res. 2011, 201–203, 2287. [Google Scholar] [CrossRef]

- Ding, X.X.; Li, C.Y.; Xu, Y.Y.; Li, F.L.; Zhao, S.B. Experimental study on long-term compressive strength of concrete with manufactured sand. Constr. Build. Mater. 2016, 108, 67–73. [Google Scholar] [CrossRef]

- Li, C.Y.; Wang, F.; Deng, X.S.; Li, Y.Z.; Zhao, S.B. Testing and prediction of the strength development of recycled-aggregate concrete with large particle natural aggregate. Materials 2019, 12, 1891. [Google Scholar] [CrossRef]

- Zhao, S.B.; Ding, X.X.; Zhao, M.S.; Li, C.Y.; Pei, S.W. Experimental study on tensile strength development of concrete with manufactured sand. Constr. Build. Mater. 2017, 138, 247–253. [Google Scholar] [CrossRef]

| Density(g/cm3) | Water for Standard Consistency (%) | Specific Surface Area (m2/kg) | Setting Time (min) | Compressive Strength (MPa) | Flexural Strength (MPa) | |||

|---|---|---|---|---|---|---|---|---|

| Initial | Final | 3d | 28d | 3d | 28d | |||

| 3.09 | 27 | 360 | 170 | 215 | 27.8 | 58.4 | 5.2 | 8.3 |

| Material | Apparent Density(kg/m3) | Specific Surface Area (m2/kg) | Activity Index (%) | Water Demand Ratio (%) | Mobility Ratio (%) | Fineness: Residual on Sieve (%) | |

|---|---|---|---|---|---|---|---|

| 80 μm | 45 μm | ||||||

| FA | 2350 | 406 | 73.3 | 84 | - | 5.48 | 21.75 |

| GL | 2780 | 428 | 61.6 | - | 103 | 1.2 | 25 |

| Fineness | Water of Standard Consistency (%) | Setting Time (min) | Restrained Expansion Rate (%) | Compressive Strength (MPa) | ||||

|---|---|---|---|---|---|---|---|---|

| Specific Surface Area (m2/kg) | Residual on 1.18 mm Sieve (%) | Initial | Final | In Water 7d | In Air 21d | 7d | 28d | |

| 375 | 0.155 | 30 | 260 | 351 | 0.042 | 0.075 | 29.5 | 44.6 |

| Material | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | f-Cao | Na2O | K2O | LOI | Others |

|---|---|---|---|---|---|---|---|---|---|---|---|

| PC | 20.81 | 5.99 | 3.28 | 60.12 | 2.13 | 2.23 | 0.67 | 0.11 | 0.55 | 3.52 | 0.59 |

| FA | 55.92 | 17.31 | 5.91 | 6.95 | 3.82 | 1.93 | 0.26 | 0.48 | 1.96 | 2.63 | 2.83 |

| GL | 0.89 | 0.51 | 0.29 | 47.56 | 4.45 | 0.06 | 0.02 | 0.67 | 0.27 | 40.71 | 4.57 |

| EA | 3.48 | 9.27 | 1.44 | 42.78 | 0.48 | 27.38 | 6.65 | 0.62 | 0.47 | 5.51 | 1.92 |

| Particle Size (mm) | Apparent Density (kg/m3) | Bulk Density (kg/m3) | Closed-Compact Density (kg/m3) | Moisture Content (%) | Water Absorption (%) | Porosity (%) |

|---|---|---|---|---|---|---|

| 5~20 | 2730 | 1548 | 1613 | 0.30 | 1.17 | 42 |

| 5~16 | 2760 | 1554 | 1678 | 0.23 | 1.05 | 41 |

| Sand | 2689 | 1583 | 1726 | 0.6 | 2.0 |

| Concrete | Water to Binder Ratio | Dosage of Raw Materials (kg/m³) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Water | Cement | FA | GL | Crushed Limestone | Sand | Water Reducer | EA | ||

| Precast components | 0.47 | 175 | 335 | 37 | - | 1086 | 786 | 3.7 | - |

| 0.57 | 185 | 292 | 32 | - | 1060 | 831 | 3.2 | - | |

| Cast-in-situ joints | 0.37 | 190 | 308 | 51 | 103 | 885 | 816 | 5.6 | 51.4 |

| 0.34 | 185 | 326 | 54 | 109 | 873 | 806 | 5.4 | 54.4 | |

| 0.31 | 185 | 358 | 60 | 119 | 851 | 786 | 7.2 | 59. 7 | |

| 0.28 | 185 | 396 | 66 | 132 | 816 | 754 | 7.3 | 66.1 | |

| Concrete | Water to Binder Ratio | Strength Grade | Cubic Compressive Strength (MPa) | Axial Compressive Strength (MPa) | Splitting Tensile Strength (MPa) | Modulus of Elasticity (GPa) |

|---|---|---|---|---|---|---|

| Precast | 0.57 | C30 | 33.1 | 28.7 | 2.38 | 30.5 |

| 0.47 | C40 | 48.4 | 35.5 | 3.18 | 31.7 | |

| Cast-in-situ | 0.37 | C30 | 37.5 | 28.7 | 2.08 | 28.9 |

| 0.34 | C35 | 43.6 | 30.1 | 2.77 | 30.5 | |

| 0.31 | C40 | 47.0 | 32.4 | 2.94 | 31.3 | |

| 0.28 | C45 | 54.7 | 35.7 | 3.71 | 33.3 |

| Surface of Precast Concrete | Strength Grade of Concrete | fb (MPa) | βe | |

|---|---|---|---|---|

| Precast | Cast-In-Situ | |||

| Original surface | C40 | C30 | 1.08 | 0.34 |

| C40 | 1.32 | 0.41 | ||

| Closing net formed surface | C40 | C30 | 1.29 | 0.40 |

| C40 | 1.67 | 0.53 | ||

| Washed rough surface | C40 | C30 | 2.02 | 0.64 |

| C40 | 2.98 | 0.94 | ||

| Roughness Range | Average Depth of Filled Sand (mm) | |||||

|---|---|---|---|---|---|---|

| C40 Precast Concrete | C30 Precast Concrete | |||||

| 1 | 2 | 3 | 1 | 2 | 3 | |

| 4~5 mm | 4.57 | 4.73 | 4.81 | 4.20 | 4.44 | 4.73 |

| 5~6 mm | 5.04 | 5.36 | 5.73 | 5.14 | 5.33 | 5.95 |

| 6~7 mm | 6.30 | 6.73 | 6.94 | 6.13 | 6.36 | 6.92 |

| 7~8 mm | 7.02 | 7.24 | 7.46 | 7.31 | 7.33 | 7.96 |

| Strength Grade of Concrete | C40 Precast, C45 Cast-In-Situ | C30 Precast, C35 Cast-In-Situ | ||

|---|---|---|---|---|

| Roughness of Precast Concrete | fb (MPa) | βe | fb (MPa) | βe |

| 4~5 mm | 2.69 | 0.85 | 1.99 | 0.84 |

| 5~6 mm | 2.72 | 0.86 | 2.08 | 0.87 |

| 6~7 mm | 3.09 | 0.97 | 2.32 | 0.97 |

| 7~8 mm | 3.24 | 1.02 | 2.46 | 1.03 |

| Strength Grade of Concrete | C40 Precast, C45 Cast-In-Situ | C30 Precast, C35 Cast-In-Situ | ||

|---|---|---|---|---|

| Age of Precast Concrete (d) | fb (MPa) | βe | fb (MPa) | βe |

| 14 | 3.24 | 1.02 | 2.46 | 1.03 |

| 28 | 3.16 | 0.99 | 2.40 | 1.01 |

| 56 | 2.88 | 0.91 | 2.08 | 0.87 |

| 90 | 2.68 | 0.84 | 1.93 | 0.81 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, C.; Yang, Y.; Su, J.; Meng, H.; Pan, L.; Zhao, S. Experimental Research on Interfacial Bonding Strength between Vertical Cast-In-Situ Joint and Precast Concrete Walls. Crystals 2021, 11, 494. https://doi.org/10.3390/cryst11050494

Li C, Yang Y, Su J, Meng H, Pan L, Zhao S. Experimental Research on Interfacial Bonding Strength between Vertical Cast-In-Situ Joint and Precast Concrete Walls. Crystals. 2021; 11(5):494. https://doi.org/10.3390/cryst11050494

Chicago/Turabian StyleLi, Changyong, Yabin Yang, Jiuzhou Su, Huidi Meng, Liyun Pan, and Shunbo Zhao. 2021. "Experimental Research on Interfacial Bonding Strength between Vertical Cast-In-Situ Joint and Precast Concrete Walls" Crystals 11, no. 5: 494. https://doi.org/10.3390/cryst11050494

APA StyleLi, C., Yang, Y., Su, J., Meng, H., Pan, L., & Zhao, S. (2021). Experimental Research on Interfacial Bonding Strength between Vertical Cast-In-Situ Joint and Precast Concrete Walls. Crystals, 11(5), 494. https://doi.org/10.3390/cryst11050494