Analysis of In Situ Optical Signals during Laser Metal Deposition of Aluminum Alloys

Abstract

:1. Introduction

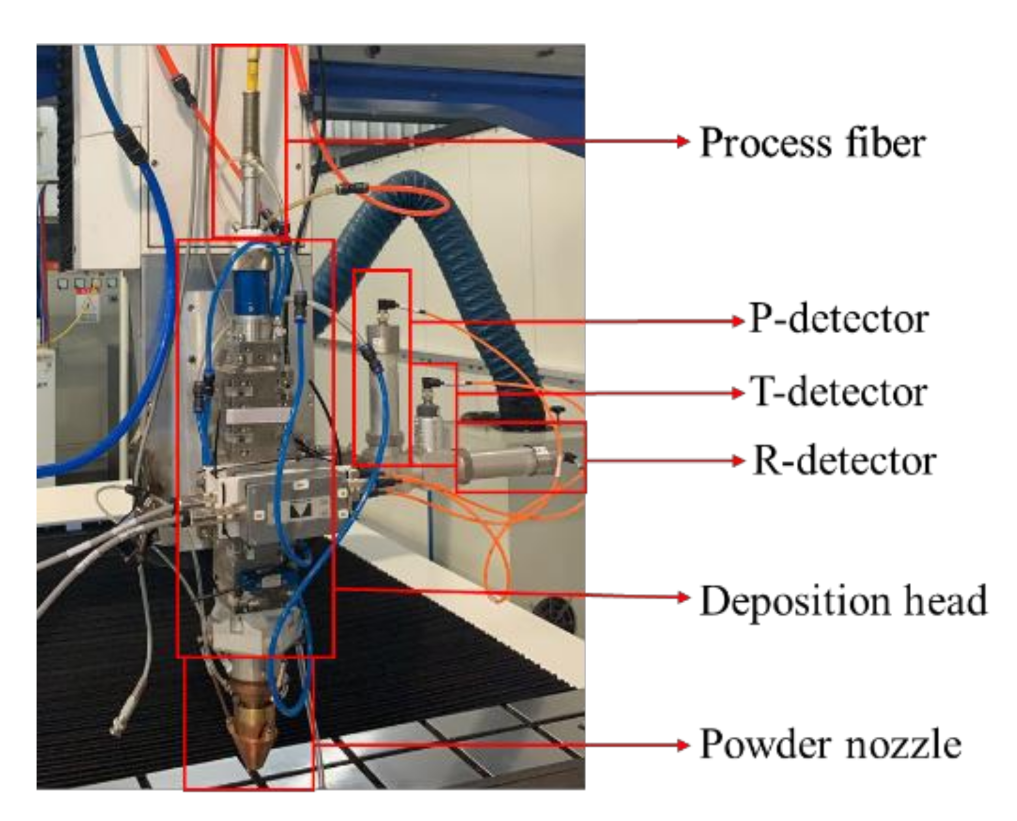

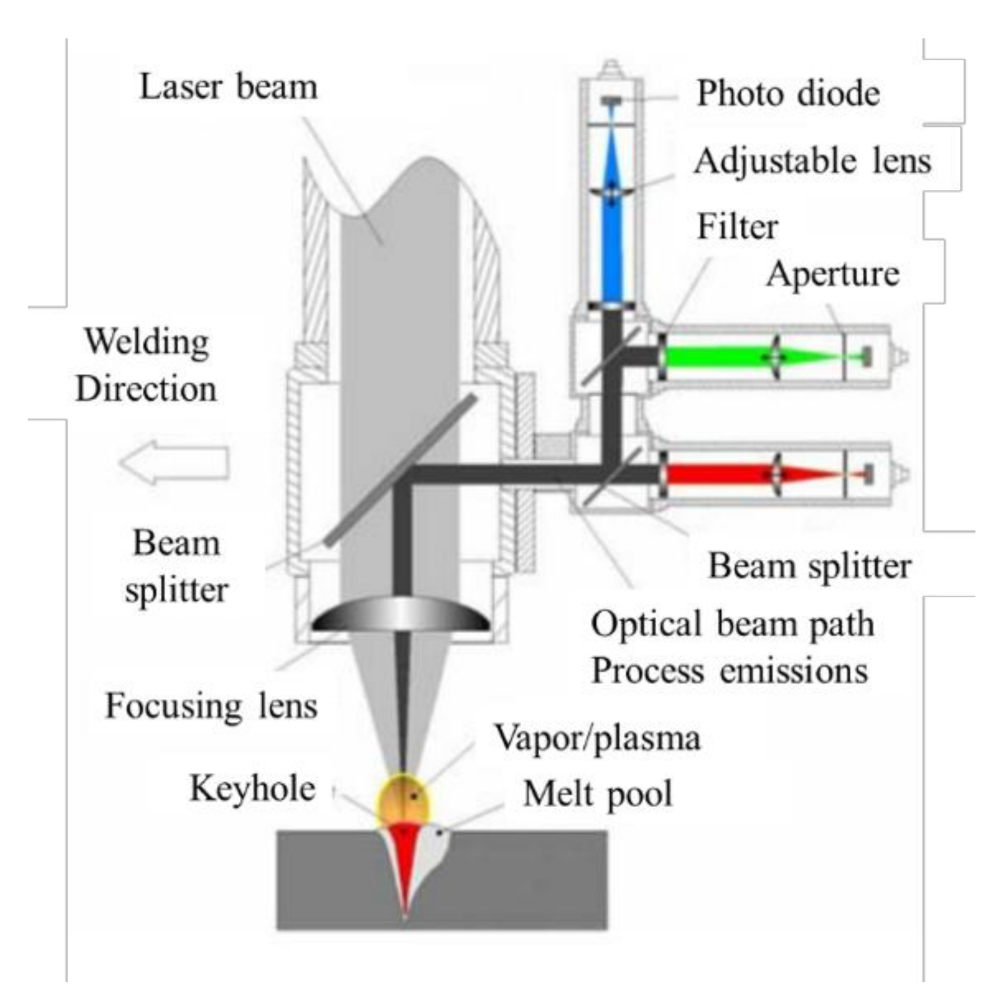

2. Experimental Procedure

3. Results and Discussion

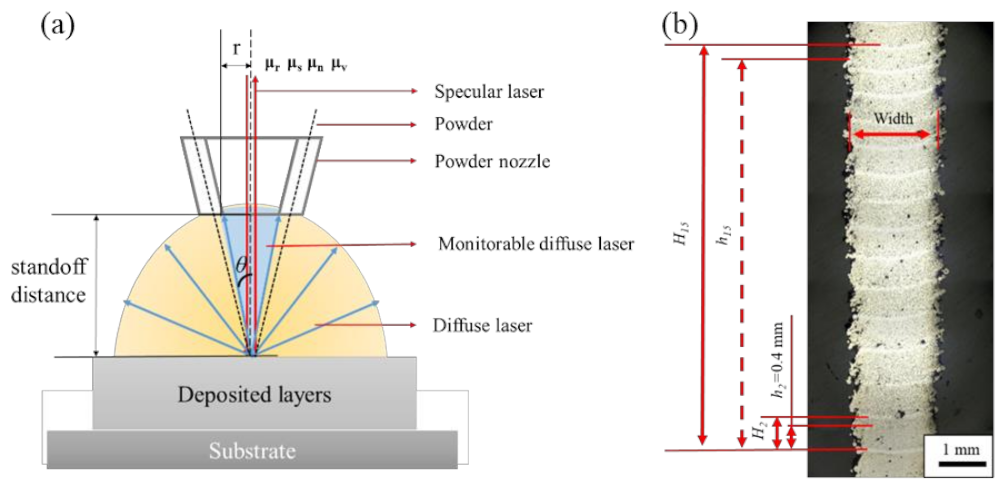

3.1. Characteristics of Aluminum LMD

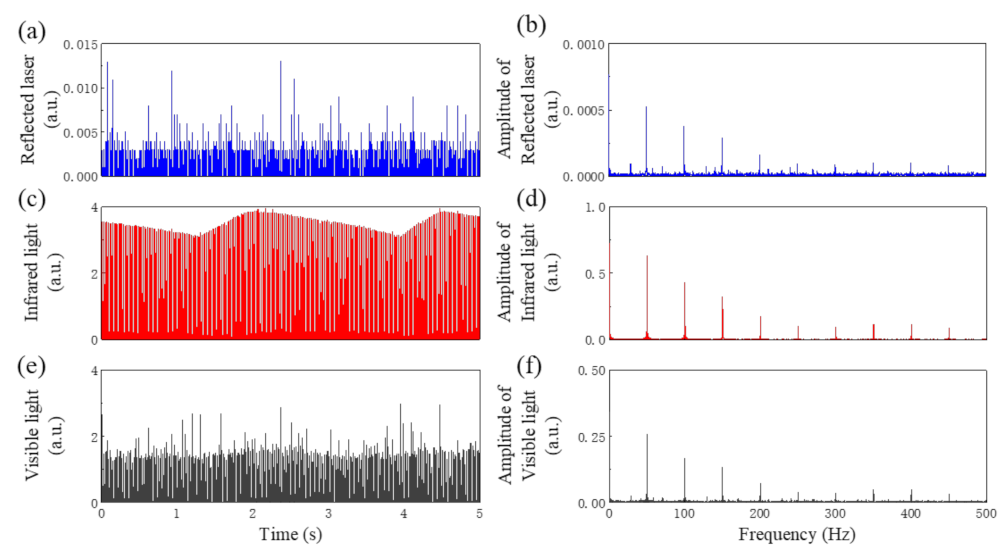

3.2. Original Signal Processing

3.2.1. Sampling Range

3.2.2. Data Denoising

3.2.3. Processing Method of Signals

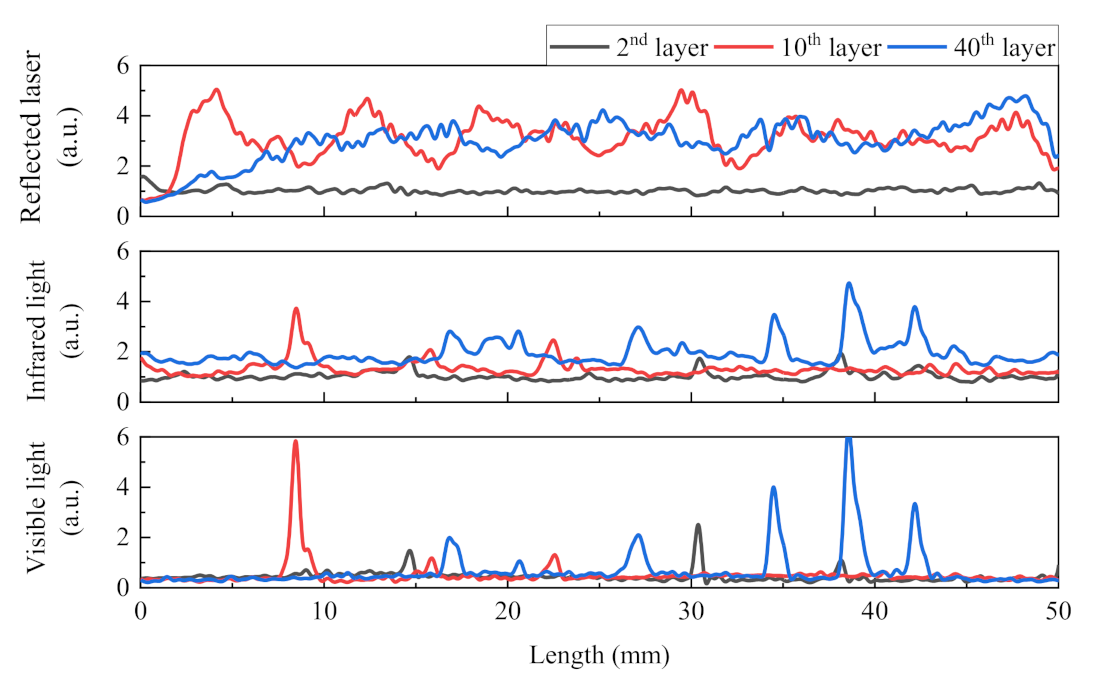

3.3. Variation of the Signals during the LMD Process

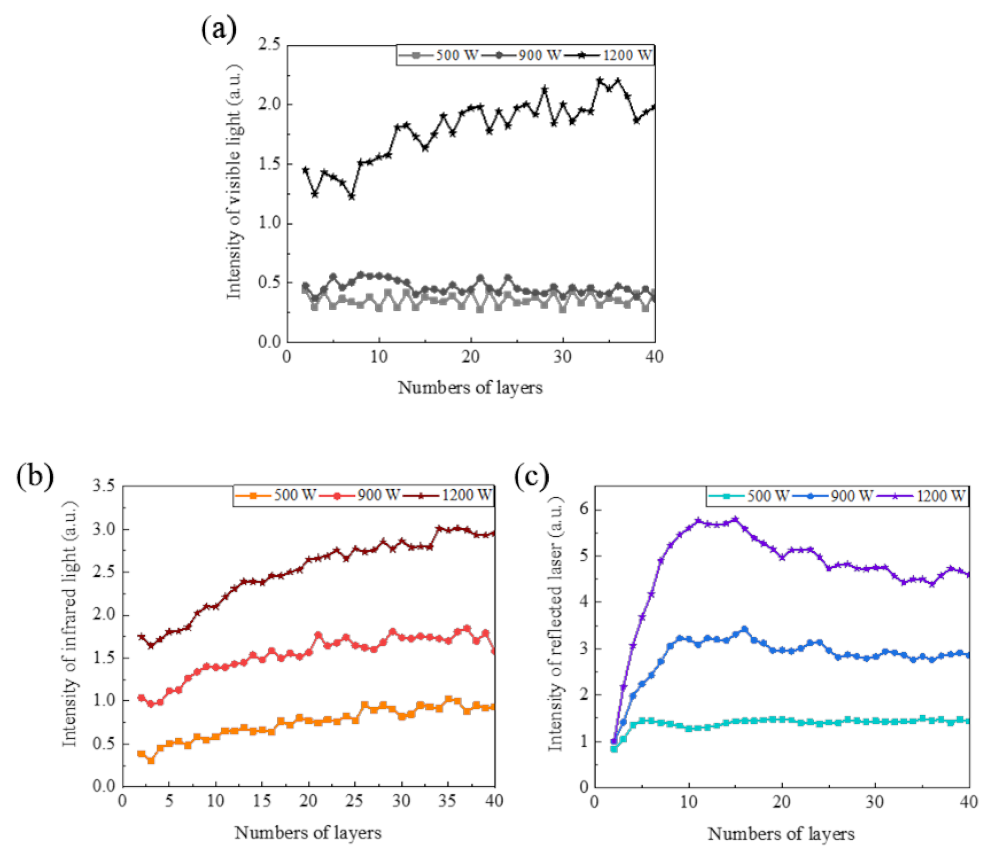

3.4. Effects of Laser Power on Process Stability

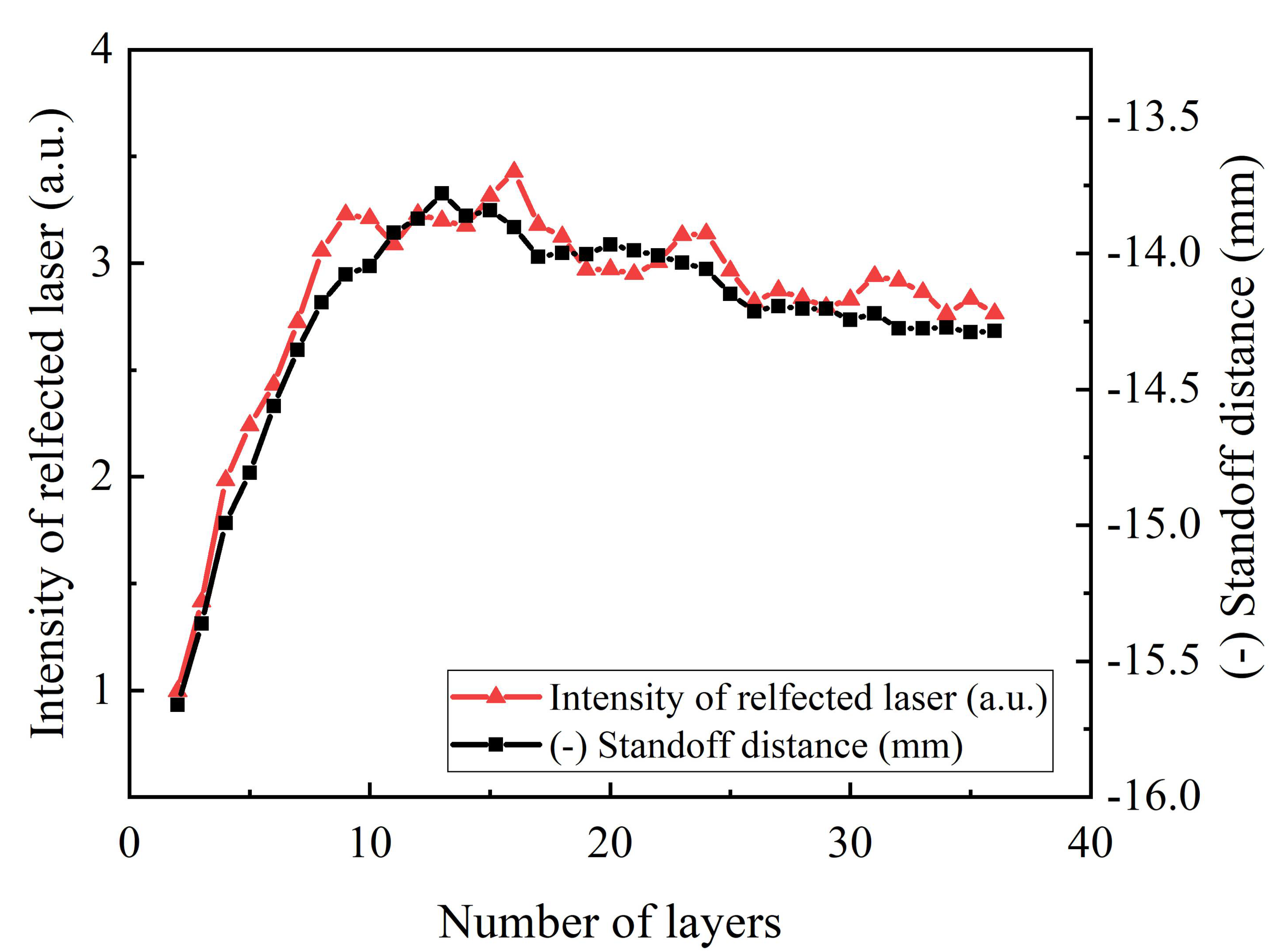

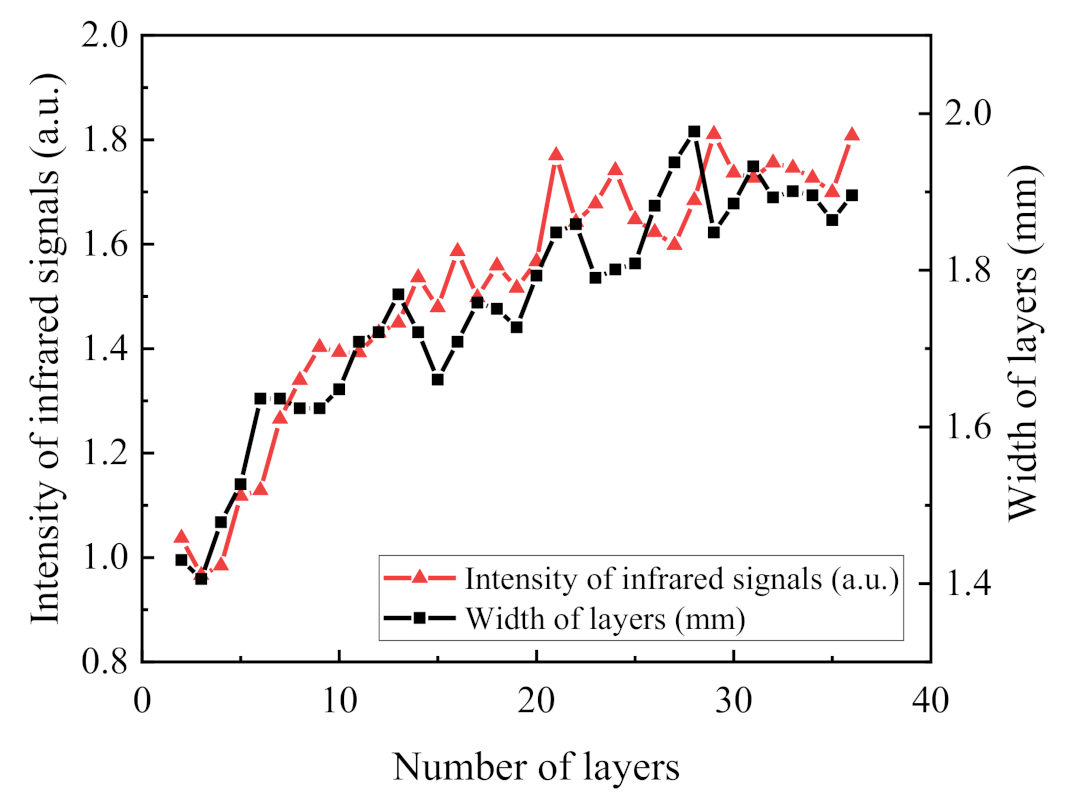

3.5. Online Monitoring of Deposition Height and Width

4. Conclusions

- (1)

- The visible light is not suitable for monitoring the process stability of the aluminum alloy LMD process.

- (2)

- There exists a trend of progressive increase through the first several layers in reflected laser signals, which coincides with accumulated deposition height. Reflected laser is linearly correlated with accumulated deposition height.

- (3)

- The infrared light signals are in a continual process of climbing because of the heat accumulation during the LMD process. A linear correlation is exhibited between infrared light and deposition width.

- (4)

- Accumulated deposition height and deposition width during the LMD process of aluminum alloys can be monitored with reflected laser and infrared light simultaneously. Reflected laser signals and infrared light signals have the potential to serve as the input of online feedback geometry control systems and real-time defect alarm systems of the LMD process.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Huang, S.H.; Liu, P.; Mokasdar, A.; Hou, L. Additive manufacturing and its societal impact: A literature review. Int. J. Adv. Manuf. Technol. 2013, 67, 1191–1203. [Google Scholar] [CrossRef]

- Campanelli, S.L.; Angelastro, A.; Signorile, C.G.; Casalino, G. Investigation on direct laser powder deposition of 18 Ni (300) marage steel using mathematical model and experimental characterisation. Int. J. Adv. Manuf. Technol. 2016, 89, 885–895. [Google Scholar] [CrossRef]

- Sun, J.; Zhao, Y.; Yang, L.; Zhao, X.; Qu, W.; Yu, T. Effect of shielding gas flow rate on cladding quality of direct laser fabrication AISI 316L stainless steel. J. Manuf. Process. 2019, 48, 51–65. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, Z.; Zhao, J.; He, Z.; Zhang, H. Comparison of Substrate Preheating on Mechanical and Microstructural Properties of Hybrid Specimens Fabricated by Laser Metal Deposition 316 L with Different Wrought Steel Substrate. Crystals 2020, 10, 891. [Google Scholar] [CrossRef]

- Wei, P.; Wei, Z.; Chen, Z.; Du, J.; He, Y.; Li, J.; Zhou, Y. The AlSi10Mg samples produced by selective laser melting: Single track, densification, microstructure and mechanical behavior. Appl. Surf. Sci. 2017, 408, 38–50. [Google Scholar] [CrossRef]

- Kempen, K.; Thijs, L.; Van Humbeeck, J.; Kruth, J.-P. Mechanical Properties of AlSi10Mg Produced by Selective Laser Melting. Phys. Procedia 2012, 39, 439–446. [Google Scholar] [CrossRef] [Green Version]

- Kiani, P.; Dupuy, A.D.; Ma, K.; Schoenung, J.M. Directed energy deposition of AlSi10Mg: Single track nonscalability and bulk properties. Mater. Des. 2020, 194, 108847. [Google Scholar] [CrossRef]

- Bi, G.; Sun, C.; Gasser, A. Study on influential factors for process monitoring and control in laser aided additive manufacturing. J. Mater. Process. Technol. 2013, 213, 463–468. [Google Scholar] [CrossRef]

- Ding, X.; Li, H.; Zhu, J.; Wang, G.; Cao, H.; Zhang, Q.; Ma, H. Application of infrared thermography for laser metal-wire additive manufacturing in vacuum. Infrared Phys. Technol. 2017, 81, 166–169. [Google Scholar] [CrossRef]

- Zheng, L.; Zhang, Q.; Cao, H.; Wu, W.; Ma, H.; Ding, X.; Yang, J.; Duan, X.; Fan, S. Melt pool boundary extraction and its width prediction from infrared images in selective laser melting. Mater. Des. 2019, 183, 108110. [Google Scholar] [CrossRef]

- Bi, G.; Schürmann, B.; Gasser, A.; Wissenbach, K.; Poprawe, R. Development and qualification of a novel laser-cladding head with integrated sensors. Int. J. Mach. Tools Manuf. 2007, 47, 555–561. [Google Scholar] [CrossRef]

- Everton, S.K.; Hirsch, M.; Stravroulakis, P.; Leach, R.K.; Clare, A.T. Review of in-situ process monitoring and in-situ metrology for metal additive manufacturing. Mater. Des. 2016, 95, 431–445. [Google Scholar] [CrossRef]

- Garmendia, I.; Leunda, J.; Pujana, J.; Lamikiz, A. In-process height control during laser metal deposition based on structured light 3D scanning. Procedia CIRP 2018, 68, 375–380. [Google Scholar] [CrossRef]

- Ocylok, S.; Alexeev, E.; Mann, S.; Weisheit, A.; Wissenbach, K.; Kelbassa, I. Correlations of Melt Pool Geometry and Process Parameters During Laser Metal Deposition by Coaxial Process Monitoring. Phys. Procedia 2014, 56, 228–238. [Google Scholar] [CrossRef]

- Iravani-Tabrizipour, M.; Toyserkani, E. An image-based feature tracking algorithm for real-time measurement of clad height. Mach. Vis. Appl. 2007, 18, 343–354. [Google Scholar] [CrossRef]

- Song, L.; Bagavath-Singh, V.; Dutta, B.; Mazumder, J. Control of melt pool temperature and deposition height during direct metal deposition process. Int. J. Adv. Manuf. Technol. 2011, 58, 247–256. [Google Scholar] [CrossRef]

- Biegler, M.; Graf, B.; Rethmeier, M. In-situ distortions in LMD additive manufacturing walls can be measured with digital image correlation and predicted using numerical simulations. Addit. Manuf. 2018, 20, 101–110. [Google Scholar] [CrossRef]

- He, W.; Shi, W.; Li, J.; Xie, H. In-situ monitoring and deformation characterization by optical techniques; Part I: Laser-aided direct metal deposition for additive manufacturing. Opt. Lasers Eng. 2019, 122, 74–88. [Google Scholar] [CrossRef]

- Heralić, A.; Christiansson, A.-K.; Ottosson, M.; Lennartson, B. Increased stability in laser metal wire deposition through feedback from optical measurements. Opt. Lasers Eng. 2010, 48, 478–485. [Google Scholar] [CrossRef]

- Tang, L.; Ruan, J.; Sparks, T.E.; Landers, R.G.; Liou, F. Layer-to-layer height control of Laser Metal Deposition processes. Am. Control. Conf. 2009, 133, 5582–5587. [Google Scholar] [CrossRef]

- Heigel, J.; Michaleris, P.; Palmer, T. In situ monitoring and characterization of distortion during laser cladding of Inconel 625. J. Mater. Process. Technol. 2015, 220, 135–145. [Google Scholar] [CrossRef]

- Segerstark, A.; Andersson, J.; Svensson, L.-E. Investigation of laser metal deposited Alloy 718 onto an EN 1.4401 stainless steel substrate. Opt. Laser Technol. 2017, 97, 144–153. [Google Scholar] [CrossRef]

- Donadello, S.; Motta, M.; Demir, A.G.; Previtali, B. Monitoring of laser metal deposition height by means of coaxial laser triangulation. Opt. Lasers Eng. 2019, 112, 136–144. [Google Scholar] [CrossRef] [Green Version]

- Garmendia, I.; Pujana, J.; Lamikiz, A.; Madarieta, M.; Leunda, J. Structured light-based height control for laser metal deposition. J. Manuf. Process. 2019, 42, 20–27. [Google Scholar] [CrossRef]

- Donadello, S.; Motta, M.; Demir, A.G.; Previtali, B. Coaxial laser triangulation for height monitoring in laser metal deposition. Procedia CIRP 2018, 74, 144–148. [Google Scholar] [CrossRef]

- George, N. Process Monitoring and Control for Laser Welding. Available online: https://assets.lia.org/s3fs-public/pdf/conferences/Najah%20George%20-%20Process%20Monitoring%20and%20Control%20for%20Laser%20Welding.pdf (accessed on 21 May 2021).

- Zhao, Y.; Yu, T.; Li, B.; Wang, Z.; Chen, H. Calculation and verification of Start/Stop optimum overlapping rate on metal DLF technology. Int. J. Adv. Manuf. Technol. 2018, 99, 437–452. [Google Scholar] [CrossRef]

- Boisselier, D.; Sankaré, S.; Engel, T. Improvement of the Laser Direct Metal Deposition Process in 5-axis Configuration. Phys. Procedia 2014, 56, 239–249. [Google Scholar] [CrossRef] [Green Version]

- Rodgers, J.L.; Nicewander, W.A. Thirteen Ways to Look at the Correlation Coefficient. Am. Stat. 1988, 42, 59–66. [Google Scholar] [CrossRef]

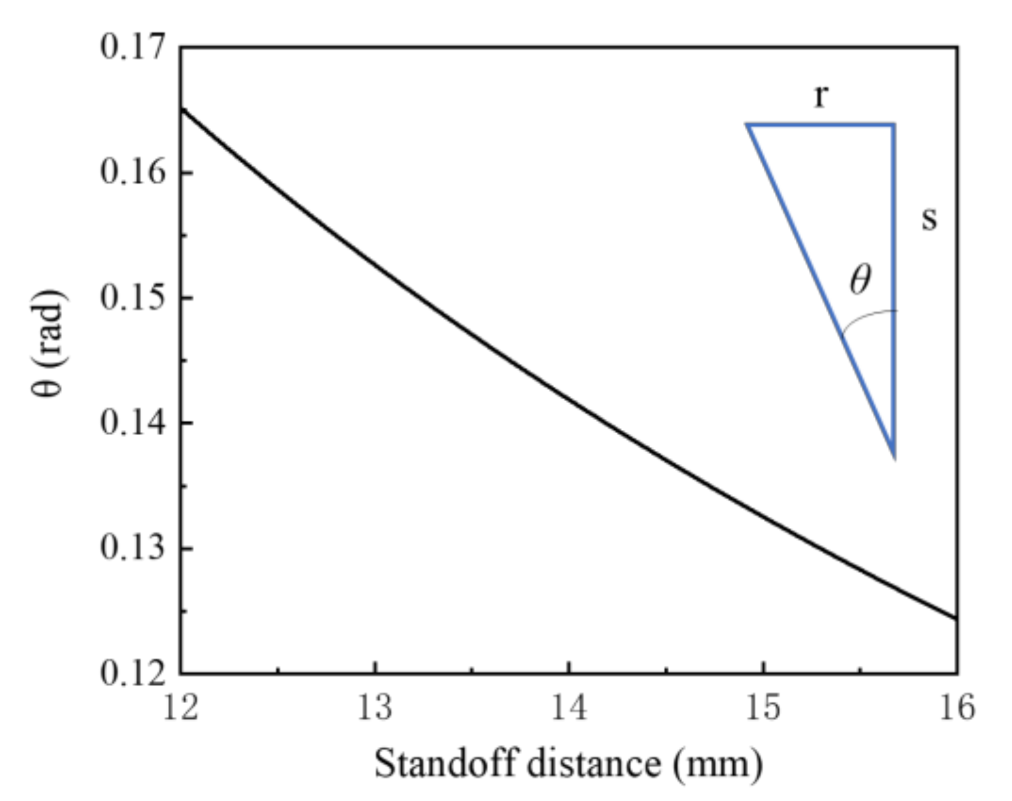

- Zhu, G.; Li, D.; Zhang, A.; Pi, G.; Tang, Y. The influence of standoff variations on the forming accuracy in laser direct metal deposition. Rapid Prototyp. J. 2011, 17, 98–106. [Google Scholar] [CrossRef]

- Xiao, X.; Liu, X.; Cheng, M.; Song, L. Towards monitoring laser welding process via a coaxial pyrometer. J. Mater. Process. Technol. 2020, 277, 116409. [Google Scholar] [CrossRef]

- Novotny, P.; Ferrier, N. Using infrared sensors and the Phong illumination model to measure distances. In Proceedings of the IEEE International Conference on Robotics & Automation, Detroit, MI, USA, 10–15 May 1999; pp. 1644–1649. [Google Scholar] [CrossRef]

- Ryu, D.; Um, D.; Tanofsky, P.; Koh, D.H.; Ryu, Y.S.; Kang, S. T-less: A novel touchless human-machine interface based on infrared proximity sensing. In Proceedings of the 2010 IEEE/RSJ International Conference on Intelligent Robots and Systems, Taipei, Taiwan, 18–22 October 2010. [Google Scholar] [CrossRef]

| Si | Mg | Zn | Mn | Ni | Fe | O | Al |

|---|---|---|---|---|---|---|---|

| 10.11 | 0.35 | 0.043 | 0.2 | 0.0046 | 0.085 | 0.01 | Bal. |

| Signals | Deposition Height | Deposition Width | Geometry Control of Each Layer | Real-Time Defect Alarm |

|---|---|---|---|---|

| Infrared light | √ | √ | ||

| Reflected laser | √ | √ | √ |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, L.; Wang, X.; Huang, Y. Analysis of In Situ Optical Signals during Laser Metal Deposition of Aluminum Alloys. Crystals 2021, 11, 589. https://doi.org/10.3390/cryst11060589

Li L, Wang X, Huang Y. Analysis of In Situ Optical Signals during Laser Metal Deposition of Aluminum Alloys. Crystals. 2021; 11(6):589. https://doi.org/10.3390/cryst11060589

Chicago/Turabian StyleLi, Liqun, Xian Wang, and Yichen Huang. 2021. "Analysis of In Situ Optical Signals during Laser Metal Deposition of Aluminum Alloys" Crystals 11, no. 6: 589. https://doi.org/10.3390/cryst11060589

APA StyleLi, L., Wang, X., & Huang, Y. (2021). Analysis of In Situ Optical Signals during Laser Metal Deposition of Aluminum Alloys. Crystals, 11(6), 589. https://doi.org/10.3390/cryst11060589