Study on the Performance of Synergistic Preparation of Sulphoaluminate Based Recycled Concrete by RP and RCA

Abstract

:1. Introduction

2. Materials and Methods

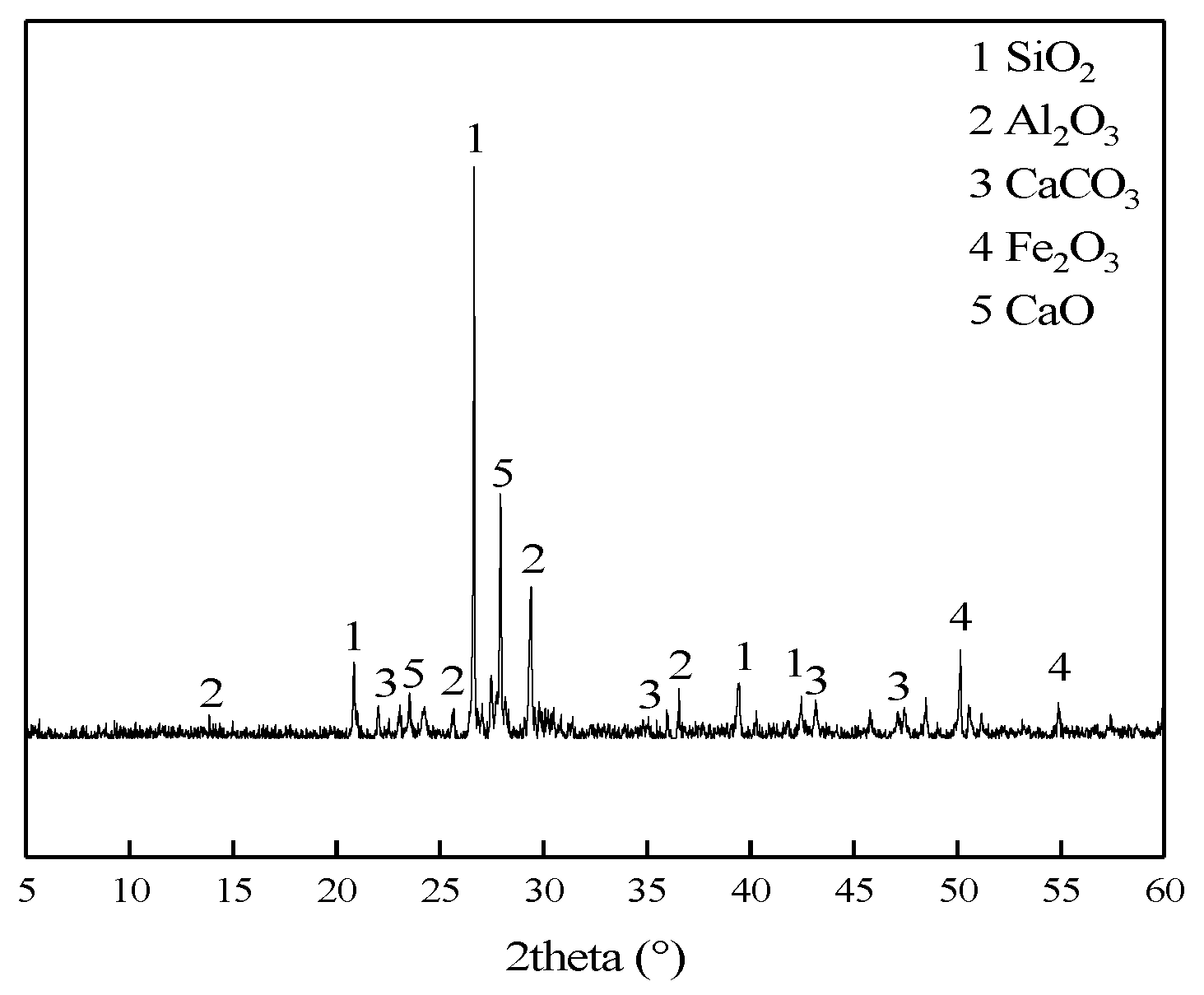

2.1. Test Materials

2.2. Concrete Mix Design

2.3. Concrete Preparation, Curing, and Performance Testing

3. Results and Discussion

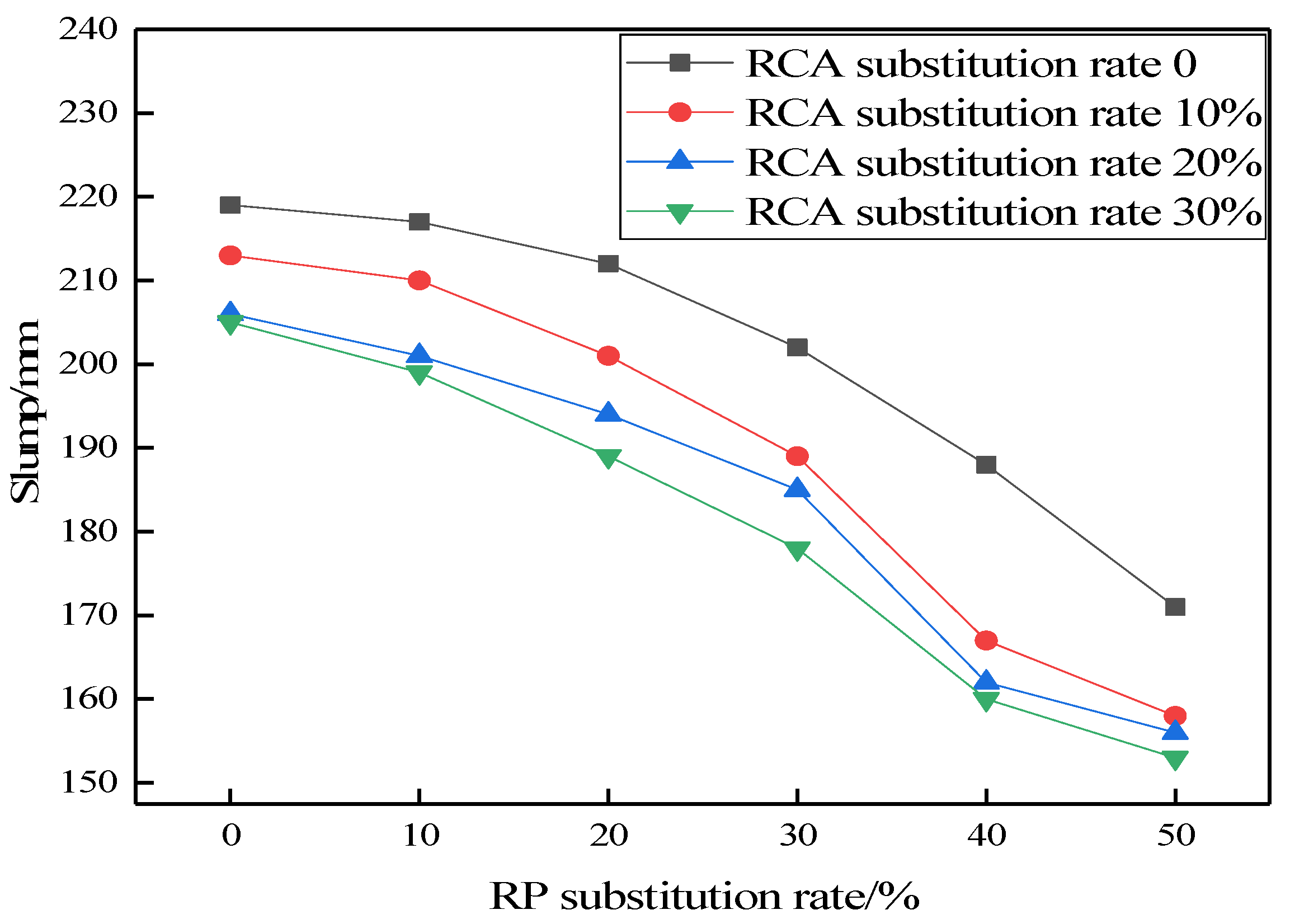

3.1. Concrete Workability

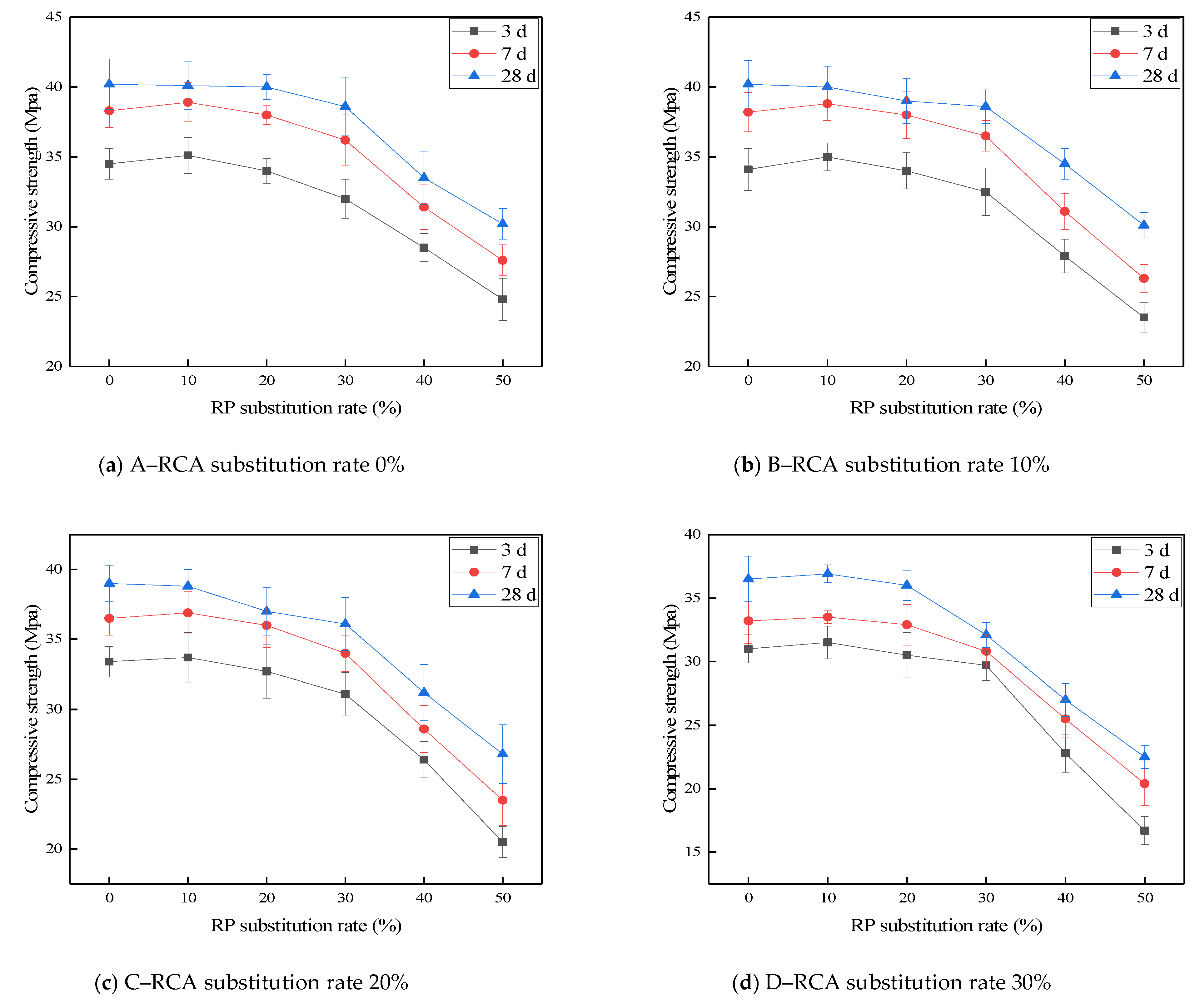

3.2. Mechanical Properties of Concrete

3.3. Carbonization Performance

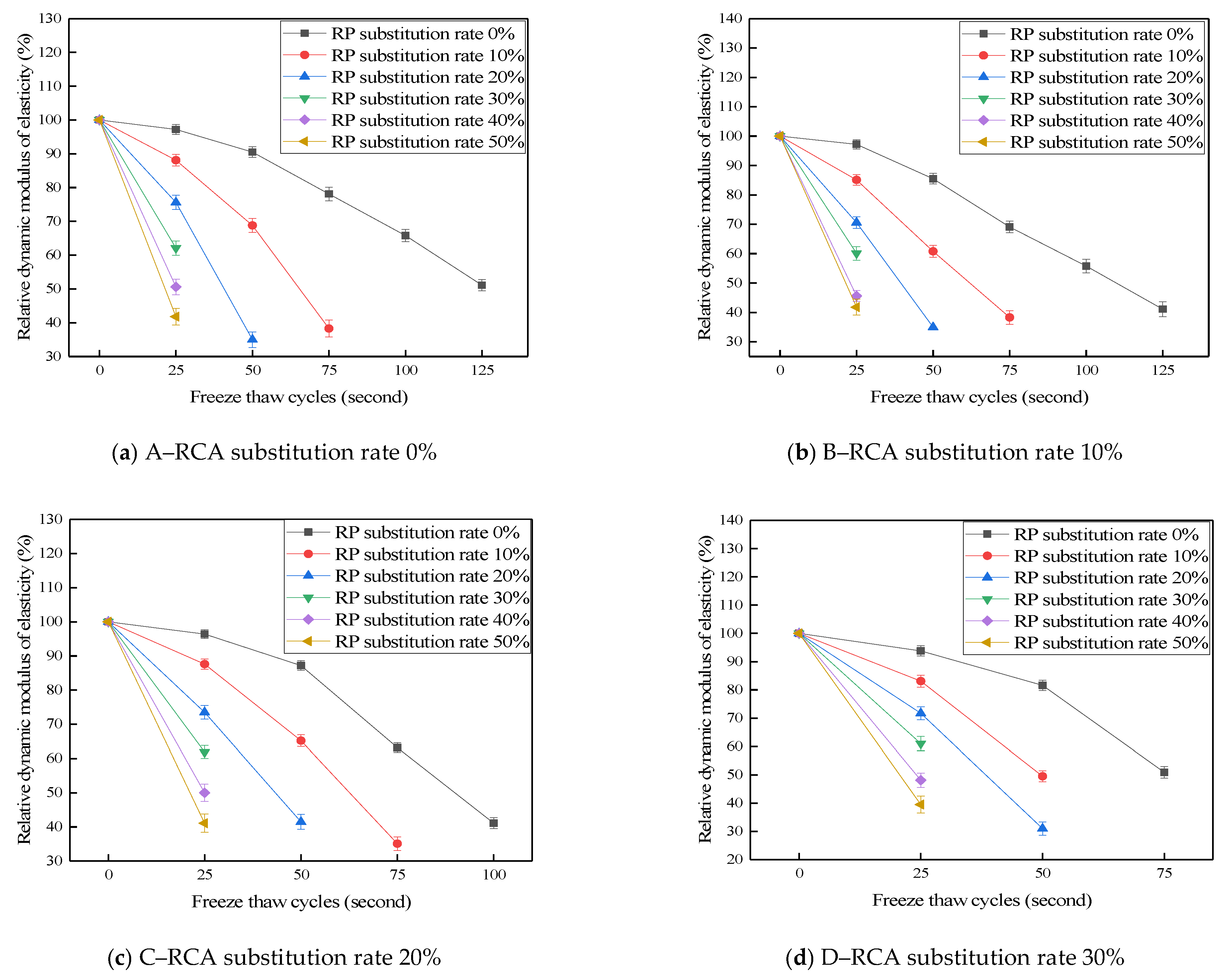

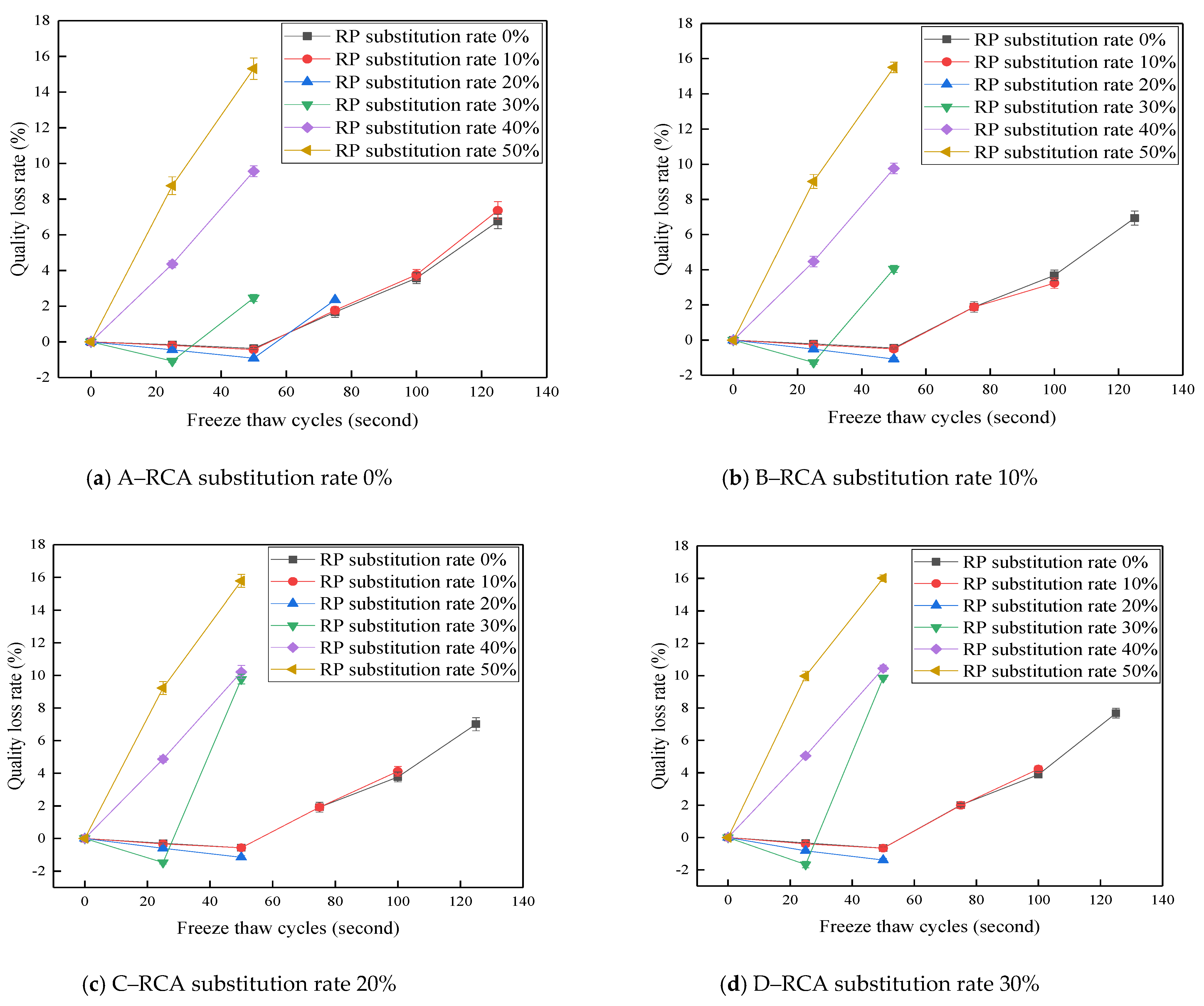

3.4. Frost Resistance

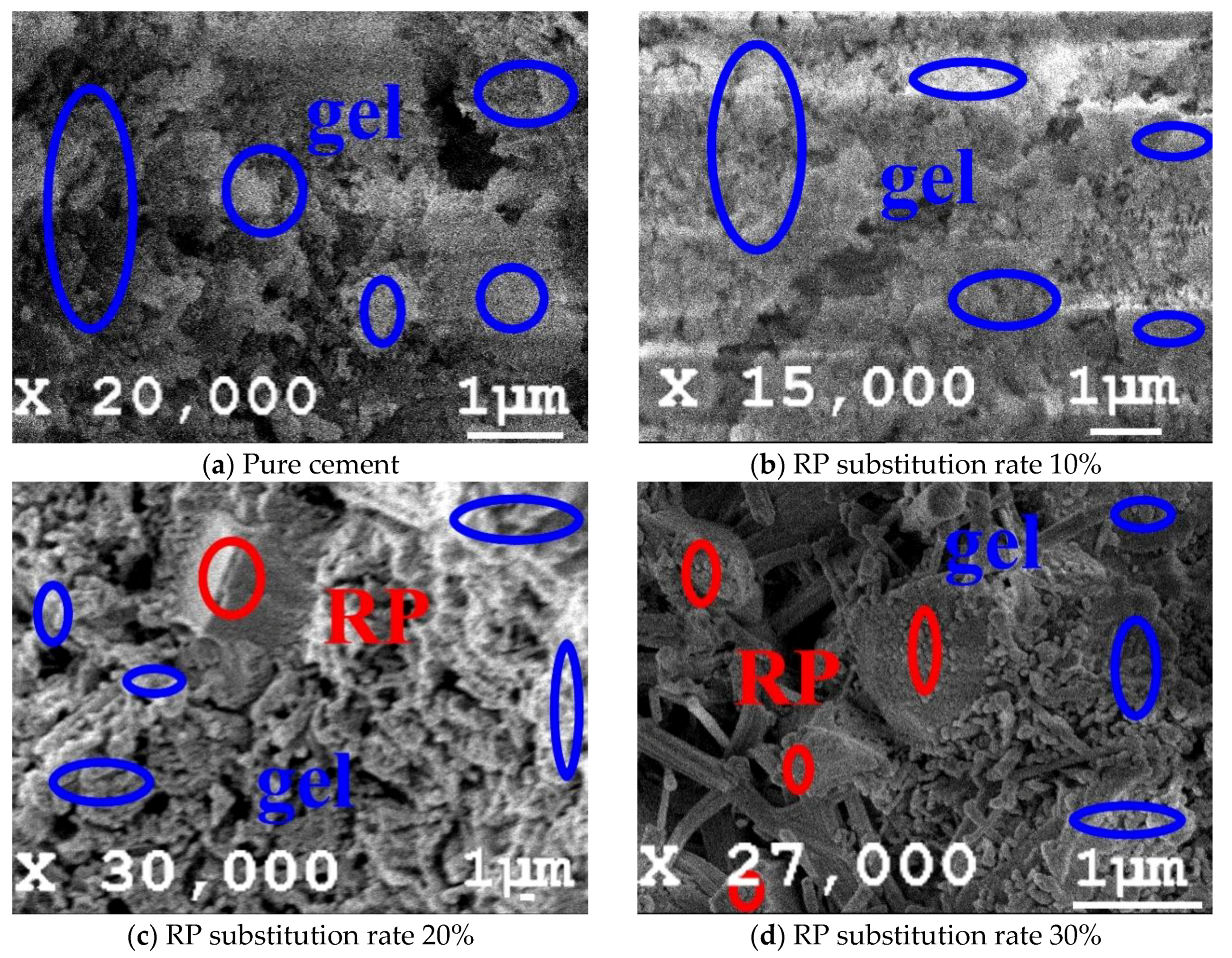

3.5. Microscopic Analysis of Hydration Products

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, C.; Hu, M.; Dong, L.; Xiang, P.; Zhang, Q.; Wu, J.; Li, B.; Shi, S. Co-benefits of urban concrete recycling on the mitigation of greenhouse gas emissions and land use change: A case in Chongqing metropolis, China. J. Clean. Prod. 2018, 201, 481–498. [Google Scholar] [CrossRef]

- Xiao, J.; Li, W.; Fan, Y.; Huang, X. An overview of study on recycled aggregate concrete in China (1996–2011). Constr. Build. Mater. 2012, 31, 364–383. [Google Scholar] [CrossRef]

- Tang, Q.; Ma, Z.; Wu, H.; Wang, W. The utilization of eco-friendly recycled powder from concrete and brick waste in new concrete: A critical review. Cem. Concr. Compos. 2020, 114, 103807. [Google Scholar] [CrossRef]

- Yue, G.; Ma, Z.; Liu, M.; Liang, C.; Ba, G. Damage behavior of the multiple ITZs in recycled aggregate concrete subjected to aggressive ion environment. Constr. Build. Mater. 2020, 245, 118419. [Google Scholar] [CrossRef]

- Kapoor, K.; Singh, S.; Singh, B.; Singh, P. Effect of recycled aggregates on fresh and hardened properties of self compacting concrete. Mater. Today Proc. 2020, 32, 600–607. [Google Scholar] [CrossRef]

- Lu, W. Big data analytics to identify illegal construction waste dumping: A Hong Kong study. Resour. Conserv. Recycl. 2019, 141, 264–272. [Google Scholar] [CrossRef]

- Guerra, B.C.; Bakchan, A.; Leite, F.; Faust, K.M. BIM-based automated construction waste estimation algorithms: The case of concrete and drywall waste streams. Waste Manag. 2019, 87, 825–832. [Google Scholar] [CrossRef]

- Wu, H.; Zuo, J.; Zillante, G.; Wang, J.; Yuan, H. Status quo and future directions of construction and demolition waste research: A critical review. J. Clean. Prod. 2019, 240, 118163. [Google Scholar] [CrossRef]

- Seror, N.; Portnov, B.A. Estimating the effectiveness of different environmental law enforcement policies on illegal C&D waste dumping in Israel. Waste Manag. 2020, 102, 241–248. [Google Scholar] [CrossRef] [PubMed]

- Xiao, J.; Ma, Z.; Ding, T. Reclamation chain of waste concrete: A case study of Shanghai. Waste Manag. 2016, 48, 334–343. [Google Scholar] [CrossRef] [PubMed]

- Tam, V.W. Economic comparison of concrete recycling: A case study approach. Resour. Conserv. Recycl. 2008, 52, 821–828. [Google Scholar] [CrossRef] [Green Version]

- Ohemeng, E.A.; Ekolu, S.O. Comparative analysis on costs and benefits of producing natural and recycled concrete aggregates: A South African case study. Case Stud. Constr. Mater. 2020, 13, e00450. [Google Scholar] [CrossRef]

- Rao, M.C.; Bhattacharyya, S.K.; Barai, S.V. Influence of field recycled coarse aggregate on properties of concrete. Mater. Struct. 2010, 44, 205–220. [Google Scholar] [CrossRef]

- Wang, R.; Yu, N.; Li, Y. Methods for improving the microstructure of recycled concrete aggregate: A review. Constr. Build. Mater. 2020, 242, 118164. [Google Scholar] [CrossRef]

- Mistri, A.; Bhattacharyya, S.K.; Dhami, N.K.; Mukherjee, A.; Barai, S.V. A review on different treatment methods for enhancing the properties of recycled aggregates for sustainable construction materials. Constr. Build. Mater. 2020, 233, 117894. [Google Scholar] [CrossRef]

- Yehia, S.; Helal, K.; Abusharkh, A.; Zaher, A.; Istaitiyeh, H. Strength and Durability Evaluation of Recycled Aggregate Concrete. Int. J. Concr. Struct. Mater. 2015, 9, 219–239. [Google Scholar] [CrossRef] [Green Version]

- Al Zand, A.W.; Hosseinpour, E.; Badaruzzaman, W.H.W.; Ali, M.M.; Yaseen, Z.M.; Hanoon, A.N. Performance of the novel C-purlin tubular beams filled with recycled-lightweight concrete strengthened with CFRP sheet. J. Build. Eng. 2021, 43, 102532. [Google Scholar] [CrossRef]

- Bhat, J.A. Effect of strength of parent concrete on the mechanical properties of recycled aggregate concrete. Mater. Today Proc. 2021, 42, 1462–1469. [Google Scholar] [CrossRef]

- Attri, G.K.; Gupta, R.; Shrivastava, S. Impact of recycled concrete aggregate on mechanical and durability properties of concrete paver blocks. Mater. Today Proc. 2021, 42, 975–981. [Google Scholar] [CrossRef]

- Zhu, C.; Liu, C.; Bai, G.; Fan, J. Study on long-term performance and flexural stiffness of recycled aggregate concrete beams. Constr. Build. Mater. 2020, 262, 120503. [Google Scholar] [CrossRef]

- Zhao, Z.; Rémond, S.; Damidot, D.; Xu, W. Influence of fine recycled concrete aggregates on the properties of mortars. Constr. Build. Mater. 2015, 81, 179–186. [Google Scholar] [CrossRef]

- Duan, Z.; Singh, A.; Xiao, J.; Hou, S. Combined use of recycled powder and recycled coarse aggregate derived from construction and demolition waste in self-compacting concrete. Constr. Build. Mater. 2020, 254, 119323. [Google Scholar] [CrossRef]

- Xiao, J.; Ma, Z.; Sui, T.; Nezhad, A.A.; Duan, Z. Mechanical properties of concrete mixed with recycled powder produced from construction and demolition waste. J. Clean. Prod. 2018, 188, 720–731. [Google Scholar] [CrossRef]

- Gupta, T.; Siddique, S.; Sharma, R.K.; Chaudhary, S. Behaviour of waste rubber powder and hybrid rubber concrete in aggressive environment. Constr. Build. Mater. 2019, 217, 283–291. [Google Scholar] [CrossRef]

- Gebremariam, A.T.; Vahidi, A.; Di Maio, F.; Moreno-Juez, J.; Vegas-Ramiro, I.; Łagosz, A.; Mróz, R.; Rem, P. Comprehensive study on the most sustainable concrete design made of recycled concrete, glass and mineral wool from C&D wastes. Constr. Build. Mater. 2021, 273, 121697. [Google Scholar] [CrossRef]

- Huo, W.; Zhu, Z.; Chen, W.; Zhang, J.; Kang, Z.; Pu, S.; Wan, Y. Effect of synthesis parameters on the development of unconfined compressive strength of recycled waste concrete powder-based geopolymers. Constr. Build. Mater. 2021, 292, 123264. [Google Scholar] [CrossRef]

- Deng, X.; Guo, H.; Tan, H.; He, X.; Zheng, Z.; Su, Y.; Yang, J. An accelerator prepared from waste concrete recycled powder and its effect on hydration of cement-based materials. Constr. Build. Mater. 2021, 296, 123767. [Google Scholar] [CrossRef]

- Ren, P.; Li, B.; Yu, J.-G.; Ling, T.-C. Utilization of recycled concrete fines and powders to produce alkali-activated slag concrete blocks. J. Clean. Prod. 2020, 267, 122115. [Google Scholar] [CrossRef]

- Szeląg, M.; Zegardło, B.; Andrzejuk, W. The Use of Fragmented, Worn-Out Car Side Windows as an Aggregate for Cementitious Composites. Materials 2019, 12, 1467. [Google Scholar] [CrossRef] [Green Version]

- Khan, Q.S.; Sheikh, M.N.; McCarthy, T.J.; Robati, M.; Allen, M. Experimental investigation on foam concrete without and with recycled glass powder: A sustainable solution for future construction. Constr. Build. Mater. 2019, 201, 369–379. [Google Scholar] [CrossRef]

- Siddique, S.; Chaudhary, S.; Shrivastava, S.; Gupta, T. Sustainable utilisation of ceramic waste in concrete: Exposure to adverse conditions. J. Clean. Prod. 2019, 210, 246–255. [Google Scholar] [CrossRef]

- Xu, K.; Huang, W.; Zhang, L.; Fu, S.; Chen, M.; Ding, S.; Han, B. Mechanical properties of low-carbon ultrahigh-performance concrete with ceramic tile waste powder. Constr. Build. Mater. 2021, 287, 123036. [Google Scholar] [CrossRef]

- Gao, Y.; Li, Z.; Zhang, J.; Zhang, Q.; Wang, Y. Synergistic use of industrial solid wastes to prepare belite-rich sulphoaluminate cement and its feasibility use in repairing materials. Constr. Build. Mater. 2020, 264, 120201. [Google Scholar] [CrossRef]

- Lu, Z.; Hou, D.; Ma, H.; Fan, T.; Li, Z. Effects of graphene oxide on the properties and microstructures of the magnesium potassium phosphate cement paste. Constr. Build. Mater. 2016, 119, 107–112. [Google Scholar] [CrossRef]

- Liu, C.; Luo, J.; Li, Q.; Gao, S.; Su, D.; Zhang, J.; Chen, S. Calcination of green high-belite sulphoaluminate cement (GHSC) and performance optimizations of GHSC-based foamed concrete. Mater. Des. 2019, 182, 107986. [Google Scholar] [CrossRef]

- Zhang, J.; Zhou, Z.H.; Cheng, X. Formation Kinetics of Regenerated Cement Clinker Calcined by Using Wasted Recycling Concrete Powders as Raw Meals. Adv. Mater. Res. 2014, 1073–1076, 1309–1312. [Google Scholar] [CrossRef]

- Miličević, I.; Bjegović, D.; Siddique, R. Experimental research of concrete floor blocks with crushed bricks and tiles aggregate. Constr. Build. Mater. 2015, 94, 775–783. [Google Scholar] [CrossRef]

- Hou, Y.F.; Chen, J.L. Performance of powders in recycled aggregate. J. Beijing Univ. Civ. Eng. Archit. 2010, 26, 8–11. [Google Scholar] [CrossRef]

- Olofinnade, O.; Ogara, J. Workability, strength, and microstructure of high strength sustainable concrete incorporating recycled clay brick aggregate and calcined clay. Clean. Eng. Technol. 2021, 3, 100123. [Google Scholar] [CrossRef]

- Pedro, D.; de Brito, J.; Evangelista, L. Evaluation of high-performance concrete with recycled aggregates: Use of densified silica fume as cement replacement. Constr. Build. Mater. 2017, 147, 803–814. [Google Scholar] [CrossRef]

- Wang, H.; Xia, Y. Influence of recycled fine powder on shrinkage cracking of concrete. Ind. Constr. 2016, 46, 122–125. [Google Scholar] [CrossRef]

- Xu, C.; Zhao, T.; Yu, F. Application of waste clay brick powder in grouting material. Concrete 2019, 6, 71–75. (in Chinese) [Google Scholar] [CrossRef]

- Awoyera, P.O.; Okoro, U.C. Filler-Ability of Highly Active Metakaolin for Improving Morphology and Strength Characteristics of Recycled Aggregate Concrete. Silicon 2018, 11, 1971–1978. [Google Scholar] [CrossRef]

- Lei, B.; Li, W.; Tang, Z.; Tam, V.W.; Sun, Z. Durability of recycled aggregate concrete under coupling mechanical loading and freeze-thaw cycle in salt-solution. Constr. Build. Mater. 2018, 163, 840–849. [Google Scholar] [CrossRef]

| Sample | SiO2/% | CaO/% | Al2O3/% | Fe2O3/% | MgO/% | K2O/% | Na2O/% | SO3/% |

|---|---|---|---|---|---|---|---|---|

| Cement | 18.62 | 44.52 | 14.30 | 1.81 | 3.76 | 0.01 | 0.17 | 15.64 |

| RP | 40.51 | 28.18 | 14.54 | 5.38 | 1.73 | 2.50 | 1.56 | 0.88 |

| Table 3. | Powder Content (%) | Water Absorption (%) | Content of Needle like Particles (%) | Crushing Index (%) | Apparent Density (kg/m3) | Porosity (%) |

|---|---|---|---|---|---|---|

| RCA | 1.1 | 4.2 | 7.8 | 15.6 | 2395.2 | 48.9 |

| NCA | – | 0.9 | 3.5 | 10.2 | 2687.1 | 44.1 |

| Type | Powder Content (%) | Fineness Modulus | Apparent Density (kg/m3) | Bulk Density (kg/m3) | Water Absorption (%) |

|---|---|---|---|---|---|

| Machine-made sand | 0.8 | 2.7 | 2701.1 | 1489.2 | 0.67 |

| Test Number | Water Binder Ratio | Water Reducer (kg/m3) | Fine Aggregate (kg/m3) | Coarse Aggregate (kg/m3) | Cementitious Materials (kg/m3) | ||

|---|---|---|---|---|---|---|---|

| RCA | NCA | RP | Cement | ||||

| A–1 | 0.45 | 5.6 | 608.0 | 0 | 1351.0 | 0 | 281.0 |

| A–2 | 0.45 | 5.6 | 608.0 | 0 | 1351.0 | 28.1 | 252.9 |

| A–3 | 0.45 | 5.6 | 608.0 | 0 | 1351.0 | 56.2 | 224.8 |

| A–4 | 0.45 | 5.6 | 608.0 | 0 | 1351.0 | 84.3 | 196.7 |

| A–5 | 0.45 | 5.6 | 608.0 | 0 | 1351.0 | 112.4 | 168.6 |

| A–6 | 0.45 | 5.6 | 608.0 | 0 | 1351.0 | 140.5 | 140.5 |

| B–1 | 0.45 | 5.6 | 608.0 | 135.1 | 1215.9 | 0 | 281.0 |

| B–2 | 0.45 | 5.6 | 608.0 | 135.1 | 1215.9 | 28.1 | 252.9 |

| B–3 | 0.45 | 5.6 | 608.0 | 135.1 | 1215.9 | 56.2 | 224.8 |

| B–4 | 0.45 | 5.6 | 608.0 | 135.1 | 1215.9 | 84.3 | 196.7 |

| B–5 | 0.45 | 5.6 | 608.0 | 135.1 | 1215.9 | 112.4 | 168.6 |

| B–6 | 0.45 | 5.6 | 608.0 | 135.1 | 1215.9 | 140.5 | 140.5 |

| C–1 | 0.45 | 5.6 | 608.0 | 270.2 | 1080.8 | 0 | 281.0 |

| C–2 | 0.45 | 5.6 | 608.0 | 270.2 | 1080.8 | 28.1 | 252.9 |

| C–3 | 0.45 | 5.6 | 608.0 | 270.2 | 1080.8 | 56.2 | 224.8 |

| C–4 | 0.45 | 5.6 | 608.0 | 270.2 | 1080.8 | 84.3 | 196.7 |

| C–5 | 0.45 | 5.6 | 608.0 | 270.2 | 1080.8 | 112.4 | 168.6 |

| C–6 | 0.45 | 5.6 | 608.0 | 270.2 | 1080.8 | 140.5 | 140.5 |

| D–1 | 0.45 | 5.6 | 608.0 | 405.3 | 945.7 | 0 | 281.0 |

| D–2 | 0.45 | 5.6 | 608.0 | 405.3 | 945.7 | 28.1 | 252.9 |

| D–3 | 0.45 | 5.6 | 608.0 | 405.3 | 945.7 | 56.2 | 224.8 |

| D–4 | 0.45 | 5.6 | 608.0 | 405.3 | 945.7 | 84.3 | 196.7 |

| D–5 | 0.45 | 5.6 | 608.0 | 405.3 | 945.7 | 112.4 | 168.6 |

| D–6 | 0.45 | 5.6 | 608.0 | 405.3 | 945.7 | 140.5 | 140.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, Z.; Li, Q.; Guo, Y.; Lin, X.; Liu, J.; Zheng, S. Study on the Performance of Synergistic Preparation of Sulphoaluminate Based Recycled Concrete by RP and RCA. Crystals 2021, 11, 748. https://doi.org/10.3390/cryst11070748

Hu Z, Li Q, Guo Y, Lin X, Liu J, Zheng S. Study on the Performance of Synergistic Preparation of Sulphoaluminate Based Recycled Concrete by RP and RCA. Crystals. 2021; 11(7):748. https://doi.org/10.3390/cryst11070748

Chicago/Turabian StyleHu, Zhenwen, Qiuyi Li, Yuanxin Guo, Xiangling Lin, Junzhe Liu, and Shidong Zheng. 2021. "Study on the Performance of Synergistic Preparation of Sulphoaluminate Based Recycled Concrete by RP and RCA" Crystals 11, no. 7: 748. https://doi.org/10.3390/cryst11070748

APA StyleHu, Z., Li, Q., Guo, Y., Lin, X., Liu, J., & Zheng, S. (2021). Study on the Performance of Synergistic Preparation of Sulphoaluminate Based Recycled Concrete by RP and RCA. Crystals, 11(7), 748. https://doi.org/10.3390/cryst11070748