Effect of Vanadium Reinforcement on the Microstructure and Mechanical Properties of Magnesium Matrix Composites

Abstract

:1. Introduction

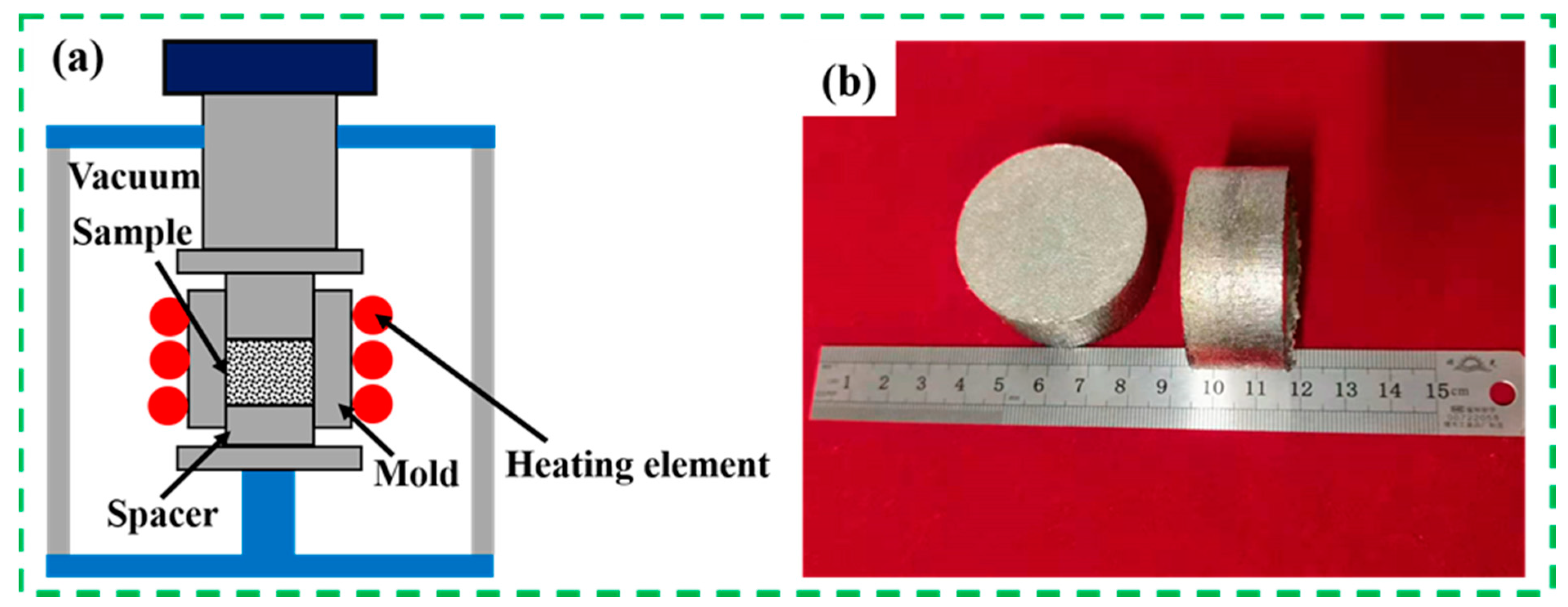

2. Materials and Methods

3. Results and Discussion

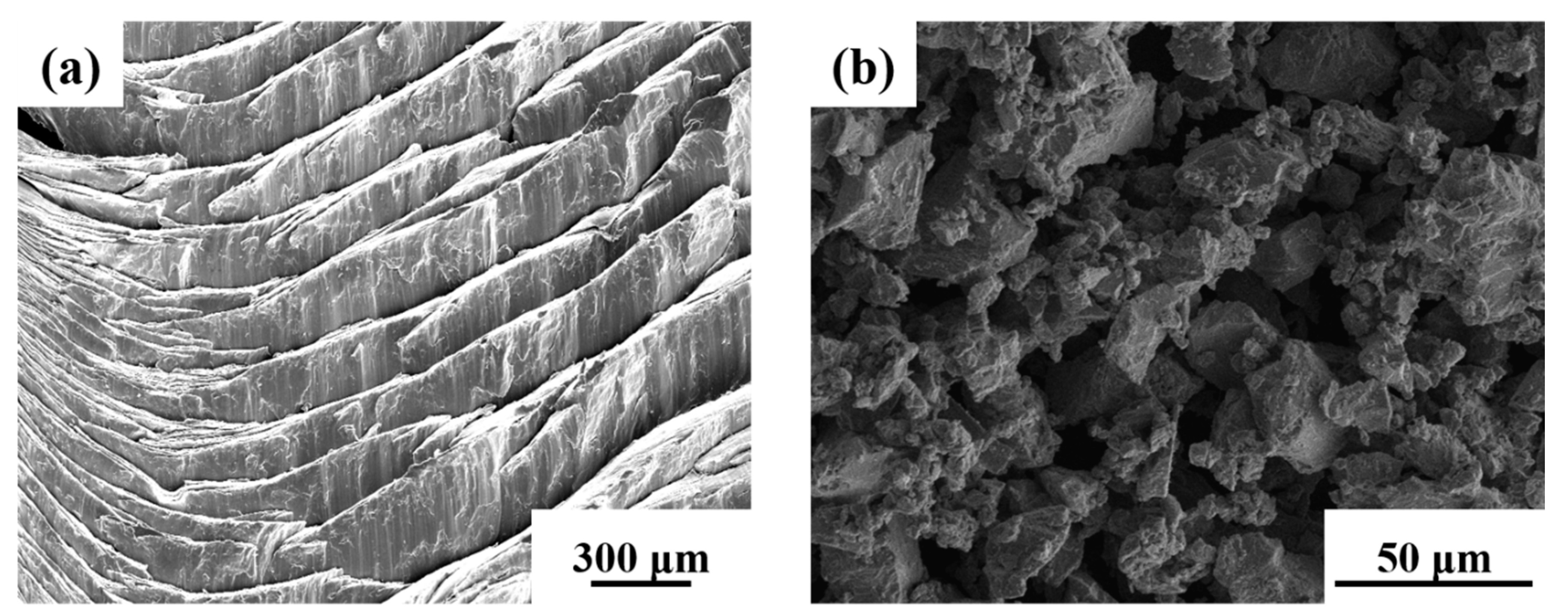

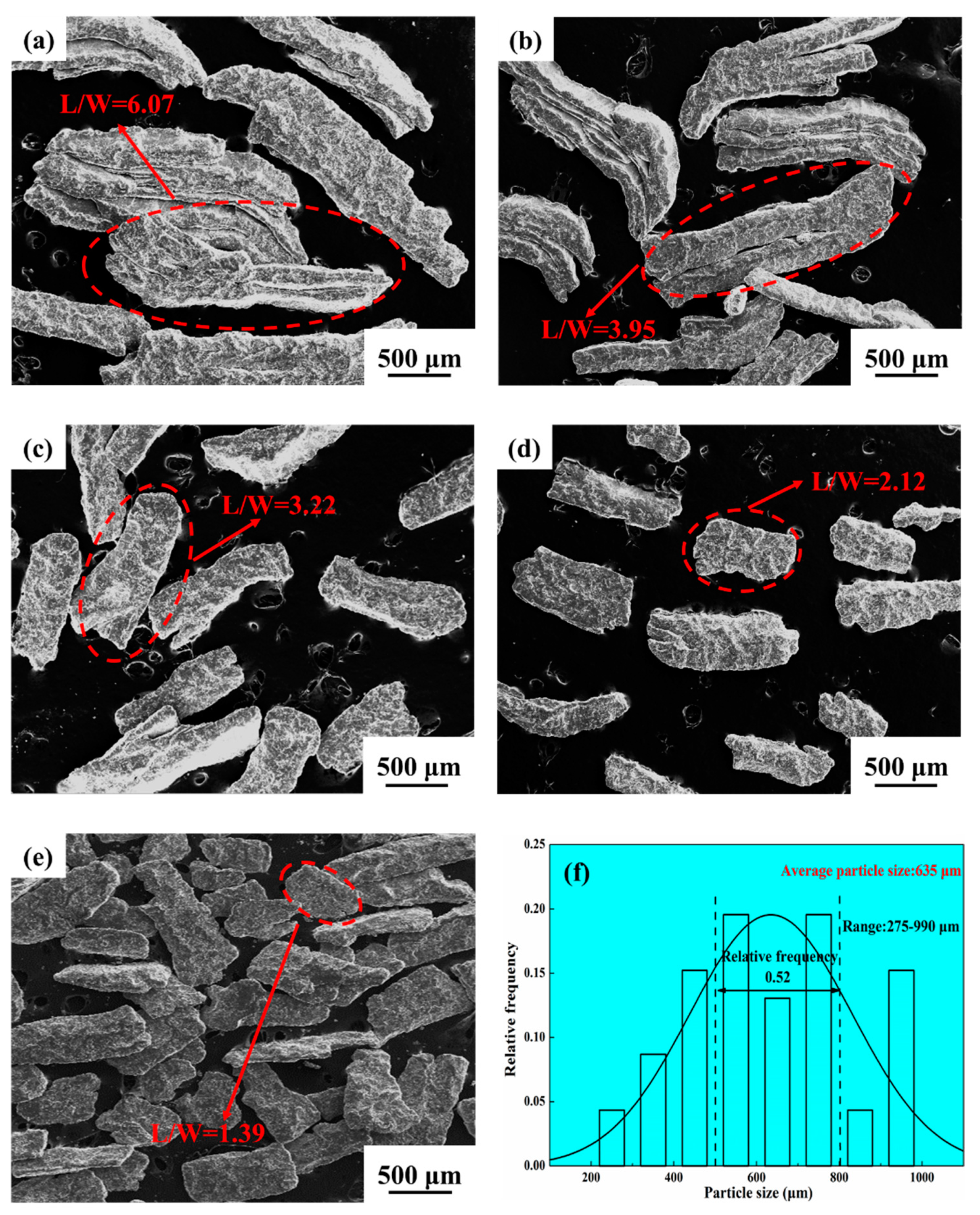

3.1. Evolution of Powder Morphology during the Milling Process

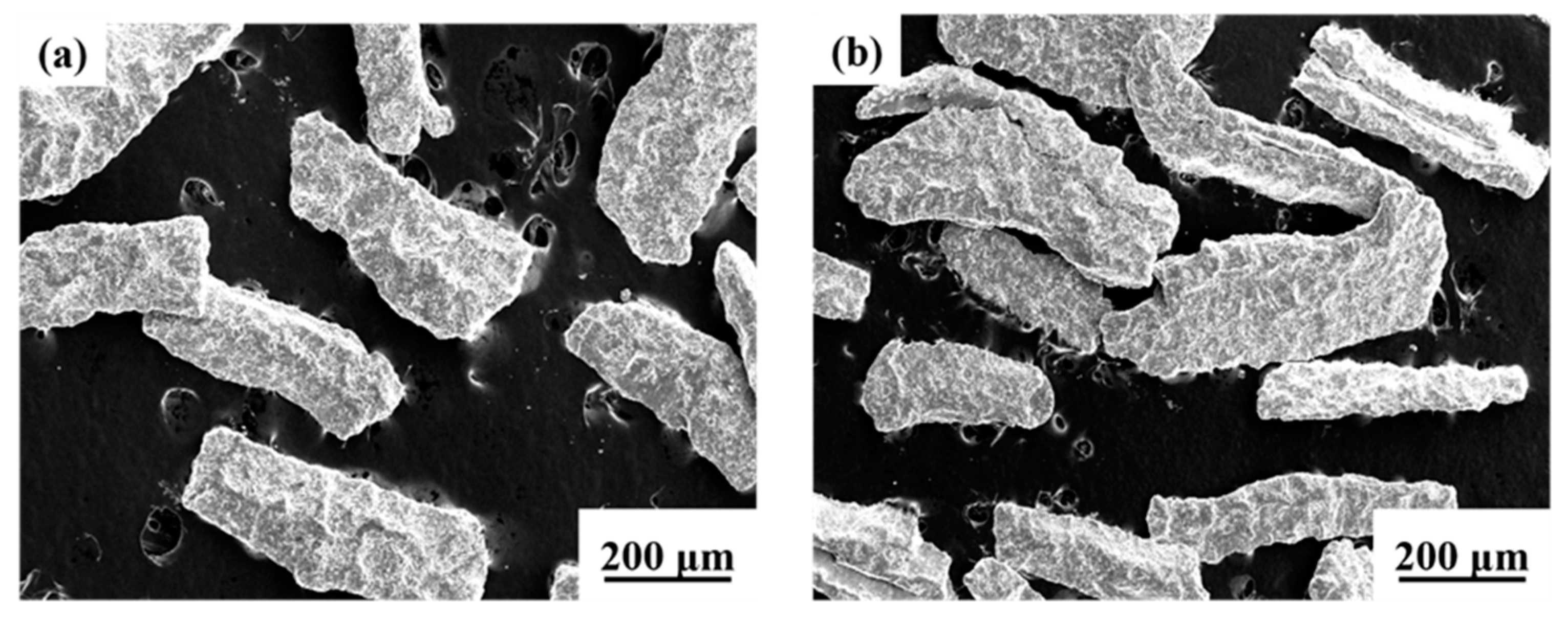

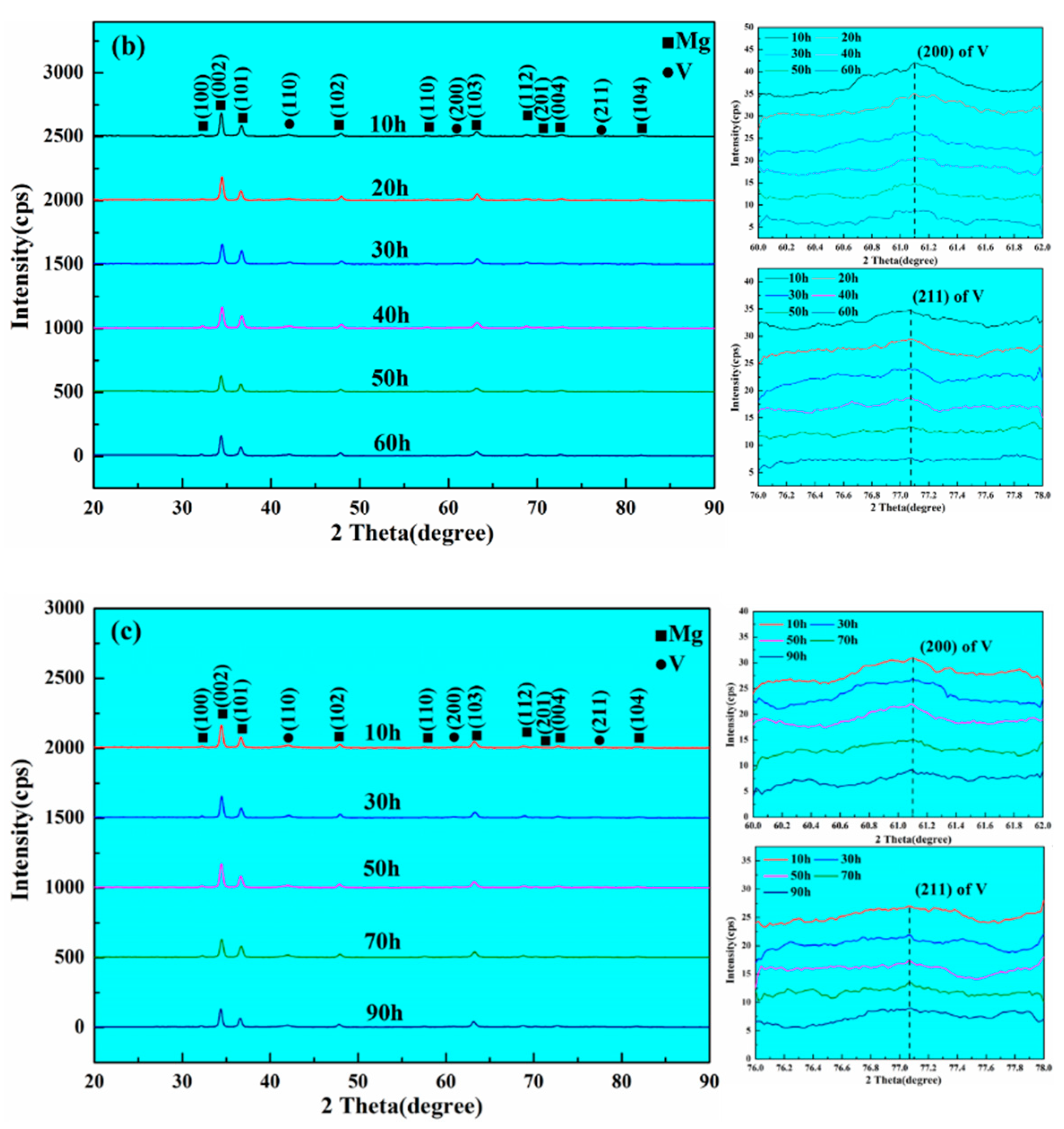

3.2. Microstructure of AZ31–VP Composite Powders

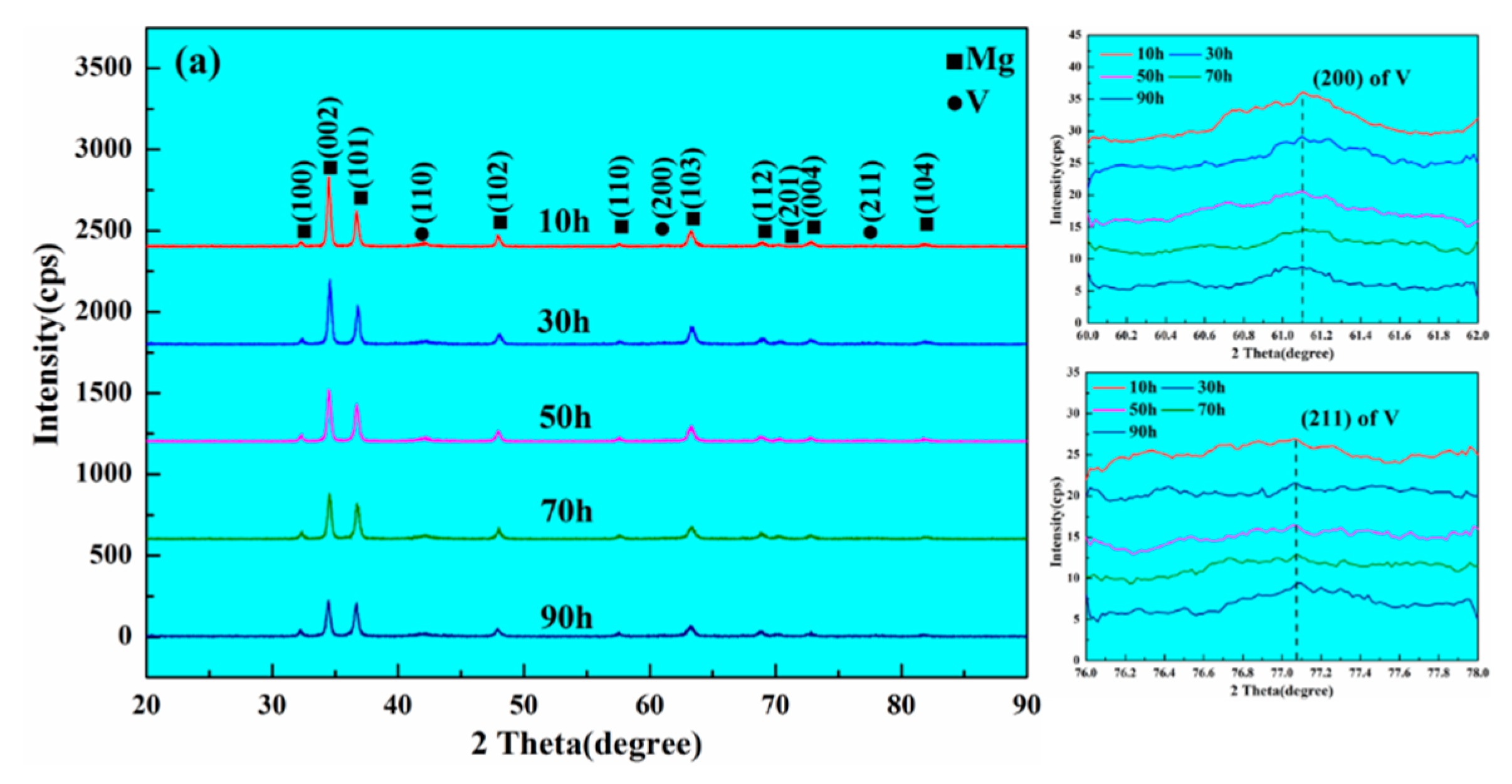

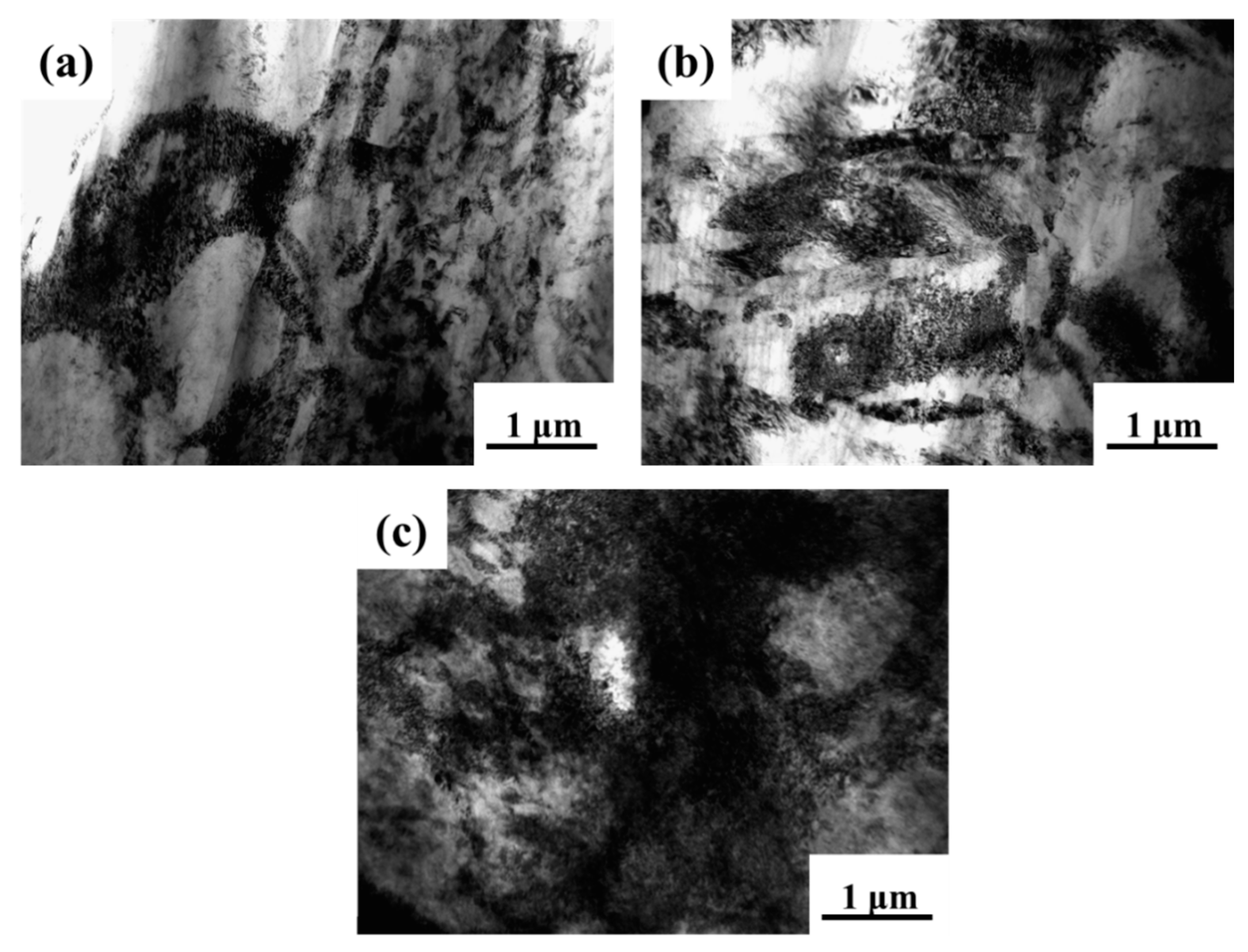

3.2.1. Phase Composition and Matrix Structure

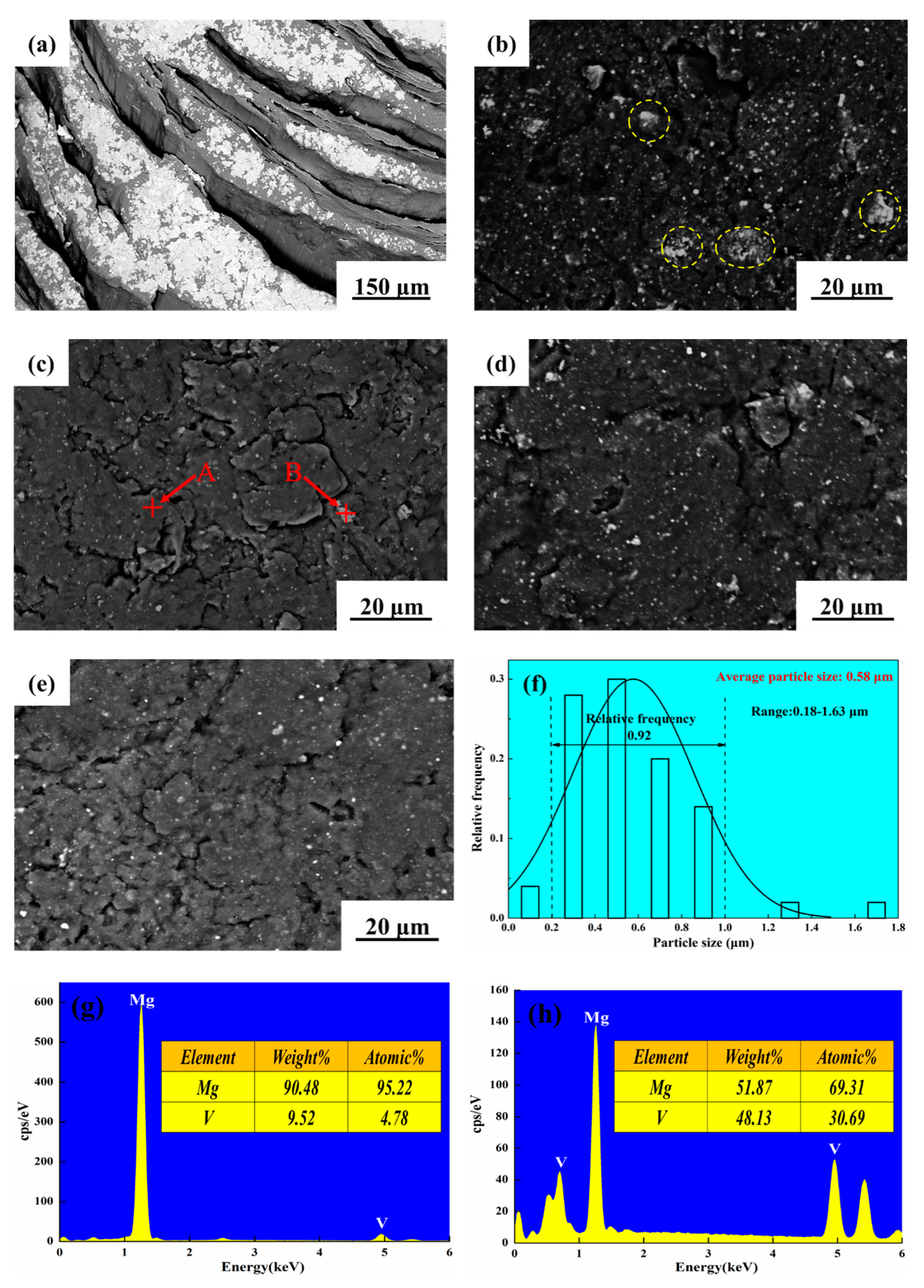

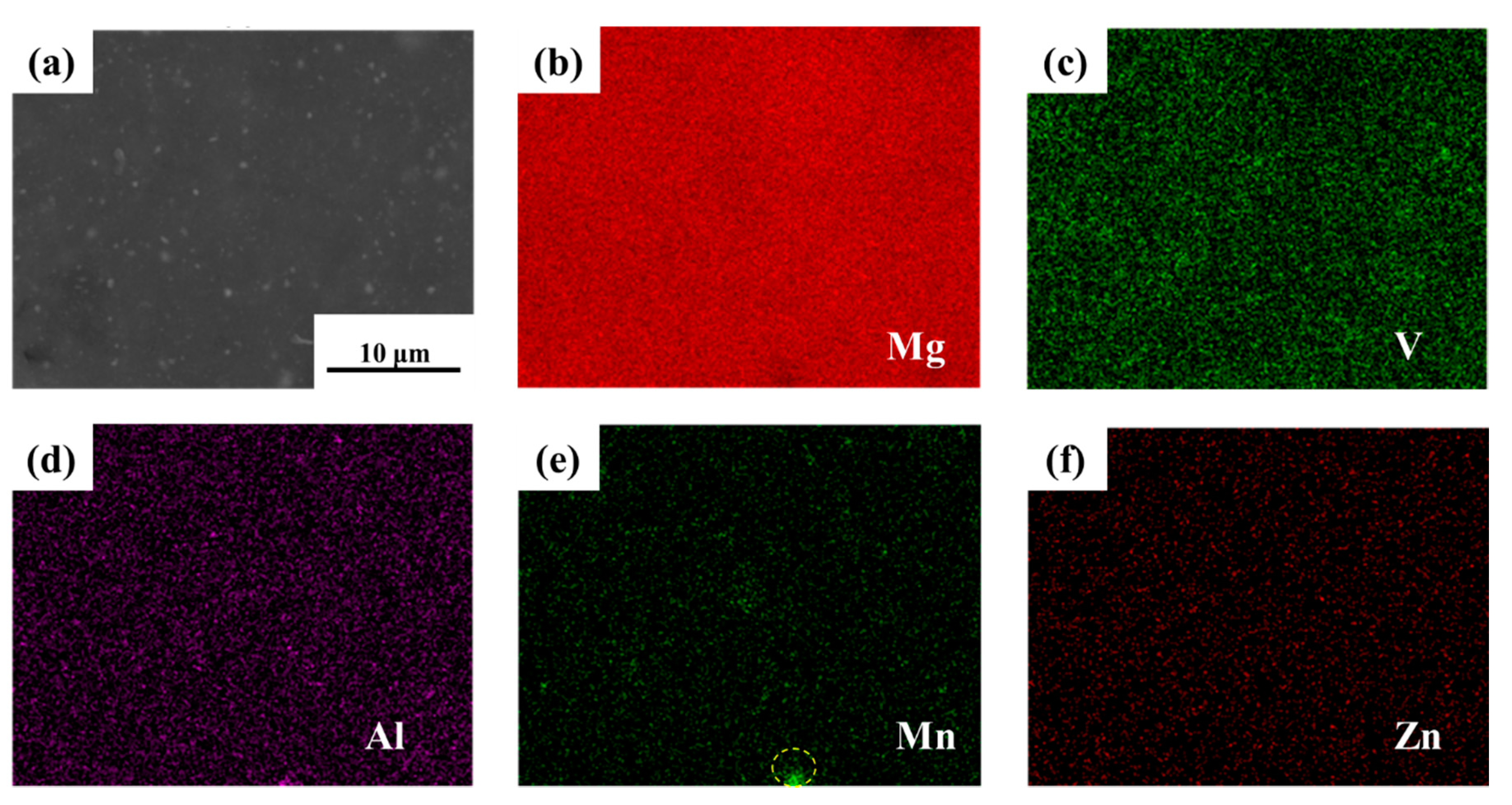

3.2.2. Evolution of VP during the Milling Process

3.3. Density Evolution and Microstructure of Sintered AZ31–VP Composites

3.4. Microhardness Analysis

4. Conclusions

- (1)

- The presence of VP could contribute to the cold welding and fracture mechanism, resulting in the acceleration of the milling process. Simultaneously, VP was refined to sub-micron scale (0.58 μm) and distributed uniformly in the matrix, which also exhibited excellent interfacial bonding with the matrix, after milling for 90 h.

- (2)

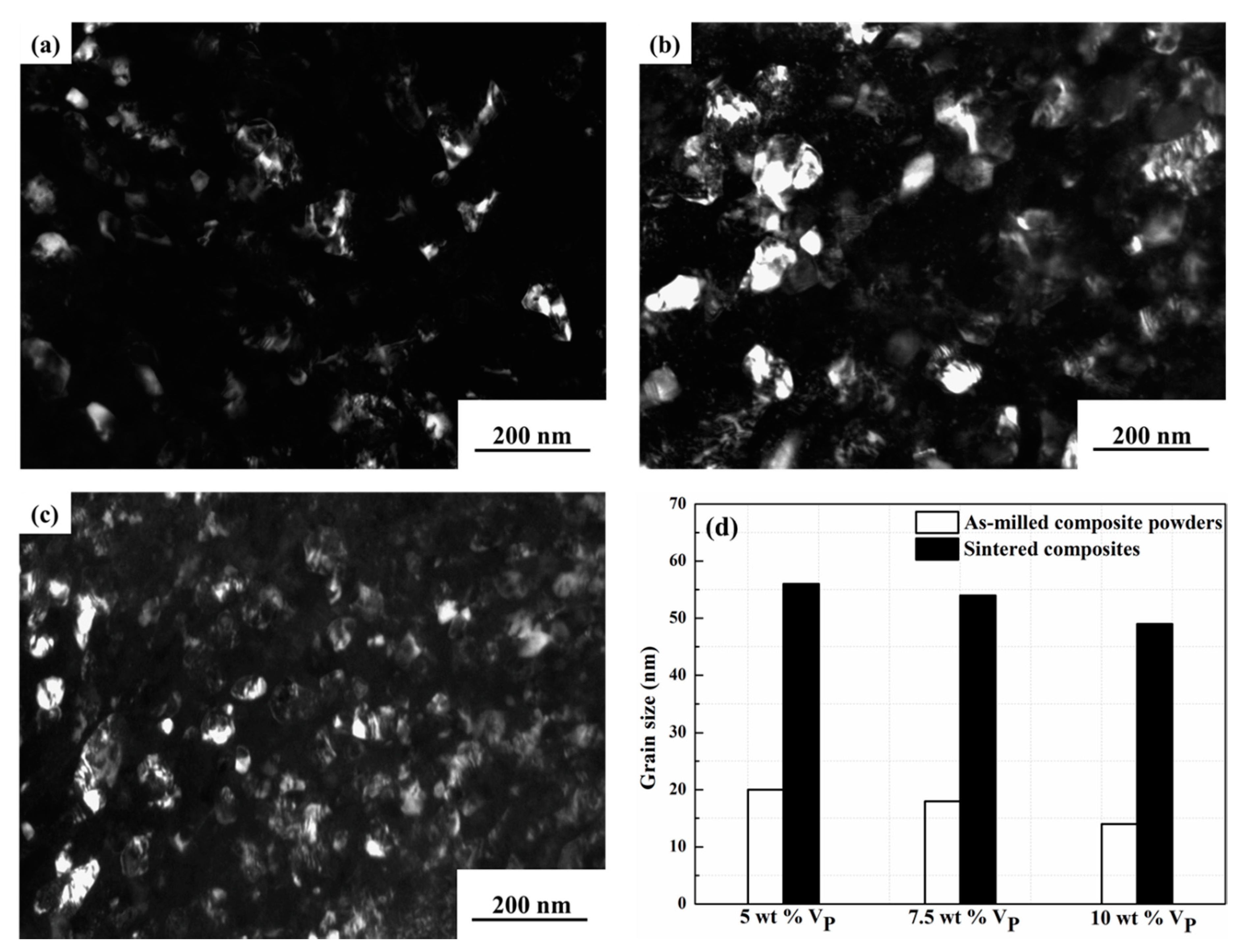

- During the milling process, the matrix grain size decreased with the increasing milling time and VP content. After milling for 90 h, the average grain size of AZ31-X wt % VP (X = 5, 7.5, 10) was refined to only 23 nm, 19 nm and 16 nm, respectively. Besides that, the average grain size of AZ31–VP composites increased to 56, 54, 49 nm, respectively, after the sintering process, which still remained at NC scale due to the pinning effect of sub-micron VP.

- (3)

- The porosity of the AZ31–VP composites was no more than 7.8%, indicating a good densification effect. Moreover, the effect of small porosity on mechanical properties was little. Compared to as-cast AZ31 Mg alloy, the microhardness of AZ31-X wt % VP (X = 5, 7.5, 10) composites increased by 65%, 87% and 96%, respectively. The corresponding strengthening mechanisms included grain refinement strengthening, Orowan strengthening and load-bearing effects.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Suryanarayana, C.; Al-Aqeeli, N. Mechanically alloyed nanocomposites. Prog. Mater. Sci. 2013, 58, 383–502. [Google Scholar] [CrossRef]

- Xu, T.; Yang, Y.; Peng, X.; Song, J.; Pan, F. Overview of advancement and development trend on magnesium alloy. J. Magnes. Alloys 2019, 7, 536–544. [Google Scholar] [CrossRef]

- Feng, J.; Sun, H.; Li, X.; Zhang, J.; Fang, W.; Fang, W. Microstructures and mechanical properties of the ultrafine-grained Mg–3Al–Zn alloys fabricated by powder metallurgy. Adv. Powder Technol. 2016, 27, 550–556. [Google Scholar] [CrossRef]

- Kondo, H.; Hegedus, M. Current trends and challenges in the global aviation industry. Acta Metall. Slovaca 2020, 26, 141–143. [Google Scholar] [CrossRef]

- Yeganeh, M.; Mohammadi, N. Superhydrophobic surface of Mg alloys: A review. J. Magnes. Alloys 2018, 6, 59–70. [Google Scholar] [CrossRef]

- Asgharzadeh, H.; Yoon, E.Y.; Chae, H.J.; Kim, T.S.; Lee, J.W.; Kim, H.S. Microstructure and mechanical properties of a Mg–Zn–Y alloy produced by a powder metallurgy route. J. Alloys Compd. 2014, 586, 95–100. [Google Scholar] [CrossRef]

- Ponhan, K.; Tassenberg, K.; Weston, D.; Nicholls, K.G.M.; Thornton, R. Effect of SiC nanoparticle content and milling time on the microstructural characteristics and properties of Mg-SiC nanocomposites synthesized with powder metallurgy incorporating high-energy ball milling. Ceram. Int. 2020, 46, 26956–26969. [Google Scholar] [CrossRef]

- Wang, H.Y.; Jiang, Q.C.; Wang, Y. Fabrication of TiB2 participate reinforced magnesium matrix composites by powder metallurgy. Mater. Lett. 2004, 58, 3509–3513. [Google Scholar] [CrossRef]

- Lee, C.J.; Huang, J.C.; Hsieh, P.J. Mg based nano-composites fabricated by friction stir processing. Scr. Mater. 2006, 54, 1415–1420. [Google Scholar] [CrossRef]

- Zhou, H.; Hu, L.; Sun, Y.; Zhang, H.; Duan, C.; Yu, H. Synthesis of nanocrystalline AZ31 magnesium alloy with titanium addition by mechanical milling. Mater. Charact. 2016, 113, 108–116. [Google Scholar] [CrossRef]

- Wong, W.L.E.; Gupta, M. Development of Mg/Cu nanocomposites using microwave assisted rapid sintering. Compos. Sci. Technol. 2007, 67, 1541–1552. [Google Scholar] [CrossRef]

- Liu, L.; Yu, S.; Liu, E.; Zhao, Y.; Wang, B.; Niu, Y. Effect of Ni addition on the mechanical and degradation properties of hollow glass microsphere/Mg alloy composites. J. Alloys Compd. 2021, 853. [Google Scholar] [CrossRef]

- Li, X.; Zhang, H.; Lu, S.; Li, W.; Zhao, J.; Johansson, B.R.; Vitos, L. Elastic properties of vanadium-based alloys from first-principles theory. Phys. Rev. B 2012, 86, 2867–2875. [Google Scholar] [CrossRef]

- Meyers, M.A.; Mishra, A.; Benson, D.J. Mechanical properties of nanocrystalline materials. Prog. Mater. Sci. 2006, 51, 427–556. [Google Scholar] [CrossRef]

- Yuan, W.; Panigrahi, S.K.; Su, J.Q.; Mishra, R.S. Influence of grain size and texture on Hall–Petch relationship for a magnesium alloy. Scr. Mater. 2011, 65, 994–997. [Google Scholar] [CrossRef]

- Hu, Y.; Zhang, C.; Zheng, T.; Pan, F.; Tang, A. Strengthening Effects of Zn Addition on an Ultrahigh Ductility Mg-Gd-Zr Magnesium Alloy. Materials 2018, 11, 1942. [Google Scholar] [CrossRef] [Green Version]

- Yu, H.; Zhou, H.; Sun, Y.; Ren, L.; Hu, L. Microstructures and mechanical properties of ultrafine-grained Ti/AZ31 magnesium matrix composite prepared by powder metallurgy. Adv. Powder Technol. 2018, 29, 3241–3249. [Google Scholar] [CrossRef]

- Gzyl, M.; Rosochowski, A.; Boczkal, S.; Olejnik, L. The role of microstructure and texture in controlling mechanical properties of AZ31B magnesium alloy processed by I-ECAP. Mater. Sci. Eng. A 2015, 638, 20–29. [Google Scholar] [CrossRef] [Green Version]

- Stráská, J.; Janeček, M.; Gubicza, J.; Krajňák, T.; Yoon, E.Y.; Kim, H.S. Evolution of microstructure and hardness in AZ31 alloy processed by high pressure torsion. Mater. Sci. Eng. A 2015, 625, 98–106. [Google Scholar] [CrossRef]

- Del Valle, J.A.; Rey, P.; Gesto, D.; Verdera, D.; Jiménez, J.A.; Ruano, O.A. Mechanical properties of ultra-fine grained AZ91 magnesium alloy processed by friction stir processing. Mater. Sci. Eng. A 2015, 628, 198–206. [Google Scholar] [CrossRef] [Green Version]

- Veronesi, P.; Colombini, E.; Rosa, R.; Leonelli, C.; Garuti, M. Microwave processing of high entropy alloys: A powder metallurgy approach. Chem. Eng. Process. 2017, 122, 397–403. [Google Scholar] [CrossRef] [Green Version]

- Muramatsu, H.; Kondoh, K.; Yuasa, E.; Aizawa, T. Mechanical Properties of Mg2Si/Mg Composites via Powder Metallurgy Process. JSME Int. J. 2015, 46, 247–250. [Google Scholar] [CrossRef] [Green Version]

- Dlapka, M.; Danninger, H.; Gierl, C.; Lindqvist, B. Defining the pores in PM components. Met. Powder Rep. 2010, 65, 30–33. [Google Scholar] [CrossRef]

- Zaludin, M.; Jamaludin, S.B.; Idris, M.S.; Llah, N.A. Effect of 45S5 Bio-Glass Particles on Physical Properties and Corrosion Resistance of the Mg-5Zn Matrix Composite. Open J. Met. 2014, 4, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Zhou, H.; Zhang, C.; Han, B.; Qiu, J.; Zhang, H. Microstructures and Mechanical Properties of Nanocrystalline AZ31 Magnesium Alloy Powders with Submicron TiB2 Additions Prepared by Mechanical Milling. Crystals 2020, 10, 550. [Google Scholar] [CrossRef]

- Fogagnolo, J.B.; Velasco, F.; Robert, M.H.; Torralba, J.M. Effect of mechanical alloying on the morphology, microstructure and properties of aluminium matrix composite powders. Mater. Sci. Eng. A 2003, 342, 131–143. [Google Scholar] [CrossRef]

- Zhou, H.; Hu, L.; Sun, H.; Chen, X. Synthesis of nanocrystalline Mg-based Mg-Ti composite powders by mechanical milling. Mater. Charact. 2015, 106, 44–51. [Google Scholar] [CrossRef]

- Hesabi, Z.R.; Simchi, A.; Reihani, S.M.S. Structural evolution during mechanical milling of nanometric and micrometric Al2O3 reinforced Al matrix composites. Mater. Sci. Eng. A 2006, 428, 159–168. [Google Scholar] [CrossRef]

- Yu, H.; Sun, Y.; Hu, L.; Wan, Z.; Zhou, H. The effect of Ti addition on microstructure evolution of AZ61 Mg alloy during mechanical milling. J. Alloys Compd. 2017, 704, 537–544. [Google Scholar] [CrossRef]

- Lei, R.S.; Wang, M.P.; Li, Z.; Wei, H.G.; Yang, W.C.; Jia, Y.L.; Gong, S. Structure evolution and solid solubility extension of copper–niobium powders during mechanical alloying. Mater. Sci. Eng. A 2011, 528, 4475–4481. [Google Scholar] [CrossRef]

- Yu, H.; Sun, Y.; Hu, L.; Zhou, H.; Wan, Z. Microstructural evolution of AZ61-10 at.%Ti composite powders during mechanical milling. Mater. Des. 2016, 104, 265–275. [Google Scholar] [CrossRef]

- Liang, G.; Schulz, R. Synthesis of Mg-Ti alloy by mechanical alloying. J. Mater. Sci. 2003, 38, 1179–1184. [Google Scholar] [CrossRef]

- Cao, N.Q.; Narita, K.; Kobayashi, E.; Sato, T. Evolution of the microstructure and mechanical properties of Mg-matrix in situ composites during spark plasma sintering. Powder Metall. 2016, 59, 302–307. [Google Scholar] [CrossRef]

- Lee, T.J.; Kim, W.J. Microstructure and tensile properties of magnesium nanocomposites fabricated using magnesium chips and carbon black. J. Magnes. Alloys 2020, 8, 860–872. [Google Scholar] [CrossRef]

- Aydin, F.; Sun, Y.; Ahlatci, H.; Turen, Y. Investigation of Microstructure, Mechanical and Wear Behaviour of B4C Particulate Reinforced Magnesium Matrix Composites by Powder Metallurgy. Trans. Indian Inst. Met. 2018, 71, 873–882. [Google Scholar] [CrossRef]

- Bidulská, J.; KvaCKaj, T.; Pokorny, I.; Bidulsky, R.; Grande, M.A. Identification of the critical pore sizes in sintered and ECAPed aluminium 6xxx alloy. Arch. Metall. Mater. 2013, 58, 371–375. [Google Scholar] [CrossRef] [Green Version]

- Bidulská, J.; KvaCKaj, T.; Bidulsky, R.; Grande, M.A. The Porosity Evaluation during ECAP in Aluminium PM Alloy. Acta Phys. Pol. A 2012, 122, 553–556. [Google Scholar] [CrossRef]

- Yu, H.; Yu, S.; Wan, Z.; Zhou, H.; Hu, L. Nanocrystalline Ti/AZ61 magnesium matrix composite: Evolution of microstructure and mechanical property during annealing treatment. J. Alloys Compd. 2018, 741, 231–239. [Google Scholar] [CrossRef]

- Razavi-Tousi, S.S.; Yazdani-Rad, R.; Manafi, S.A. Effect of volume fraction and particle size of alumina reinforcement on compaction and densification behavior of Al-Al2O3 nanocomposites. Mater. Sci. Eng. A 2011, 528, 1105–1110. [Google Scholar] [CrossRef]

- Rao, B.S.; Agarwal, A.; Lahiri, D. Carbon Nanotubes: Reinforced Metal Matrix Composites; CRC Press: Boca Raton, FL, USA, 2010; pp. 181–199. [Google Scholar]

- Rashad, M.; Pan, F.; Tang, A.; Asif, M.; Hussain, S.; Gou, J.; Mao, J. Improved strength and ductility of magnesium with addition of aluminum and graphene nanoplatelets (Al + GNPs) using semi powder metallurgy method. J. Ind. Eng. Chem. 2015, 23, 243–250. [Google Scholar] [CrossRef]

- Yuan, Q.H.; Qiu, Z.Q.; Zhou, G.H.; Zeng, X.S.; Luo, L.; Rao, X.X.; Ding, Y.; Liu, Y. Interfacial design and strengthening mechanisms of AZ91 alloy reinforced with in-situ reduced graphene oxide. Mater. Charact. 2018, 138, 215–228. [Google Scholar] [CrossRef]

- Bidulsk, R.; Bidulská, J.; Gobber, F.S.; Kvakaj, T.; Manfredi, D. Case Study of the Tensile Fracture Investigation of Additive Manufactured Austenitic Stainless Steels Treated at Cryogenic Conditions. Materials 2020, 13, 3328. [Google Scholar] [CrossRef] [PubMed]

- Murphy, T.F.; Schade, C.T.; Horvay, K.M. Metallographic characterization of porous low-alloy steel samples manufactured using both press-and-sinter and additive manufacturing techniques. Int. J. Powder Metall. 2019, 55, 37–47. [Google Scholar]

- Goh, C.S.; Wei, J.; Lee, L.C.; Gupta, M. Properties and deformation behaviour of Mg–Y2O3 nanocomposites. Acta Mater. 2007, 55, 5115–5121. [Google Scholar] [CrossRef]

- Han, G.; Wang, Z.; Ke, L.; Li, S.; Xian, D.; Du, W. Synthesis of CNT-reinforced AZ31 magnesium alloy composites with uniformly distributed CNTs. Mater. Sci. Eng. A 2015, 628, 350–357. [Google Scholar] [CrossRef]

| Material | Theoretical Density (g/cm3) | Real Density (g/cm3) | Porosity (%) |

|---|---|---|---|

| AZ31-5 wt % VP | 1.845 | 1.718 | 6.9 |

| AZ31-7.5 wt % VP | 1.879 | 1.741 | 7.3 |

| AZ31-10 wt % VP | 1.915 | 1.766 | 7.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, L.; Sun, S.; Zhou, H.; Zhang, H.; Wang, G.; Zhang, C.; He, L.; Wang, X. Effect of Vanadium Reinforcement on the Microstructure and Mechanical Properties of Magnesium Matrix Composites. Crystals 2021, 11, 806. https://doi.org/10.3390/cryst11070806

Sun L, Sun S, Zhou H, Zhang H, Wang G, Zhang C, He L, Wang X. Effect of Vanadium Reinforcement on the Microstructure and Mechanical Properties of Magnesium Matrix Composites. Crystals. 2021; 11(7):806. https://doi.org/10.3390/cryst11070806

Chicago/Turabian StyleSun, Liqing, Shuai Sun, Haiping Zhou, Hongbin Zhang, Gang Wang, Chengcai Zhang, Lianfang He, and Xin Wang. 2021. "Effect of Vanadium Reinforcement on the Microstructure and Mechanical Properties of Magnesium Matrix Composites" Crystals 11, no. 7: 806. https://doi.org/10.3390/cryst11070806

APA StyleSun, L., Sun, S., Zhou, H., Zhang, H., Wang, G., Zhang, C., He, L., & Wang, X. (2021). Effect of Vanadium Reinforcement on the Microstructure and Mechanical Properties of Magnesium Matrix Composites. Crystals, 11(7), 806. https://doi.org/10.3390/cryst11070806