Numerical Alloy Development for Additive Manufacturing towards Reduced Cracking Susceptibility

Abstract

:1. Introduction

2. Materials and Methods

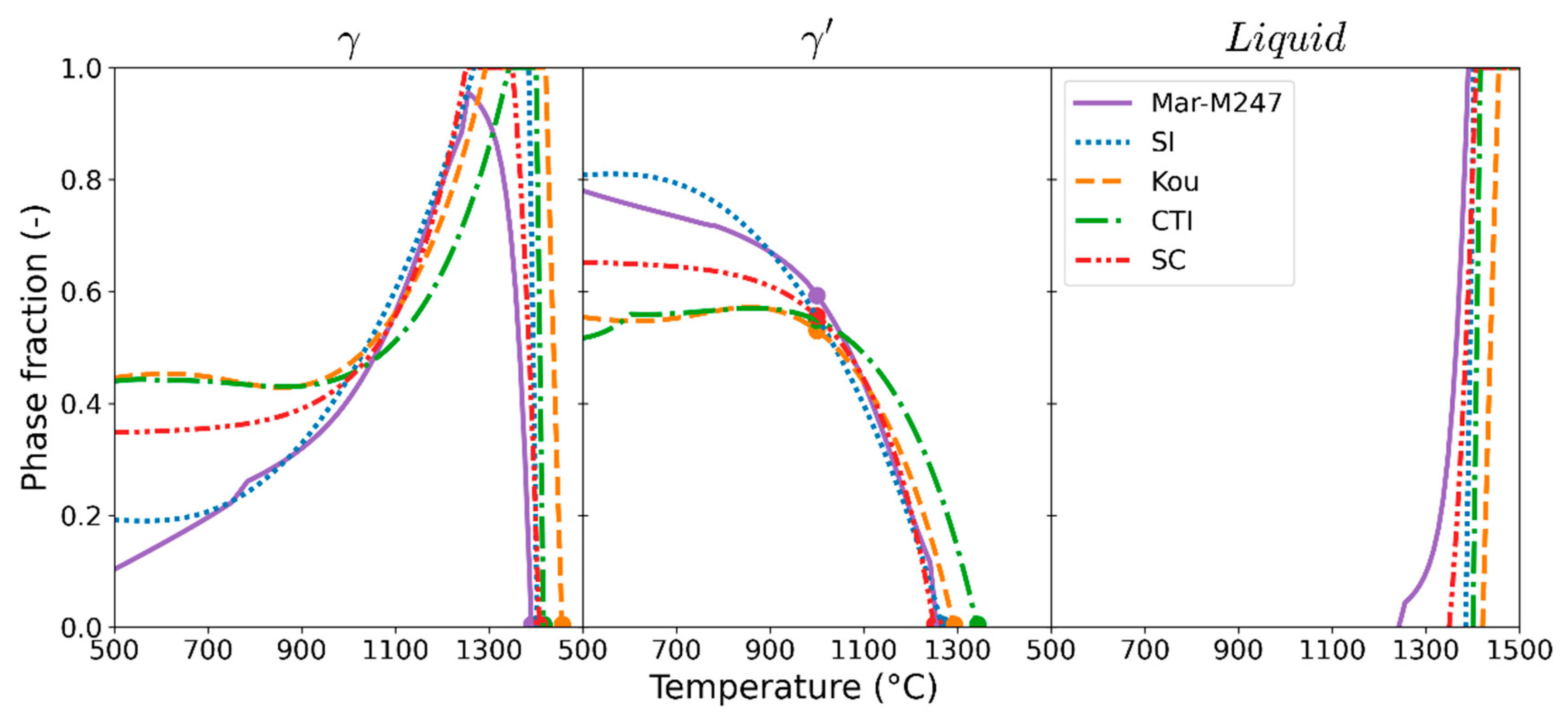

2.1. Cracking Susceptibility Models

- Solidification interval (SI):

- Kou criterion (Kou):

- Critical temperature interval (CTI):

- Strain coefficient (SC):

2.2. Reference Material

2.3. Implementation Details

2.4. Optimization

2.5. Experimental Procedure

3. Results

3.1. Alloy Selection

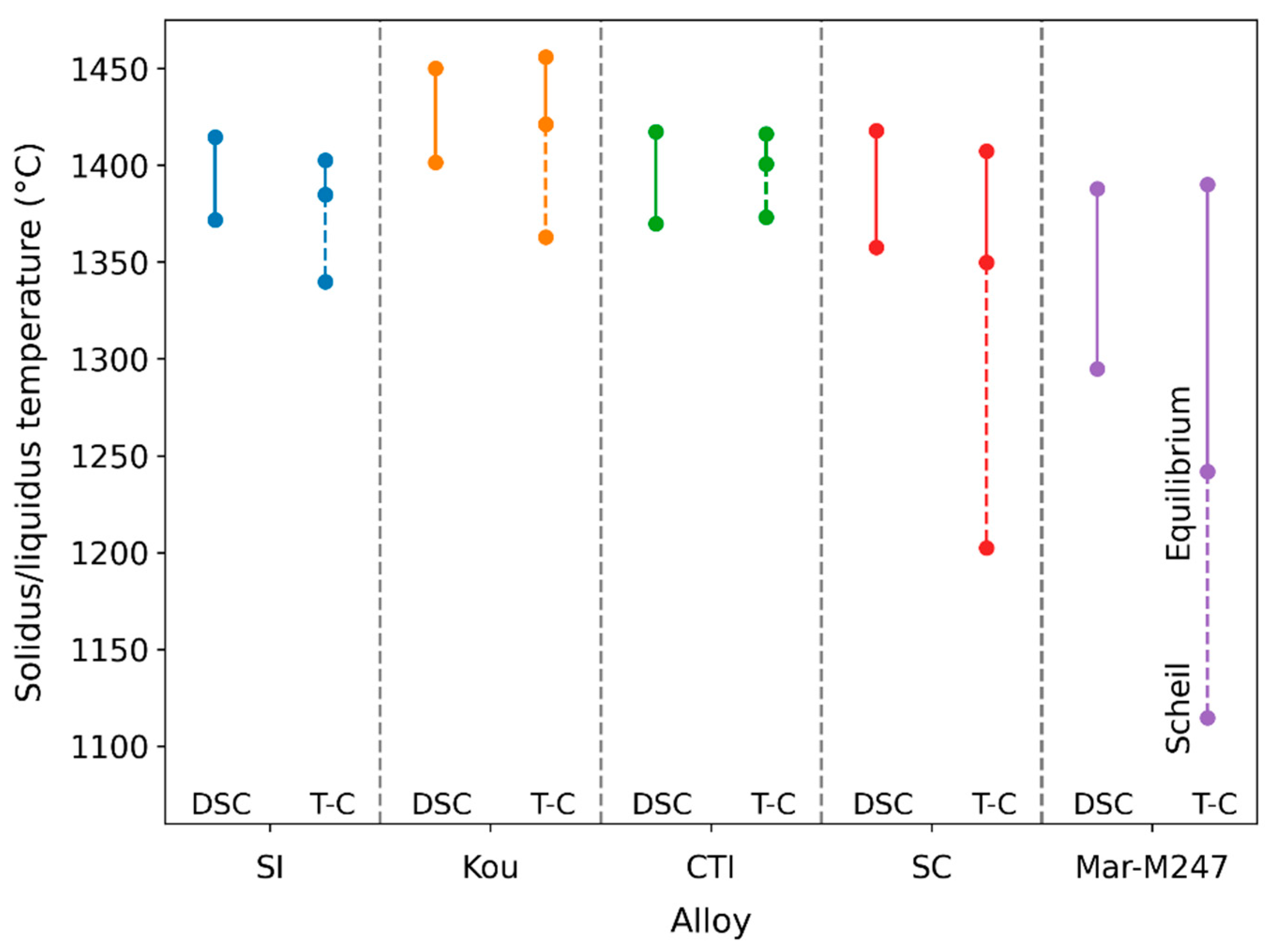

3.2. DSC Analysis

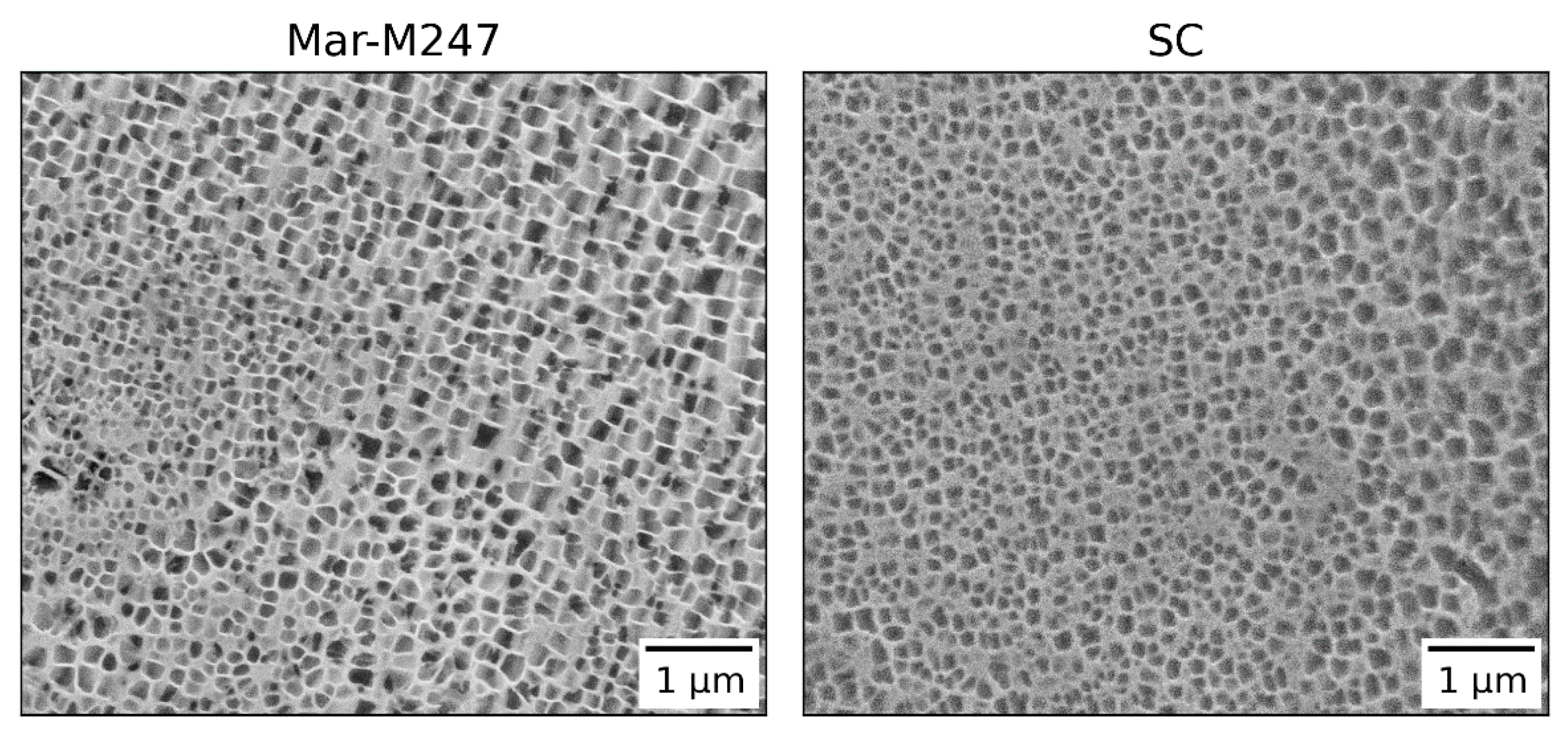

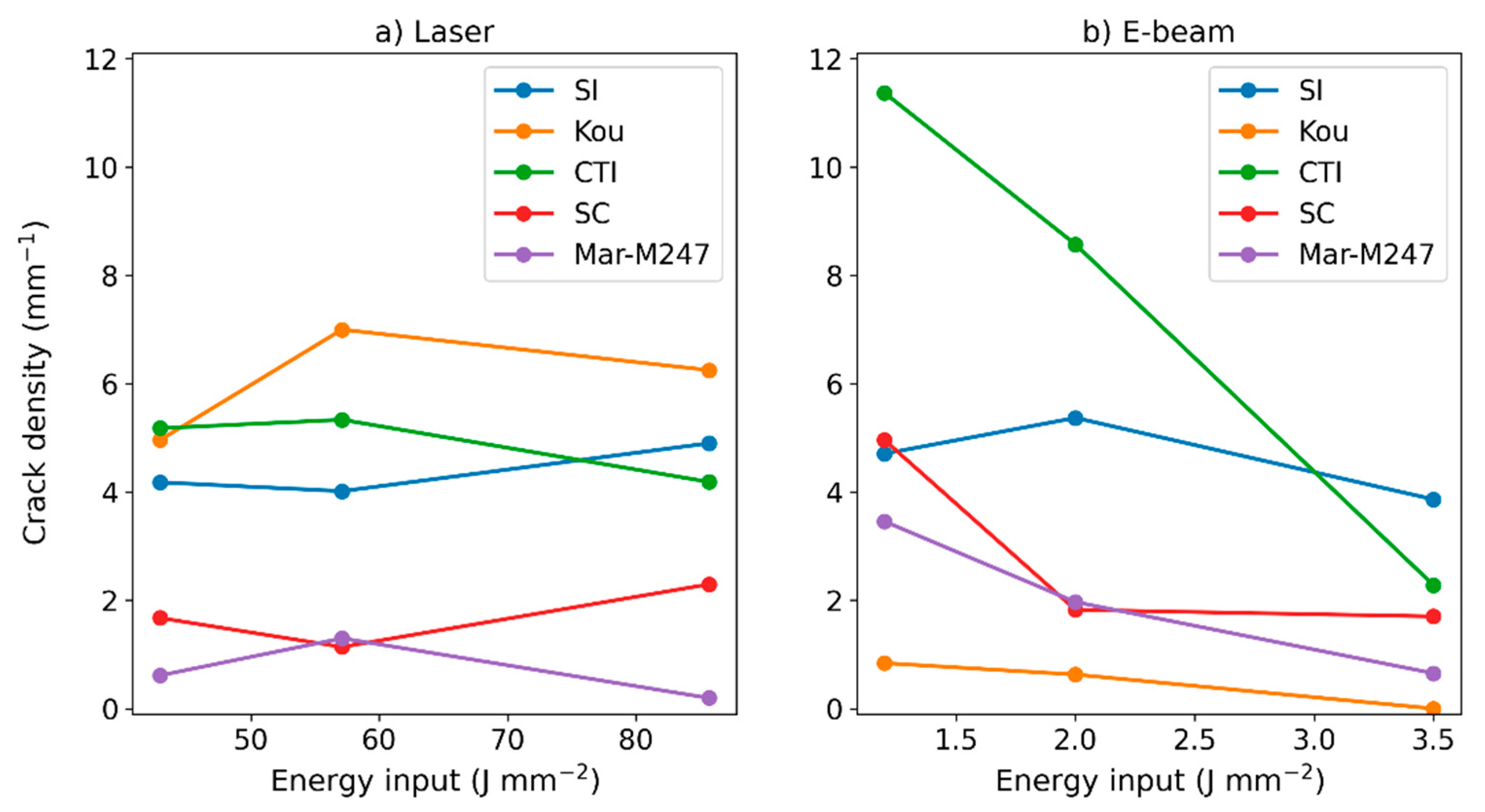

3.3. Cracking Susceptibility

4. Discussion

4.1. Cracking Mechanisms

4.2. Correlation Analysis

5. Conclusions

- Hot cracking occurred predominantly during electron beam melting at high process temperature, while only cold cracking was observed after laser melting due to the low process temperature. No improvement in cracking susceptibility could be achieved for laser melting.

- The hot cracking susceptibility of the alloy based on the Kou criterion could be improved compared to the reference Mar-M247 alloy under electron beam melting conditions.

- Most cracking criteria favor low-alloy compositions, which lead to high solidus and liquidus temperatures. Therefore, the susceptibility to cold cracking is increased.

- In order to develop alloys suitable for real applications, the cracking indicator must be chosen based on the expected cracking mechanism or should reflect multiple possible mechanisms. Furthermore, mechanical or corrosion properties must be considered.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chauvet, E.; Tassin, C.; Blandin, J.-J.; Dendievel, R.; Martin, G. Producing Ni-base superalloys single crystal by selective electron beam melting. Scr. Mater. 2018, 152, 15–19. [Google Scholar] [CrossRef]

- Körner, C.; Ramsperger, M.; Meid, C.; Bürger, D.; Wollgramm, P.; Bartsch, M.; Eggeler, G. Microstructure and mechanical properties of CMSX-4 single crystals prepared by additive manufacturing. Metall. Mater. Trans. A 2018, 49, 3781–3792. [Google Scholar] [CrossRef] [Green Version]

- Gotterbarm, M.R.; Rausch, A.M.; Körner, C. Fabrication of Single Crystals through a µ-Helix Grain Selection Process during Electron Beam Metal Additive Manufacturing. Metals 2020, 10, 313. [Google Scholar] [CrossRef] [Green Version]

- Kontis, P.; Chauvet, E.; Peng, Z.; He, J.; da Silva, A.K.; Raabe, D.; Tassin, C.; Blandin, J.-J.; Abed, S.; Dendievel, R.; et al. Atomic-scale grain boundary engineering to overcome hot-cracking in additively manufactured superalloys. Acta Mater. 2019, 177, 209–221. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.; Lu, F.; Zhang, K.; Nie, P.; Hosseini, S.R.E.; Feng, K.; Li, Z. Dendritic microstructure and hot cracking of laser additive manufactured Inconel 718 under improved base cooling. J. Alloys Compd. 2016, 670, 312–321. [Google Scholar] [CrossRef]

- Li, Y.; Chen, K.; Tamura, N. Mechanism of heat affected zone cracking in Ni-based superalloy DZ125L fabricated by laser 3D printing technique. Mater. Des. 2018, 150, 171–181. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.; Zhang, K.; Huang, J.; Hosseini, S.R.E.; Li, Z. Characterization of heat affected zone liquation cracking in laser additive manufacturing of Inconel 718. Mater. Des. 2016, 90, 586–594. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, H.; Xu, L.; Xu, J.; Ren, X.; Chen, X. Cracking mechanism and susceptibility of laser melting deposited Inconel 738 superalloy. Mater. Des. 2018, 183, 108105. [Google Scholar] [CrossRef]

- Chauvet, E.; Kontis, P.; Jägle, E.A.; Gault, B.; Raabe, D.; Tassin, C.; Blandin, J.-J.; Dendievel, R.; Vayre, B.; Abed, S.; et al. Hot cracking mechanism affecting a non-weldable Ni-based superalloy produced by selective electron beam melting. Acta Mater. 2018, 142, 82–94. [Google Scholar] [CrossRef]

- Ojo, O.A.; Richards, N.L.; Chaturvedi, M.C. Study of the fusion zone and heat-affected zone microstructures in tungsten inert gas-welded INCONEL 738LC superalloy. Metall. Mater. Trans. A 2006, 37, 421–433. [Google Scholar] [CrossRef]

- Li, C.; Liu, Z.Y.; Fang, X.Y.; Guo, Y.B. Residual stress in metal additive manufacturing. Procedia CIRP 2018, 71, 348–353. [Google Scholar] [CrossRef]

- Yokokawa, T.; Harada, H.; Kawagishi, K.; Kobayashi, T.; Yuyama, M.; Takata, Y. Advanced Alloy Design Program and Improvement of Sixth-Generation Ni-Base Single Crystal Superalloy TMS-238. In Superalloys 2020; Tin, S., Hardy, M., Clews, J., Cormier, J., Feng, Q., Marcin, J., O’Brien, C., Suzuki, A., Eds.; Springer: Cham, Switzerland, 2020; pp. 122–130. [Google Scholar]

- Reed, R.C.; Tao, T.; Warnken, N. Alloys-by-design: Application to nickel-based single crystal superalloys. Acta Mater. 2009, 57, 5898–5913. [Google Scholar] [CrossRef]

- Tang, Y.T.; Panwisawas, C.; Ghoussoub, J.N.; Gong, Y.; Clark, J.W.; Németh, A.A.N.; McCartney, D.G.; Reed, R.C. Alloys-by-design: Application to new superalloys for additive manufacturing. Acta Mater. 2021, 202, 417–436. [Google Scholar] [CrossRef]

- Alabort, E.; Barba, D.; Shagiev, M.R.; Murzinova, M.A.; Galeyev, R.M.; Valiakhmetov, O.R.; Aletdinov, A.F.; Reed, R.C. Alloys-by-design: Application to titanium alloys for optimal superplasticity. Acta Mater. 2019, 178, 275–287. [Google Scholar] [CrossRef]

- Rettig, R.; Ritter, N.C.; Helmer, H.E.; Neumeier, S.; Singer, R.F. Single-crystal nickel-based superalloys developed by numerical multi-criteria optimization techniques: Design based on thermodynamic calculations and experimental validation. Modell. Simul. Mater. Sci. Eng. 2015, 23, 035004. [Google Scholar] [CrossRef]

- Menou, E.; Toda-Caraballo, I.; Rivera-Díaz-del, P.E.J.; Pineau, C.; Bertrand, E.; Ramstein, G.; Tancret, F. Evolutionary design of strong and stable high entropy alloys using multi-objective optimisation based on physical models, statistics and thermodynamics. Mater. Des. 2018, 143, 185–195. [Google Scholar] [CrossRef]

- Markl, M.; Müller, A.; Ritter, N.; Hofmeister, M.; Naujoks, D.; Schaar, H.; Abrahams, K.; Frenzel, J.; Subramanyam, A.P.A.; Ludwig, A.; et al. Development of single-crystal Ni-base superalloys based on multi-criteria numerical optimization and efficient use of refractory elements. Metall. Mater. Trans. A 2018, 49, 4134–4145. [Google Scholar] [CrossRef] [Green Version]

- Müller, A.; Roslyakova, I.; Sprenger, M.; Git, P.; Rettig, R.; Markl, M.; Körner, C.; Singer, R.F. MultOpt++: A fast regression-based model for the development of compositions with high robustness against scatter of element concentrations. Modell. Simul. Mater. Sci. Eng. 2019, 27, 024001. [Google Scholar] [CrossRef]

- Rettig, R.; Matuszewski, K.; Müller, A.; Helmer, H.E.; Ritter, N.C.; Singer, R.F. Development of a low-density rhenium-free single crystal nickel-based superalloy by application of numerical multi-criteria optimization using thermodynamic calculations. In Superalloys 2016; Hardy, M., Huron, E., Glatzel, U., Griffin, B., Lewis, B., Rae, C., Seetharaman, V., Tin, S., Eds.; John Wiley & Sons: Hoboken, NJ, USA, 2016; pp. 35–44. [Google Scholar]

- Basak, C.B.; Krishnan, M. Applicability of Scheil–Gulliver solidification model in real alloy: A case study with Cu-9wt% Ni-6wt% Sn alloy. Philos. Mag. Lett. 2015, 95, 376–383. [Google Scholar] [CrossRef]

- Ghoussoub, J.N.; Tang, Y.T.; Panwisawas, P.; Németh, A.; Reed, R.C. On the influence of alloy chemistry and processing conditions on additive manufacturability of Ni-based superalloys. In Superalloys 2020; Tin, S., Hardy, M., Clews, J., Cormier, J., Feng, Q., Marcin, J., O’Brien, C., Suzuki, A., Eds.; Springer: Cham, Switzerland, 2020; pp. 153–162. [Google Scholar]

- Kou, S. A simple index for predicting the susceptibility to solidification cracking. Weld. J. 2015, 94, 374–388. [Google Scholar]

- Kou, S. A criterion for cracking during solidification. Acta Mater. 2015, 88, 366–374. [Google Scholar] [CrossRef]

- Xia, C.; Kou, S. Evaluating susceptibility of Ni-base alloys to solidification cracking by transverse-motion weldability test. Sci. Tech. Weld. Join. 2020, 25, 690–697. [Google Scholar] [CrossRef]

- Shukla, A.; Sarkar, S.; Durga, A.; Adharapurapu, R.; Dial, L.; Sondhi, S.K. Computational design of additively printable nickel superalloys. In Superalloys 2020; Tin, S., Hardy, M., Clews, J., Cormier, J., Feng, Q., Marcin, J., O’Brien, C., Suzuki, A., Eds.; Springer: Cham, Switzerland, 2020; pp. 1066–1074. [Google Scholar]

- Zhang, J.; Singer, R.F. Hot tearing of nickel-based superalloys during directional solidification. Acta Mater. 2002, 50, 1869–1879. [Google Scholar] [CrossRef]

- Rappaz, M.; Drezet, J.M.; Gremaud, M. A new hot-tearing criterion. Metall. Mater. Trans. A 1999, 30, 449–455. [Google Scholar] [CrossRef]

- Harris, K.; Erickson, G.L.; Schwer, R.E. MAR-M247 derivations—CM247 LC DS alloy, CMSX single crystal alloys, properties and performance. In Superalloys 1984; Gell, M., Ed.; Metallurgical Society of AIME: Englewood, NJ, USA, 1984; pp. 221–230. [Google Scholar]

- Andersson, J.O.; Helander, T.; Höglund, L.; Shi, P.; Sundman, B. Thermo-Calc & DICTRA, computational tools for materials science. Calphad 2002, 26, 273–312. [Google Scholar]

- Blank, J.; Deb, K. pymoo: Multi-objective optimization in python. IEEE Access 2020, 8, 89497–89509. [Google Scholar] [CrossRef]

- Deb, K.; Pratap, A.; Agarwal, S.; Meyarivan, T.A.M.T. A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans. Evol. Comput. 2002, 6, 182–197. [Google Scholar] [CrossRef] [Green Version]

- Auger, A.; Bader, J.; Brockhoff, D.; Zitzler, E. Hypervolume-based multiobjective optimization: Theoretical foundations and practical implications. Theor. Comput. Sci. 2012, 425, 75–103. [Google Scholar] [CrossRef]

- Helmer, H.E.; Körner, C.; Singer, R.F. Additive manufacturing of nickel-based superalloy Inconel 718 by selective electron beam melting: Processing window and microstructure. J. Mater. Res. 2014, 29, 1987–1996. [Google Scholar] [CrossRef]

- Arnold, C.; Pobel, C.; Osmanlic, F.; Körner, C. Layerwise monitoring of electron beam melting via backscatter electron detection. Rapid Prototyp. J. 2018, 24, 1401–1406. [Google Scholar] [CrossRef]

- Rachmawati, L.; Srinivasan, D. Multiobjective evolutionary algorithm with controllable focus on the knees of the Pareto front. IEEE Trans. Evol. Comput. 2009, 13, 810–824. [Google Scholar] [CrossRef]

- Seidel, A.; Finaske, T.; Straubel, A.; Wendrock, H.; Maiwald, T.; Riede, M.; Lopez, E.; Brueckner, F.; Leyens, C. Additive manufacturing of powdery Ni-based superalloys Mar-M-247 and CM 247 LC in hybrid laser metal deposition. Metall. Mater. Trans. A 2018, 49, 3812–3830. [Google Scholar] [CrossRef]

- Dovgyy, B.; Simonelli, M.; Pham, M.S. Alloy design against the solidification cracking in fusion additive manufacturing: An application to a FeCrAl alloy. Mater. Res. Lett. 2021, 9, 350–357. [Google Scholar] [CrossRef]

- Horst, O.M.; Schmitz, D.; Schreuer, J.; Git, P.; Wang, H.; Körner, C.; Eggeler, G. Thermoelastic properties and γ’-solvus temperatures of single-crystal Ni-base superalloys. J. Mater. Sci. 2021, 56, 7637–7658. [Google Scholar] [CrossRef]

- Divya, V.D.; Muñoz-Moreno, R.; Messé, O.M.D.M.; Barnard, J.S.; Baker, S.; Illston, T.; Stone, H.J. Microstructure of selective laser melted CM247LC nickel-based superalloy and its evolution through heat treatment. Mater. Charact. 2016, 114, 62–74. [Google Scholar] [CrossRef] [Green Version]

| Element | Mar-M247 |

|---|---|

| Al | 12.3 |

| Ti | 1.3 |

| Cr | 9.7 |

| Co | 10.2 |

| Mo | 0.4 |

| Ta | 1.0 |

| W | 3.3 |

| Hf | 0.5 |

| Ni | 61.3 |

| Optimization Goals | Constraints |

|---|---|

| Beam Type | Beam Power P (W) | Scan Speed v (mm/s) | Hatch Spacing h (mm) | Energy Input (J mm−2) 1 |

|---|---|---|---|---|

| Laser beam | 300 | 10 | 0.35 | 85.7 |

| 300 | 20 | 0.35 | 42.9 | |

| 200 | 10 | 0.35 | 57.7 | |

| Electron beam | 350 | 500 | 0.2 | 3.5 |

| 400 | 1000 | 0.2 | 2 | |

| 500 | 2000 | 0.2 | 1.25 |

| Element | Alloy SI | Alloy Kou | Alloy CTI | Alloy SC |

|---|---|---|---|---|

| Al | 14.0 | 11.7 | 10.9 | 10.4 |

| Ti | - | 1.0 | - | 3.9 |

| Cr | 6.5 | 0.3 | 0.4 | 2.1 |

| Co | 0.3 | 0.5 | 3.4 | 7.4 |

| Mo | - | 0.3 | - | - |

| Ta | 1.2 | 1.7 | 4.8 | 1.0 |

| W | - | 3.0 | 0.1 | 4.2 |

| Hf | - | - | - | - |

| Ni | 78.0 | 81.5 | 80.4 | 71.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wahlmann, B.; Leidel, D.; Markl, M.; Körner, C. Numerical Alloy Development for Additive Manufacturing towards Reduced Cracking Susceptibility. Crystals 2021, 11, 902. https://doi.org/10.3390/cryst11080902

Wahlmann B, Leidel D, Markl M, Körner C. Numerical Alloy Development for Additive Manufacturing towards Reduced Cracking Susceptibility. Crystals. 2021; 11(8):902. https://doi.org/10.3390/cryst11080902

Chicago/Turabian StyleWahlmann, Benjamin, Dominik Leidel, Matthias Markl, and Carolin Körner. 2021. "Numerical Alloy Development for Additive Manufacturing towards Reduced Cracking Susceptibility" Crystals 11, no. 8: 902. https://doi.org/10.3390/cryst11080902

APA StyleWahlmann, B., Leidel, D., Markl, M., & Körner, C. (2021). Numerical Alloy Development for Additive Manufacturing towards Reduced Cracking Susceptibility. Crystals, 11(8), 902. https://doi.org/10.3390/cryst11080902