Study on Flexural Performance of Concrete Beams Reinforced by Steel Fiber and Nano–SiO2 Materials

Abstract

:1. Introduction

2. Experimental Programs

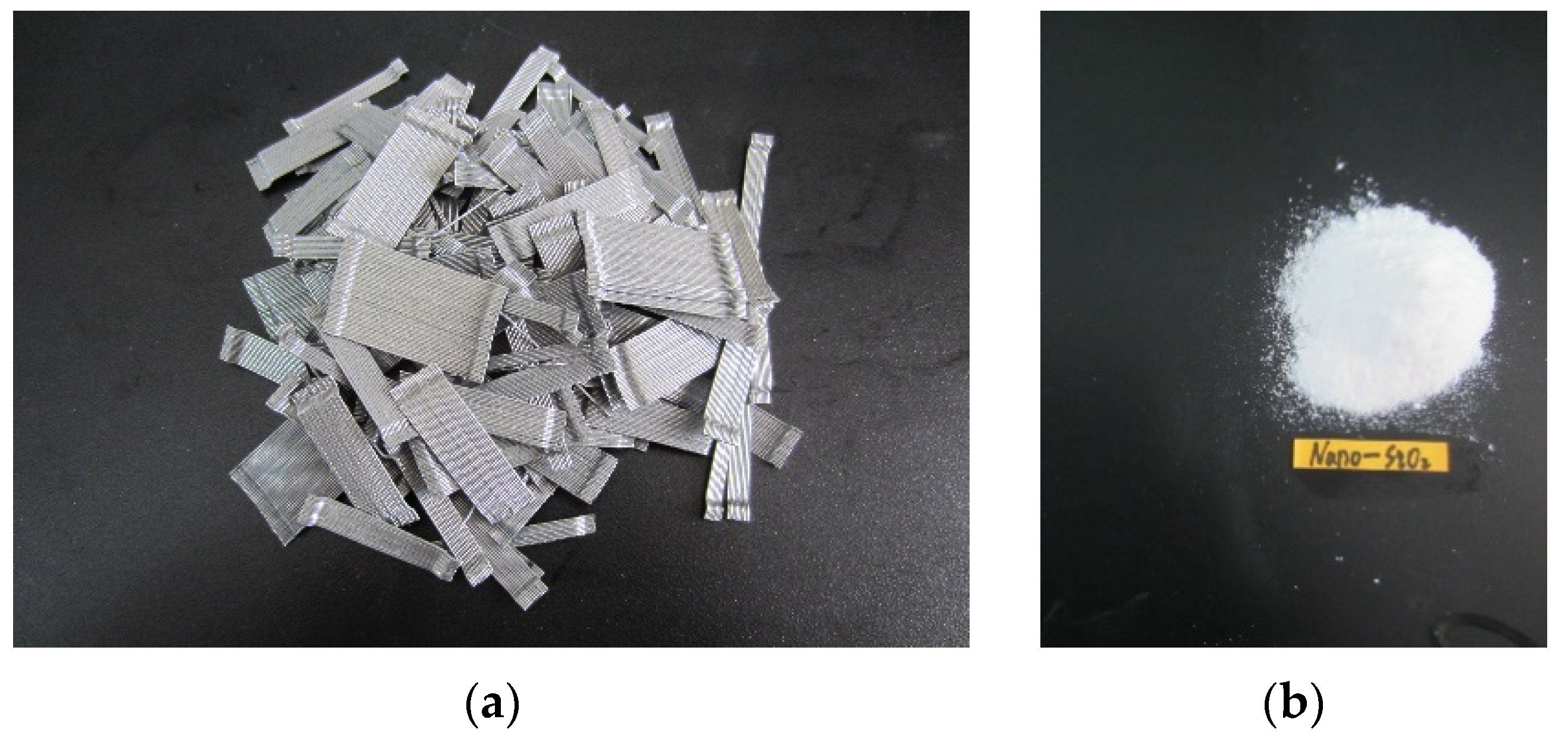

2.1. Materials

2.2. Specimen Design

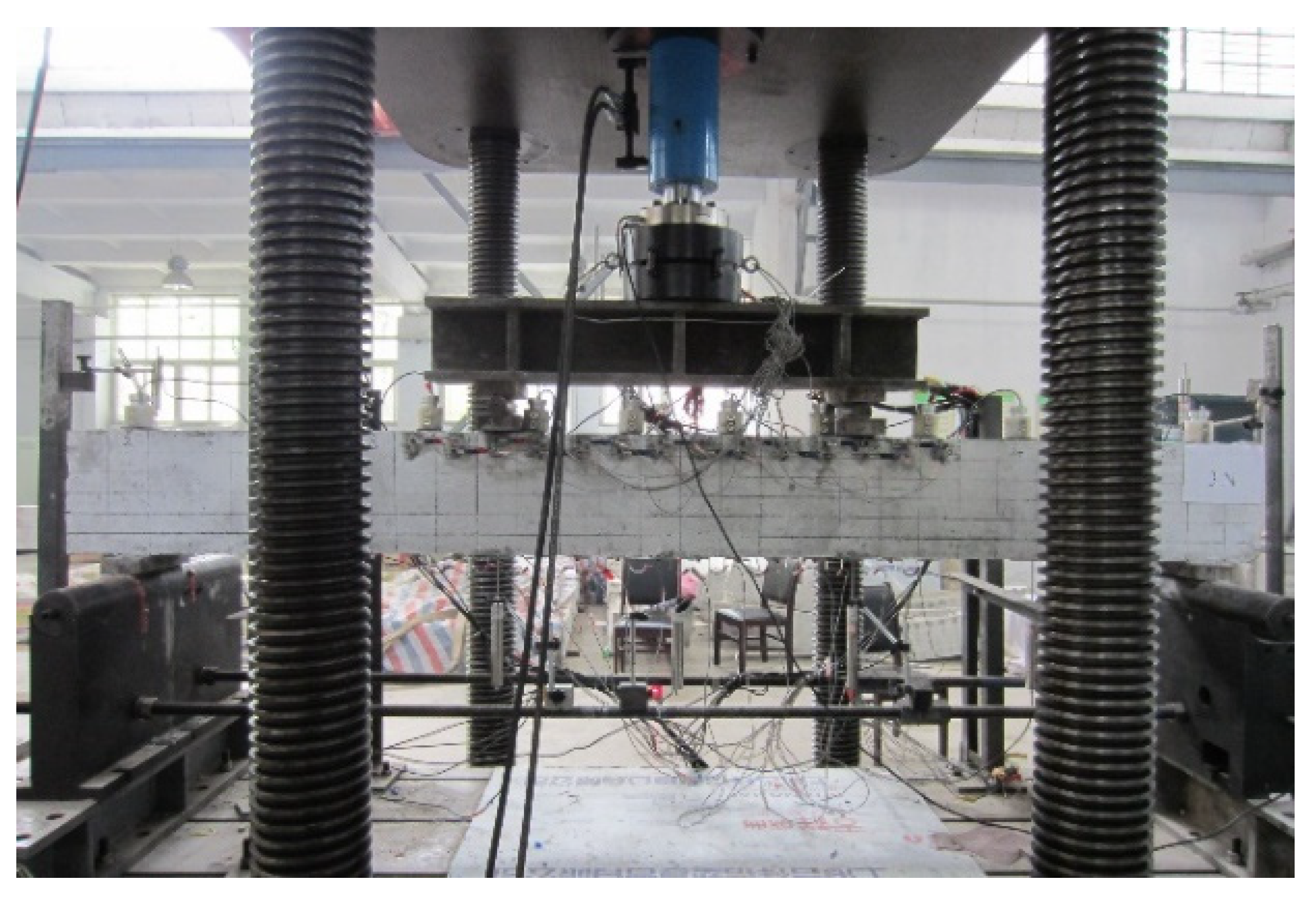

2.3. Test Procedure

3. Experimental Results and Discussion

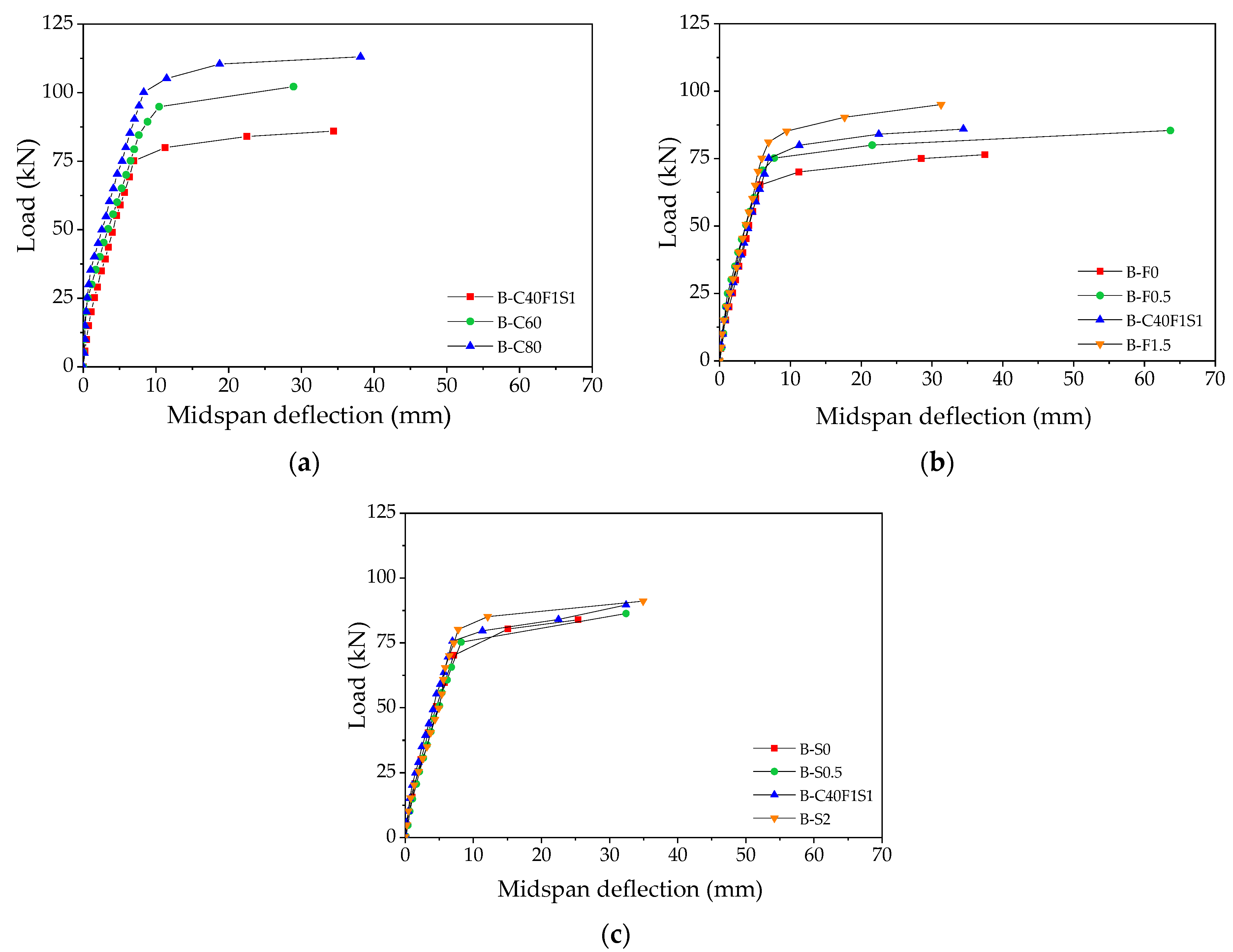

3.1. Load–Midspan Deflection Relationship

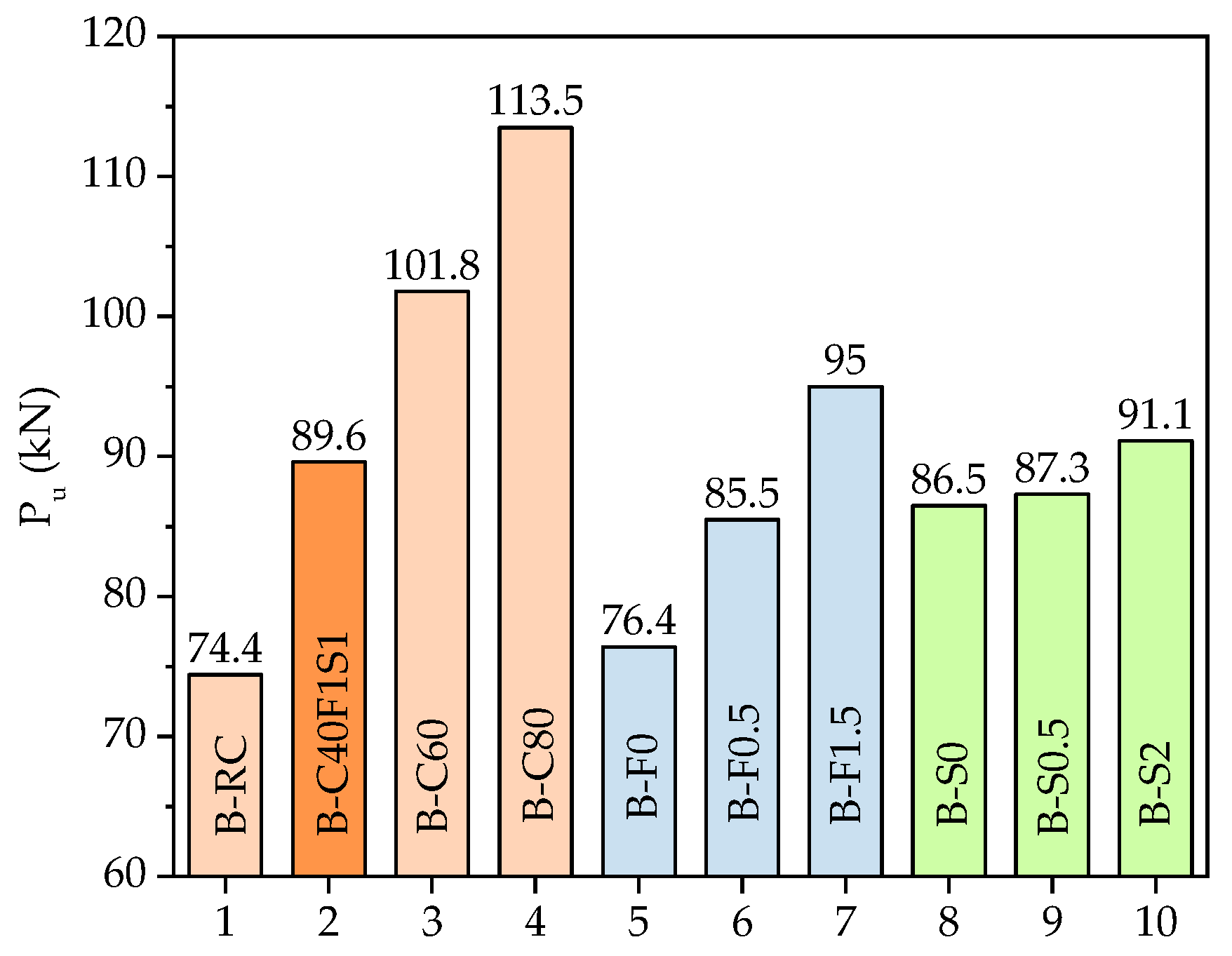

3.2. Ultimate Load (Pu)

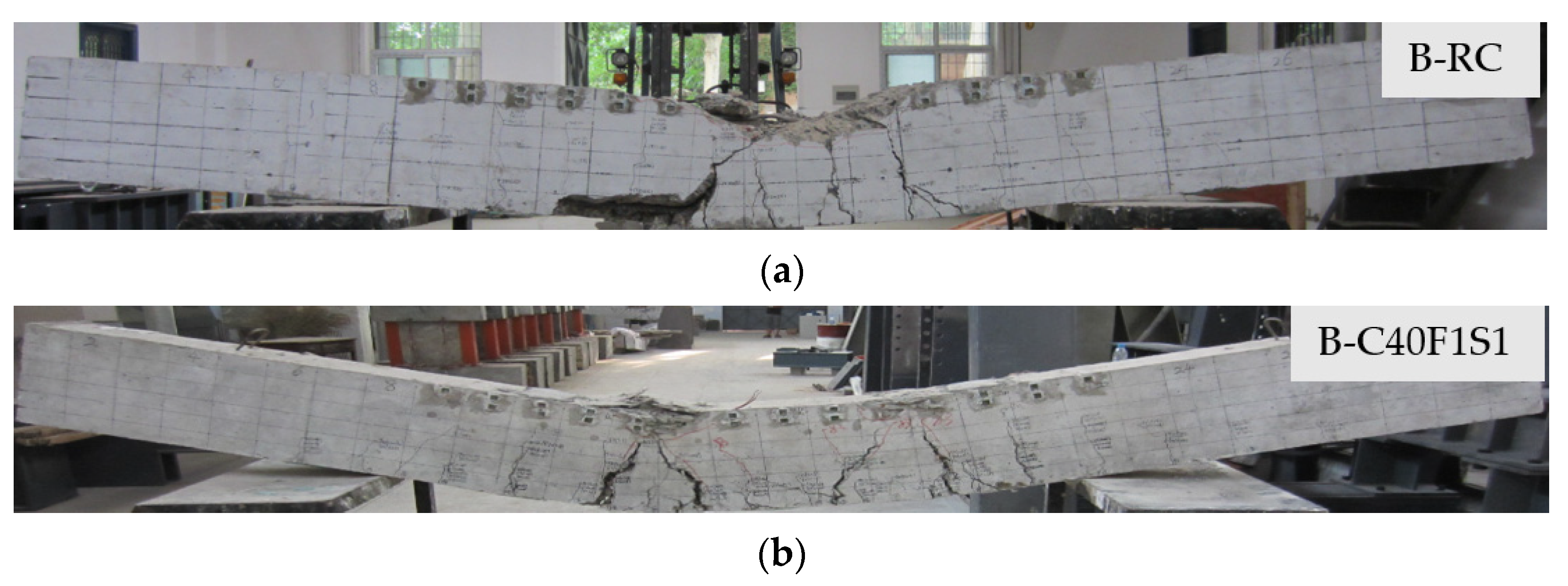

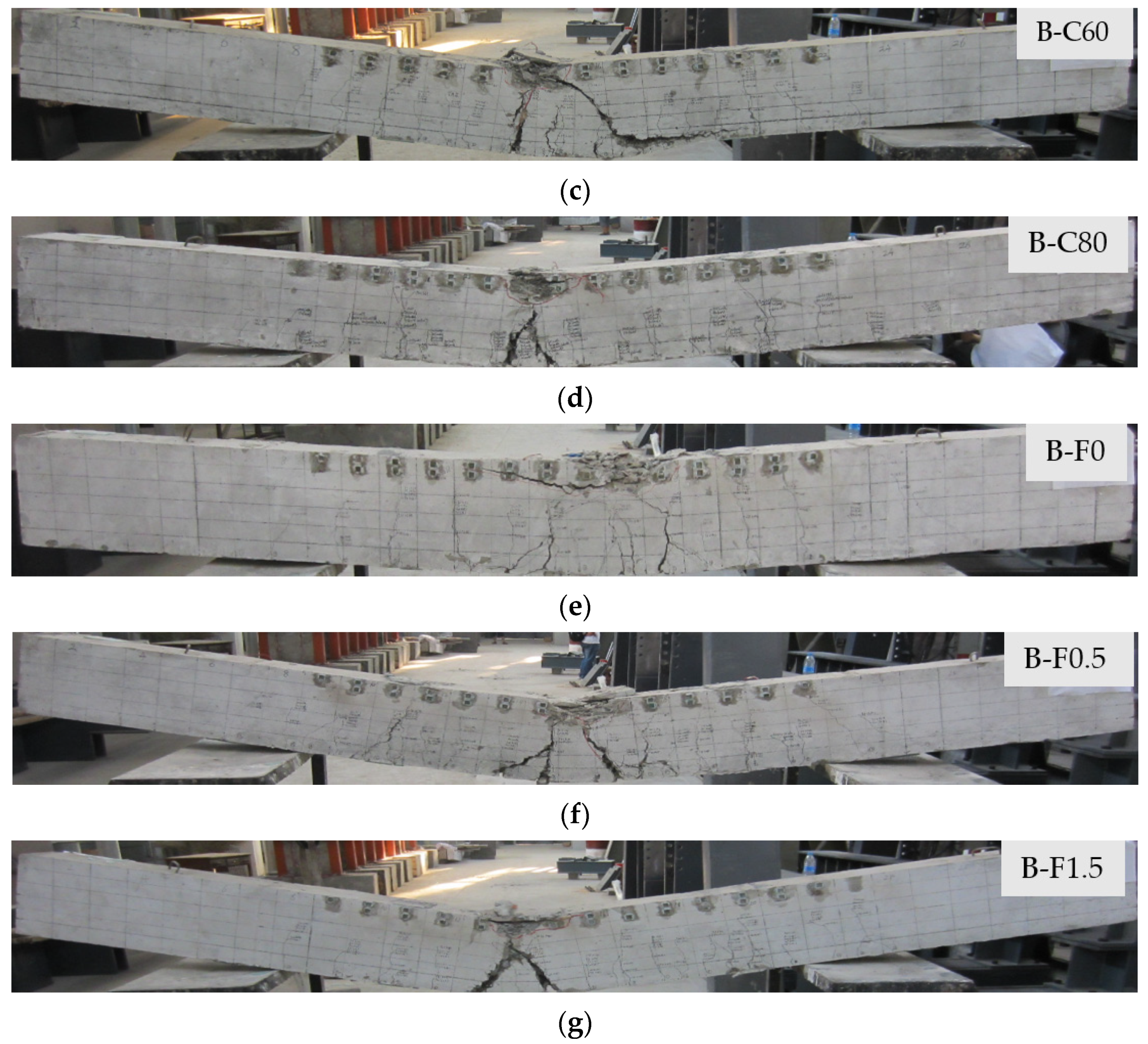

3.3. Failure Modes

3.4. Cracking Load

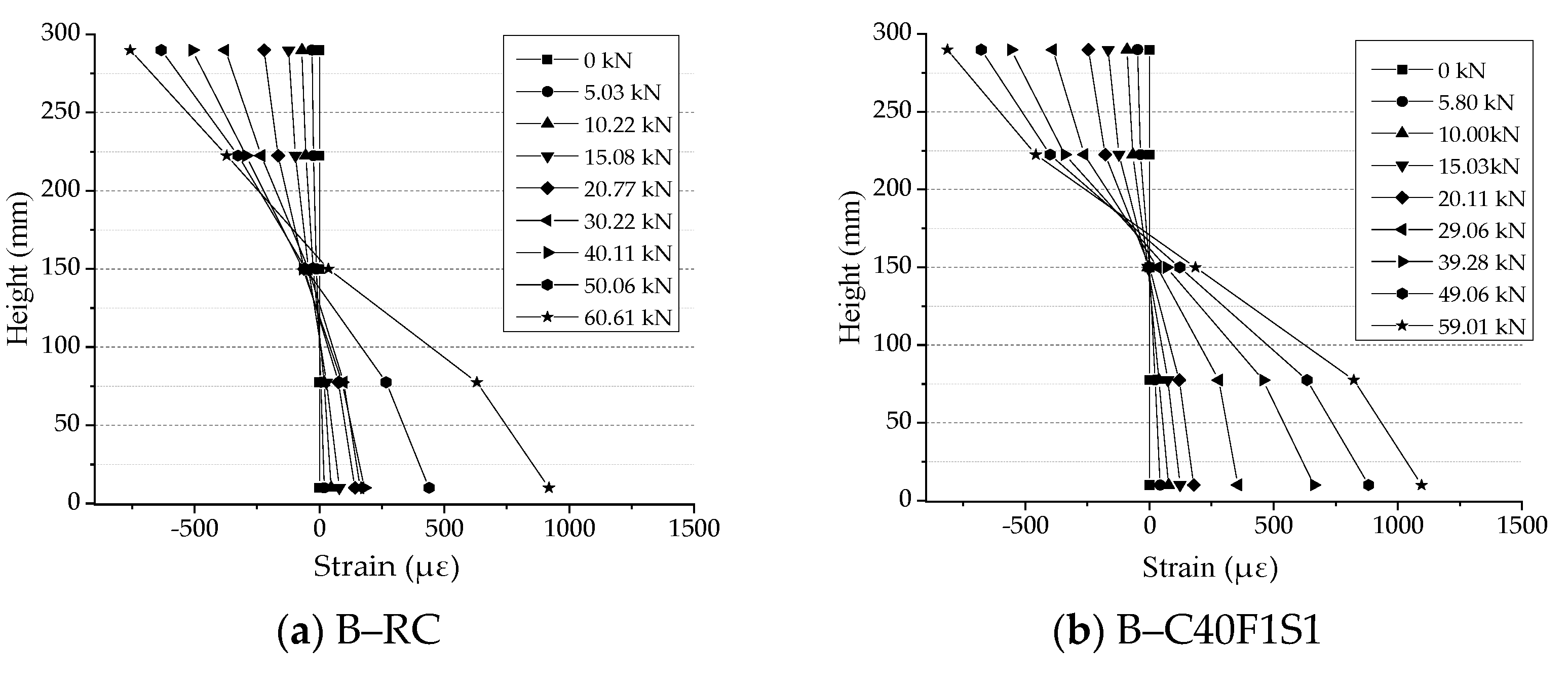

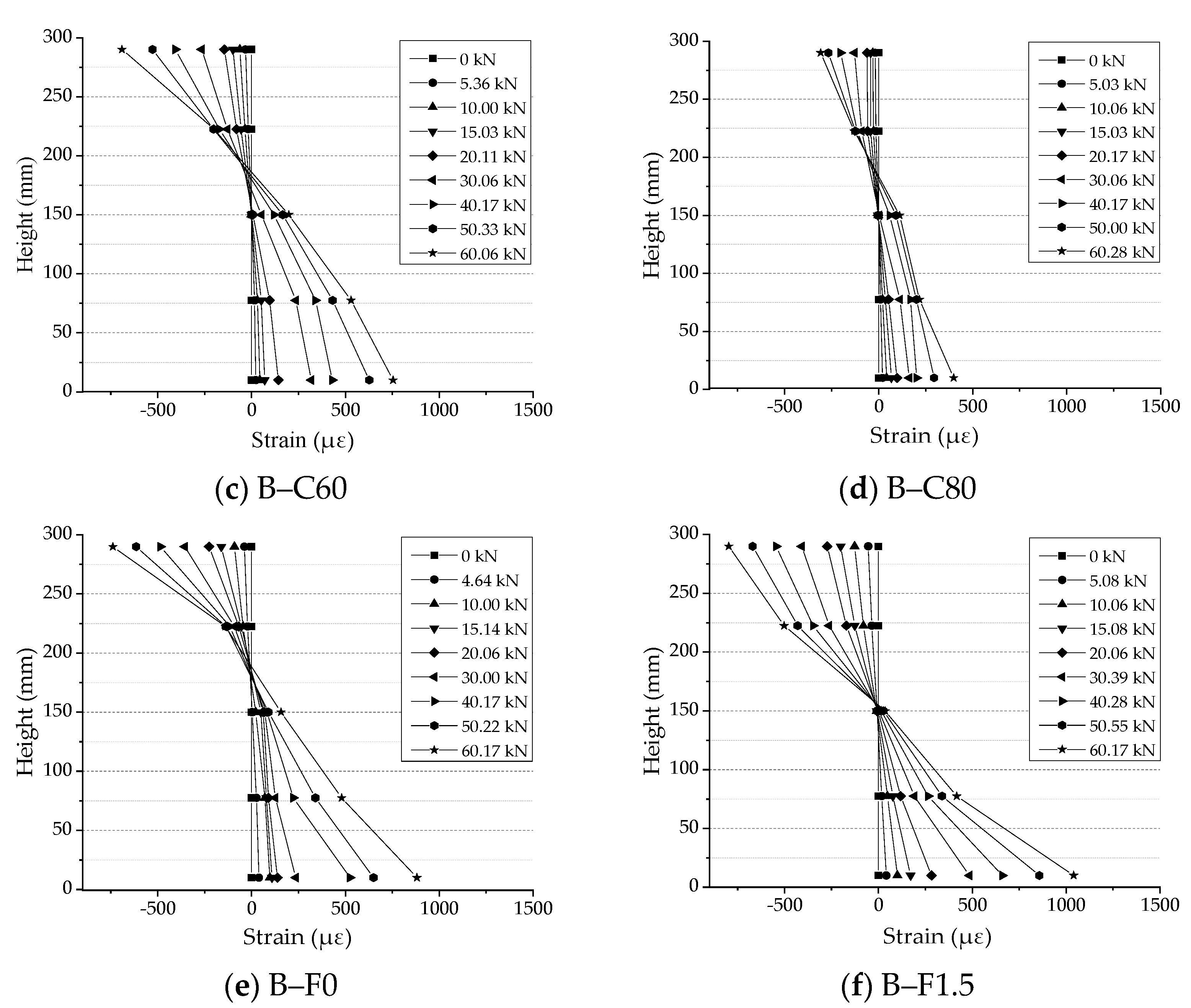

3.5. Load–Strain Relationship

4. Calculation Method of Flexural Bearing Capacity

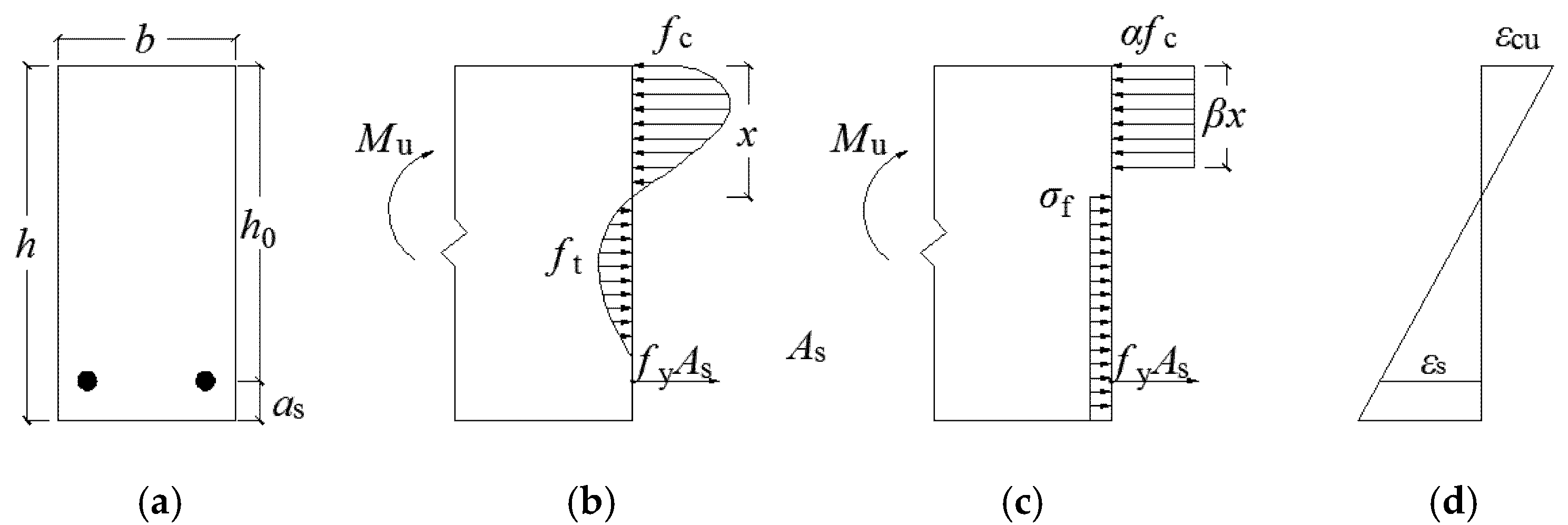

4.1. Fundamental Assumptions

- (1)

- It can be seen from the height vs. strain in Figure 8 that the section strain approximately changes linearly along with the beam height, which is consistent with the assumption of the planar cross-section behavior.

- (2)

- The compressive stress of SFNMRC beams in the compression zone is simplified as equivalent rectangular stress. The simplification principle is that the resultant force of compressive stress is constant, and the moment of the resultant force of compressive stress on the neutral axis remains the same. Therefore, the compressive stress distribution height adopts the conversion height. The equivalent compression zone height is the measured compression zone height multiplied by the coefficient β; compressive stress is the axial compressive strength of steel fiber reinforced concrete multiplying fc by a coefficient α.

- (3)

- Because steel fiber bears a part of tensile stress in the tensile zone of the beam, the role of steel fiber should be considered when calculating the bearing capacity. Therefore, the tensile stress distribution of steel fiber reinforced nano-concrete in the tensile zone is simplified as an equivalent rectangular stress diagram. The simplification principle is that the resultant force of tensile stress remains unchanged, and the moment of the resultant force of tensile stress on the neutral axis is constant.

- (4)

- The bond between the steel bar and SFNMRC is good, and there is no bond failure. When the beam is damaged, the tensile reinforcement has reached the yield strength.

4.2. Materials Constitutive Model

- Concrete

- Steel bar

4.3. Calculation of Flexural Bearing Capacity

4.4. Formula Validation

5. Conclusions

- Flexural specimens are considered to experience three stages until failure: loading stage, cracking stage, and yield stage of steel bars. Bending cracks and concrete crushing are formed in the compression zone for all specimen beams.

- Increasing concrete strength can reduce the width of cracks and therefore help to enhance the flexural performance of beams. Besides, adding steel fiber can effectively resist and prevent cracks in the core concrete from propagating quickly. The higher the fiber volume fraction is, the greater the improvement is. Moreover, increasing the amount of NS can reduce the crack spacing and increase the number of cracks.

- Based on the equilibrium condition between axial force and bending moment, the calculation method for predicting the flexural bearing capacity of SFNMRC beams is derived. The proposed formula can reasonably predict the flexural capacity of SFNMRC and steel fiber reinforced concrete beams at the same time. In addition, the proposed approach is concise and accurate to use in engineering practices. Therefore, this formula is recommended to be used for calculating the bearing capacity of SFNMRC beams.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rizzuti, L.; Bencardino, F. Effects of fiber volume fraction on the compressive and flexural experimental behavior of SFRC. Contemp. Eng. Sci. 2014, 7, 379–390. [Google Scholar] [CrossRef]

- Long, N.M.; Rovňák, M. New formula for the estimation of shear resistance of fibre reinforced beams. Can. J. Civil. Eng. 2011, 38, 23–35. [Google Scholar]

- Nguyen-Minn, L.; Rovnak, M.; Tran-Quoc, T. Punching Shear Capacity of Interior SFRC Slab–Column Connections. J. Struct. Eng. 2012, 138, 613–624. [Google Scholar] [CrossRef]

- Long, N.M.; Rovňák, M.; Tran-Ngoc, T.; Le-Phuoc, T. Punching shear resistance of post–tensioned steel fiber reinforced concrete flat plates. Eng. Struct. 2012, 45, 324–337. [Google Scholar]

- Lee, J.Y.; Shin, H.O.; Yoo, D.Y.; Yoon, Y.S. Structural response of steel–fiber–reinforced concrete beams under various loading rates. Eng. Struct. 2018, 156, 271–283. [Google Scholar] [CrossRef]

- Yun, H.-D.; Lim, S.-H.; Choi, W.-C. Effects of Reinforcing Fiber Strength on Mechanical Properties of High-Strength Concrete. Fibers 2019, 7, 93. [Google Scholar] [CrossRef] [Green Version]

- Abbass, W.; Khan, M.I.; Mourad, S. Evaluation of mechanical properties of steel fiber reinforced concrete with different strengths of concrete. Constr. Build. Mater. 2018, 168, 556–569. [Google Scholar] [CrossRef]

- Zwa, B.; Cs, A.; Khk, B. Investigation of mechanical properties and shrinkage of ultra–high performance concrete: Influence of steel fiber content and shape. Compos. Part B Eng. 2019, 174, 107021. [Google Scholar]

- Yazc, E.; Nan, G.; Tabak, V. Effect of aspect ratio and volume fraction of steel fiber on the mechanical properties of SFRC. Constr. Build. Mater. 2007, 21, 1250–1253. [Google Scholar]

- Xie, X.P.; Yang, G.J.; Gao, D.Y. Compressive Strength of Steel Fiber Reinforced High–strength Concrete. J. Henan Univ. Sci. Technol. Nat. Sci. 2008, 5, 54–56, 69, 117. [Google Scholar]

- Lee, S.-C.; Oh, J.-H.; Cho, J.-Y. Compressive Behavior of Fiber-Reinforced Concrete with End-Hooked Steel Fibers. Materials 2015, 8, 1442–1458. [Google Scholar] [CrossRef] [Green Version]

- Khalaj, G.; Nazari, A. Modeling split tensile strength of high strength self compacting concrete incorporating randomly oriented steel fibers and SiO2 nanoparticles. Composites 2012, 43, 1887–1892. [Google Scholar] [CrossRef]

- Zhang, J.; Yan, C.W.; Jia, J.Q. Compressive Strength and Splitting Tensile Strength of Steel Fiber Reinforced Ultra High Strength Concrete (SFRC). Appl. Mech. Mater. 2010, 34–35, 1441–1444. [Google Scholar] [CrossRef]

- Chowdhury, M.A.; Islam, M.M.; Zahid, Z.I. Finite Element Modeling of Compressive and Splitting Tensile Behavior of Plain Concrete and Steel Fiber Reinforced Concrete Cylinder Specimens. Adv. Civil. Eng. 2016, 2016, 11. [Google Scholar] [CrossRef]

- Jang, S.J.; Yun, Y.J.; Yun, H.D. Influence of Fiber Volume Fraction and Aggregate Size on Flexural Behavior of High Strength Steel Fiber–Reinforced Concrete (SFRC). Appl. Mech. Mater. 2013, 372, 223–226. [Google Scholar] [CrossRef]

- Moon, D.Y.; Kang, T.S.; Chang, S.H.; Lee, G.P.; Bae, G.J. Flexural performance evaluation of SFRC with design strength of 60 MPa. J. Korean Tunn. Undergr. Space Assoc. 2013, 15, 175–186. [Google Scholar]

- Aldossari, K.M.; Elsaigh, W.A.; Shannag, M.J.M. Effect of Steel Fibers on Flexural Behavior of Normal and High Strength Concrete. Int. J. Civ. Archit. Struct. Constr. Eng. 2014, 8, 22–26. [Google Scholar]

- Wang, L.L.; Lin, X. Mechanical Properties and Micro mechanism of Concrete Modified by Carbon Nanofibers. Concr. Cem. Products. 2020, 1, 51–54. [Google Scholar]

- Rezania, M.; Panahandeh, M.; Razavi, M.J.; Berto, F. Experimental study of the simultaneous effect of nano–silica and nano–carbon black on permeability and mechanical properties of the concrete. Theor. Appl. Fract. Mec. 2019, 104, 102391. [Google Scholar] [CrossRef]

- Sanchez, F.; Sobolev, K. Nanotechnology in concrete—A review. Constr. Build. Mater. 2010, 24, 2060–2071. [Google Scholar] [CrossRef]

- Sobolev, K.; Shah, S.P. Nanotechnology of Concrete: Recent Developments and Future Perspectives; ACI Publication, SP-254; American Concrete Institute: Farmington Hills, MI, USA, 2008. [Google Scholar]

- Han, L.I.; Gao, D.Y.; Zhao, J. Research on Mechanical Properties and Chloride Ion Penetration Resistance of Fiber and Nanometer Materials Reinforced Concrete. J. North China Inst. Water Conserv. Hydroelectr. Power 2012, 33, 39–45. [Google Scholar]

- Zhang, M.H.; Islam, J.; Peethamparan, S. Use of nano–silica to increase early strength and reduce setting time of concretes with high volumes of slag. Cem. Concr. Comp. 2012, 34, 650–662. [Google Scholar] [CrossRef]

- Shaikh, F.; Supit, S.; Sarker, P.K. A study on the effect of nano silica on compressive strength of high volume fly ash mortars and concretes. Mater. Des. 2014, 60, 433–442. [Google Scholar] [CrossRef]

- Jo, B.W.; Kim, C.H.; Tae, G.H.; Park, J.B. Characteristics of cement mortar with nano–SiO2 particles. Constr. Build. Mater. 2007, 21, 1351–1355. [Google Scholar] [CrossRef]

- Ji, T. Preliminary study on the water permeability and microstructure of concrete incorporating nano–SiO2. Cem. Concr. Res. 2005, 35, 1943–1947. [Google Scholar] [CrossRef]

- Björnström, J.; Martinelli, A.; Matic, A.; Börjesson, L.; Panas, I. Accelerating effects of colloidal nano–silica for beneficial calcium–silicate–hydrate formation in cement. Chem. Phys. Lett. 2004, 392, 242–248. [Google Scholar] [CrossRef]

- Khed, V.C.; Mohammed, B.S.; Nuruddin, M.F. Effects of Nano–Silica modified Self–Compacted, High Volume Fly Ash Mortar on Slump Flow and Compressive Strength. Madr. J. Nano Tec. Sci. 2016, 1, 7–10. [Google Scholar] [CrossRef]

- Gaitero, J.J.; Campillo, I.; Guerrero, A. Reduction of the calcium leaching rate of cement paste by addition of silica nanoparticles. Cem. Concr. Res. 2008, 38, 1112–1118. [Google Scholar] [CrossRef] [Green Version]

- Kong, D.; Du, X.; Su, W.; Hua, Z.; Yang, Y.; Shah, S.P. Influence of nano–silica agglomeration on microstructure and properties of the hardened cement–based materials. Constr. Build. Mater. 2012, 37, 707–715. [Google Scholar] [CrossRef]

- Wang, L.M.; Song-Song, H.E. Influence of Nano Materials on Properties of Cement Concrete Roads. J. Dalian Jiaotong Univ. 2014, 35, 56–60. [Google Scholar]

- Shih, J.Y.; Chang, T.P.; Hsiao, T.C. Effect of nano-silica on characterization of Portland cement composite. Mater. Sci. Eng. A 2006, 424, 266–274. [Google Scholar] [CrossRef]

- Li, H.; Xiao, H.G.; Yuan, J.; Ou, J. Microstructure of cement mortar with nano-particles. Compos. Part B Eng. 2004, 35, 185–189. [Google Scholar] [CrossRef]

- Zhang, S. Testing Research on Doped Nano-Silica Steel Fiber Reinforced Concrete. Mater. Thesis Zhengzhou Univ. 2010, 2, 20–50. [Google Scholar]

- Tian, P.; Wang, L. Application Guide of National Standard GB 8076-2008 Concrete Admixtures; China Standards Press: Beijing, China, 2009. [Google Scholar]

- Rong, J.; Lu, J. GB/T 50081–2002, Standard for Test Method of Mechanical Properties on Ordinary Concrete; China Architecture & Building Press: Beijing, China, 2002. [Google Scholar]

- Huang, S.; Wang, Y. GB 50011-2010, Code for Seismic Design of Buildings; China Architecture & Building Press: Beijing, China, 2010. [Google Scholar]

- Gao, D. Stress–strain curves of steel fibre concrete under axial compression. J. Hydraul. Eng. 1991, 10, 43–48. [Google Scholar]

- Rong, H. Experimental study on the tensile performance of steel fiber reinforced concrete. China Civil. Eng. J. 2006, 39, 63–67. [Google Scholar]

- Guan, Q.; Jia, Y.; Zhang, M. Research on Flexural Behavior of Steel Fiber Reinforced High–strength Concrete Beams. New Build. Mater. 2007, 12, 15–18. [Google Scholar]

- Zhang, H. Experimental Study on the Flexural Performance of Steel Fiber High–Strength Ceramsite Concrete Beams; Huaqiao University: Quanzhou, China, 2015. [Google Scholar]

| Beam Number | B × D × L (mm3) | Concrete Strength (Mpa) | Volume Fraction of Steel Fiber (%) | Amount of NS (%) | Cubic Compressive Strength (Mpa) | Modulus of Elasticity (Mpa) |

|---|---|---|---|---|---|---|

| B–RC | 150 × 300 × 3000 | C40 | 0 | 0 | 39.82 | 31,500 |

| B–C40F1S1 | 150 × 300 × 3000 | C40 | 1.0 | 1.0 | 43.03 | 32,500 |

| B–C60 | 150 × 300 × 3000 | C60 | 1.0 | 1.0 | 65.82 | 37,400 |

| B–C80 | 150 × 300 × 3000 | C80 | 1.0 | 1.0 | 75.23 | 39,400 |

| B–F0 | 150 × 300 × 3000 | C40 | 0 | 1.0 | 39.22 | 32,500 |

| B–F0.5 | 150 × 300 × 3000 | C40 | 0.5 | 1.0 | 40.29 | 31,900 |

| B–F1.5 | 150 × 300 × 3000 | C40 | 1.5 | 1.0 | 46.06 | 32,000 |

| B–S0 | 150 × 300 × 3000 | C40 | 1.0 | 0 | 41.32 | 30,600 |

| B–S0.5 | 150 × 300 × 3000 | C40 | 1.0 | 0.5 | 42.09 | 29,400 |

| B–S2 | 150 × 300 × 3000 | C40 | 1.0 | 2.0 | 43.93 | 29,500 |

| Reference | Specimen Labels | |||

|---|---|---|---|---|

| This paper | B–F0.5 | 38.44 | 38.45 | 1.00 |

| B–40F1S1 | 40.30 | 40.44 | 1.00 | |

| B–F1.5 | 42.76 | 42.39 | 1.01 | |

| [40] | 2–0.5–III–300 | 80.10 | 91.32 | 0.88 |

| 2–1.0–III–300 | 82.80 | 92.97 | 0.89 | |

| 2–2.0–III–300 | 94.50 | 91.67 | 1.03 | |

| [41] | LCB0.5–3 | 56.20 | 60.42 | 0.93 |

| LCB1.0–3 | 60.60 | 53.70 | 1.13 | |

| LCB1.5–3 | 63.80 | 55.04 | 1.16 | |

| Average | 1.00 | |||

| COV | 0.09 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, K.; Zhang, M.; Zhang, T.; Xue, R.; Li, P.; Chen, G. Study on Flexural Performance of Concrete Beams Reinforced by Steel Fiber and Nano–SiO2 Materials. Crystals 2021, 11, 927. https://doi.org/10.3390/cryst11080927

Shi K, Zhang M, Zhang T, Xue R, Li P, Chen G. Study on Flexural Performance of Concrete Beams Reinforced by Steel Fiber and Nano–SiO2 Materials. Crystals. 2021; 11(8):927. https://doi.org/10.3390/cryst11080927

Chicago/Turabian StyleShi, Ke, Mengyue Zhang, Tao Zhang, Ru Xue, Pengfei Li, and Gang Chen. 2021. "Study on Flexural Performance of Concrete Beams Reinforced by Steel Fiber and Nano–SiO2 Materials" Crystals 11, no. 8: 927. https://doi.org/10.3390/cryst11080927

APA StyleShi, K., Zhang, M., Zhang, T., Xue, R., Li, P., & Chen, G. (2021). Study on Flexural Performance of Concrete Beams Reinforced by Steel Fiber and Nano–SiO2 Materials. Crystals, 11(8), 927. https://doi.org/10.3390/cryst11080927