Paraffin Wax [As a Phase Changing Material (PCM)] Based Composites Containing Multi-Walled Carbon Nanotubes for Thermal Energy Storage (TES) Development

Abstract

:1. Introduction

2. Materials

2.1. TES System Evaluation and Experimental Set-Up

2.2. Materials: Paraffin Wax (PW) and Multi-Walled Carbon Nanotubes (MWCNTs)

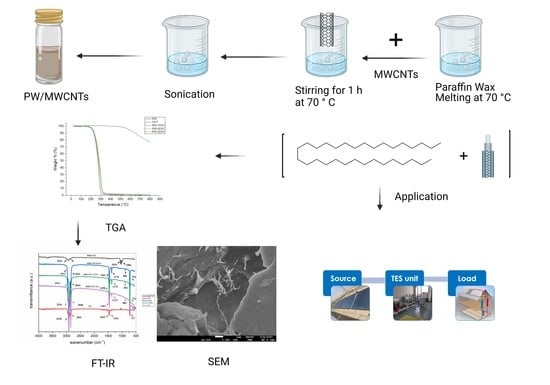

2.3. Preparation of PW Using the Melting Method

2.4. Thoretical Background of TES System Evaluation

3. Results and Discussion

3.1. TES System Evaluation

3.2. Characterizations of Paraffin Wax Containing Multi-Walled Carbon Nanotube Composites

3.2.1. SEM and EDX Characterizations

3.2.2. FTIR Analysis

3.2.3. TGA Analysis

4. Conclusions

- Studying the effect of PW/MWCNT composites (of various lengths and diameters) on the thermal conductivity and diffusivity of PW nanocomposites.

- Comparing the effect of MWCNTs on heat storage/release rates to pristine PW.

- Investigating the durability of these composites considering the number of possible circular (heating/cooling) applications and any possible degradation of PCM over time.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Element Analysis for PW from the TES Unit and the Pristine One from the Techno Pharm Chem Company

| PW (TES Unit Bed) | |

| Element | Conc (mg/kg) |

| Li | 0.022 ± 0.001 |

| B | 1.83 ± 0.011 |

| Na | 545 ± 0.2 |

| Mg | 7.88 ± 0.2 |

| Al | 31 ± 0.15 |

| Si | 85 ± 0.2 |

| Ca | 191 ± 0.5 |

| Sc | 0.02 ± 0.003 |

| Ti | 1 ± 0.005 |

| V | 0.058 ± 0.001 |

| Cr | 11 ± 0.05 |

| Mn | 0.8 ± 0.04 |

| Fe | 21 ± 0.1 |

| Co | 0.065 ± 0.005 |

| Ni | 0.33 ± 0.005 |

| Cu | 0.66 ± 0.007 |

| Zn | 2 ± 0.05 |

| Se | 0.22 ± 0.005 |

| Sr | 0.3 ± 0.015 |

| Mo | 0.29 ± 0.005 |

| Ag | 0.048 ± 0.001 |

| Sn | 107 ± 0.2 |

| Sb | 0.044 ± 0.001 |

| Ba | 0.29 ± 0.005 |

| W | 0.11 ± 0.004 |

| Pb | 0.11 ± 0.003 |

| Ge | UDL |

| Sb | UDL |

| Cs | UDL |

Appendix B. Nomenclature of Quantities Used in Equations

| Tw1—water inlet temperature Tw2—water outlet temperature Tw,aw—average temperature of the water supply and return Tm—phase change temperature of a phase change material F(T)—the actual density or specific heat of the water F(T0)—the density or specific heat of water at a stationary point F(T1)—the density or specific heat of water at another known stationary point ρw—average water density at constant pressure Vw—water volume flow Cw—specific heat at constant pressure Q—real heat capacity Qt—theoretical heat capacity mPCM—mass of the phase change material CPCM,S—the sensible heat of a phase change material (solid) CPCM,L—the sensible heat of a phase change material (liquid) L—the latent heat of a phase change material |

References

- Karaipekli, A.; Biçer, A.; Sari, A.; Tyagi, V.V. Thermal characteristics of expanded perlite/paraffin composite phase change material with enhanced thermal conductivity using carbon nanotubes. Energy Convers. Manag. 2017, 134, 373–381. [Google Scholar] [CrossRef]

- Yan, T.; Li, T.; Wang, R.; Jia, R. Experimental investigation on the ammonia adsorption and heat transfer characteristics of the packed multi-walled carbon nanotubes. Appl. Therm. Eng. 2015, 77, 20–29. [Google Scholar] [CrossRef]

- Tao, Y.; Lin, C.; He, Y. Preparation and thermal properties characterization of carbonate salt/carbon nanomaterial composite phase change material. Energy Convers. Manag. 2015, 97, 103–110. [Google Scholar] [CrossRef]

- Kim, P.; Shi, L.; Majumdar, A.; McEuen, P.L. Thermal transport measurements of individual multiwalled nanotubes. Phys. Rev. Lett. 2001, 87, 215502. [Google Scholar] [CrossRef] [Green Version]

- Wu, S.; Yan, T.; Kuai, Z.; Pan, W. Thermal conductivity enhancement on phase change materials for thermal energy storage: A review. Energy Storage Mater. 2020, 25, 251–295. [Google Scholar] [CrossRef]

- Hersam, M.C. Progress towards monodisperse single-walled carbon nanotubes. Nat. Nanotechnol. 2008, 3, 387–394. [Google Scholar] [CrossRef]

- Iijima, S. Helical microtubules of graphitic carbon. Nat. Cell Biol. 1991, 354, 56–58. [Google Scholar] [CrossRef]

- Warzoha, R.; Fleischer, A.S. Effect of carbon nanotube interfacial geometry on thermal transport in solid–liquid phase change materials. Appl. Energy 2015, 154, 271–276. [Google Scholar] [CrossRef] [Green Version]

- Berber, S.; Kwon, Y.-K.; Tomanek, D. Unusually high thermal conductivity of carbon nanotubes. Phys. Rev. Lett. 2000, 84, 4613–4616. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Xie, H.; Xin, Z. Thermal properties of paraffin based composites containing multi-walled carbon nanotubes. Thermochim. Acta 2009, 488, 39–42. [Google Scholar] [CrossRef]

- Wang, J.; Xie, H.; Xin, Z.; Li, Y.; Chen, L. Enhancing thermal conductivity of palmitic acid based phase change materials with carbon nanotubes as fillers. Sol. Energy 2010, 84, 339–344. [Google Scholar] [CrossRef]

- Wang, J.; Xie, H.; Xin, Z. Preparation and thermal properties of grafted CNTs composites. J. Mater. Sci. Technol. 2011, 27, 233–238. [Google Scholar] [CrossRef]

- Teng, T.-P.; Cheng, C.-M.; Cheng, C.-P. Performance assessment of heat storage by phase change materials containing MWCNTs and graphite. Appl. Therm. Eng. 2013, 50, 637–644. [Google Scholar] [CrossRef]

- Ye, F.; Ge, Z.; Ding, Y.; Yang, J. Multi-walled carbon nanotubes added to Na2CO3/MgO composites for thermal energy storage. Particuology 2014, 15, 56–60. [Google Scholar] [CrossRef]

- Xu, B.; Li, Z. Paraffin/diatomite/multi-wall carbon nanotubes composite phase change material tailor-made for thermal energy storage cement-based composites. Energy 2014, 72, 371–380. [Google Scholar] [CrossRef]

- Li, M.; Chen, M.; Wu, Z. Enhancement in thermal property and mechanical property of phase change microcapsule with modified carbon nanotube. Appl. Energy 2014, 127, 166–171. [Google Scholar] [CrossRef]

- Tang, Q.; Sun, J.; Yu, S.; Wang, G. Improving thermal conductivity and decreasing supercooling of paraffin phase change materials by n-octadecylamine-functionalized multi-walled carbon nanotubes. RSC Adv. 2014, 4, 36584–36590. [Google Scholar] [CrossRef]

- Xiao, D.; Qu, Y.; Hu, S.; Han, H.; Li, Y.; Zhai, J.; Jiang, Y.; Yang, H. Study on the phase change thermal storage performance of palmitic acid/carbon nanotubes composites. Compos. Part A Appl. Sci. Manuf. 2015, 77, 50–55. [Google Scholar] [CrossRef]

- Varshney, D.; Ahmadi, M.; Guinel, M.J.-F.; Weiner, B.R.; Morell, G. Single-step route to diamond-nanotube composite. Nanoscale Res. Lett. 2012, 7, 535. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nie, C.; Tong, X.; Wu, S.; Gong, S.; Peng, D. Paraffin confined in carbon nanotubes as nano-encapsulated phase change materials: Experimental and molecular dynamics studies. RSC Adv. 2015, 5, 92812–92817. [Google Scholar] [CrossRef]

- Maleki, A.; Hamesadeghi, U.; Daraei, H.; Hayati, B.; Najafi, F.; McKay, G.; Rezaee, R. Amine functionalized multi-walled carbon nanotubes: Single and binary systems for high capacity dye removal. Chem. Eng. J. 2017, 313, 826–835. [Google Scholar] [CrossRef]

- Ovsiienko, I.; Len, T.; Matzui, L.; Tkachuk, V.; Berkutov, I.; Mirzoiev, I.; Prylutskyy, Y.; Tsierkezos, N.; Ritter, U. Magnetore-sistance of functionalized carbon nanotubes. Materwiss. Werksttech. 2016, 47, 254–262. [Google Scholar] [CrossRef]

- Metwally, N.H.; Saad, G.R.; El-Wahab, E.A.A. Grafting of multiwalled carbon nanotubes with pyrazole derivatives: Characterization, antimicrobial activity and molecular docking study. Int. J. Nanomed. 2019, 14, 6645–6659. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Han, L.; Jia, X.; Li, Z.; Yang, Z.; Wang, G.; Ning, G. Effective encapsulation of paraffin wax in carbon nanotube agglomerates for a new shape-stabilized phase change material with enhanced thermal-storage capacity and stability. Ind. Eng. Chem. Res. 2018, 57, 13026–13035. [Google Scholar] [CrossRef]

- Elgafy, A.; Lafdi, K. Effect of carbon nanofiber additives on thermal behavior of phase change materials. Carbon 2005, 43, 3067–3074. [Google Scholar] [CrossRef]

- Jeong, N.; Park, Y.C.; Yoo, J.H. Preparation of highly pure and crystalline carbon nanotubes and their infiltration by paraffin wax. Carbon 2013, 63, 240–252. [Google Scholar] [CrossRef]

- Kuziel, A.W.; Dzido, G.; Turczyn, R.; Jedrysiak, R.; Kolanowska, A.; Tracz, A.; Zieba, W.; Cyganiuk, A.; Terzyk, A.; Boncel, S. Ultra-long carbon nanotube-paraffin composites of record thermal conductivity and high phase change enthalby among par-affin-based heat storage materials. J. Energy Storage 2021, 36, 102396. [Google Scholar] [CrossRef]

- Dincer, I.; Rosen, M. Thermal Energy Storage: Systems and Applications, 2nd ed.; Wiley: New York, NY, USA, 2011. [Google Scholar]

- Souayfane, F.; Fardoun, F.; Biwole, P. Phase change materials (PCM) for cooling applications in buildings: A review. Energy Build. 2016, 129, 396–431. [Google Scholar] [CrossRef]

- Günther, E.; Hiebler, S.; Mehling, H. Determination of the heat storage capacity of PCM and PCM-objects as a function of temperature. In Proceedings of the ECOSTOCK, 10th International Conference on Thermal Energy Storage, Galloway, NJ, USA, 31 May–2 June 2006. [Google Scholar]

| Thermal-Related Parameters | Value | Unit | |

|---|---|---|---|

| 1 | Melting temperature | 54.32 | °C |

| 2 | Latent heat of fusion | 184.48 | kJ/kg |

| 3 | Density of PW (liquid phase) | 775.00 | kg/m3 |

| 4 | Density of PW | 833.60 | kg/m3 |

| 5 | Specific heat of PW (liquid phase) | 2.44 | kJ/kgK |

| 6 | Thermal conductivity | 0.15 | W/mK |

| 7 | Viscosity | 6.3 × 10−3 | P.S (Pascal Second) |

| 8 | Kinematic viscosity | 8.31 × 10−5 | m2/s |

| 9 | Prandtl number | 1001.23 | - |

| 10 | Thermal expansion coefficient | 7.14 × 10−3 | 1/°C |

| Temperature (°C) | Density (kg/m3) | Specific Heat (J/kg. K) |

|---|---|---|

| 0.01 | 999.90 | 4.212 |

| 10.00 | 999.70 | 4.191 |

| 20.00 | 998.20 | 4.183 |

| 30.00 | 995.70 | 4.174 |

| 40.00 | 992.20 | 4.174 |

| 50.00 | 988.10 | 4.174 |

| 60.00 | 983.20 | 4.179 |

| 70.00 | 977.80 | 4.187 |

| 80.00 | 971.80 | 4.195 |

| 90.00 | 965.30 | 4.208 |

| 100.00 | 958.40 | 4.220 |

| Time (s) | Water Temperature at the Inlet to the Tank (°C) | Water Temperature at the Outlet to the Tank (°C) | Water Flow (kg/s) |

|---|---|---|---|

| 10 | 42.6 ± 0.4 | 34.6 ± 0.4 | 1.90 |

| 660 | 46.5 ± 0.4 | 44.8 ± 0.4 | 2.85 |

| 1340 | 53.0 ± 0.4 | 51.2 ± 0.4 | 2.86 |

| 2000 | 57.4 ± 0.4 | 55.8 ± 0.4 | 2.86 |

| 2660 | 62.7 ± 0.4 | 61.1 ± 0.4 | 2.86 |

| 3340 | 66.7 ± 0.4 | 66.0 ± 0.4 | 2.87 |

| 4000 | 67.7 ± 0.4 | 66.1 ± 0.4 | 2.87 |

| 4660 | 68.1 ± 0.4 | 66.8 ± 0.4 | 2.88 |

| 5340 | 67.2 ± 0.4 | 66.0 ± 0.4 | 2.87 |

| 6000 | 68.1 ± 0.4 | 66.3 ± 0.4 | 2.86 |

| 6660 | 67. 9 ± 0.4 | 66.3 ± 0.4 | 2.87 |

| Total heat (kWh) | 35.04 | ||

| Theoretical heat (kWh) | 57.39 | ||

| Efficiency (%) | 61.07 | ||

| Average heat flux (kW/m2) | 19.18 | ||

| Sample Code | Onset Temperature °C | Mass Loss at 600 °C | Mass Loss % at 700 °C |

|---|---|---|---|

| CNT | 533.56 | 94.237 | 85.234 |

| PW (2) | 243.12 | 0.281 | 0.195 |

| Composite 1 | 249.26 | 0.171 | −0.043 |

| Composite 2 | 244.56 | 1.603 | 0.639 |

| Composite 3 | 239.97 | 1.493 | 0.98 |

| Authors (Year) | PCM | Type of Additives | Fraction of Additives | Comments |

|---|---|---|---|---|

| Wang et al. (2009) [10] | Paraffin | MWCNTs | 0.2, 0.5, 1 and 2 | The composite containing 2.0 wt.% had a higher thermal conductivity of 35% and 40%, respectively, in solid and liquid states. |

| Wang et al. (2011) [12] | Paraffin Palmitic acid | G8-CNT G18-CNT | - | The thermal conductivity of paraffin and palmitic acid were improved by adding a small amount of G8-CNT. The results showed that the thermal conductivity of CNTs is clearly affected by the length of the grafted chain. |

| Teng et al. (2013) [13] | Paraffin | MWCNTs Graphite | 1, 2 and 3 | MWCNTs were more effective in enhancing paraffin performance in all experimental parameters compared to graphite. |

| Ye et al. (2014) [14] | Na2CO3/ MgO | MWCNTs | 0.1%, 0.2%, 0.3% and 0.5% | As the weight percentage of the MWCNTs increased, the thermal conductivity of the composite PCMs increased by approximately 96% (the highest) for 0.5% of MWCNTs. |

| Xu and Li (2014) [15] | paraffin (R27, Rubitherm) | MWCNTs Diatomite materials | 0.26% - | The thermal conductivity of PCM-DP600-CNTs was substantially improved, with an improvement level of up to 42.45%. |

| Li et al. (2014) [16] | Paraffin | CNTs CNTs-SA | - | The thermal conductivity of MicroPCMs/CNTs-SA with 4% CNTs increased by 79.2% when compared to MicroPCMs. |

| Tang et al. (2014) [17] | Paraffin | (f-MWCNT) | 1, 5 and 10% | With 10 wt.% of f-MWCNTs, the thermal conductivity and the heat transfer of the paraffin/f-MWCNTs composite PCMs increased by 86.7%. |

| Xiao et al. (2015) [18] | Palmitic acid | CNTs, oxidized CNTs and grafted CNTs | 1/100 | CNTs, O-CNTs, and G-CNTs improved the palmitic acid thermal conductivity, but G-CNT composites had the highest latent heat. |

| Tao et al. (2015) [3] | Salt | SWCNT, MWCNT, graphene and C60 | 0.1%, 0.5%, 1.0%, 1.5%, 2.5% | SWCNTs and MWCNTs exhibited significant enhancement in the PCMs’ thermal conductivity with mass fractions near 1.5% by 57% and 50%, respectively. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Almousa, N.H.; Alotaibi, M.R.; Alsohybani, M.; Radziszewski, D.; AlNoman, S.M.; Alotaibi, B.M.; Khayyat, M.M. Paraffin Wax [As a Phase Changing Material (PCM)] Based Composites Containing Multi-Walled Carbon Nanotubes for Thermal Energy Storage (TES) Development. Crystals 2021, 11, 951. https://doi.org/10.3390/cryst11080951

Almousa NH, Alotaibi MR, Alsohybani M, Radziszewski D, AlNoman SM, Alotaibi BM, Khayyat MM. Paraffin Wax [As a Phase Changing Material (PCM)] Based Composites Containing Multi-Walled Carbon Nanotubes for Thermal Energy Storage (TES) Development. Crystals. 2021; 11(8):951. https://doi.org/10.3390/cryst11080951

Chicago/Turabian StyleAlmousa, Norah Hamad, Maha R. Alotaibi, Mohammad Alsohybani, Dominik Radziszewski, Saeed M. AlNoman, Bandar M. Alotaibi, and Maha M. Khayyat. 2021. "Paraffin Wax [As a Phase Changing Material (PCM)] Based Composites Containing Multi-Walled Carbon Nanotubes for Thermal Energy Storage (TES) Development" Crystals 11, no. 8: 951. https://doi.org/10.3390/cryst11080951

APA StyleAlmousa, N. H., Alotaibi, M. R., Alsohybani, M., Radziszewski, D., AlNoman, S. M., Alotaibi, B. M., & Khayyat, M. M. (2021). Paraffin Wax [As a Phase Changing Material (PCM)] Based Composites Containing Multi-Walled Carbon Nanotubes for Thermal Energy Storage (TES) Development. Crystals, 11(8), 951. https://doi.org/10.3390/cryst11080951