1. Introduction

SrB

4O

7 (SBO) belongs to an orthorhombic structure with the space group of

Pmn2

1 (

a = 4.4273 Å,

b = 10.714 Å,

c = 4.2359 Å) [

1,

2]. SBO crystals also show high nonlinearity [

3,

4,

5,

6,

7] and are transparent down to the deepest ultraviolet wavelength (125 nm) [

4,

5,

6,

7,

8,

9]. Hence, SBO receives much attention as solid-state ultraviolet lasers for semiconductor photolithography, micro-machining, photochemical synthesis, laser spectroscopy, and photoemission spectroscopy.

For the application of SBO, the SBO crystals require the appearance of the periodic twin structure, which is so-called quasi-phase-matching (QPM) structures. The QPM is the structure in which the sign of the nonlinear optical coefficient is periodically reversed and enabled to compensate the phase shift of the second harmonic generation [

10,

11]. Hence, the conversion light is, generally, amplified owing to the QPM structure. It is well-known that QPM structures in ferroelectric oxide materials can be formed by the application of an external electric field such as the poling method [

10,

12,

13,

14,

15] and hot-pressing method [

16]. However, since borates are non-ferroelectric crystals, with the utilization of the poling method and the hot-pressing method it is difficult to control twin boundary orientation.

Aleksandrovsky et al., for the first time, reported twinned structures of SBO crystals [

17,

18]. They succeeded in growing partially twinned SBO crystals by the Czochralski method (CZ). We expect that to control the formation of twin boundaries, the active incorporation of defects is further required by combining the growth under high temperature gradient

G with the periodic application of electric fields. The growth by the micro-pulling-down method (

μ-PD method) can be a suitable method. The orientation of the ions in the melt and the dipoles in the crystals can be controlled by alternating the application of electric fields. The temperature gradient range of the

μ-PD method is 1–2 units larger than that of the CZ method because of the small hot zone [

19,

20,

21], and electric fields can be applied homogeneously. The incorporation of homogenous composition in crystals is also possible owing to a high temperature gradient. Actually, in the case of the ferroelectric LiNbO

3 (LN), Uda et al. succeeded in the domain inversion by applying an external electric current during the growth through the

μ-PD method [

22].

Recently, we tried to grow twinned SBO crystals along the

b-axis during the application of electric fields by the

μ-PD method [

23]. Then, our previous study explored that the growth of SBO by the

μ-PD method via alternating the application of opposing electric fields (

E) exhibits two mechanisms. At

E ≧ 400 V/cm needles of SrB

2O

4 appeared inside SBO fibers. At

E≧ 1000 V/cm, new domains of SBO grew from the seed crystals, and growth twins were, interestingly, formed perpendicular to growth fronts. The twin face was (100) face. Thus, we revealed new challenges that the twin boundary is formed perpendicular to the growth front. Furthermore, we found the inversion of surface shapes during the growth even by the

μ-PD method. We can explain the relationship between the two mechanisms and the inversion of surface shapes, using the concept of convection.

We expect that the inhibitation of the SrB2O4 appearance by the convection is the key for the fabrication of twins. Furthermore, the growth conditions, under which defects are further incorporated, are necessary for the formation of twins, as described so far. The orientation of the growth face is crucial for the fabrication of twins as well. Here we show the growth of SBO crystal fibers along the c-axis by the μ-PD method.

2. Materials and Methods

The

μ-PD furnace used in this study was the same as in our previous studies [

23,

24,

25,

26].

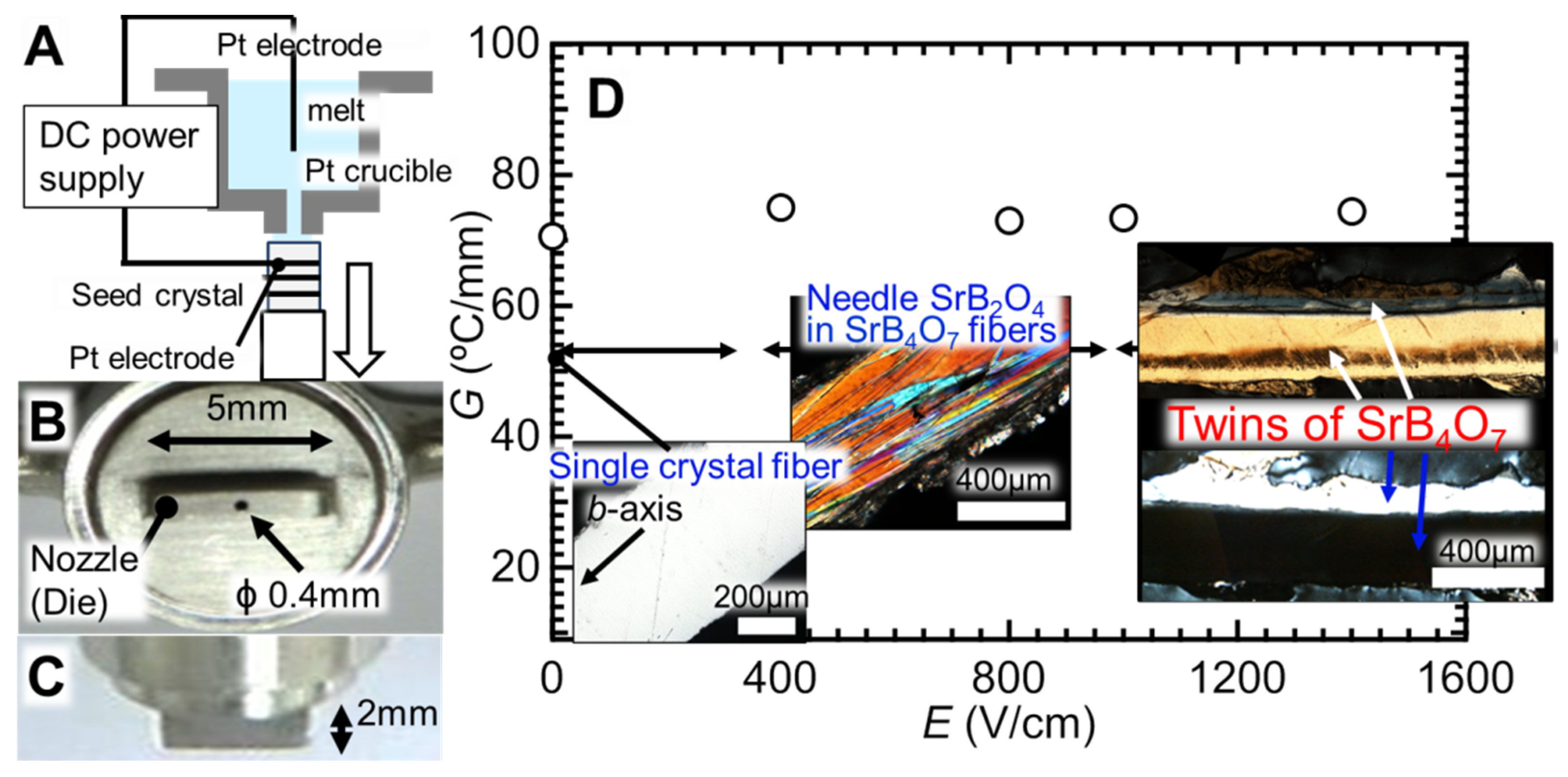

Figure 1A–C show a hot zone of the

μ-PD furnace. A platinum crucible with a rectangular nozzle (5 mm × 1 mm × 2 mm (height)), which has a 0.4 mm cylindrical hole at the center of the base, was used. To set a temperature gradient (

G) in crystals, the platinum crucible was surrounded by the refractory [

23]. SBO ceramic powders with stoichiometric composition were prepared, and the raw material was melted in the platinum crucible by applying DC power. The temperature near the bottom of a nozzle remained at 1050 °C during the growth. Afterheaters were not placed in the furnace to carry out a high temperature gradient. Then, Pt electrodes were immersed in the melt. The tip of the Pt electrodes was placed on ca. 5 mm from the bottom of the nozzle. Seed crystals were fixed on an aluminum rod by Pt wire. The orientation of the seed crystals was confirmed by X-ray diffraction, transmittance electron microscopy (TEM), and the selected area electron diffraction (SAED). Then, they were attached to the bottom of the platinum nozzle, and were pulled down in air along the

c-axis.

Figure 1D shows the growth conditions. The photographs corresponded to the summary of our previous study, which grew at 50–55 K/mm [

23]. At that time, the pulling-down direction was the

b-axis. In this study, the

G of 70–75 K/mm just below the nozzle, and larger than in our previous study [

23] was selected. Before the growth, the temperature profile from the bottom of the nozzle along the pulling-down direction was confirmed by a thermocouple. Then, the temperature gradient of 0.5–1 mm away from the nozzle was determined by the linear approximation [

25]. These values would correspond to the intrinsic temperature gradient in the crystals near the interface to understand the crystal growth.

A pulling-down rate was also 0.02 mm/min. During the growth, various voltages were applied to the seed crystals through Pt wires and Pt electrodes. During the growth, various voltages of

E in the range of 0–1400 V/cm were applied to the growth fronts of seed crystals through Pt electrodes [

23]. The external voltage was switched every 30 min through a power supply.

After the growth, the fiber crystals were fixed in resin, and test pieces were polished. Then the fibers were observed by polarized optical microscopy (BX51, Olympus, Japan). During the growth, photographs of the meniscus just below the die were taken by a camera (SZ-31MR, Olympus, Japan). To determine the crystal faces of the boundaries in the test pieces, the fibers were cut off. The cross sections of fiber crystals were also processed by focused ion beam (FIB) (JIB-4000, JEOL, Japan), and the orientation of domain boundaries in crystal fibers was evaluated by TEM and SAED. The TEM/SAED observation was carried out, using a JEOL JEM-2100 electron microscope at an acceleration voltage of 200 kV. The camera length was 80 cm. The thickness of the samples, which were obtained by FIB, was ca. 200 ± 20 nm. The sample widths were ca. 5 μm, and the samples almost had no gradient at the surface. The brightness and contrast of the images were adjusted, using a software (ImageJ) [

27]. The reciprocal lattice was evaluated and the zone axes were finally obtained, using the ReciPro software which can calculate the relation between the orientation of the crystals and 2D diffraction patterns [

28,

29]. In addition, the schematic drawing of the crystal structures was illustrated by a software (VESTA) [

30].

3. Results

Figure 2 shows the SBO crystal fibers grown without the application of electric fields. Although the crystal has rough surfaces, the sample was almost transparent. The test piece was observed under crossed Nicols, and symbols in

Figure 2C correspond to the crystallographic orientation of the seed crystals. The crystal showed uniform polarized light. In addition, the boundary between the seed crystals and grown crystals did not exist. Hence, we confirmed that the orientation of seed crystals remained in the grown crystal. Since SBO is too hard and fragile, polishing the test piece was difficult. By polishing, the test piece received scratches, and there were cracks. Sometimes the samples also partially lacked. When the stage was rotated by 45°, the polarized light was uniformly extinguished. This result demonstrates that the sample is a single crystal.

In this study, we separated and considered the growth conditions into

E < 1000 and 1000 ≦

E to understand the growth mechanism.

Figure 3 shows SBO crystal fibers grown at 400 V/cm. The fibers were slightly opaque owing to rough surfaces. The alternating timing of electric fields corresponded to the increase in the radius of the fiber. At the tip of fibers, no change in the radius was observed since the electrode of the Pt wire became away from the growth front of the seed crystals. Just above the surface of the seed crystal, additional domains appeared and grew (

Figure 3B). In contrast, needle domains of SrB

2O

4 did not appear, and the inside of the fibers was not uniform. The number of domains decreased with a distance from the seed crystals owing to the geometrical selection. In the tip of the fiber, two domains survived (

Figure 3C).

Figure 3D shows the cross-sectional view of the fiber in

Figure 3B,C. The two domains were confirmed. Then, the portions of the black lines were processed by FIB to determine the crystallographic face of the boundary by TEM/SAED.

Figure 3F,G show electron diffraction patterns of the two domains near the boundary. In

Figure 3F, reciprocal vectors of OF, OF′, and FF′ were ca. 2.3, 2.4, and 3.3 nm

−1, respectively. In contrast, reciprocal vectors of OG, OG′, and GG′ were ca. 2.5, 2.3, and 3.3 nm

−1, respectively. The spatial resolution of the measurement was calculated. Consequently, the errors of the reciprocal vectors were ± 0.17 nm

−1. The ReciPro calculation shows that the crystallographic orientations of OF, OF′, and FF′ corresponded to [100], [001], and [

], respectively. The crystallographic orientations of OG, OG′, and GG′ also corresponded to [100], [011], and [

], respectively. The calculation of the zone axes demonstrated that the orientation perpendicular to the paper in

Figure 3F,G were [

] and [

], respectively. Thus, the boundary in

Figure 3D was the composition plane given by [

] and [

].

The next SBO crystal fibers were grown at 800 V/cm (

Figure A1). The fibers were slightly opaque owing to rough surfaces. Just above the surface of the seed crystal additional domains appeared and grew. The geometrical selection also occurred. In contrast, needle domains of SrB

2O

4 did not appear as well as at 400 V/cm. Thus, no SrB

2O

4 appeared even at low

E. Furthermore, we determined that the composition plane of [

] and [

] was formed perpendicular to the growth front.

Figure 4 shows SBO crystal fibers grown at 1000 V/cm. The fibers were slightly opaque owing to rough surfaces. When alternating electric fields, the radius of the fiber slightly increased. Just above the surface of the seed crystal, additional domains appeared and grew.

Figure 4D shows the cross-sectional view of the fiber. The two domains existed.

Figure 4F,G show electron diffractions of the two domains on the white lines in

Figure 4E. In

Figure 4F, reciprocal vectors of OF, OF′, and FF′ were ca. 2.2, 2.3, and 3.1 nm

−1, respectively. In contrast, reciprocal vectors of OG, OG′, and GG′ were ca. 3.2, 5.4, and 5.3 nm

−1, respectively. The ReciPro calculation shows the orientations of OF, OF′, and FF′ corresponded to [100], [001], and [

], respectively. In addition, the orientations of OG, OG′, and GG′ corresponded to [112], [

], and [211], respectively. Consequently, from the calculation of zone axes, we determined that the crystallographic orientation perpendicular to the paper in

Figure 4F,G were [

] and [

], respectively. Thus, we can determine that the boundary corresponded to the composition plane of [

] and [

].

Figure A2 shows SBO crystal fibers grown at 1400 V/cm. The fibers were slightly opaque. Just above the surface of the seed crystal, additional domains appeared and grew. The geometrical selection was observed as well. The boundary in the cross-section was the composition plane of [

] and [

]. Thus, no twin boundary appeared in this study.

In contrast, we attempted to determine whether the domains remained in the orientation of the seed crystals except without the application. However, it was difficult to determine the relationship between the pulling-down direction and the electron diffraction patterns owing to the error observed through the processing of test pieces.

Figure 5 shows the relation between the geometrical selection and growth conditions. Here we defined fiber width over average domain width as domain density at a distance from the surfaces of seed crystals. To compare the effects of the growth conditions, we also analyzed the data (filled squares) in our previous study [

23]. With a distance from the surfaces of the seed crystals, the domain density decreased. Furthermore, when comparing open squares with filled squares, at 75 K/mm the domain density decreased slower than at 55 K/mm. When comparing open circles with filled squares, at 400 V/cm the domain density decreased earlier than at 1000 V/cm. In general, the geometrical selection means that when the crystal faces of preferential growth are oriented fully perpendicular to the growth front, such domains survive. Then, the crystal faces at the side of the preferential domains remain. Hence, the results demonstrate that the condition, under which the geometrical selection strongly occurs, is the key to the growth of SBO crystals with twin faces. If we selected under mild growth conditions, the preferential growth of (001) faces would provide the facet of the intrinsic domains such as (100) face and (010) face.

Figure 6 shows the shapes of the meniscus between SBO crystals and the melt to understand the growth mechanism. The surface morphology without the application of electric fields was concave (

Figure 6A,B). The result was the same as the growth along the

b-axis shown in our previous study. In general, the limited process of the melt growth is the removal of the latent heat, and the heat flow corresponds to the surface morphology in the melt growth. Hence, this result demonstrates that the latent heat of crystal growth remains at the center of the growth front. Since the center was hotter than the peripherical region, this result should be valid.

On the other hand, the application of electric fields provides surface-morphological changes.

Figure 6C–F show the growth along the

b-axis at 55 K/mm and 1000 V/cm. When the electrodes in the melt and growth fronts became + and −, respectively, a convex shape was generated at the center of the growth front. In 30 min, the surface morphology was back to concave. At 75 K/mm and 400 V/cm, when the electrodes in the melt and growth fronts during the growth along the

c-axis became − and +, respectively, a convex shape was formed at the center of the growth front (

Figure 6G,H). In 30 min, the surface morphology of the SBO was also back to concave (

Figure 6I,J). At 75 K/mm and 1000 V/cm, the morphological change was observed as well (

Figure 6K–N). These results demonstrate that when the electrodes in the melt and growth fronts became + and −, respectively, the latent heat flowed from the top of the convex shape to the peripheral parts. In other words, the convex shape demonstrates that convection is compulsorily generated perpendicular to the growth front by alternating the application of electric fields. The convection also emerged irrespective of crystal faces of growth fronts.

Furthermore, the convex shape with a size larger than

Figure 6C,D were observed. Since the pulling-down rate corresponds to the growth rate, and the growth rate was not changed in this study. In this study, the surface kinetics of the growth should be governed by the application of electric fields and temperature gradients. Therefore, these results suggest that a high temperature gradient accelerates the convection formed by alternating the application of electric fields.

4. Discussion

We revealed that unfortunately, the growth along the

c-axis is not proper for the formation of twins. As shown in

Figure 7, only the (100) faces include the twin faces in (100), (010), and (001) faces. Hence, we expected that twin boundaries perpendicular to the growth fronts would appear. However, only composition planes were formed under the growth conditions. Twin boundaries perpendicular to the growth fronts did not appear unlike the previous study [

23].

Now we focus on the frequency of the geometrical selection to understand the reason. During the geometrical selection, the growth faces, which show fast crystal growth, preferentially survive. We expect that some domains in

Figure 3F,

Figure 4F,

Figure A1F, and

Figure A2F have a relatively large area in the domains, and these can keep the crystal orientations of seed crystals according to the geometrical selection mechanism. However, our growth condition does not strongly provide the geometrical selection, compared with our previous study (

Figure 5). Since the growth rate of (100) faces can be slower than that of high indexes faces, the facets of (100) faces cannot survive perpendicular to the growth front.

In contrast, a high temperature gradient accelerates the convection formed by alternating the application of electric fields, and the appearance of the SrB

2O

4 was further inhibited in the broad region of the temperature gradient. Hence, the utilization of high temperature gradients can be useful for the fabrication of twins. In addition, it is well-known that the growth by

μ-PD method does not exhibit the generation of the convection even in the growth during the application of electric fields [

21,

26,

31,

32]. Many researchers strongly believe that borates, which show extremely high viscosity, grow without convection. Therefore, the finding contradicts the conventional concept of growth by the

μ-PD method. The convection also emerged irrespective of crystal faces of growth fronts.

However, from the viewpoint of twin formation, effects of the geometrical selection and the convection compete under high temperature-gradient conditions. We need to consider such two factors when the growth conditions are selected. In addition, our growth conditions are different from the previous LN study [

22]. The pulling-down rate in the previous study was 10 times larger than that in our case. We need to reconsider the pulling-down rate conditions. In the future, we are going to systematically investigate the effects of crystallographic orientation and temperature gradient. Afterheaters will be set in the furnace, and the growth at a low temperature gradient will be essential.