Atomic Simulations of Si@Ge and Ge@Si Nanowires for Mechanical and Thermal Properties

Abstract

1. Introduction

2. Simulation Detail

2.1. Tersoff Potential

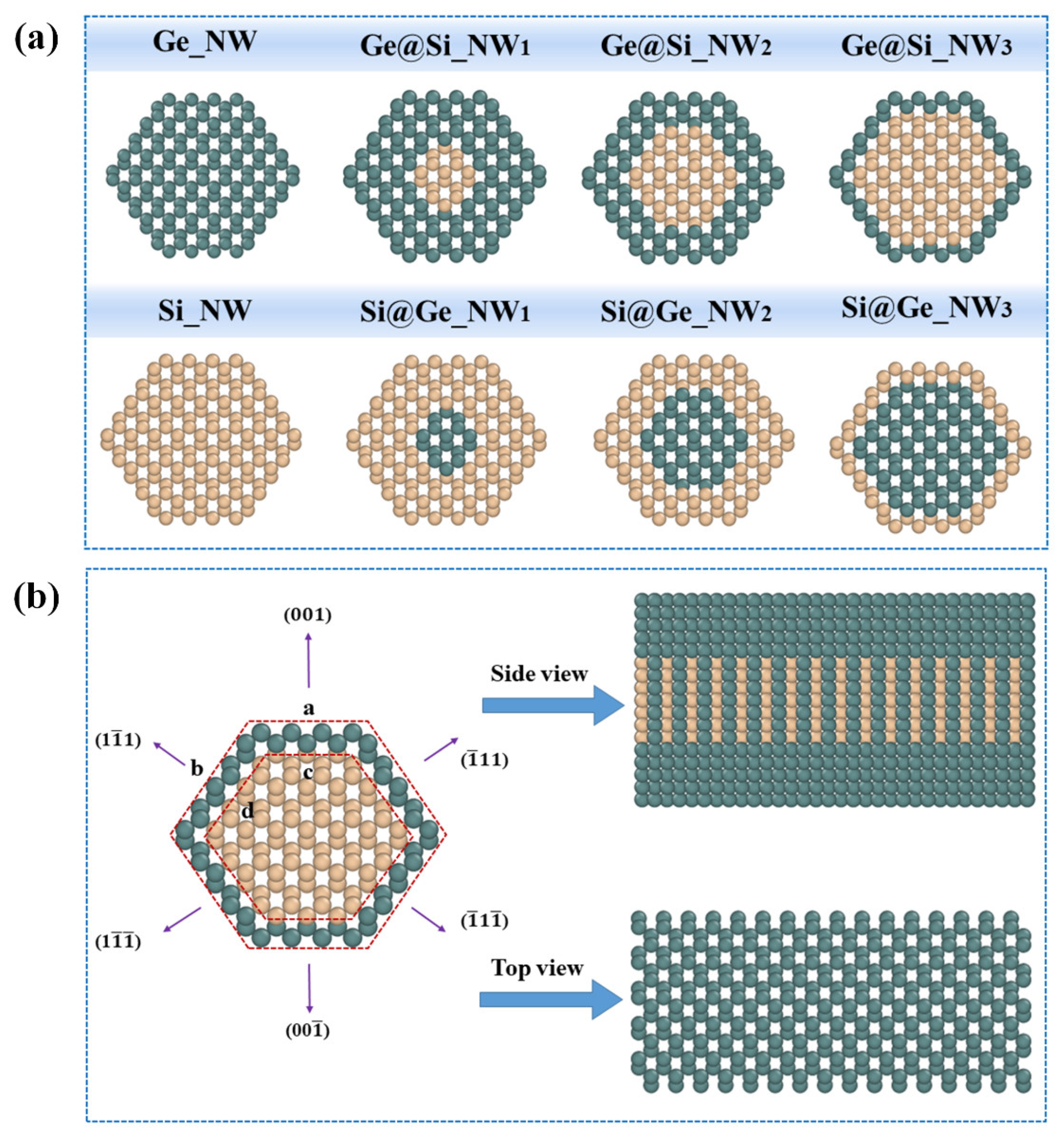

2.2. The Initial NW Models

2.3. Simulation Protocol

2.4. Analysis Functions

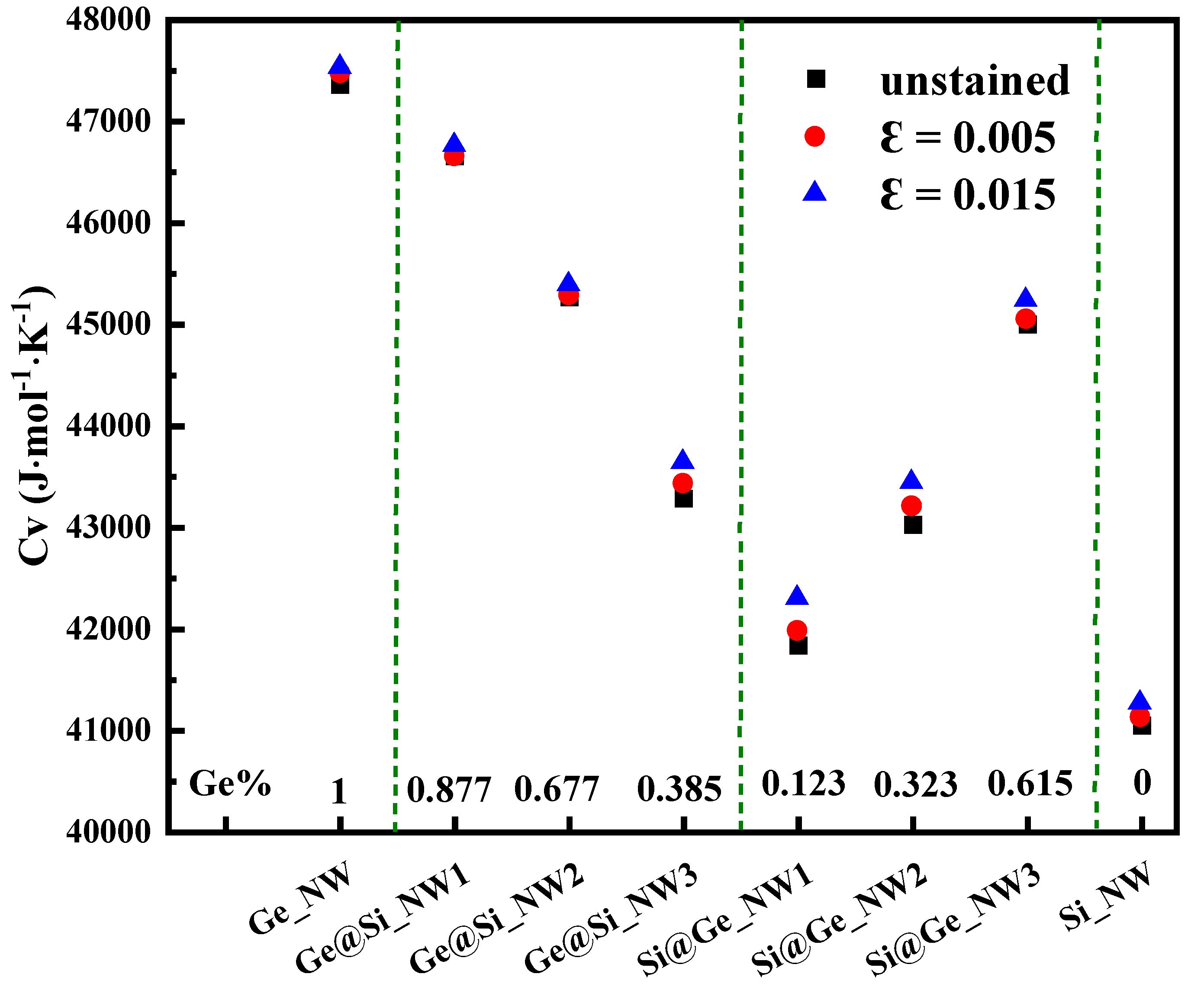

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Beattie, S.D.; Larcher, D.; Morcrette, M.; Simon, B.; Tarascon, J.-M. Si Electrodes for Li-Ion Batteries—A New Way to Look at an Old Problem. J. Electrochem. Soc. 2008, 155, A158. [Google Scholar] [CrossRef]

- Gu, M.; He, Y.; Zheng, J.; Wang, C. Nanoscale Silicon as Anode for Li-Ion Batteries: The Fundamentals, Promises, and Challenges. Nano Energy 2015, 17, 366–383. [Google Scholar] [CrossRef]

- Dai, F.; Zhao, D.; Zhang, L. Atomic Simulations of Packing Structures, Local Stress and Mechanical Properties for One Silicon Lattice with Single Vacancy on Heating. Materials 2021, 14, 3127. [Google Scholar] [CrossRef]

- Song, P.; Ma, Z.; Ma, J.; Yang, L.; Wei, J.; Zhao, Y.; Zhang, M.; Yang, F.; Wang, X. Recent Progress of Miniature MEMS Pressure Sensors. Micromachines 2020, 11, 56. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Sun, X.; Yu, Y. Si-, Ge-, Sn-Based Anode Materials for Lithium-Ion Batteries: From Structure Design to Electrochemical Performance. Small Methods 2017, 1, 1600037. [Google Scholar] [CrossRef]

- Tian, H.; Xin, F.; Wang, X.; He, W.; Han, W. High Capacity Group-IV Elements (Si, Ge, Sn) Based Anodes for Lithium-Ion Batteries. J. Mater. 2015, 1, 153–169. [Google Scholar] [CrossRef]

- Larcher, D.; Beattie, S.; Morcrette, M.; Edström, K.; Jumas, J.-C.; Tarascon, J.-M. Recent Findings and Prospects in the Field of Pure Metals as Negative Electrodes for Li-Ion Batteries. J. Mater. Chem. 2007, 17, 3759. [Google Scholar] [CrossRef]

- Zhang, M.; Zhang, T.; Ma, Y.; Chen, Y. Latest Development of Nanostructured Si/C Materials for Lithium Anode Studies and Applications. Energy Storage Mater. 2016, 4, 1–14. [Google Scholar] [CrossRef]

- Evanoff, K.; Magasinski, A.; Yang, J.; Yushin, G. Nanosilicon-Coated Graphene Granules as Anodes for Li-Ion Batteries. Adv. Energy Mater. 2011, 1, 495–498. [Google Scholar] [CrossRef]

- Zamfir, M.R.; Nguyen, H.T.; Moyen, E.; Lee, Y.H.; Pribat, D. Silicon Nanowires for Li-Based Battery Anodes: A Review. J. Mater. Chem. A 2013, 1, 9566. [Google Scholar] [CrossRef]

- Feng, K.; Li, M.; Liu, W.; Kashkooli, A.G.; Xiao, X.; Cai, M.; Chen, Z. Silicon-Based Anodes for Lithium-Ion Batteries: From Fundamentals to Practical Applications. Small 2018, 14, 1702737. [Google Scholar] [CrossRef] [PubMed]

- Song, T.; Cheng, H.; Choi, H.; Lee, J.-H.; Han, H.; Lee, D.H.; Yoo, D.S.; Kwon, M.-S.; Choi, J.-M.; Doo, S.G.; et al. Si/Ge Double-Layered Nanotube Array as a Lithium Ion Battery Anode. ACS Nano 2012, 6, 303–309. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Fan, R.; Yang, P. Block-by-Block Growth of Single-Crystalline Si/SiGe Superlattice Nanowires. Nano Lett. 2002, 2, 83–86. [Google Scholar] [CrossRef]

- Shimizu, T.; Zhang, Z.; Shingubara, S.; Senz, S. Vertical Epitaxial Wire-on-Wire Growth of Ge/Si on Si(100) Substrate. Nano Lett. 2009, 9, 4. [Google Scholar] [CrossRef]

- Dayeh, S.A.; Wang, J.; Li, N.; Huang, J.Y.; Gin, A.V.; Picraux, S.T. Growth, Defect Formation, and Morphology Control of GermaniumÀSilicon Semiconductor Nanowire Heterostructures. Nano Lett. 2011, 11, 4200–4206. [Google Scholar] [CrossRef] [PubMed]

- Varahramyan, K.M.; Ferrer, D.; Tutuc, E.; Banerjee, S.K. Band Engineered Epitaxial Ge–SixGe1−x Core-Shell Nanowire Heterostructures. Appl. Phys. Lett. 2009, 95, 033101. [Google Scholar] [CrossRef]

- Lauhon, L.J.; Gudiksen, M.S.; Wang, D.; Lieber, C.M. Epitaxial Core–Shell and Core–Multishell Nanowire Heterostructures. Nature 2002, 420, 57–61. [Google Scholar] [CrossRef]

- Bi, K.; Wang, J.; Wang, Y.; Sha, J.; Wang, Z.; Chen, M.; Chen, Y. The Thermal Conductivity of SiGe Heterostructure Nanowires with Different Cores and Shells. Phys. Lett. A 2012, 376, 2668–2671. [Google Scholar] [CrossRef]

- Xie, G.; Li, B.; Yang, L.; Cao, J.; Guo, Z.; Tang, M.; Zhong, J. Ultralow Thermal Conductivity in Si/Ge x Si 1−x Core-Shell Nanowires. J. Appl. Phys. 2013, 113, 083501. [Google Scholar] [CrossRef]

- Hu, M.; Giapis, K.P.; Goicochea, J.V.; Zhang, X.; Poulikakos, D. Significant Reduction of Thermal Conductivity in Si/Ge Core−Shell Nanowires. Nano Lett. 2011, 11, 618–623. [Google Scholar] [CrossRef] [PubMed]

- Dresselhaus, M.S.; Chen, G.; Tang, M.Y.; Yang, R.G.; Lee, H.; Wang, D.Z.; Ren, Z.F.; Fleurial, J.-P.; Gogna, P. New Directions for Low-Dimensional Thermoelectric Materials. Adv. Mater. 2007, 19, 1043–1053. [Google Scholar] [CrossRef]

- Mauser, K.W.; Solà-Garcia, M.; Liebtrau, M.; Damilano, B.; Coulon, P.-M.; Vézian, S.; Shields, P.A.; Meuret, S.; Polman, A. Employing Cathodoluminescence for Nanothermometry and Thermal Transport Measurements in Semiconductor Nanowires. ACS Nano 2021, 15, 11385–11395. [Google Scholar] [CrossRef] [PubMed]

- Lim, B.; Cui, X.Y.; Ringer, S.P. Strain-Mediated Bandgap Engineering of Straight and Bent Semiconductor Nanowires. Phys. Chem. Chem. Phys. 2021, 23, 5407–5414. [Google Scholar] [CrossRef] [PubMed]

- Li, J.-F.; Liu, W.-S.; Zhao, L.-D.; Zhou, M. High-Performance Nanostructured Thermoelectric Materials. NPG Asia Mater 2010, 2, 152–158. [Google Scholar] [CrossRef]

- Vineis, C.J.; Shakouri, A.; Majumdar, A.; Kanatzidis, M.G. Nanostructured Thermoelectrics: Big Efficiency Gains from Small Features. Adv. Mater. 2010, 22, 3970–3980. [Google Scholar] [CrossRef]

- Tang, D.-M.; Ren, C.-L.; Wang, M.-S.; Wei, X.; Kawamoto, N.; Liu, C.; Bando, Y.; Mitome, M.; Fukata, N.; Golberg, D. Mechanical Properties of Si Nanowires as Revealed by in Situ Transmission Electron Microscopy and Molecular Dynamics Simulations. Nano Lett. 2012, 12, 1898–1904. [Google Scholar] [CrossRef]

- Zhang, C.; Kvashnin, D.G.; Bourgeois, L.; Fernando, J.F.S.; Firestein, K.; Sorokin, P.B.; Fukata, N.; Golberg, D. Mechanical, Electrical, and Crystallographic Property Dynamics of Bent and Strained Ge/Si Core–Shell Nanowires as Revealed by in Situ Transmission Electron Microscopy. Nano Lett. 2018, 18, 7238–7246. [Google Scholar] [CrossRef]

- Jing, Y.; Meng, Q. Molecular Dynamics Simulations of the Mechanical Properties of Crystalline/Amorphous Silicon Core/Shell Nanowires. Phys. B Condens. Matter 2010, 405, 2413–2417. [Google Scholar] [CrossRef]

- Sarkar, J. Investigation of Mechanical Properties and Deformation Behavior of Single-Crystal Al-Cu Core-Shell Nanowire Generated Using Non-Equilibrium Molecular Dynamics Simulation. J. Nanopart. Res. 2018, 20, 153. [Google Scholar] [CrossRef]

- Sarkar, J.; Das, D.K. Molecular Dynamics Study of Defect and Dislocation Behaviors during Tensile Deformation of Copper-Silver Core-Shell Nanowires with Varying Core Diameter and Shell Thickness. J. Nanopart. Res. 2018, 20, 272. [Google Scholar] [CrossRef]

- Liu, X.W.; Hu, J.; Pan, B.C. The Composition-Dependent Mechanical Properties of Ge/Si Core–Shell Nanowires. Phys. E Low-Dimens. Syst. Nanostructures 2008, 40, 3042–3048. [Google Scholar] [CrossRef]

- Thanh, V.; Quang, T.; Hung, N.; Vu, H.; Truong, D. Investigate the Mechanical Properties of Si/Ge (Ge/Si) Core-Shell Nanowires: A Molecular Dynamics Study. Sci. Technol. Dev. J.-Eng. Technol. 2020, 3, first. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhang, X.; Zhang, S.; Sun, X.; Wang, L.; Ma, M.; Liu, R. First-Principles Investigations on Thermodynamic Properties of the Ordered and Disordered Si0.5Ge0.5 Alloys. Appl. Phys. A 2014, 115, 667–670. [Google Scholar] [CrossRef]

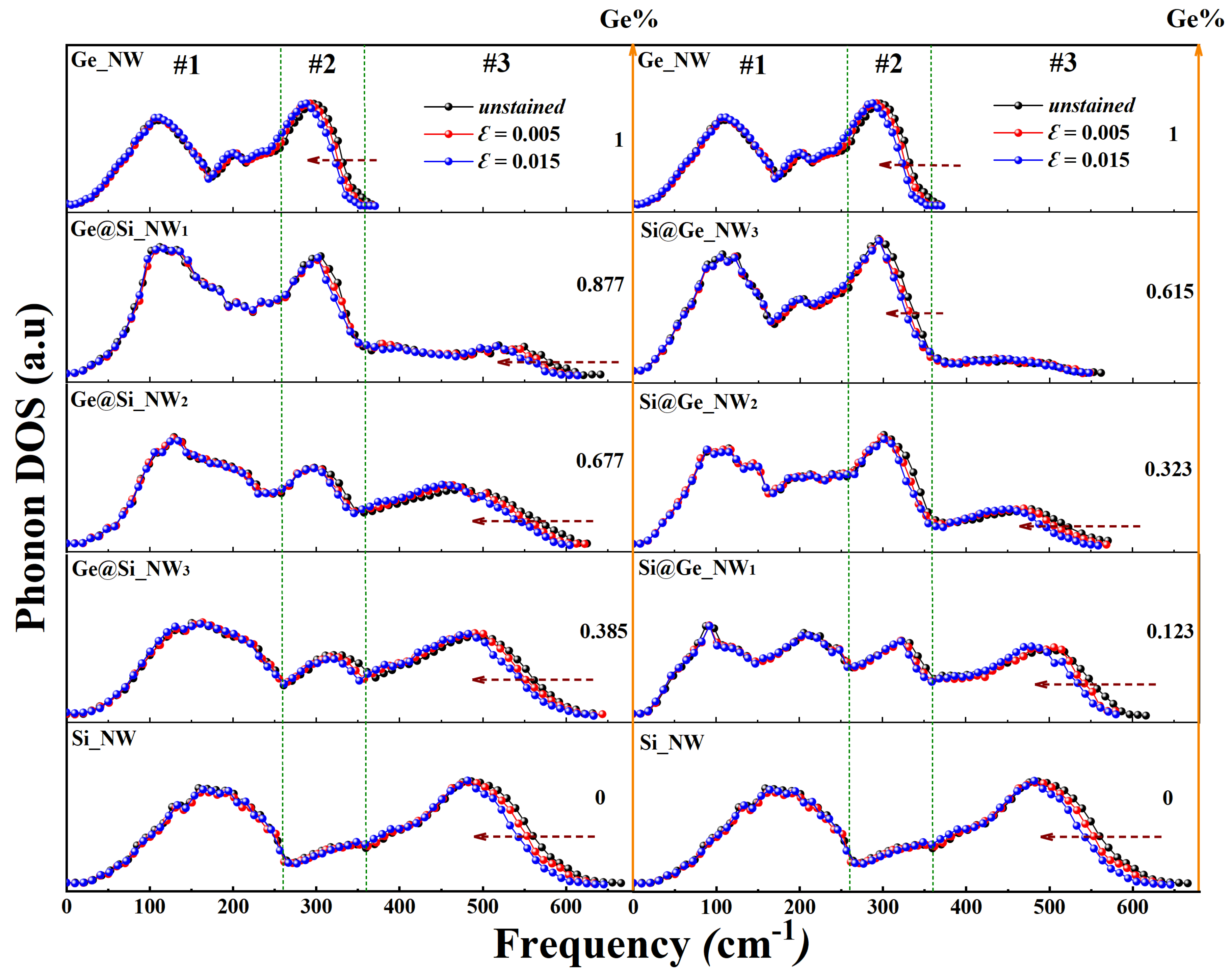

- Zhang, Y.; Cao, J.X.; Xiao, Y.; Yan, X.H. Phonon Spectrum and Specific Heat of Silicon Nanowires. J. Appl. Phys. 2007, 102, 104303. [Google Scholar] [CrossRef]

- Xu, Y.; Li, G. Strain Effect Analysis on Phonon Thermal Conductivity of Two-Dimensional Nanocomposites. J. Appl. Phys. 2009, 106, 114302. [Google Scholar] [CrossRef]

- Meyer, R.; Scherthan, L.; Hochdörffer, T.; Sadashivaiah, S.; Wolny, J.A.; Klein, M.W.; Smaga, M.; Beck, T.; Schünemann, V.; Urbassek, H.M. Changes in the Phonon Density of States of Fe Induced by External Strain. Appl. Phys. A 2021, 127, 5. [Google Scholar] [CrossRef]

- Algharagholy, L.A.A.; Pope, T.; Lambert, C.J. Strain-Induced Bi-Thermoelectricity in Tapered Carbon Nanotubes. J. Phys. Condens. Matter 2018, 30, 105304. [Google Scholar] [CrossRef]

- Hunt, M.; Salmon, K.; Haney, J.; Evans, C.; Gozen, A.; Leachman, J. Ultimate Tensile Strengths of 3D Printed Carbon-Fiber Reinforced Thermoplastics in Liquid Nitrogen. IOP Conf. Ser. Mater. Sci. Eng. 2020, 755, 012118. [Google Scholar] [CrossRef]

- Xiang, J.; Lu, W.; Hu, Y.; Wu, Y.; Yan, H.; Lieber, C.M. Ge/Si Nanowire Heterostructures as High-Performance Field-Effect Transistors. Nature 2006, 441, 489–493. [Google Scholar] [CrossRef]

- Aryal, S.; Pati, R. Spin Filtering with Mn-Doped Ge-Core/Si-Shell Nanowires. Nanoscale Adv. 2020, 2, 1843–1849. [Google Scholar] [CrossRef]

- Stukowski, A. Visualization and Analysis of Atomistic Simulation Data with OVITO–the Open Visualization Tool. Model. Simul. Mater. Sci. Eng. 2009, 18, 015012. [Google Scholar] [CrossRef]

- Gale, J.D. Computer Session on Molecular Dynamics: Tutorial in Force Field Simulation of Materials with GULP. EPJ Web Conf. 2011, 14, 03005. [Google Scholar] [CrossRef]

- Gale, J.D.; Rohl, A.L. The General Utility Lattice Program (GULP). Mol. Simul. 2003, 29, 291–341. [Google Scholar] [CrossRef]

- Aryal, S.; Paudyal, D.; Pati, R. Cr-Doped Ge-Core/Si-Shell Nanowire: An Antiferromagnetic Semiconductor. Nano Lett. 2021, 21, 1856–1862. [Google Scholar] [CrossRef]

- Laasonen, K.; Panizon, E.; Bochicchio, D.; Ferrando, R. Competition between Icosahedral Motifs in AgCu, AgNi, and AgCo Nanoalloys: A Combined Atomistic–DFT Study. J. Phys. Chem. C 2013, 117, 26405–26413. [Google Scholar] [CrossRef]

- Bochicchio, D.; Ferrando, R.; Panizon, E.; Rossi, G. Structures and Segregation Patterns of Ag–Cu and Ag–Ni Nanoalloys Adsorbed on MgO(0 0 1). J. Phys. Condens. Matter 2016, 28, 064005. [Google Scholar] [CrossRef] [PubMed]

- Zhao, D.; Dai, F.; Li, J.; Zhang, L. Thermal Stability and Mechanical Properties of Si/Ge Superlattice Nanowires Having Inclination Interfaces from Simulations at Atomic Scale. Appl. Phys. A 2022, 128. [Google Scholar] [CrossRef]

- Smirnov, S.V.; Konovalov, A.V.; Myasnikova, M.V.; Khalevitsky, Y.V.; Smirnov, A.S.; Igumnov, A.S. A Hierarchial Modeling of Stress-Strain State of Multiphase Material Subjected to Uniaxial Loading. In AIP Conference Proceedings; AIP Publishing LLC: Ekaterinburg, Russia, 2016; p. 040066. [Google Scholar]

- Flubacher, P.; Leadbetter, A.J.; Morrison, J.A. The Heat Capacity of Pure Silicon and Germanium and Properties of Their Vibrational Frequency Spectra. Philos. Mag. 1959, 4, 273–294. [Google Scholar] [CrossRef]

| Parameter | Si | Ge |

|---|---|---|

| A (eV) | 1.8308 × 103 | 1.769 × 103 |

| B (eV) | 4.7118 × 102 | 4.1923 × 102 |

| λ (Å−1) | 2.4799 | 2.4551 |

| μ (Å−1) | 1.7322 | 1.7047 |

| β | 1.1000 × 10−6 | 9.0166 × 10−7 |

| n | 7.8734 × 10−1 | 7.5627 × 10−1 |

| c | 1.0039 × 105 | 1.0643 × 105 |

| d | 1.6217 × 101 | 1.5652 × 101 |

| h | −5.9825 × 10−1 | −4.3884 × 10−1 |

| R (Å) | 2.7 | 2.8 |

| S (Å) | 3.0 | 3.1 |

| = 1.00061 | ||

| Type | Side Length of Shell (nm) | Label | Ge% | Side Length of Core (nm) | ||

|---|---|---|---|---|---|---|

| a | b | c | d | |||

| Pure_Ge | 1.5539 | 1.1520 | Ge_NW | 1 | - | - |

| Ge_shell_Si_core | 1.5539 | 1.1520 | Ge@Si_NW1 | 0.877 | 0 | 0.5918 |

| Ge@Si_NW2 | 0.677 | 0.3840 | 0.8903 | |||

| Ge@Si_NW3 | 0.385 | 0.7680 | 1.2369 | |||

| Si_shell_Ge_core | 1.5539 | 1.1520 | Si@Ge_NW1 | 0.123 | 0.7680 | 1.2369 |

| Si@Ge_NW2 | 0.323 | 0.3840 | 0.8903 | |||

| Si@Ge_NW3 | 0.615 | 0 | 0.5918 | |||

| Pure_Si | 1.5539 | 1.1520 | Si_NW | 0 | - | - |

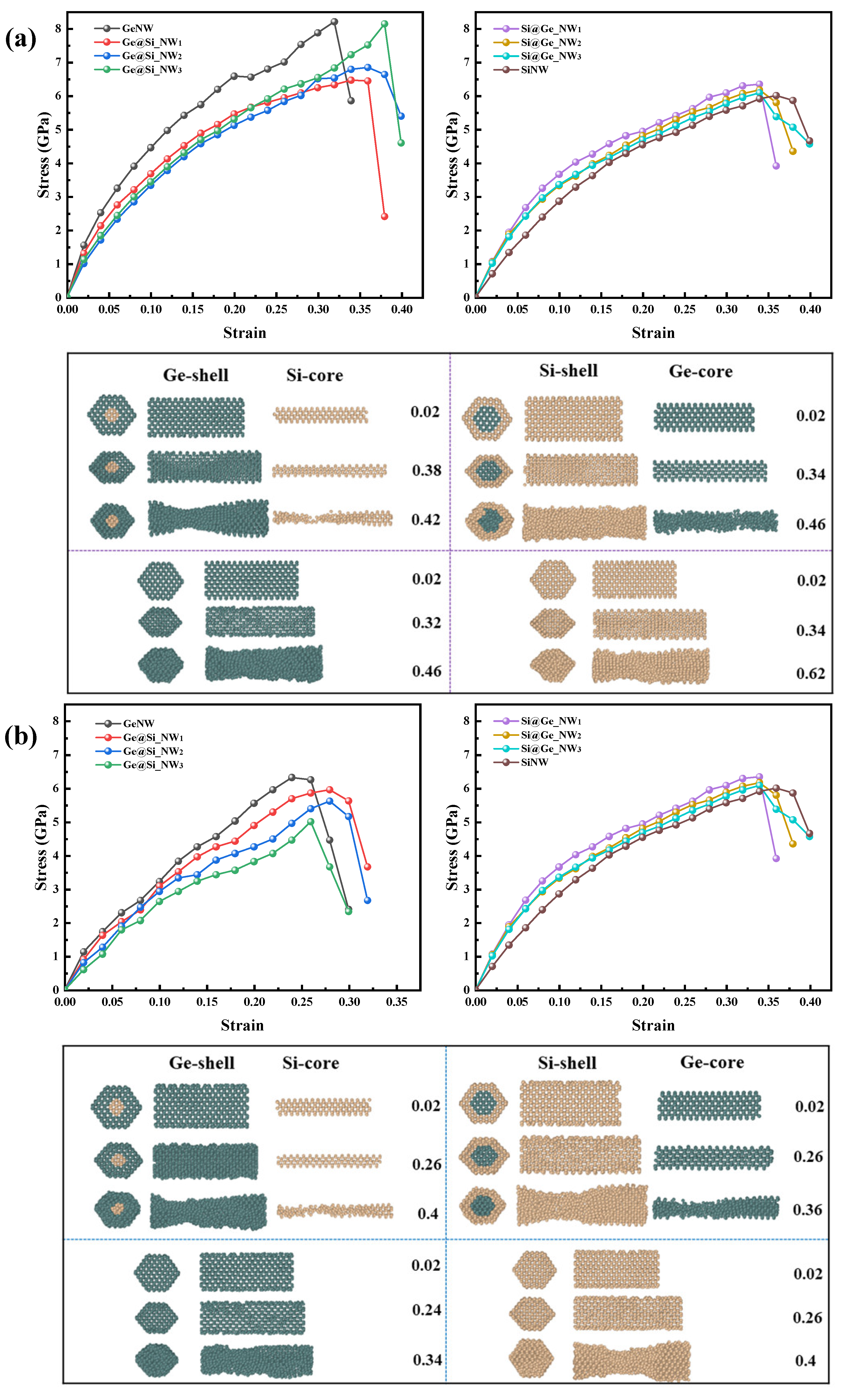

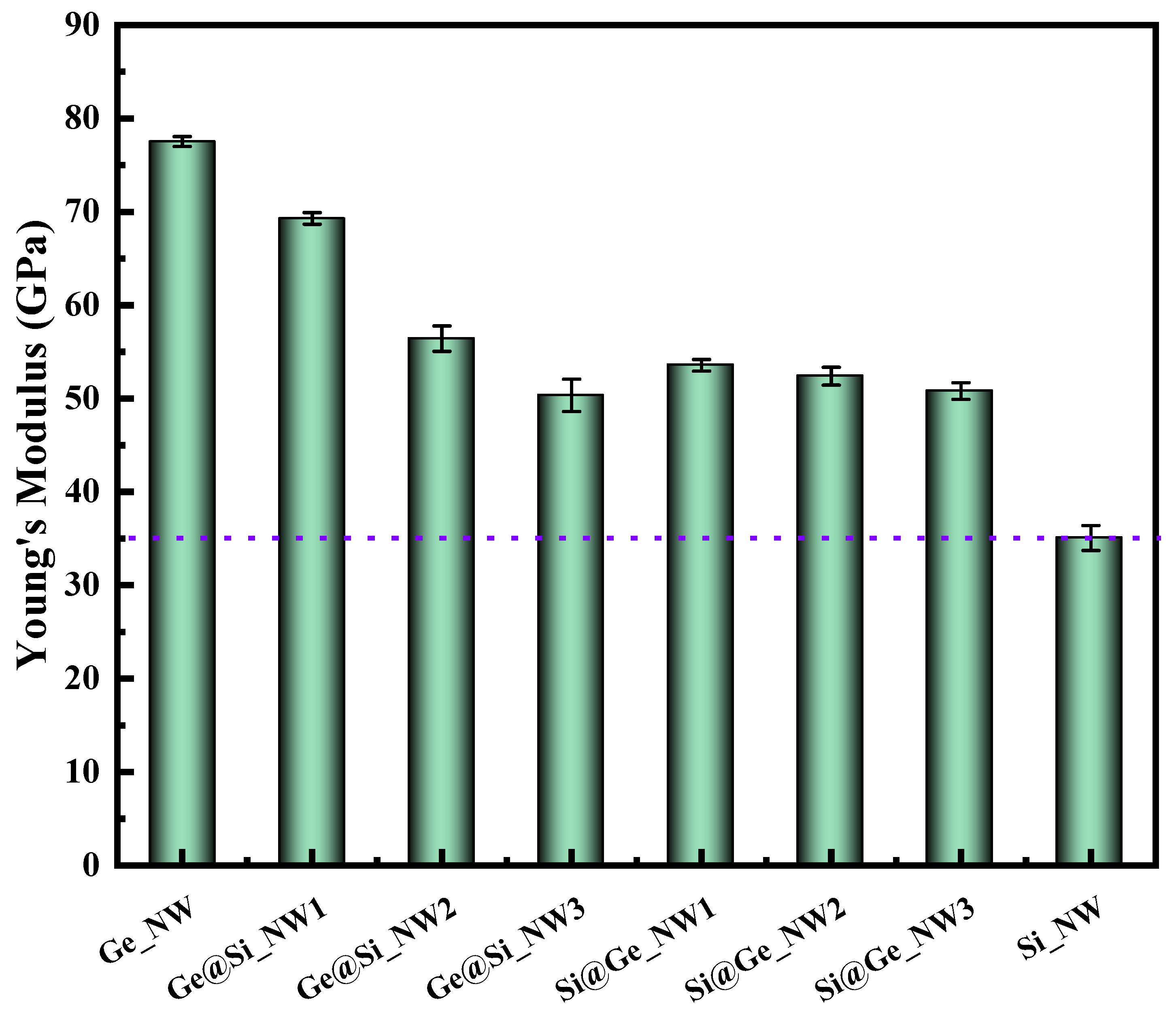

| Label | 300 K | 800 K | ||

|---|---|---|---|---|

| Strain | Tensile Strength (Rm/GPa) | Strain | Tensile Strength (Rm/GPa) | |

| Ge_NW | 0.32 | 8.213 | 0.24 | 6.333 |

| Ge@Si_NW1 | 0.38 | 8.154 | 0.28 | 5.967 |

| Ge@Si_NW2 | 0.36 | 6.850 | 0.28 | 5.625 |

| Ge@Si_NW3 | 0.34 | 6.471 | 0.26 | 5.013 |

| Si@Ge_NW1 | 0.34 | 6.355 | 0.26 | 5.949 |

| Si@Ge_NW2 | 0.34 | 6.180 | 0.26 | 5.635 |

| Si@Ge_NW3 | 0.34 | 6.096 | 0.26 | 5.530 |

| Si_NW | 0.36 | 6.016 | 0.30 | 5.766 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, D.; Cui, Y.; Li, J.; Zhang, L. Atomic Simulations of Si@Ge and Ge@Si Nanowires for Mechanical and Thermal Properties. Crystals 2022, 12, 1447. https://doi.org/10.3390/cryst12101447

Zhao D, Cui Y, Li J, Zhang L. Atomic Simulations of Si@Ge and Ge@Si Nanowires for Mechanical and Thermal Properties. Crystals. 2022; 12(10):1447. https://doi.org/10.3390/cryst12101447

Chicago/Turabian StyleZhao, Dandan, Yang Cui, Jing Li, and Lin Zhang. 2022. "Atomic Simulations of Si@Ge and Ge@Si Nanowires for Mechanical and Thermal Properties" Crystals 12, no. 10: 1447. https://doi.org/10.3390/cryst12101447

APA StyleZhao, D., Cui, Y., Li, J., & Zhang, L. (2022). Atomic Simulations of Si@Ge and Ge@Si Nanowires for Mechanical and Thermal Properties. Crystals, 12(10), 1447. https://doi.org/10.3390/cryst12101447