In Situ Synchrotron Radiation Diffraction Study of Compression of AZ91 Composites Reinforced with Recycled Carbon Fibres

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Microstructural Investigation

2.3. Synchrotron Diffraction Measurements

3. Results

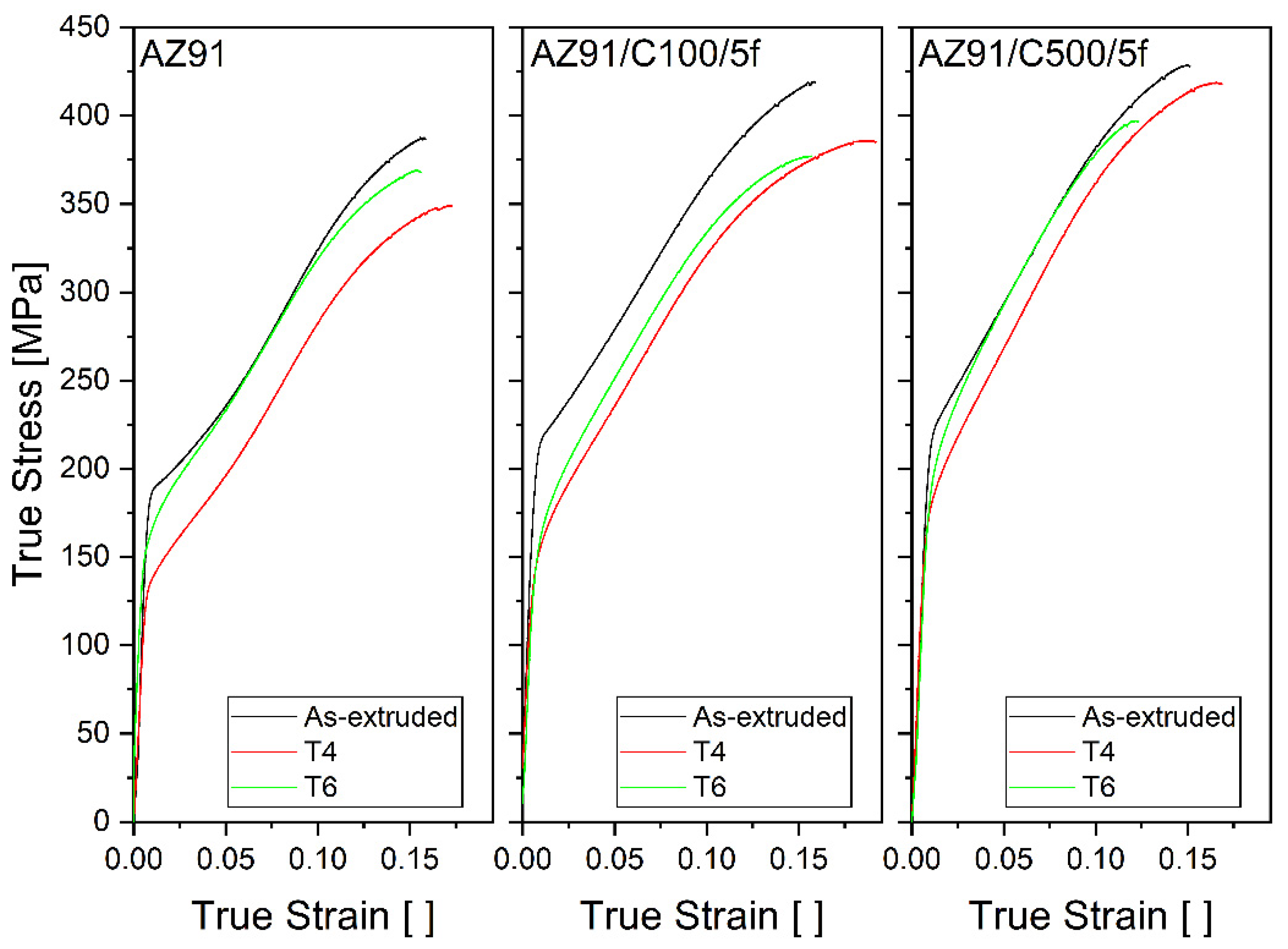

3.1. Deformation Behaviour

3.2. Microstructure

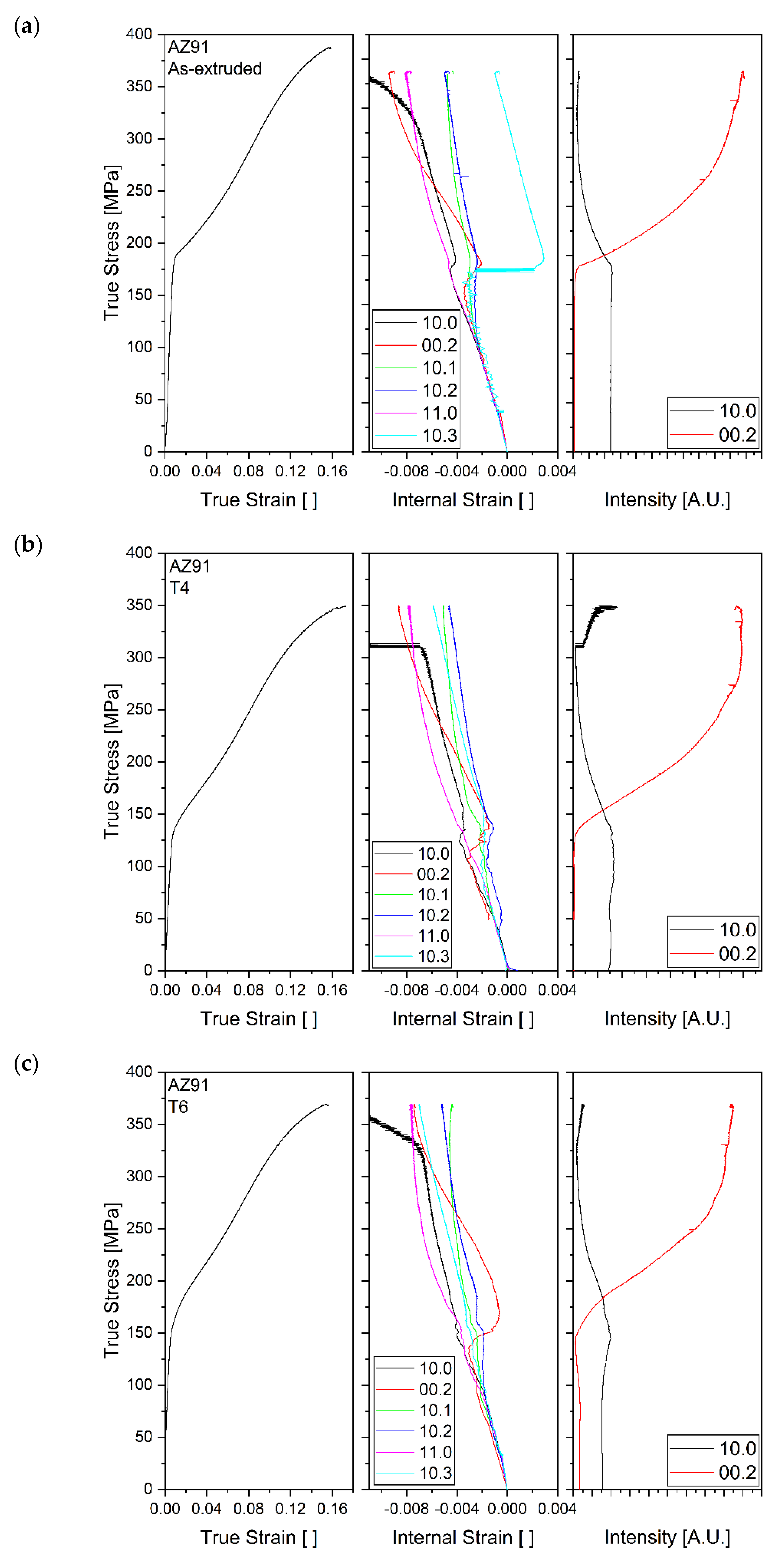

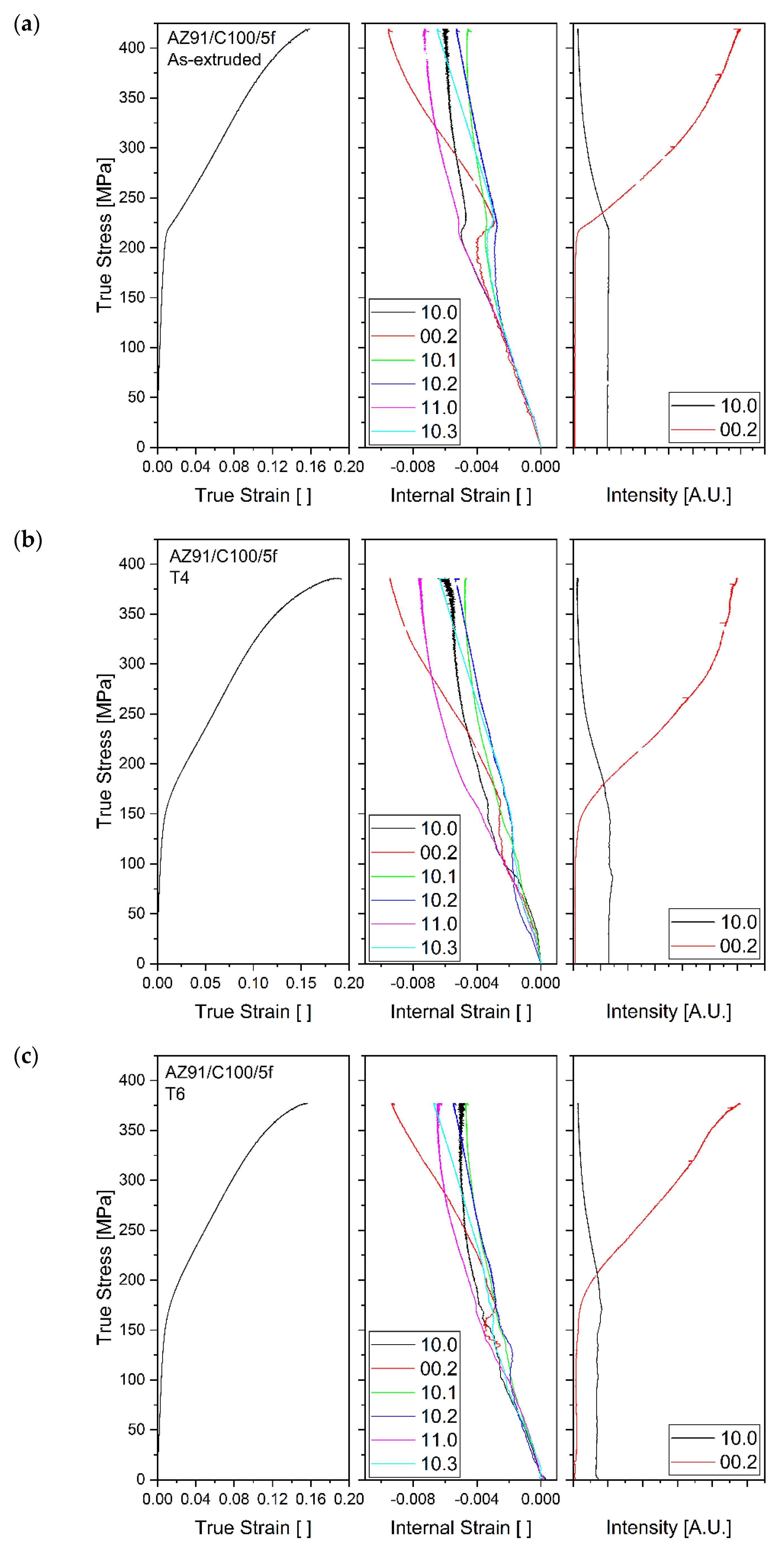

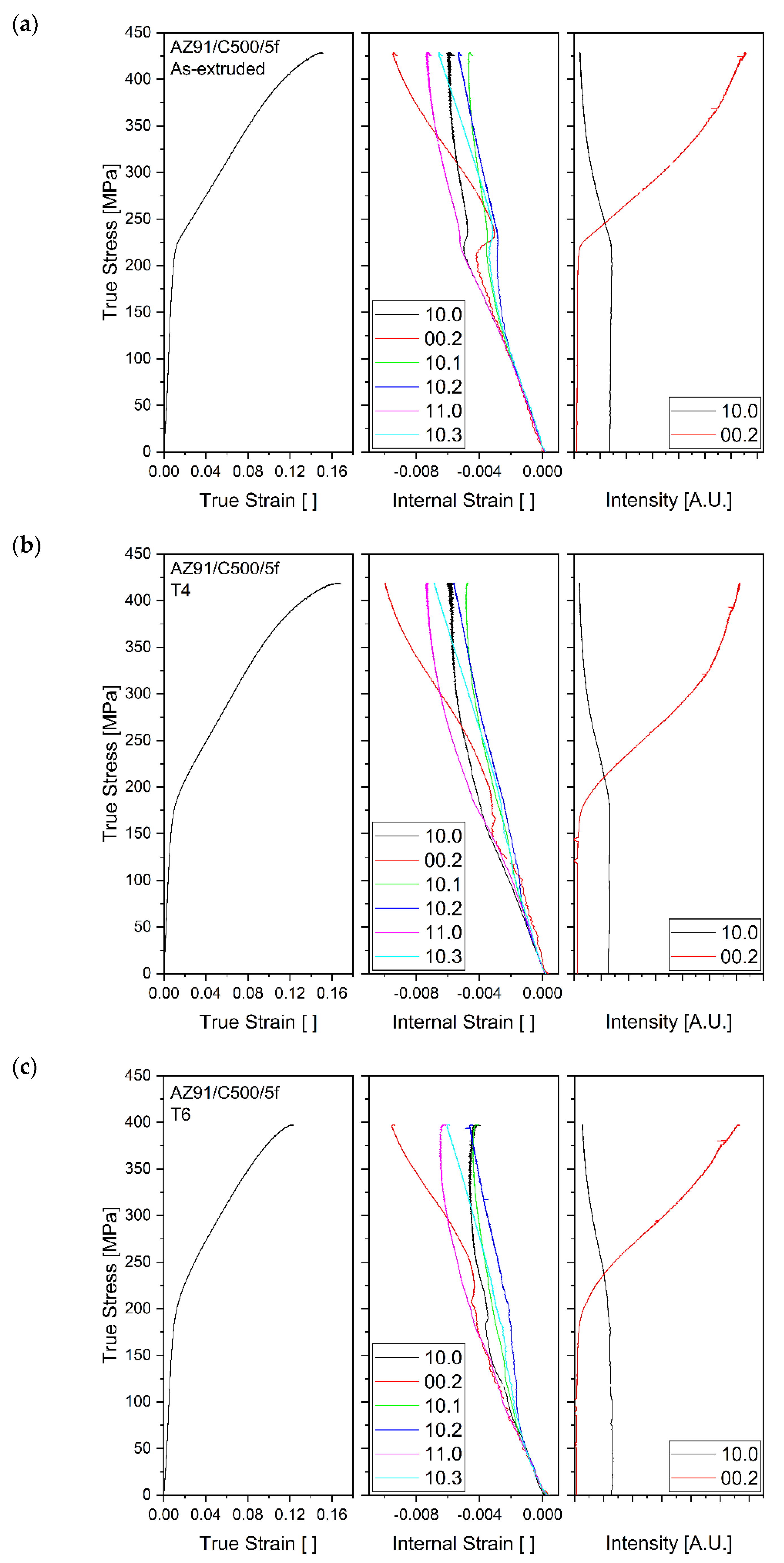

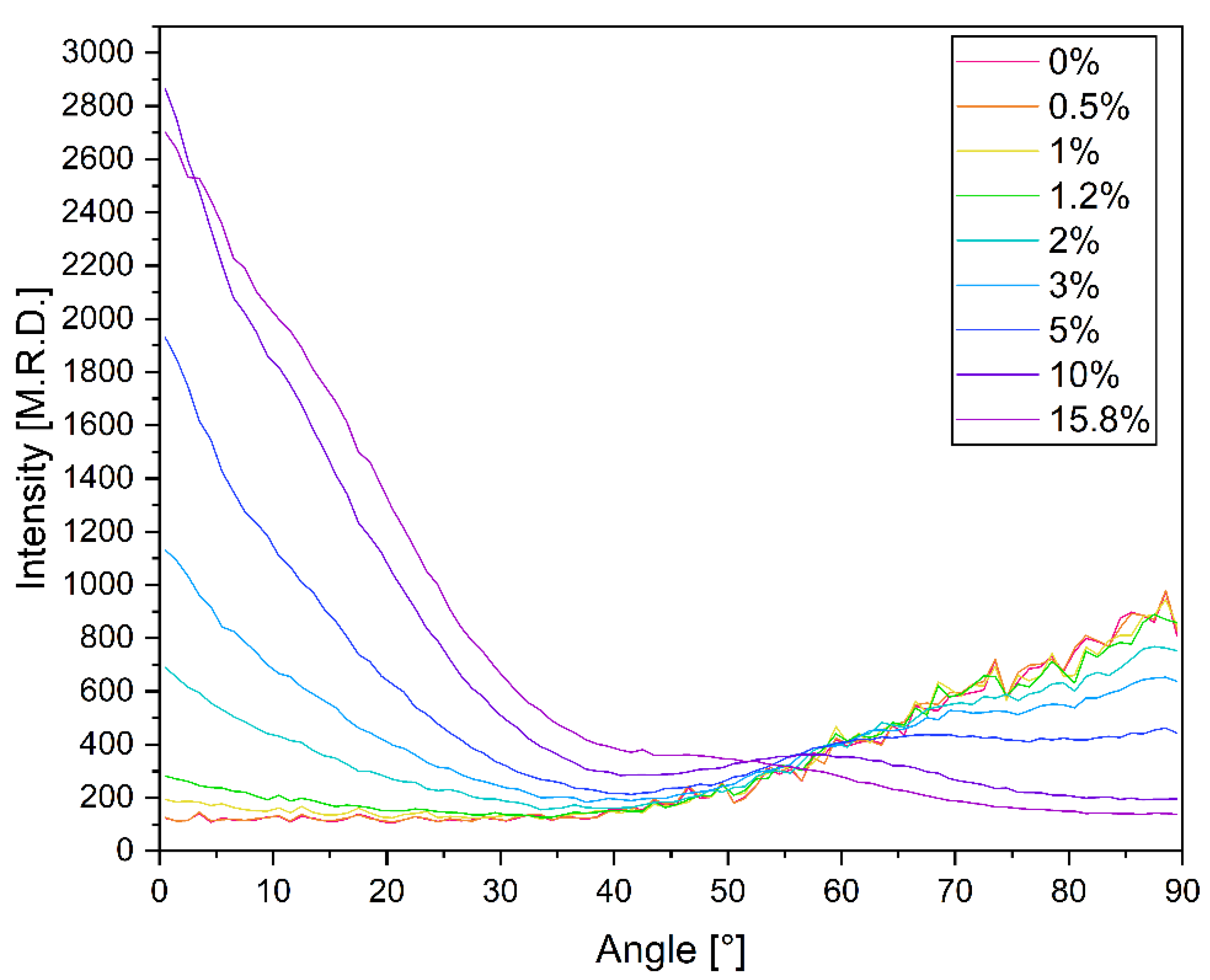

3.3. Synchrotron Diffraction

4. Discussion

5. Conclusions

- Two AZ91 rCF composites, with reinforcements of 100 µm and 500 µm, were manufactured with 32 and 41 MPa increases in UCS compared to AZ91, respectively. This was achieved through the addition of 5 wt % rCFs to the melt followed by high dispersion shearing, casting, and extrusion. The T6 heat treatment used was not successful at improving UCS, and it is suggested that it resulted in under-ageing.

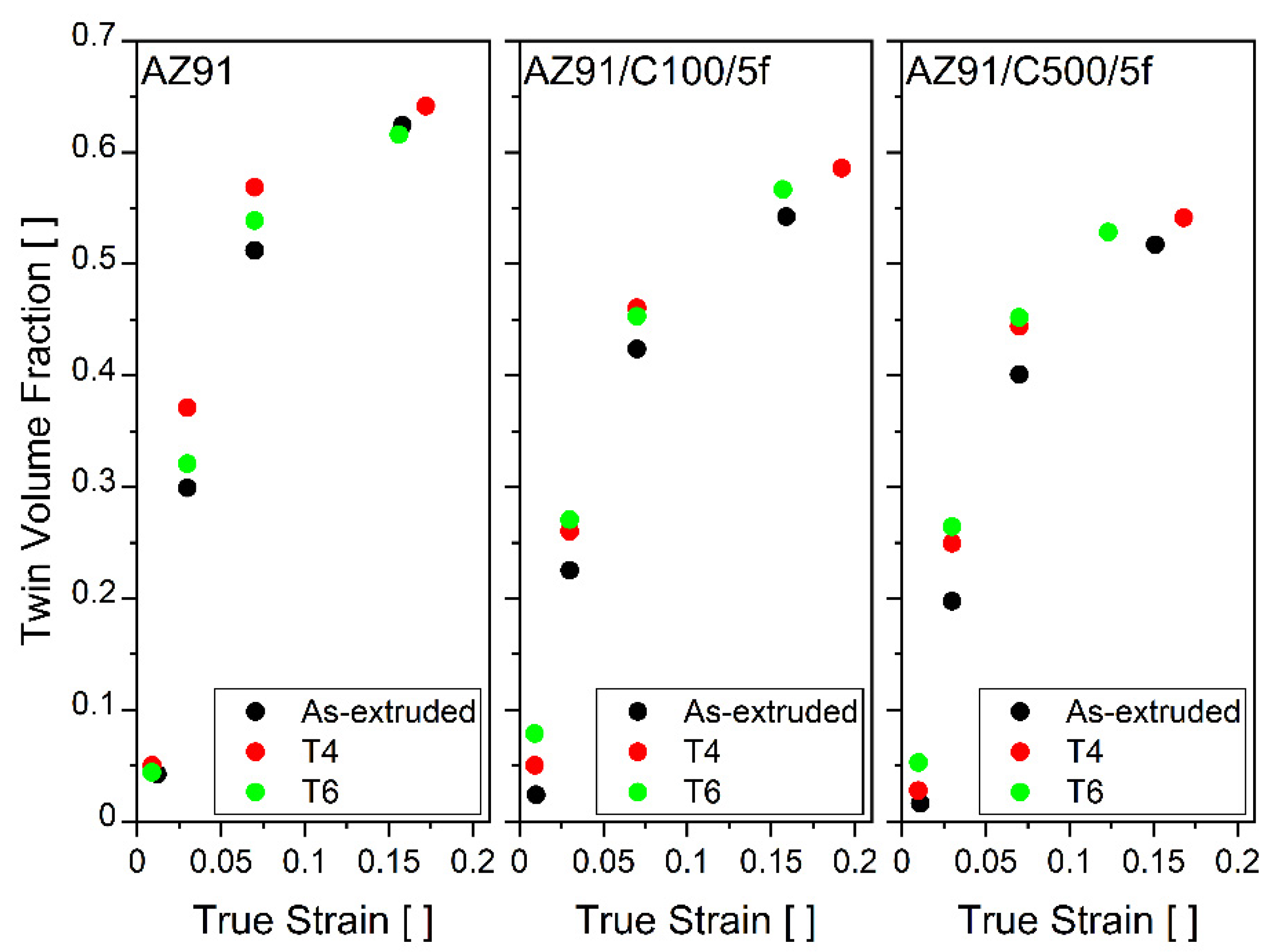

- In situ synchrotron diffraction was used to investigate the active deformation mechanisms in the magnesium-based matrix. The deformation mechanisms in the heat-treated alloys and composites were similar. Extension twinning was found to be significant in both, although the TVF of the matrix was lower in the composites compared to unreinforced AZ91. The stress at the onset of twinning was increased by approximately 30 MPa in the composites compared to AZ91.

- Basal slip appeared to have had a larger impact on the macroscopic deformation in the composites and heat-treated alloys and composites. The onset of microyielding in heat-treated alloys and composites was lowered by 30–50 MPa.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pekguleryuz, M.O.; Kainer, K.; Kaya, A. Fundamentals of Magnesium Alloy Metallurgy; Woodhead Publishing Series in Metals and Surface Engineering; Woodhead Publishing: Philadelphia, PA, USA, 2013; ISBN 978-0-85709-088-1. [Google Scholar]

- Zeller-Plumhoff, B.; Tolnai, D.; Wolff, M.; Greving, I.; Hort, N.; Willumeit-Römer, R. Utilizing Synchrotron Radiation for the Characterization of Biodegradable Magnesium Alloys—From Alloy Development to the Application as Implant Material. Adv. Eng. Mater. 2021, 23, 2100197. [Google Scholar] [CrossRef]

- Hort, N.; Huang, Y.; Fechner, D.; Störmer, M.; Blawert, C.; Witte, F.; Vogt, C.; Drücker, H.; Willumeit, R.; Kainer, K.U.; et al. Magnesium Alloys as Implant Materials—Principles of Property Design for Mg–RE Alloys. Acta Biomater. 2010, 6, 1714–1725. [Google Scholar] [CrossRef]

- Witte, F.; Hort, N.; Vogt, C.; Cohen, S.; Kainer, K.U.; Willumeit, R.; Feyerabend, F. Degradable Biomaterials Based on Magnesium Corrosion. Curr. Opin. Solid State Mater. Sci. 2008, 12, 63–72. [Google Scholar] [CrossRef]

- Garcés, G.; Oñorbe, E.; Pérez, P.; Denks, I.A.; Adeva, P. Evolution of Internal Strain during Plastic Deformation in Magnesium Matrix Composites. Mater. Sci. Eng. A 2009, 523, 21–26. [Google Scholar] [CrossRef]

- Garcés, G.; Oñorbe, E.; Pérez, P.; Klaus, M.; Genzel, C.; Adeva, P. Influence of SiC Particles on Compressive Deformation of Magnesium Matrix Composites. Mater. Sci. Eng. A 2012, 533, 119–123. [Google Scholar] [CrossRef]

- Garcés, G.; Máthis, K.; Pérez, P.; Čapek, J.; Adeva, P. Effect of Reinforcing Shape on Twinning in Extruded Magnesium Matrix Composites. Mater. Sci. Eng. A 2016, 666, 48–53. [Google Scholar] [CrossRef]

- Goh, C.S.; Wei, J.; Lee, L.C.; Gupta, M. Effect of Fabrication Techniques on the Properties of Carbon Nanotubes Reinforced Magnesium. SSP 2006, 111, 179–182. [Google Scholar]

- Morisada, Y.; Fujii, H.; Nagaoka, T.; Fukusumi, M. MWCNTs/AZ31 Surface Composites Fabricated by Friction Stir Processing. Mater. Sci. Eng. A 2006, 419, 344–348. [Google Scholar] [CrossRef]

- Goh, C.S.; Wei, J.; Lee, L.C.; Gupta, M. Simultaneous Enhancement in Strength and Ductility by Reinforcing Magnesium with Carbon Nanotubes. Mater. Sci. Eng. A 2006, 423, 153–156. [Google Scholar] [CrossRef]

- Dorner-Reisel, A.; Nishida, Y.; Klemm, V.; Nestler, K.; Marx, G.; Müller, E. Investigation of Interfacial Interaction between Uncoated and Coated Carbon Fibres and the Magnesium Alloy AZ91. Anal. Bioanal. Chem. 2002, 374, 635–638. [Google Scholar] [CrossRef]

- Li, S.; Qi, L.; Zhang, T.; Zhou, J.; Li, H. Evolution of Interfacial Microstructures and Mechanical Properties of Cf/AZ91 Composite during Heat Treatment. Vacuum 2017, 145, 245–250. [Google Scholar] [CrossRef]

- Kainer, K.U. Development of Magnesium-Matrix Composites for Power Train Applications. In Proceedings of the 12th International Conference on Composite Materials, Paris, France, 5–9 July 1999; p. 10. [Google Scholar]

- Ataya, S.; El-Sayed Seleman, M.M.; Latief, F.H.; Ahmed, M.M.Z.; Hajlaoui, K.; Elshaghoul, Y.G.Y.; Habba, M.I.A. Microstructure and Mechanical Properties of AZ91 Rein-Forced with High Volume Fraction of Oriented Short Carbon Fibers. Materials 2022, 15, 4818. [Google Scholar] [CrossRef] [PubMed]

- Hufenbach, W.; Andrich, M.; Langkamp, A.; Czulak, A. Fabrication Technology and Material Characterization of Carbon Fibre Reinforced Magnesium. J. Mater. Process. Technol. 2006, 175, 218–224. [Google Scholar] [CrossRef]

- Olszówka-Myalska, A.; Botor-Probierz, A. Studies of the AZ91 Magnesium Alloy/SiO2—Coated Carbon Fibres Composite Microstructure. IOP Conf. Ser. Mater. Sci. Eng. 2010, 7, 012022. [Google Scholar] [CrossRef]

- Afrinaldi, A.; Kakiuchi, T.; Nakagawa, S.; Moritomi, H.; Kumabe, K.; Nakai, A.; Ohtani, A.; Mizutani, Y.; Uematsu, Y. Fabrication of Recycled Carbon Fiber Reinforced Magnesium Alloy Composite by Friction Stir Processing Using 3-Flat Pin Tool and Its Fatigue Properties. Mater. Trans. 2018, 59, 475–481. [Google Scholar] [CrossRef]

- Ajukumar, K.A.; Ajith Kumar, K.K.; Ravikumar, K.K.; Rajan, T.P.D.; Pillai, U.T.S.; Pai, B.C. Fabrication and Characterization of Short Carbon Fiber Reinforced AZ91 Mg Alloy Composites. MSF 2012, 710, 347–352. [Google Scholar]

- Kandemir, S.; Gavras, S.; Dieringa, H. High Temperature Tensile, Compression and Creep Behavior of Recycled Short Carbon Fibre Reinforced AZ91 Magnesium Alloy Fabricated by a High Shearing Dispersion Technique. J. Magnes. Alloy. 2021, 9, 1753–1767. [Google Scholar] [CrossRef]

- Feldhoff; Pippel. Woltersdorf Carbon-Fibre Reinforced Magnesium Alloys: Nanostructure and Chemistry of Interlayers and Their Effect on Mechanical Properties. J. Microsc. 1999, 196, 185–193. [Google Scholar] [CrossRef]

- Meng, F.; McKechnie, J.; Pickering, S.J. An Assessment of Financial Viability of Recycled Carbon Fibre in Automotive Applications. Compos. Part A Appl. Sci. Manuf. 2018, 109, 207–220. [Google Scholar] [CrossRef]

- Oliveux, G.; Dandy, L.O.; Leeke, G.A. Current Status of Recycling of Fibre Reinforced Polymers: Review of Technologies, Reuse and Resulting Properties. Prog. Mater. Sci. 2015, 72, 61–99. [Google Scholar] [CrossRef]

- Pimenta, S.; Pinho, S.T. Recycling Carbon Fibre Reinforced Polymers for Structural Applications: Technology Review and Market Outlook. Waste Manag. 2011, 31, 378–392. [Google Scholar] [CrossRef] [PubMed]

- Liss, K.-D.; Yan, K. Thermo-Mechanical Processing in a Synchrotron Beam. Mater. Sci. Eng. A 2010, 528, 11–27. [Google Scholar] [CrossRef]

- Brown, D.W.; Agnew, S.R.; Bourke, M.A.M.; Holden, T.M.; Vogel, S.C.; Tomé, C.N. Internal Strain and Texture Evolution during Deformation Twinning in Magnesium. Mater. Sci. Eng. A 2005, 399, 1–12. [Google Scholar] [CrossRef]

- Gharghouri, M.A.; Weatherly, G.C.; Embury, J.D.; Root, J. Study of the Mechanical Properties of Mg-7.7at.% Al by In Situ Neutron Diffraction. Philos. Mag. A 1999, 79, 1671–1695. [Google Scholar] [CrossRef]

- Garces, G.; Medina, J.; Chávez, B.; Perez, P.; Barea, R.; Stark, A.; Schell, N.; Adeva, P. Load Partitioning Between Mg17Al12 Precipitates and Mg Phase in the AZ91 Alloy Using In-Situ Synchrotron Radiation Diffraction Experiments. Met. Mater. Trans. A 2021, 52, 2732–2745. [Google Scholar] [CrossRef]

- Kada, S.R.; Lynch, P.A.; Kimpton, J.A.; Barnett, M.R. In-Situ X-Ray Diffraction Studies of Slip and Twinning in the Presence of Precipitates in AZ91 Alloy. Acta Mater. 2016, 119, 145–156. [Google Scholar] [CrossRef]

- Meixner, M.; Fitzpatrick, M.E.; Reimers, W. Measurement of the Evolution of Internal Strain and Load Partitioning in Magnesium Hybrid Composites under Compression Load Using In-Situ Synchrotron X-Ray Diffraction Analysis. Compos. Sci. Technol. 2011, 71, 167–176. [Google Scholar] [CrossRef]

- Yang, H.; Huang, Y.; Song, B.; Kainer, K.U.; Dieringa, H. Enhancing the Creep Resistance of AlN/Al Nanoparticles Reinforced Mg-2.85Nd-0.92Gd-0.41Zr-0.29Zn Alloy by a High Shear Dispersion Technique. Mater. Sci. Eng. A 2019, 755, 18–27. [Google Scholar] [CrossRef]

- Yang, H.; Patel, J.B.; Yang, X.; Gavras, S.; Dieringa, H. Properties of Mg-Based Metal Matrix Nanocomposites Processed by High Shear Dispersion Technique (HSDT)—A Review. CNM 2021, 6, 106–118. [Google Scholar] [CrossRef]

- Garcés, G.; Máthis, K.; Medina, J.; Horváth, K.; Drozdenko, D.; Oñorbe, E.; Dobroň, P.; Pérez, P.; Klaus, M.; Adeva, P. Combination of In-Situ Diffraction Experiments and Acoustic Emission Testing to Understand the Compression Behavior of Mg-Y-Zn Alloys Containing LPSO Phase under Different Loading Conditions. Int. J. Plast. 2018, 106, 107–128. [Google Scholar] [CrossRef]

- Stanford, N.; Taylor, A.S.; Cizek, P.; Siska, F.; Ramajayam, M.; Barnett, M.R. {101¯2} Twinning in Magnesium-Based Lamellar Microstructures. Scr. Mater. 2012, 67, 704–707. [Google Scholar] [CrossRef]

- Robson, J.D.; Stanford, N.; Barnett, M.R. Effect of Particles in Promoting Twin Nucleation in a Mg–5wt.% Zn Alloy. Scr. Mater. 2010, 63, 823–826. [Google Scholar] [CrossRef]

- Clausen, B.; Tomé, C.N.; Brown, D.W.; Agnew, S.R. Reorientation and Stress Relaxation Due to Twinning: Modeling and Experimental Characterization for Mg. Acta Mater. 2008, 56, 2456–2468. [Google Scholar] [CrossRef]

- Fekete, K.H.; Drozdenko, D.; Čapek, J.; Máthis, K.; Tolnai, D.; Stark, A.; Garcés, G.; Dobroň, P. Hot Deformation of Mg-Y-Zn Alloy with a Low Content of the LPSO Phase Studied by in-Situ Synchrotron Radiation Diffraction. J. Magnes. Alloy. 2020, 8, 199–209. [Google Scholar] [CrossRef]

- Zhang, M.-X.; Kelly, P.M. Crystallography of Mg17Al12 Precipitates in AZ91D Alloy. Scr. Mater. 2003, 48, 647–652. [Google Scholar] [CrossRef]

- Ragani, J.; Donnadieu, P.; Tassin, C.; Blandin, J.J. High-Temperature Deformation of the γ-Mg17Al12 Complex Metallic Alloy. Scr. Mater. 2011, 65, 253–256. [Google Scholar] [CrossRef]

- Stanford, N.; Geng, J.; Chun, Y.B.; Davies, C.H.J.; Nie, J.F.; Barnett, M.R. Effect of Plate-Shaped Particle Distributions on the Deformation Behaviour of Magnesium Alloy AZ91 in Tension and Compression. Acta Mater. 2012, 60, 218–228. [Google Scholar] [CrossRef]

- Bhattacharyya, J.J.; Kada, S.R.; Barnett, M.R.; Agnew, S.R. Crystal Plasticity and In-Situ Diffraction-Based Determination of the Dislocation Strengthening and Load-Sharing Effects of Precipitates in Mg Alloy, AZ91. Materialia 2019, 6, 100308. [Google Scholar] [CrossRef]

- Máthis, K.; Čapek, J.; Clausen, B.; Krajňák, T.; Nagarajan, D. Investigation of the Dependence of Deformation Mechanisms on Solute Content in Polycrystalline Mg–Al Magnesium Alloys by Neutron Diffraction and Acoustic Emission. J. Alloy. Compd. 2015, 642, 185–191. [Google Scholar] [CrossRef]

- Agnew, S.R.; Brown, D.W.; Tomé, C.N. Validating a Polycrystal Model for the Elastoplastic Response of Magnesium Alloy AZ31 Using in Situ Neutron Diffraction. Acta Mater. 2006, 54, 4841–4852. [Google Scholar] [CrossRef]

- Muránsky, O.; Barnett, M.R.; Carr, D.G.; Vogel, S.C.; Oliver, E.C. Investigation of Deformation Twinning in a Fine-Grained and Coarse-Grained ZM20 Mg Alloy: Combined in Situ Neutron Diffraction and Acoustic Emission. Acta Mater. 2010, 58, 1503–1517. [Google Scholar] [CrossRef]

- Barnett, M.R.; Keshavarz, Z.; Beer, A.G.; Atwell, D. Influence of Grain Size on the Compressive Deformation of Wrought Mg–3Al–1Zn. Acta Mater. 2004, 52, 5093–5103. [Google Scholar] [CrossRef]

- Clyne, T.W.; Withers, P.J. An Introduction to Metal Matrix Composites; Cambridge Solid State Science Series; Cambridge University Press: Cambridge, UK, 1993; ISBN 978-0-521-48357-5. [Google Scholar]

- Gharghouri, M.A.; Weatherly, G.C.; Embury, J.D. The Interaction of Twins and Precipitates in a Mg-7.7 at.% Al Alloy. Philos. Mag. A 1998, 78, 1137–1149. [Google Scholar] [CrossRef]

- Muránsky, O.; Carr, D.G.; Šittner, P.; Oliver, E.C. In Situ Neutron Diffraction Investigation of Deformation Twinning and Pseudoelastic-like Behaviour of Extruded AZ31 Magnesium Alloy. Int. J. Plast. 2009, 25, 1107–1127. [Google Scholar] [CrossRef]

| Mg | Al | Zn | Mn | Nd | Si | Ca | Cu | Fe |

|---|---|---|---|---|---|---|---|---|

| Bal. | 8.73 | 0.67 | 0.21 | 0.019 | 0.019 | 0.0014 | 0.0027 | 0.0013 |

| Sample | UCS (MPa) | Proof Stress (MPa) |

|---|---|---|

| AZ91 as extruded | 387 | 190 |

| AZ91 T4 | 349 | 135 |

| AZ91 T6 | 368 | 162 |

| AZ91/C100/5f as extruded | 419 | 217 |

| AZ91/C100/5f T4 | 384 | 153 |

| AZ91/C100/5f T6 | 377 | 157 |

| AZ91/C500/5f as extruded | 428 | 219 |

| AZ91/C500/5f T4 | 418 | 176 |

| AZ91/C500/5f T6 | 397 | 184 |

| Element | Concentration (wt %) | ||||||

|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | |

| C | 4.1 | 4 | 5.1 | 6.6 | 3.2 | 74.3 | 8.2 |

| N | - | - | - | - | - | - | 9.5 |

| O | 1.3 | 1.3 | - | 8.1 | 2.5 | 1.4 | 1.2 |

| Mg | 88.8 | 55 | 36.1 | 6.3 | 17.1 | 22.8 | 25.6 |

| Al | 5.4 | 37.1 | 38.3 | 35.2 | 49 | - | 55.3 |

| Si | - | - | 0.6 | 0.7 | 0.2 | - | 0.2 |

| Ca | - | - | - | 0.4 | - | 1.5 | - |

| Mn | - | - | 19.9 | 42.7 | 28.1 | - | - |

| Zn | 0.3 | 2.7 | - | - | - | - | - |

| Sample | Average Grain Size (µm) | ||

|---|---|---|---|

| As Extruded | T4 | T6 | |

| AZ91 | 7.6 (±2.2) | 19.0 (±4.1) | 19.4 (±9.8) |

| AZ91/C100/5f | 5.2 (±0.4) | 16.3 (±5.1) | 13.5 (±2.2) |

| AZ91/C500/5f | 5.5 (±0.4) | 11.1 (±1.6) | 12.6 (±3.5) |

| Sample | TVF |

|---|---|

| AZ91 as extruded | 0.62 |

| AZ91 T4 | 0.64 |

| AZ91 T6 | 0.62 |

| AZ91/C100/5f as extruded | 0.54 |

| AZ91/C100/5f T4 | 0.59 |

| AZ91/C100/5f T6 | 0.57 |

| AZ91/C500/5f as extruded | 0.52 |

| AZ91/C500/5f T4 | 0.54 |

| AZ91/C500/5f T6 | 0.53 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mance, S.; Dieringa, H.; Bohlen, J.; Gavras, S.; Stark, A.; Schell, N.; Pereira da Silva, J.; Tolnai, D. In Situ Synchrotron Radiation Diffraction Study of Compression of AZ91 Composites Reinforced with Recycled Carbon Fibres. Crystals 2022, 12, 1502. https://doi.org/10.3390/cryst12111502

Mance S, Dieringa H, Bohlen J, Gavras S, Stark A, Schell N, Pereira da Silva J, Tolnai D. In Situ Synchrotron Radiation Diffraction Study of Compression of AZ91 Composites Reinforced with Recycled Carbon Fibres. Crystals. 2022; 12(11):1502. https://doi.org/10.3390/cryst12111502

Chicago/Turabian StyleMance, Sophie, Hajo Dieringa, Jan Bohlen, Sarkis Gavras, Andreas Stark, Norbert Schell, João Pereira da Silva, and Domonkos Tolnai. 2022. "In Situ Synchrotron Radiation Diffraction Study of Compression of AZ91 Composites Reinforced with Recycled Carbon Fibres" Crystals 12, no. 11: 1502. https://doi.org/10.3390/cryst12111502

APA StyleMance, S., Dieringa, H., Bohlen, J., Gavras, S., Stark, A., Schell, N., Pereira da Silva, J., & Tolnai, D. (2022). In Situ Synchrotron Radiation Diffraction Study of Compression of AZ91 Composites Reinforced with Recycled Carbon Fibres. Crystals, 12(11), 1502. https://doi.org/10.3390/cryst12111502