Construction of Laminated Luminescent Solar Concentrator “Smart” Window Based on Thermoresponsive Polymer and Carbon Quantum Dots

Abstract

1. Introduction

2. Experimental Section

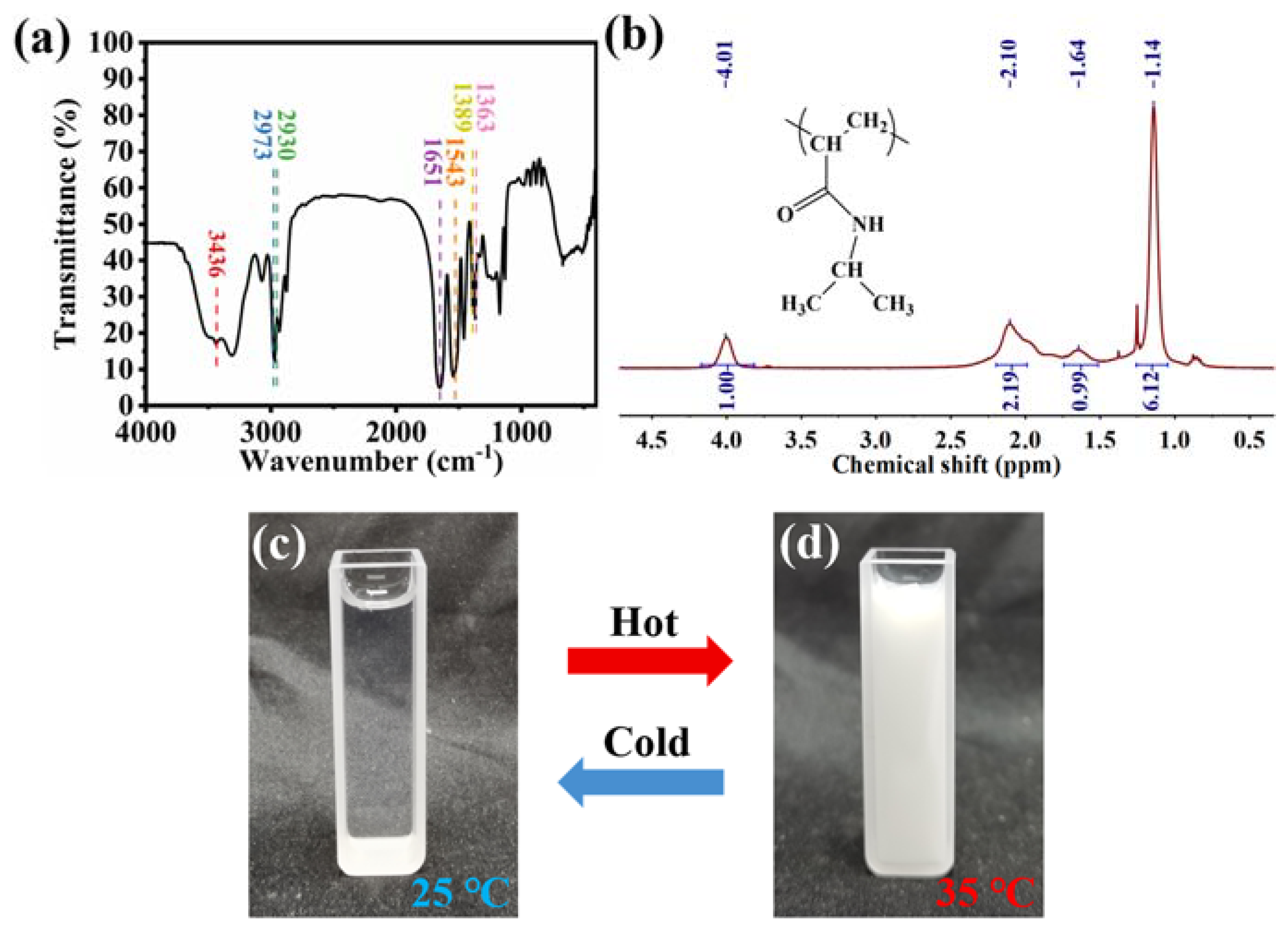

2.1. Synthesis of Thermosensitive Polymer

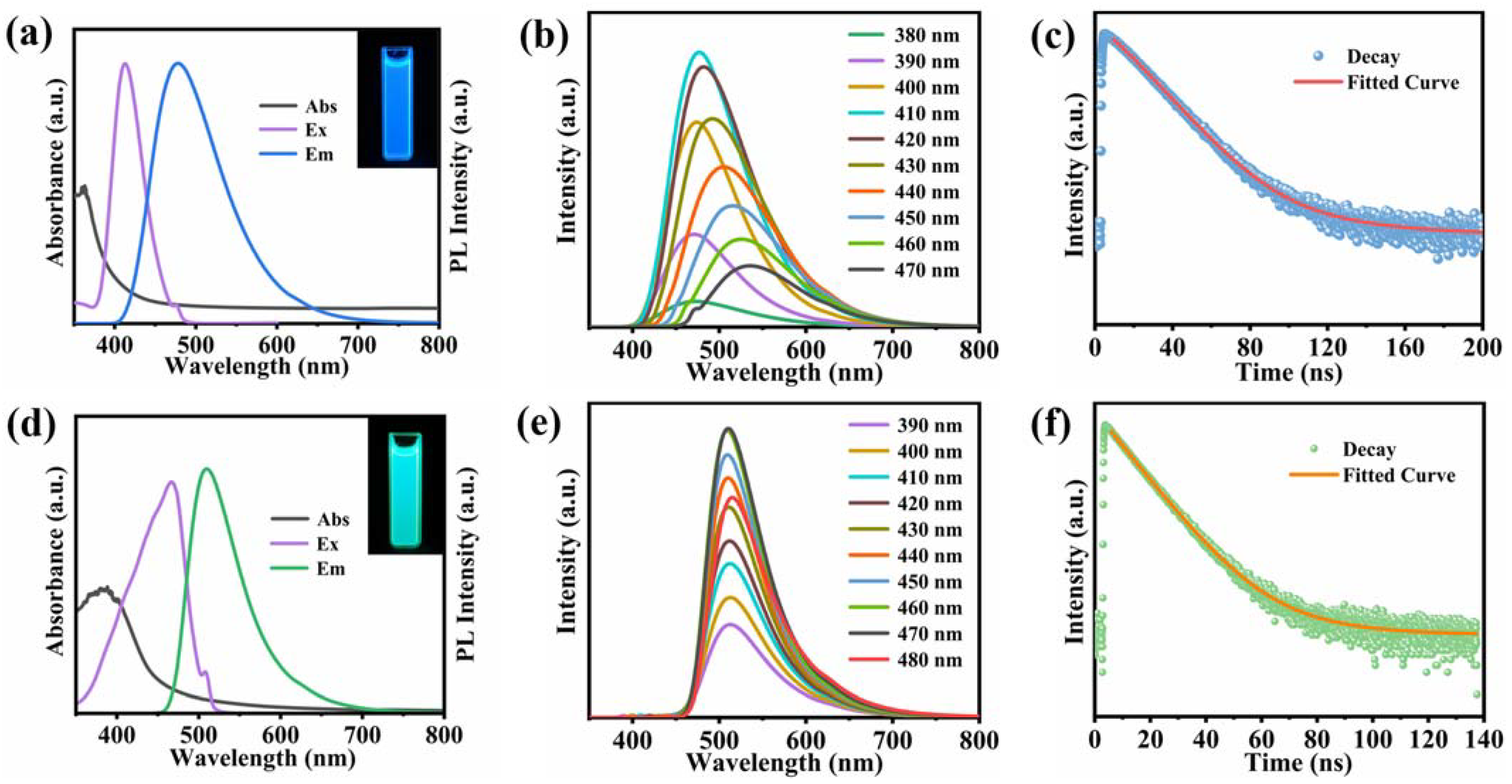

2.2. Synthesis of CQDs

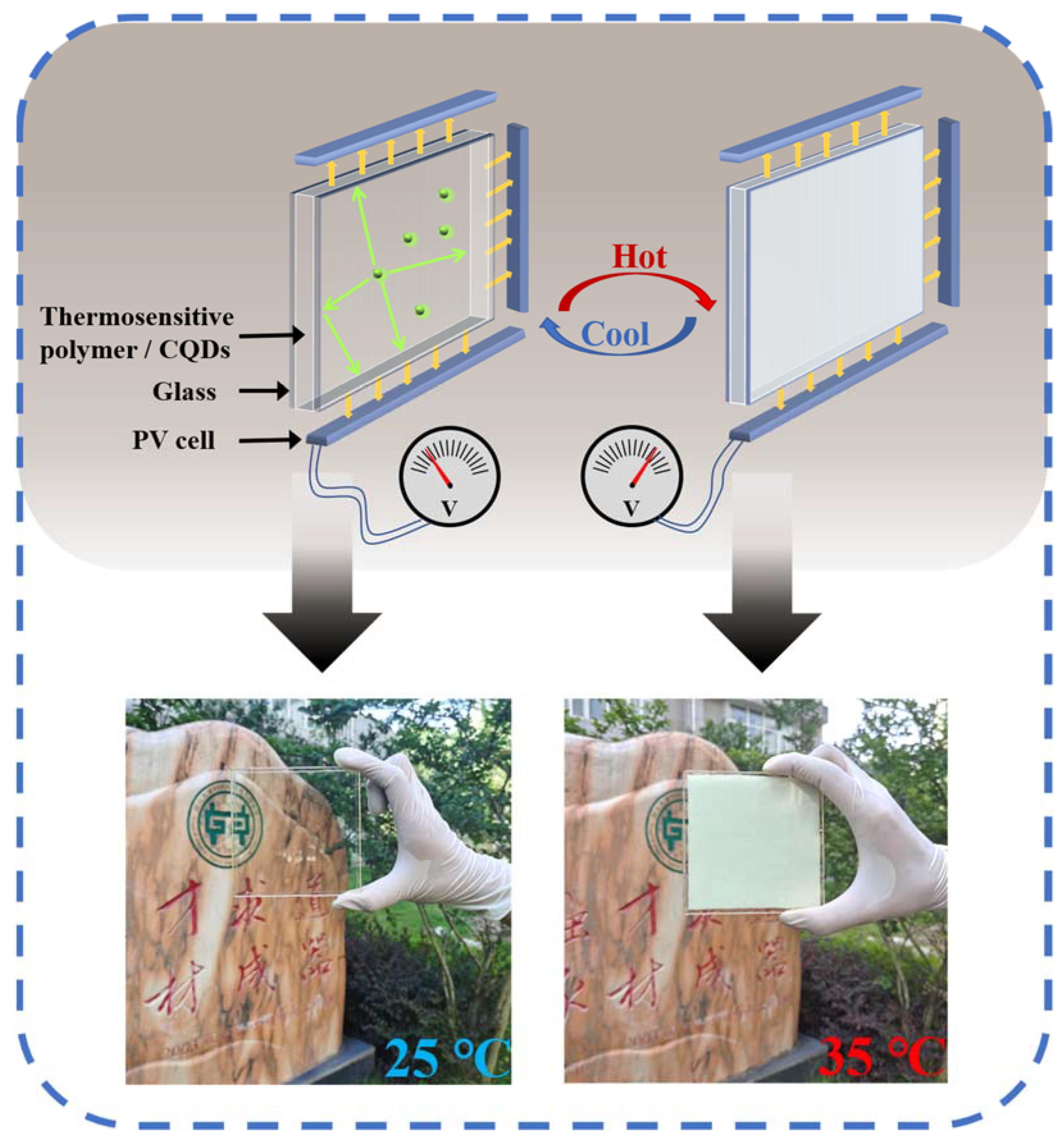

2.3. Fabrication of Laminated LSC-SW

3. Results and Discussion

3.1. Synthesis and Properties of PNIPAm and CQDs

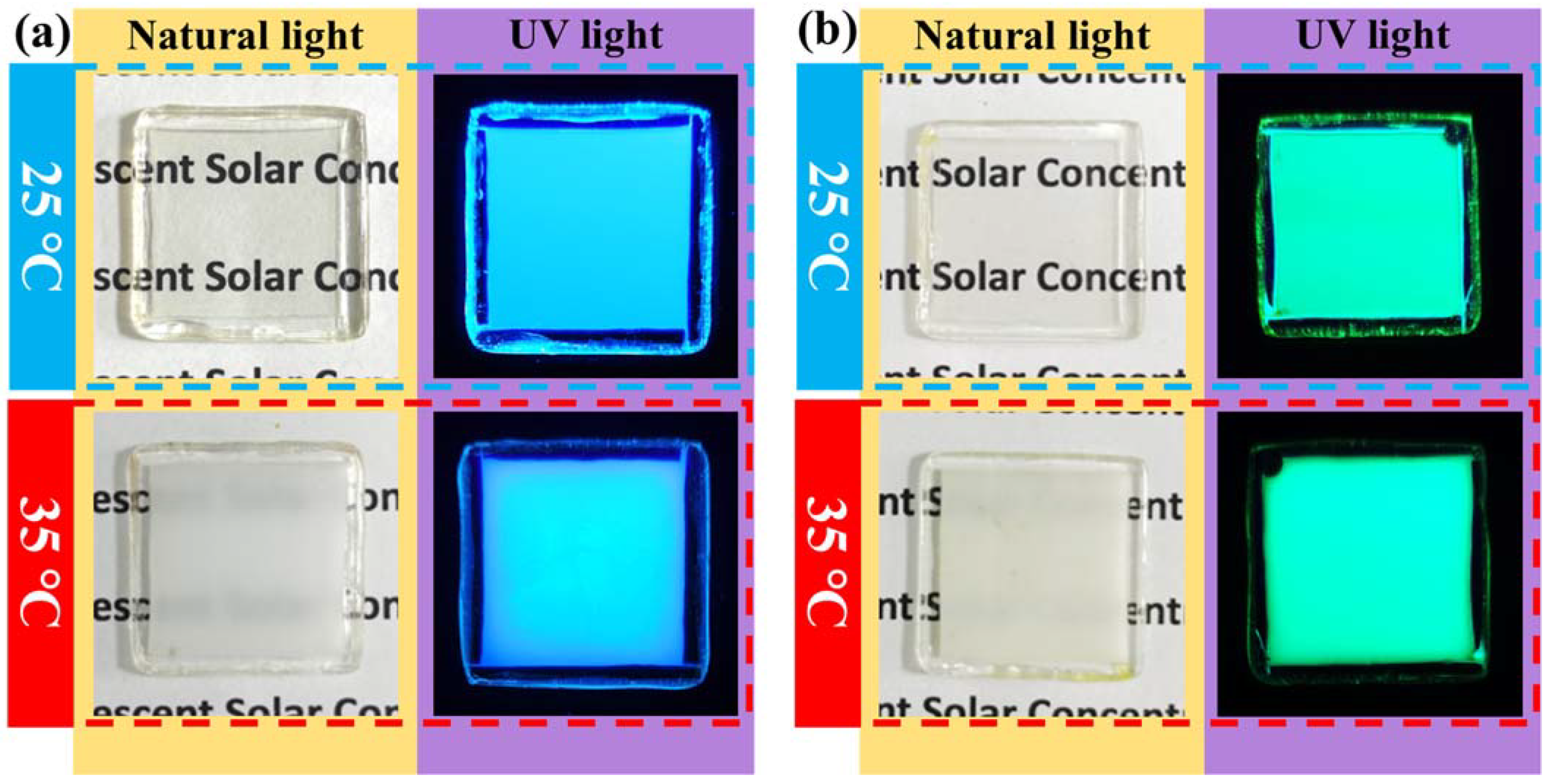

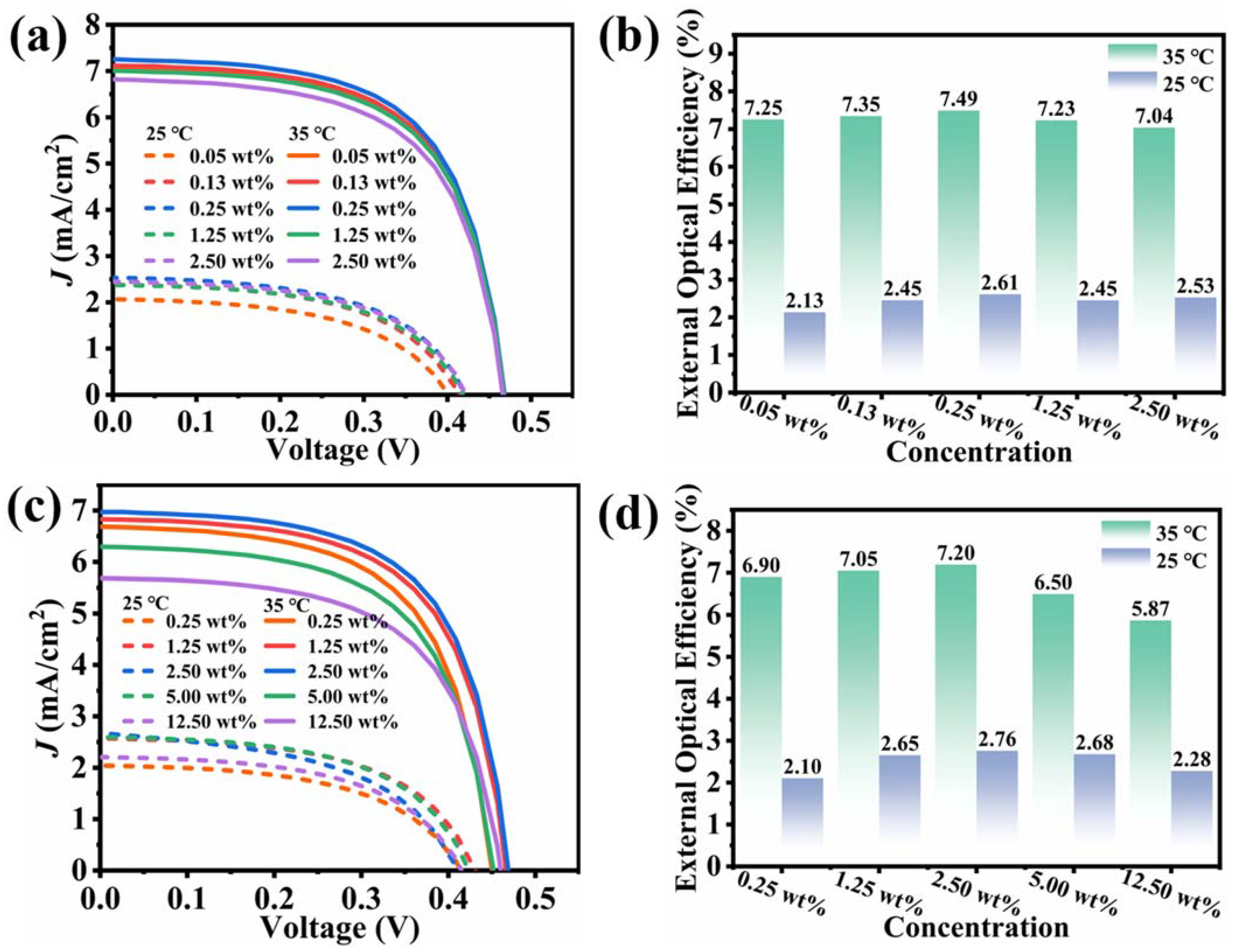

3.2. Fabrication and Performances of Laminated LSC-SW

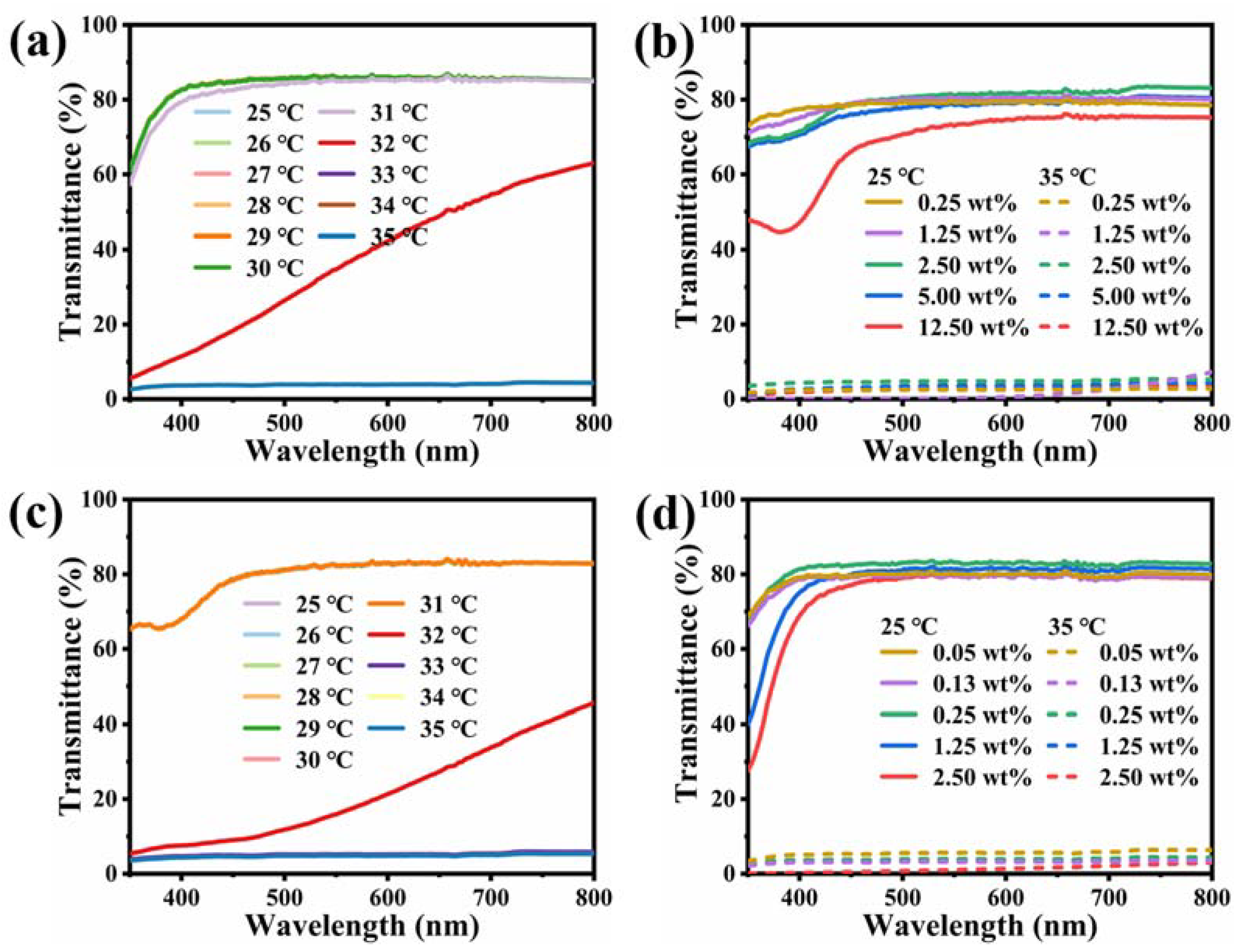

3.3. Temperature Response of Laminated LSC-SWs

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Vasiliev, M.; Nur-E-Alam, M.; Alameh, K. Recent developments in solar energy-harvesting technologies for building integration and distributed energy generation. Energies 2019, 12, 1080. [Google Scholar] [CrossRef]

- Nie, Y.; He, W.; Liu, X.; Hu, Z.; Yu, H.; Liu, H. Smart luminescent solar concentrator as a BICPV window. Build. Simul. 2022, 15, 1789–1798. [Google Scholar] [CrossRef]

- Debije, M.G.; Verbunt, P.P.C. Thirty years of luminescent solar concentrator research: Solar energy for the built environment. Adv. Energy Mater. 2012, 2, 12–35. [Google Scholar] [CrossRef]

- Papakonstantinou, I.; Portnoi, M.; Debije, M.G. The hidden potential of luminescent solar concentrators. Adv. Energy Mater. 2020, 11, 2002883. [Google Scholar] [CrossRef]

- Iasilli, G.; Francischello, R.; Lova, P.; Silvano, S.; Surace, A.; Pesce, G.; Alloisio, M.; Patrini, M.; Shimizu, M.; Comoretto, D.; et al. Luminescent solar concentrators: Boosted optical efficiency by polymer dielectric mirrors. Mater. Chem. Front. 2019, 3, 429–436. [Google Scholar] [CrossRef]

- Li, Z.; Zhao, X.; Huang, C.; Gong, X. Recent advances in green fabrication of luminescent solar concentrators using nontoxic quantum dots as fluorophores. J. Mater. Chem. C 2019, 7, 12373–12387. [Google Scholar] [CrossRef]

- Kim, A.; Hosseinmardi, A.; Annamalai, P.K.; Kumar, P.; Patel, R. Review on colloidal quantum dots luminescent solar concentrators. ChemistrySelect 2021, 6, 4948–4967. [Google Scholar] [CrossRef]

- Papucci, C.; Charaf, R.; Coppola, C.; Sinicropi, A.; di Donato, M.; Taddei, M.; Foggi, P.; Battisti, A.; de Jong, B.; Zani, L.; et al. Luminescent solar concentrators with outstanding optical properties by employment of D-A-D quinoxaline fluorophores. J. Mater. Chem. C 2021, 9, 15608–15621. [Google Scholar] [CrossRef]

- Zhao, H.; Zhou, Y.; Benetti, D.; Ma, D.; Rosei, F. Perovskite quantum dots integrated in large-area luminescent solar concentrators. Nano Energy 2017, 37, 214–223. [Google Scholar] [CrossRef]

- Li, Y.; Miao, P.; Zhou, W.; Gong, X.; Zhao, X. N-doped carbon-dots for luminescent solar concentrators. J. Mater. Chem. A 2017, 5, 21452–21459. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhao, H.; Ma, D.; Rosei, F. Harnessing the properties of colloidal quantum dots in luminescent solar concentrators. Chem. Soc. Rev. 2018, 47, 5866–5890. [Google Scholar] [CrossRef]

- Ma, W.; Li, W.; Liu, R.; Cao, M.; Zhao, X.; Gong, X. Carbon dots and AIE molecules for highly efficient tandem luminescent solar concentrators. Chem. Commun. 2019, 55, 7486–7489. [Google Scholar] [CrossRef]

- Mateen, F.; Ali, M.; Lee, S.Y.; Jeong, S.H.; Ko, M.J.; Hong, S.-K. Tandem structured luminescent solar concentrator based on inorganic carbon quantum dots and organic dyes. Solar Energy 2019, 190, 488–494. [Google Scholar] [CrossRef]

- Cohen, T.A.; Milstein, T.J.; Kroupa, D.M.; MacKenzie, J.D.; Luscombe, C.K.; Gamelin, D.R. Quantum-cutting Yb3+-doped perovskite nanocrystals for monolithic bilayer luminescent solar concentrators. J. Mater. Chem. A 2019, 7, 9279–9288. [Google Scholar] [CrossRef]

- Roncali, J. Luminescent solar collectors: Quo Vadis? Adv. Energy Mater. 2020, 10, 2001907. [Google Scholar] [CrossRef]

- Zdražil, L.; Kalytchuk, S.; Holá, K.; Petr, M.; Zmeškal, O.; Kment, S.; Rogach, A.L.; Zbořil, R. A carbon dot-based tandem luminescent solar concentrator. Nanoscale 2020, 12, 6664–6672. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Wang, J.; Xu, Y.; Jin, J.; Xiao, W.; Tan, D.; Li, J.; Mei, T.; Xue, L.; Wang, X. Controlled synthesis of long-wavelength multicolor-emitting carbon dots for highly efficient tandem luminescent solar concentrators. ACS Appl. Mater. Interfaces 2020, 3, 12230–12237. [Google Scholar] [CrossRef]

- Zhao, H.; Liu, G.; You, S.; Camargo, F.V.A.; Zavelani-Rossi, M.; Wang, X.; Sun, C.; Liu, B.; Zhang, Y.; Han, G.; et al. Gram-scale synthesis of carbon quantum dots with a large Stokes shift for the fabrication of eco-friendly and high-efficiency luminescent solar concentrators. Energy Environ. Sci. 2021, 14, 396–406. [Google Scholar] [CrossRef]

- Wu, J.; Xin, W.; Wu, Y.; Zhan, Y.; Li, J.; Wang, J.; Huang, S.; Wang, X. Solid-state photoluminescent silicone-carbon dots/dendrimer composites for highly efficient luminescent solar concentrators. Chem. Eng. J. 2021, 422, 130158. [Google Scholar] [CrossRef]

- Han, Y.; Zhao, X.; Vomiero, A.; Gong, X.; Zhao, H. Red and green-emitting biocompatible carbon quantum dots for efficient tandem luminescent solar concentrators. J. Mater. Chem. C 2021, 9, 12255–12262. [Google Scholar] [CrossRef]

- Li, J.; Zhao, H.; Zhao, X.; Gong, X. Red and yellow emissive carbon dots integrated tandem luminescent solar concentrators with significantly improved efficiency. Nanoscale 2021, 13, 9561–9569. [Google Scholar] [CrossRef] [PubMed]

- Han, Y.; Liccardo, L.; Moretti, E.; Zhao, H.; Vomiero, A. Synthesis, optical properties and applications of red/near-infrared carbon dots. J. Mater. Chem. C 2022, 10, 11827–11847. [Google Scholar] [CrossRef]

- Xin, W.; Wang, J.; Xu, B.; Wu, J.; Wang, J.; Ren, Z.; Cai, C.; Xue, C.; Li, J.; Wang, X. Construction of highly efficient carbon dots-based polymer photonic luminescent solar concentrators with sandwich structure. Nanotechnology 2022, 33, 305601. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.N.; Yang, S. Responsive smart windows from nanoparticle–polymer composites. Adv. Funct. Mater. 2019, 30, 1902597. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, C.; Chen, K.; Yin, Y. Raspberry-shaped thermochromic energy Storage nanocapsule with tunable sunlight absorption based on color change for temperature regulation. Small 2019, 15, e1903750. [Google Scholar] [CrossRef] [PubMed]

- Zhuang, B.; Dai, Z.; Pang, S.; Xu, H.; Sun, L.; Ma, F. 3D ordered macroporous VO2 thin films with an efficient thermochromic modulation capability for advanced smart windows. Adv. Opt. Mater. 2019, 7, 1900600. [Google Scholar] [CrossRef]

- Xie, Y.; Guan, F.; Li, Z.; Meng, Y.; Cheng, J.; Li, L.; Pei, Q. A phase-changing polymer film for broadband smart window applications. Macromol. Rapid Commun. 2020, 41, e2000290. [Google Scholar] [CrossRef]

- Li, K.; Meng, S.; Xia, S.; Ren, X.; Gao, G. Durable and controllable smart windows based on thermochromic hydrogels. ACS Appl. Mater. Interfaces 2020, 12, 42193–42201. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Dong, X.; Mi, Y.; Fan, F.; Xu, Q.; Zhao, H.; Wang, S.; Long, Y. Hydrogel smart windows. J. Mater. Chem. A 2020, 8, 10007–10025. [Google Scholar] [CrossRef]

- Torres-Pierna, H.; Ruiz-Molina, D.; Roscini, C. Highly transparent photochromic films with a tunable and fast solution-like response. Mater. Horiz. 2020, 7, 2749–2759. [Google Scholar] [CrossRef]

- Chen, G.; Hong, W. Mechanochromism of structural-colored materials. Adv. Opt. Mater. 2020, 8, 2000984. [Google Scholar] [CrossRef]

- Hu, F.; Yan, B.; Ren, E.; Gu, Y.; Lin, S.; Ye, L.; Chen, S.; Zeng, H. Constructing spraying-processed complementary smart windows via electrochromic materials with hierarchical nanostructures. J. Mater. Chem. C 2019, 7, 14855–14860. [Google Scholar] [CrossRef]

- Islam, S.M.; Palma, A.A.; Gautam, R.P.; Barile, C.J. Hybrid dynamic windows with color neutrality and fast switching using reversible metal electrodeposition and cobalt hexacyanoferrate electrochromism. ACS Appl. Mater. Interfaces 2020, 12, 44874–44882. [Google Scholar] [CrossRef]

- Zheng, R.; Wang, Y.; Pan, J.; Malik, H.A.; Zhang, H.; Jia, C.; Weng, X.; Xie, J.; Deng, L. Toward easy-to-assemble, large-area smart windows: All-in-one cross-linked electrochromic material and device. ACS Appl. Mater. Interfaces 2020, 12, 27526–27536. [Google Scholar] [CrossRef] [PubMed]

- Feng, M.; Bu, X.; Yang, J.; Li, D.; Zhang, Z.; Dai, Y.; Zhang, X. Review: Smart windows based on photonic crystals. J. Mater. Sci. 2020, 55, 8444–8463. [Google Scholar] [CrossRef]

- Zhang, S.; Cao, S.; Zhang, T.; Lee, J.Y. Plasmonic oxygen-deficient TiO2-x nanocrystals for dual-band electrochromic smart windows with efficient energy recycling. Adv. Mater. 2020, 32, e2004686. [Google Scholar] [CrossRef]

- Wang, J.L.; Sheng, S.Z.; He, Z.; Wang, R.; Pan, Z.; Zhao, H.Y.; Liu, J.W.; Yu, S.H. Self-powered flexible electrochromic smart window. Nano. Lett. 2021, 21, 9976–9982. [Google Scholar] [CrossRef]

- Wang, Z.; Jia, X.; Zhang, P.; Liu, Y.; Qi, H.; Zhang, P.; Kaiser, U.; Reineke, S.; Dong, R.; Feng, X. Viologen-immobilized 2D polymer film enabling highly efficient electrochromic device for solar-powered smart window. Adv. Mater. 2022, 34, e2106073. [Google Scholar] [CrossRef]

- Sol, J.; Dehm, V.; Hecht, R.; Wurthner, F.; Schenning, A.; Debije, M.G. Temperature-responsive luminescent solar concentrators: Tuning energy transfer in a liquid crystalline matrix. Angew. Chem. Int. Ed. 2018, 57, 1030–1033. [Google Scholar] [CrossRef]

- Sol, J.A.H.P.; Timmermans, G.H.; Breugel, A.J.; Schenning, A.P.H.J.; Debije, M.G. Multistate luminescent solar concentrator “smart” windows. Adv. Energy Mater. 2018, 8, 1702922. [Google Scholar] [CrossRef]

- Mateen, F.; Ali, M.; Oh, H.; Hong, S.-K. Nitrogen-doped carbon quantum dot based luminescent solar concentrator coupled with polymer dispersed liquid crystal device for smart management of solar spectrum. Sol. Energy 2019, 178, 48–55. [Google Scholar] [CrossRef]

- Havrlík, M.; Libra, M.; Poulek, V.; Kouřím, P. Analysis of Output Signal Distortion of Galvanic Isolation Circuits for Monitoring the Mains Voltage Waveform. Sensors 2022, 22, 7769. [Google Scholar] [CrossRef]

- Li, X.-H.; Liu, C.; Feng, S.-P.; Fang, N.X. Broadband light management with thermochromic hydrogel microparticles for smart windows. Joule 2019, 3, 290–302. [Google Scholar] [CrossRef]

- Zhang, Y.; Song, H.; Wang, L.; Yu, J.; Wang, B.; Hu, Y.; Zang, S.Q.; Yang, B.; Lu, S. Solid-state red laser with a single longitudinal mode from carbon dots. Angew. Chem. Int. Ed. 2021, 60, 25514–25521. [Google Scholar] [CrossRef] [PubMed]

- Yang, C.; Atwater, H.A.; Baldo, M.A.; Baran, D.; Barile, C.J.; Barr, M.C.; Bates, M.; Bawendi, M.G.; Bergren, M.R.; Borhan, B.; et al. Consensus statement: Standardized reporting of power-producing luminescent solar concentrator performance. Joule 2022, 6, 8–15. [Google Scholar] [CrossRef]

- Rana, M.M.; Rajeev, A.; Natale, G.; De la Hoz Siegler, H. Effects of synthesis-solvent polarity on the physicochemical and rheological properties of poly(N-isopropylacrylamide) (PNIPAm) hydrogels. J. Mater. Res. Technol. 2021, 13, 769–786. [Google Scholar] [CrossRef]

- Jadhav, S.A.; Brunella, V.; Miletto, I.; Berlier, G.; Scalarone, D. Synthesis of poly(N-isopropylacrylamide) by distillation precipitation polymerization and quantitative grafting on mesoporous silica. J. Appl. Polym. Sci. 2016, 133, 44181. [Google Scholar] [CrossRef]

- Li, F.; Li, Y.; Yang, X.; Han, X.; Jiao, Y.; Wei, T.; Yang, D.; Xu, H.; Nie, G. Highly fluorescent chiral N-S-doped carbon dots from cysteine: Affecting cellular energy metabolism. Angew. Chem. Int. Ed. 2018, 57, 2377–2382. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Liu, X.; Fan, Y.; Guo, X.; Zhou, L.; Lv, Y.; Lin, J. One-step microwave synthesis of N-doped hydroxyl-functionalized carbon dots with ultra-high fluorescence quantum yields. Nanoscale 2016, 8, 15281–15287. [Google Scholar] [CrossRef]

- Talite, M.J.; Huang, H.Y.; Wu, Y.H.; Sena, P.G.; Cai, K.B.; Lin, T.N.; Shen, J.L.; Chou, W.C.; Yuan, C.T. Greener luminescent solar concentrators with high loading contents based on in situ cross-linked carbon nanodots for enhancing solar energy harvesting and resisting concentration-induced quenching. ACS Appl. Mater. Interfaces 2018, 10, 34184–34192. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, C.; Fan, Y.; Wang, C.; Yang, R.; Liu, X.; Zhou, L. A self-quenching-resistant carbon nanodot powder with multicolored solid-state fluorescence for ultra-fast staining of various representative bacterial species within one minute. Nanoscale 2016, 8, 19744–19753. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Wang, S.; Peng, J.; Tan, Y.; Li, C.; Boey, F.Y.C.; Long, Y. Liquid thermo-responsive smart window derived from hydrogel. Joule 2020, 4, 2458–2474. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, B.; Wang, J.; Cai, C.; Xin, W.; Wei, L.; Yang, Q.; Peng, B.; Hu, Y.; Li, J.; Wang, X. Construction of Laminated Luminescent Solar Concentrator “Smart” Window Based on Thermoresponsive Polymer and Carbon Quantum Dots. Crystals 2022, 12, 1612. https://doi.org/10.3390/cryst12111612

Xu B, Wang J, Cai C, Xin W, Wei L, Yang Q, Peng B, Hu Y, Li J, Wang X. Construction of Laminated Luminescent Solar Concentrator “Smart” Window Based on Thermoresponsive Polymer and Carbon Quantum Dots. Crystals. 2022; 12(11):1612. https://doi.org/10.3390/cryst12111612

Chicago/Turabian StyleXu, Bing, Jianying Wang, Chen Cai, Wei Xin, Lai Wei, Qinsi Yang, Bo Peng, Yuandu Hu, Jinhua Li, and Xianbao Wang. 2022. "Construction of Laminated Luminescent Solar Concentrator “Smart” Window Based on Thermoresponsive Polymer and Carbon Quantum Dots" Crystals 12, no. 11: 1612. https://doi.org/10.3390/cryst12111612

APA StyleXu, B., Wang, J., Cai, C., Xin, W., Wei, L., Yang, Q., Peng, B., Hu, Y., Li, J., & Wang, X. (2022). Construction of Laminated Luminescent Solar Concentrator “Smart” Window Based on Thermoresponsive Polymer and Carbon Quantum Dots. Crystals, 12(11), 1612. https://doi.org/10.3390/cryst12111612