Mechanical and Microstructural Behavior of Tempered CPM® 3V High-Density Sintered Tool Steel

Abstract

1. Introduction

1.1. CPM® 3V and Tool Steels

1.2. Hardening and Tempering Steels

1.3. Microstructures of Hardenable Steel

2. Materials and Methods

2.1. Bulk Composition

2.2. Sample Preparation

2.2.1. Standard Test Specimen Machining

2.2.2. Heat Treating

2.3. Mechanical Testing

2.3.1. ASTM E8 Tensile Testing

2.3.2. Hardness Testing

2.4. Analysis

2.4.1. Fractography

2.4.2. Microstructural and Elemental Analysis

2.4.3. X-ray Diffraction

3. Results and Discussion

3.1. Mechanical Behavior

3.1.1. Strength

3.1.2. Ductility

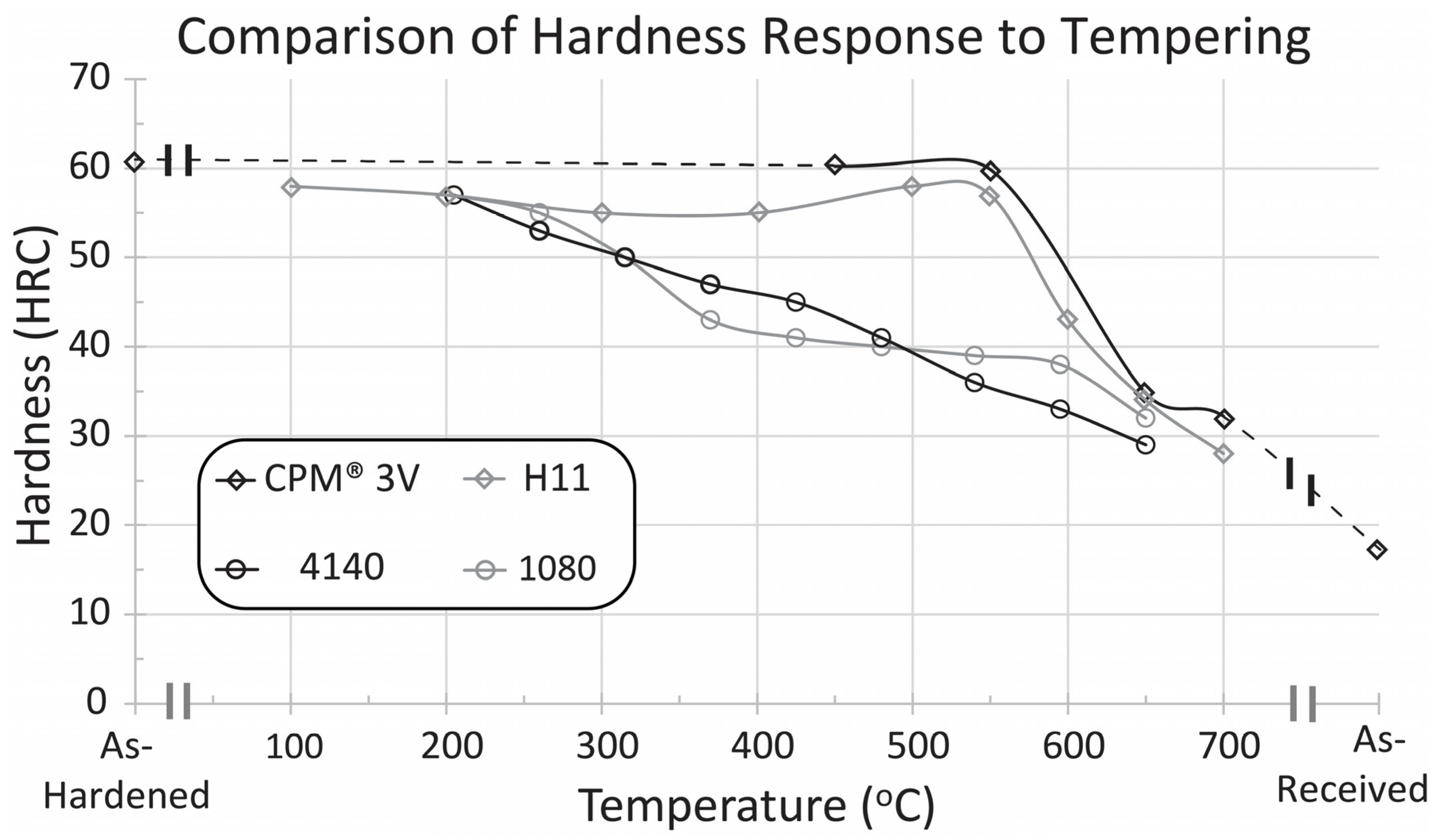

3.1.3. Hardness

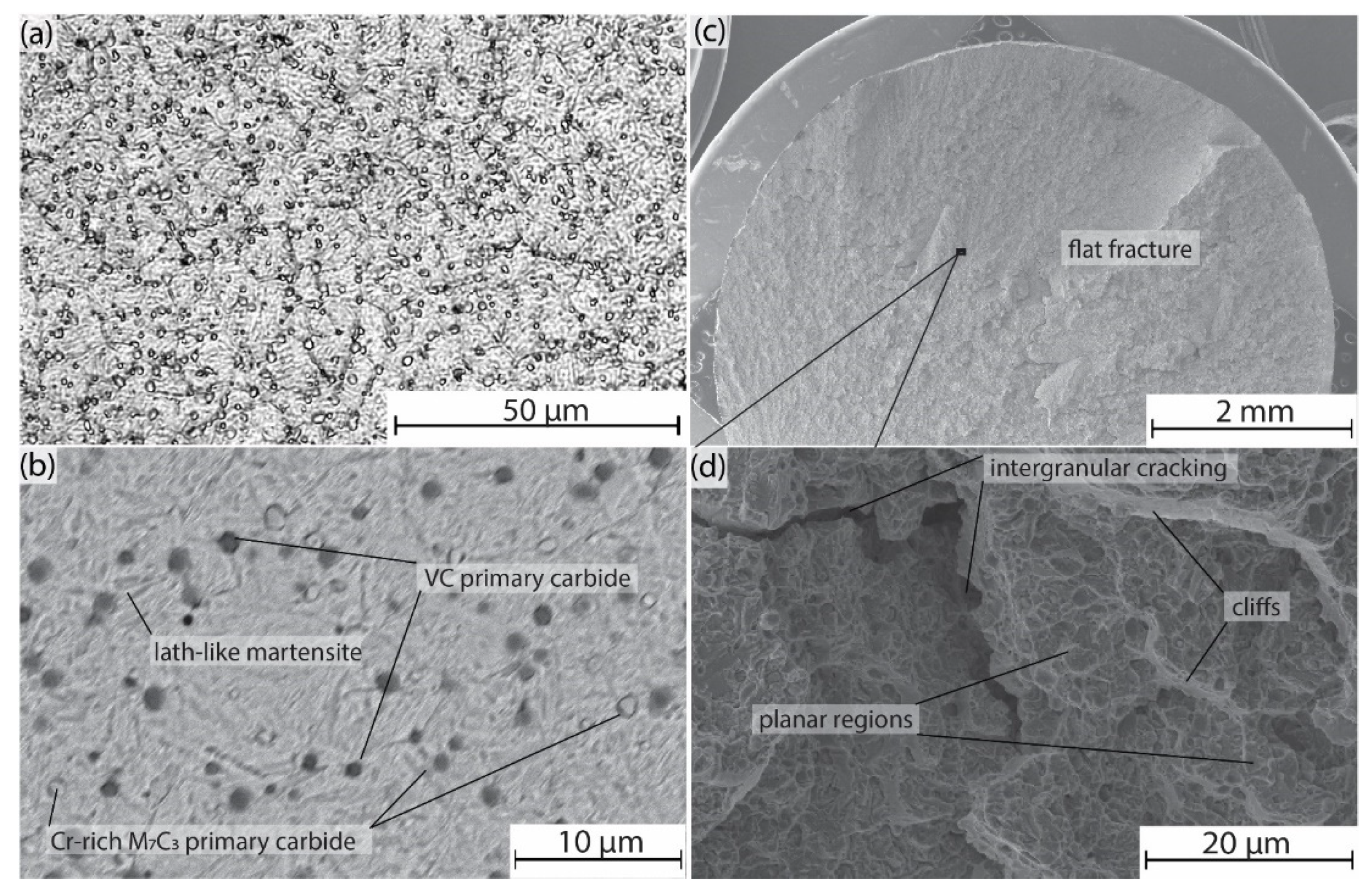

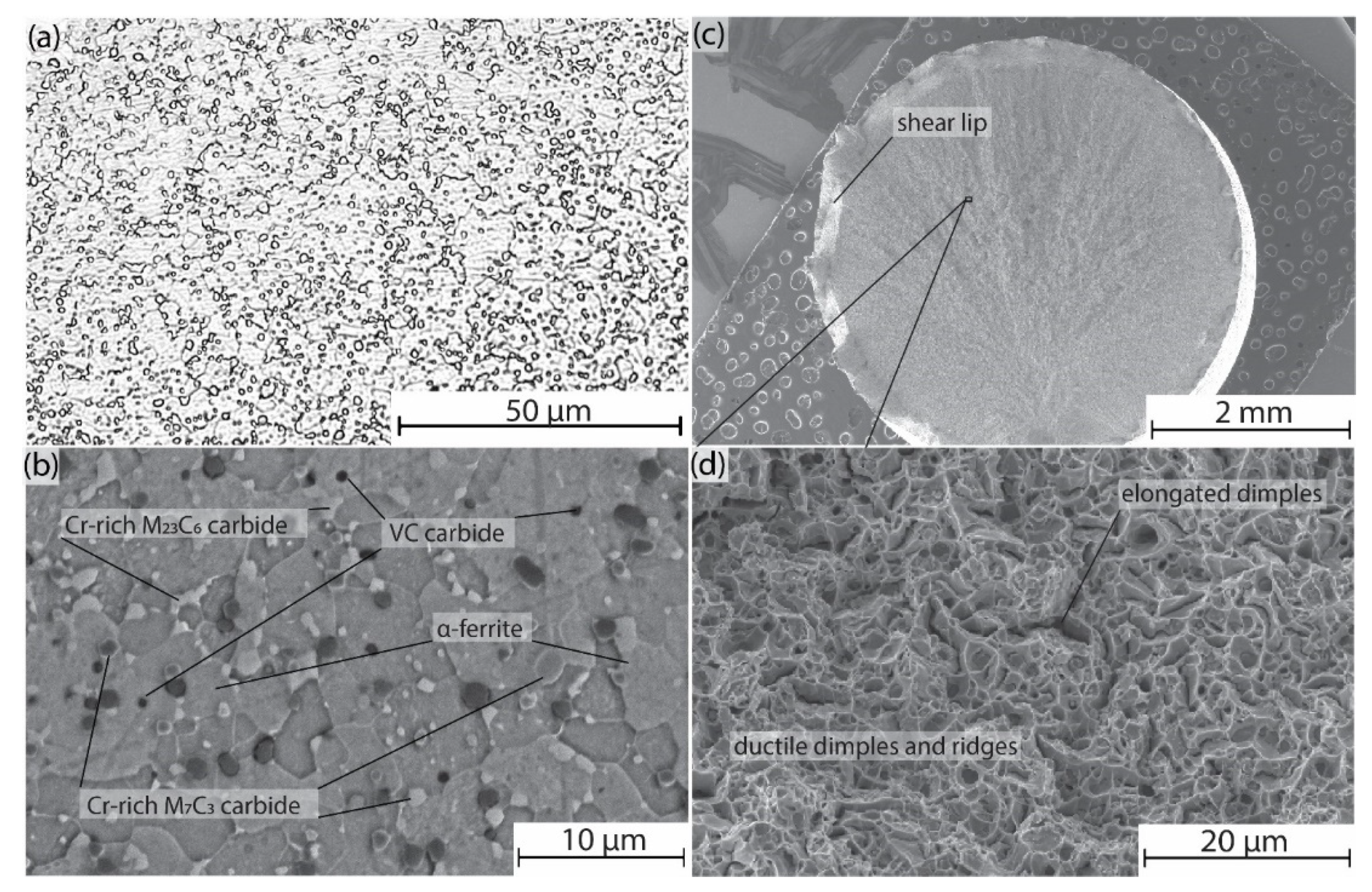

3.2. Microscopic Observations

3.2.1. As-Hardened

3.2.2. 450 °C Tempering

3.2.3. 550 °C Tempering

3.2.4. 650 °C Tempering

3.2.5. 700 °C Tempering

3.2.6. As-Received

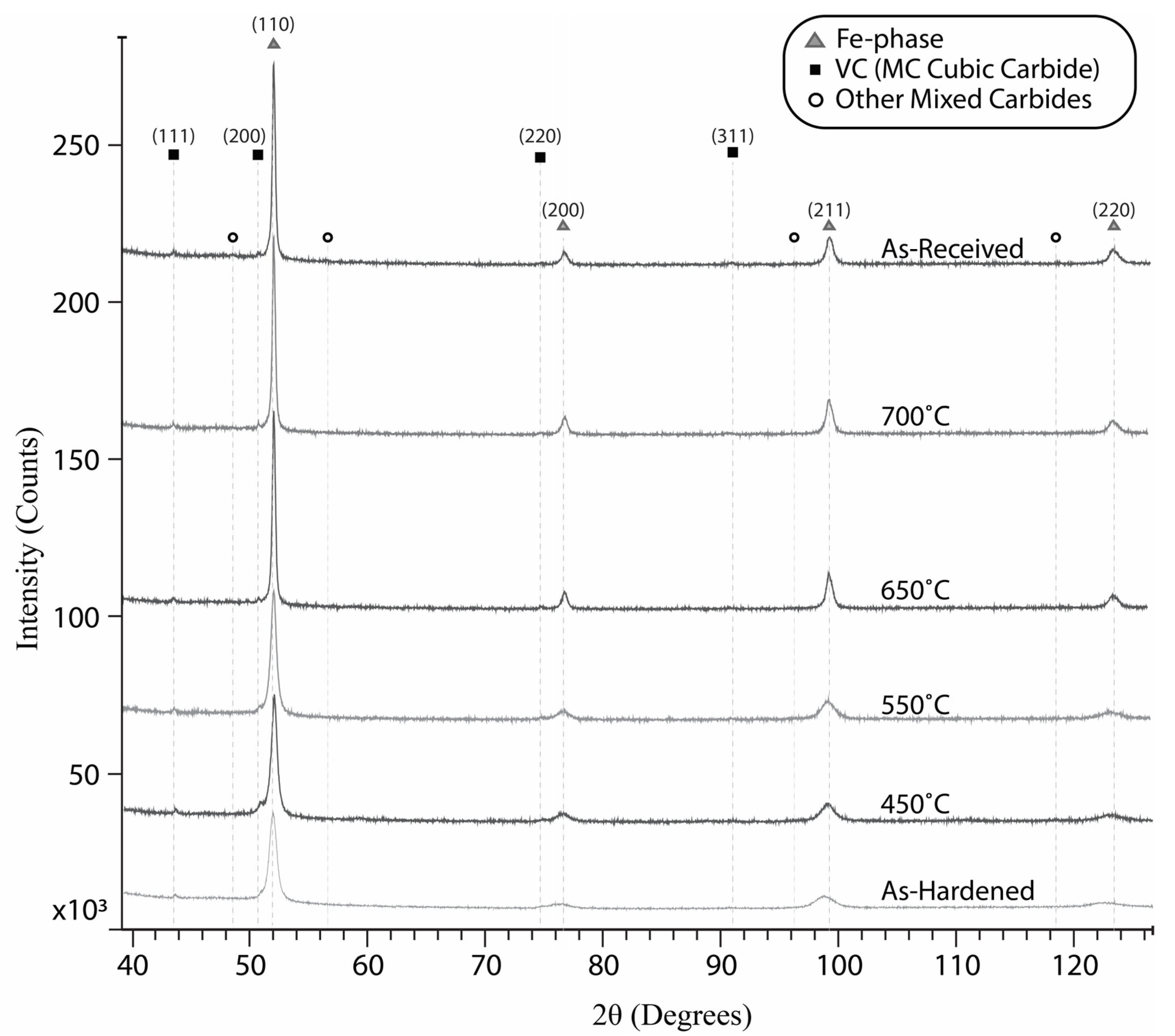

3.3. Crystallographic Trends

3.4. Relationship of Process, Microstructure, and Mechanical Behavior

3.5. CPM® 3V Mechanical Behavior Comparison with Other Steels

4. Conclusions

- Primary carbides did not appear to change among tempering treatments;

- 550 °C is the optimal tempering temperature for high strength applications;

- CPM® 3V steel tempered at ≥650° C contains tempered martensite with secondary carbides and results in a ~50% decrease in strength and a ~200% increase in ductility relative to the 550 °C treatment;

- The CPM® 3V tempering response is similar to the industrially used steel H11.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Crucible Selector—CPM® 3V. Available online: https://www.crucible.com/eselector/prodbyapp/tooldie/cpm3vt.html (accessed on 24 March 2022).

- Canale, L.C.; Albano, L.; Totten, G.E.; Meekisho, L. Hardenability of steel. Compr. Mater. Process. 2014, 12, 39–97. [Google Scholar]

- Olevsky, E.A. Theory of sintering: From discrete to continuum. Mater. Sci. Eng. R Rep. 1998, 23, 41–100. [Google Scholar] [CrossRef]

- Boccalini, M.; Goldenstein, H. Solidification of high speed steels. Int. Mater. Rev. 2001, 46, 92–115. [Google Scholar] [CrossRef]

- Song, J.; Gelin, J.C.; Barriere, T.; Liu, B. Experiments and numerical modelling of solid state sintering for 316L stainless steel components. J. Mater. Process. Technol. 2006, 177, 352–355. [Google Scholar] [CrossRef]

- Benedetti, M.; Torresani, E.; Leoni, M.; Fontanari, V.; Bandini, M.; Pederzolli, C.; Potrich, C. The effect of post-sintering treatments on the fatigue and biological behavior of Ti-6Al-4V ELI parts made by selective laser melting. J. Mech. Behav. Biomed. Mater. 2017, 71, 295–306. [Google Scholar] [CrossRef] [PubMed]

- Vander Voort, G.F. Metallography and Microstructures; ASM International: Materials Park, OH, USA, 2004; Volume 9. [Google Scholar]

- Dossett, J.L.; Totten, G.E. Heat Treating; ASM International: Materials Park, OH, USA, 1991; Volume 4. [Google Scholar]

- Callister, W.D.; Rethwisch, D.G. Fundamentals of Materials Science and Engineering; Wiley: London, UK, 2000. [Google Scholar]

- Purdy, G.R.; Brechet, Y.J. A solute drag treatment of the effects of alloying elements on the rate of the proeutectoid ferrite transformation in steels. Acta Metall. Mater. 1995, 43, 3763–3774. [Google Scholar] [CrossRef]

- Thelning, K.E. Dimensional changes during hardening and tempering. In Steel and its Heat Treatment, 2nd ed.; Butterworth-Heinemann: Oxford, UK, 1984. [Google Scholar]

- Laidler, K.J. The development of the Arrhenius equation. J. Chem. Educ. 1984, 61, 494–498. [Google Scholar] [CrossRef]

- Luo, Y.; Guo, H.; Guo, J. Effect of cooling rate on the transformation characteristics and precipitation behaviour of carbides in AISI M42 high-speed steel. Ironmak. Steelmak. 2018, 46, 698–704. [Google Scholar] [CrossRef]

- Bourithis, L.; Papadimitriou, G.D.; Sideris, J. Comparison of wear properties of tool steels AISI D2 and O1 with the same hardness. Tribol. Int. 2006, 39, 479–489. [Google Scholar] [CrossRef]

- Hetzner, D.W.; Van Geertruyden, W. Crystallography and metallography of carbides in high alloy steels. Mater. Charact. 2008, 59, 825–841. [Google Scholar] [CrossRef]

- Horovitz, M.B.; Beneduce Neto, F.; Garbogini, A.; Tschiptschin, A.P. Nitrogen bearing martensitic stainless steels: Microstructure and properties. ISIJ Int. 1996, 36, 840–845. [Google Scholar] [CrossRef]

- Wei, S.; Zhu, J.; Xu, L. Research on wear resistance of high speed steel with high vanadium content. Mater. Sci. Eng. A 2005, 404, 138–145. [Google Scholar] [CrossRef]

- ASTM E8/E8M-16a; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2016.

- Hanson, S.A.C. The Tempering Response of CPM® 3v Tool Steel Investigated through Tensile Testing and Microstructural Observations. Master’s Thesis, Montana Technological University, Butte, MT, USA, May 2022. [Google Scholar]

- Kennett, S.C.; Krauss, G.; Findley, K.O. Prior austenite grain size and tempering effects on the dislocation density of low-C Nb–Ti microalloyed lath martensite. Scr. Mater. 2015, 107, 123–126. [Google Scholar] [CrossRef]

- Li, S.; Xi, X.; Luo, Y.; Mao, M.; Shi, X.; Guo, J.; Guo, H. Carbide precipitation during tempering and its effect on the wear loss of a high-carbon 8 Mass% Cr tool steel. Materials 2018, 11, 2491. [Google Scholar] [CrossRef] [PubMed]

- Bhadeshia, H.; Honeycombe, R. Steels: Microstructure and Properties; Butterworth-Heinemann: Cambridge, MA, USA, 2017. [Google Scholar]

- Candelaria, A.F.; Pinedo, C.E. Influence of the heat treatment on the corrosion resistance of the martensitic stainless steel type AISI 420. J. Mater. Sci. Lett. 2003, 22, 1151–1153. [Google Scholar] [CrossRef]

- Hunkel, M.; Dong, J.; Epp, J.; Kaiser, D.; Dietrich, S.; Schulze, V.; Rajaei, A.; Hallstedt, B.; Broeckmann, C. Comparative study of the tempering behavior of different martensitic steels by means of in-situ diffractometry and dilatometry. Materials 2020, 13, 5058. [Google Scholar] [CrossRef] [PubMed]

- Nolze, G.; Winkelmann, A.; Cios, G.; Tokarski, T. Tetragonality mapping of martensite in a high carbon steel by EBSD. Mater. Charact. 2021, 175, 111040. [Google Scholar] [CrossRef]

- Jumov, G.V. Martensite crystal lattice, mechanism of austenite-martensite transformation and behavior of carbon atoms in martensite. Metall. Trans. A 1976, 7, 999–1011. [Google Scholar] [CrossRef]

- Cheng, L.; Böttger, A.; De Keijser, T.H.; Mittemeijer, E.J. Lattice parameters of iron-carbon and iron-nitrogen martensites and austenites. Scr. Metall. Mater. 1990, 24, 509–514. [Google Scholar] [CrossRef]

- Maruyama, N.; Tabata, S.; Kawata, H. Excess solute carbon and tetragonality in as-quenched Fe-1Mn-C (C: 0.07 to 0.8 mass pct) martensite. Metall. Mater. Trans. A 2020, 51, 1085–1097. [Google Scholar] [CrossRef]

- Christian, J.W. Tetragonal martensites in ferrous alloys—A critique. Mater. Trans. JIM 1992, 33, 208–214. [Google Scholar] [CrossRef]

- Han, K.; Van Genderen, M.J.; Böttger, A.; Zandbergen, H.W.; Mittemeijer, E.J. Initial stages of Fe-C martensite decomposition. Philos. Mag. A 2001, 81, 741–757. [Google Scholar] [CrossRef]

- Mishra, A.; Maity, J. Structure–property correlation of AISI 1080 steel subjected to cyclic quenching treatment. Mater. Sci. Eng. A 2015, 646, 169–181. [Google Scholar] [CrossRef]

- Meysami, A.H.; Ghasemzadeh, R.; Seyedein, S.H.; Aboutalebi, M.R. An investigation on the microstructure and mechanical properties of direct-quenched and tempered AISI 4140 steel. Mater. Des. 2010, 31, 1570–1575. [Google Scholar] [CrossRef]

- Huber, F.; Bischof, C.; Hentschel, O.; Heberle, J.; Zettl, J.; Nagulin, K.Y.; Schmidt, M. Laser beam melting and heat-treatment of 1.2343 (AISI H11) tool steel–microstructure and mechanical properties. Mater. Sci. Eng. A 2019, 742, 109–115. [Google Scholar] [CrossRef]

| Steel Alloy | C | Si | Mn | Cr | Mo | V | P | S | Balance of Fe |

|---|---|---|---|---|---|---|---|---|---|

| CPM® 3V | 0.71 | 0.84 | 0.38 | 7.81 | 1.32 | 2.53 | 0.0115 | 0.0138 | 86.38 |

| Spec ID | HRC Hardness (Standard Deviation) | Max Stress: ksi (MPa) | Yield Stress: ksi (MPa) | % RA | AUC * (lbf/in2) | Avg. AUC |

|---|---|---|---|---|---|---|

| AR * | 17.8 (0.61) | 107 (738) | 76 (524) | 50.6 | 18539 | |

| 700A | 32.2 (0.45) | 147 (1013) | 108 (745) | 42.7 | 20281 | 20544 |

| 700B | 32.2 (0.31) | 150 (1034) | 111 (765) | 40.9 | 20806 | |

| 650A | 34.1 (0.12) | 167 (1151) | 129 (889) | 38.0 | 16749 | 17372 |

| 650B | 34.8 (0.40) | 159 (1096) | 122 (841) | 24.1 | 17995 | |

| 550A | 58.6 (0.31) | 332 (2289) | 287 (1978) | 20.4 | 17971 | 14660 |

| 550C | 59.6 (0.25) | 323 (2227) | 274 (1889) | 7.8 | 11349 | |

| 450A | 60.4 (0.31) | 324 (2227) | 293 (2020) | 1.6 | 4434 | 3471 |

| 450B | 60.0 (0.10) | 303 (2089) | 291 (2006) | 0.8 | 2508 | |

| AH * | 59.9 (0.21) | 268 (1847) | 201 (1386) | 0.8 | 2206 |

| Steel Alloy | C | Si | Mn | Cr | Mo | V | P | S | Balance of Fe |

|---|---|---|---|---|---|---|---|---|---|

| CPM® 3V | 0.71 | 0.84 | 0.38 | 7.81 | 1.32 | 2.53 | 0.0115 | 0.0138 | 86.38 |

| 1080 | 0.80 | 0.30 | 0.75 | 0.10 | 0.03 | - | <0.0350 | <0.0500 | 98.35 |

| 4140 | 0.43 | 0.19 | 0.90 | 0.98 | 0.18 | - | <0.0350 | <0.0500 | 97.24 |

| H11 | 0.40 | 0.90 | - | 5.00 | 1.30 | 0.50 | 0.0150 | 0.0150 | 91.87 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hanson, S.A.C.; Vadiraja, S. Mechanical and Microstructural Behavior of Tempered CPM® 3V High-Density Sintered Tool Steel. Crystals 2022, 12, 1670. https://doi.org/10.3390/cryst12111670

Hanson SAC, Vadiraja S. Mechanical and Microstructural Behavior of Tempered CPM® 3V High-Density Sintered Tool Steel. Crystals. 2022; 12(11):1670. https://doi.org/10.3390/cryst12111670

Chicago/Turabian StyleHanson, Stephen A. C., and Sudhakar Vadiraja. 2022. "Mechanical and Microstructural Behavior of Tempered CPM® 3V High-Density Sintered Tool Steel" Crystals 12, no. 11: 1670. https://doi.org/10.3390/cryst12111670

APA StyleHanson, S. A. C., & Vadiraja, S. (2022). Mechanical and Microstructural Behavior of Tempered CPM® 3V High-Density Sintered Tool Steel. Crystals, 12(11), 1670. https://doi.org/10.3390/cryst12111670