Computational Analysis of Strain-Induced Effects on the Dynamic Properties of C60 in Fullerite

Abstract

:1. Introduction

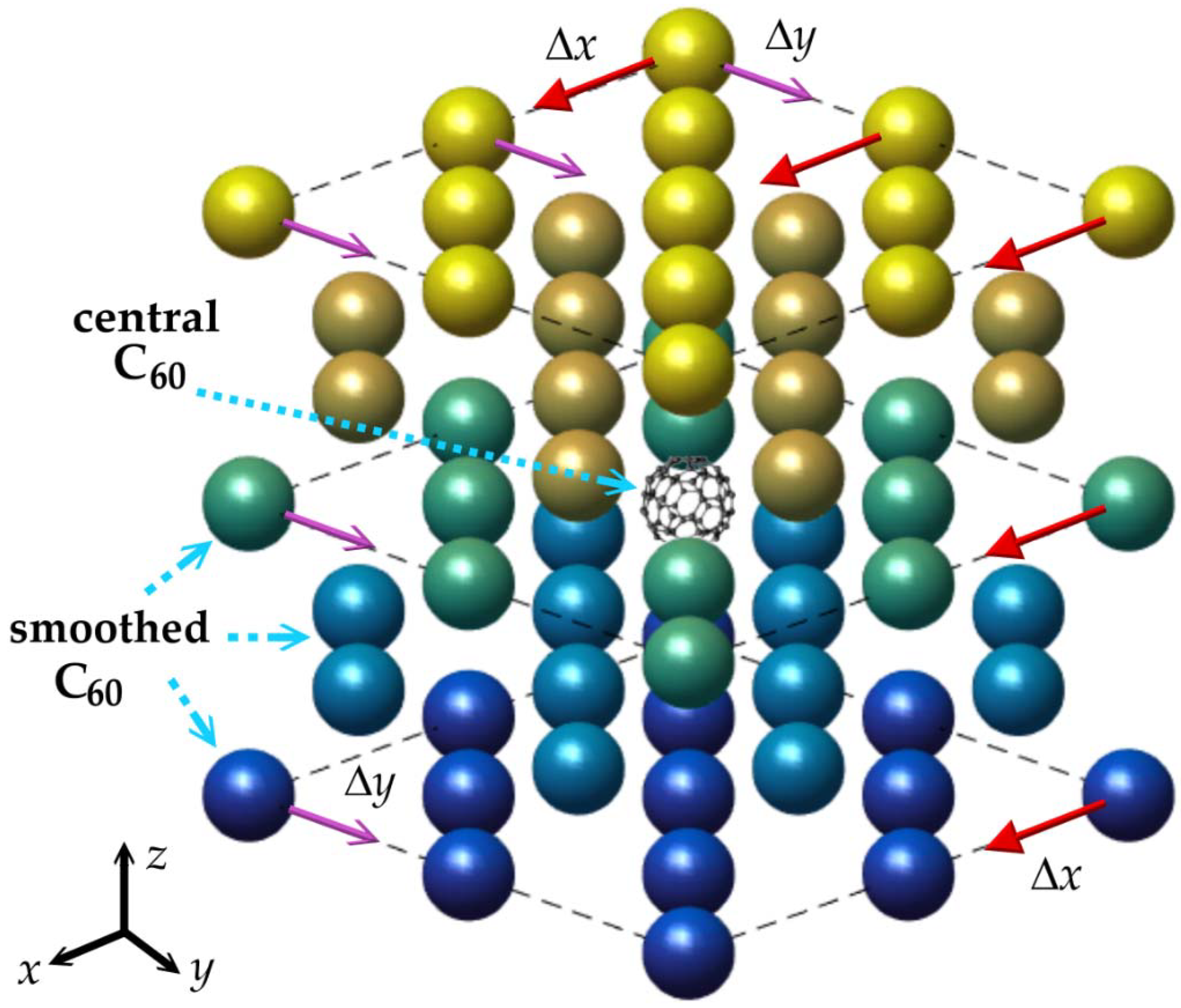

2. Physical Statement of the Problem

3. Mathematical Statement of the Problem

4. Results and Discussion

4.1. Strain Magnitude and Direction Effect on the Central C60

4.2. Strain Rate Effect on Central C60

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Du, Z.; Jannatun, N.; Yu, D.; Ren, J.; Huang, W.; Lu, X. C60-Decorated Nickel–Cobalt Phosphide as an Efficient and Robust Electrocatalyst for Hydrogen Evolution Reaction. Nanoscale 2018, 10, 23070–23079. [Google Scholar] [CrossRef] [PubMed]

- Arie, A.A.; Chang, W.; Lee, J.K. Effect of Fullerene Coating on Silicon Thin Film Anodes for Lithium Rechargeable Batteries. J. Solid State Electrochem. 2010, 14, 51–56. [Google Scholar] [CrossRef]

- Ginzburg, B.M.; Shibaev, L.A.; Kireenko, O.F.; Shepelevskii, A.A.; Baidakova, M.V.; Sitnikova, A.A. Antiwear Effect of Fullerene C60 Additives to Lubricating Oils. Russ. J. Appl. Chem. 2002, 75, 1330–1335. [Google Scholar] [CrossRef]

- Gudkov, S.V.; Simakin, A.V.; Sarimov, R.M.; Kurilov, A.D.; Chausov, D.N. Novel Biocompatible with Animal Cells Composite Material Based on Organosilicon Polymers and Fullerenes with Light-Induced Bacteriostatic Properties. Nanomaterials 2021, 11, 2804. [Google Scholar] [CrossRef] [PubMed]

- Mackiewicz, N.; Bark, T.; Cao, B.; Delaire, J.A.; Riehl, D.; Ling, W.L.; Foillard, S.; Doris, E. Fullerene-Functionalized Carbon Nanotubes as Improved Optical Limiting Devices. Carbon 2011, 49, 3998–4003. [Google Scholar] [CrossRef]

- Smazna, D.; Rodrigues, J.; Shree, S.; Postica, V.; Neubüser, G.; Martins, A.F.; Sedrine, N.B.; Jena, N.K.; Siebert, L.; Schütt, F.; et al. Buckminsterfullerene Hybridized Zinc Oxide Tetrapods: Defects and Charge Transfer Induced Optical and Electrical Response. Nanoscale 2018, 10, 10050–10062. [Google Scholar] [CrossRef]

- Penkova, A.V.; Acquah, S.F.; Piotrovskiy, L.B.; Markelov, D.A.; Semisalova, A.S.; Kroto, H.W. Fullerene Derivatives as Nano-Additives in Polymer Composites. Russ. Chem. Rev. 2017, 86, 530–566. [Google Scholar] [CrossRef]

- Prinzbach, H.; Weiler, A.; Landenberger, P.; Wahl, F.; Wörth, J.; Scott, L.T.; Gelmont, M.; Olevano, D.; Issendorff, B.V. Gas-Phase Production and Photoelectron Spectroscopy of the Smallest Fullerene, C20. Nature 2000, 407, 60–63. [Google Scholar] [CrossRef]

- Veclani, D.; Tolazzi, M.; Melchior, A. Molecular Interpretation of Pharmaceuticals’ Adsorption on Carbon Nanomaterials: Theory Meets Experiments. Processes 2020, 8, 642. [Google Scholar] [CrossRef]

- Krätschmer, W.; Lamb, L.D.; Fostiropoulos, K.; Huffman, D.R. Solid C60: A New Form of Carbon. Nature 1990, 347, 354–358. [Google Scholar] [CrossRef]

- Goodarzi, S.; Da Ros, T.; Conde, J.; Sefat, F.; Mozafari, M. Fullerene: Biomedical Engineers Get to Revisit an Old Friend. Mater. Today 2017, 20, 460–480. [Google Scholar] [CrossRef] [Green Version]

- Shen, H. The Compressive Mechanical Properties of Cn (n = 20, 60, 80, 180) and Endohedral M@C60 (M = Na, Al, Fe) Fullerene Molecules. Mol. Phys. 2007, 105, 2405–2409. [Google Scholar] [CrossRef]

- Ruoff, R.S.; Ruoff, A.L. The Bulk Modulus of C60 Molecules and Crystals: A Molecular Mechanics Approach. Appl. Phys. Lett. 1991, 59, 1553–1555. [Google Scholar] [CrossRef] [Green Version]

- Ruoff, R.S.; Ruoff, A.L. Is C60 Stiffer than Diamond? Nature 1991, 350, 663–664. [Google Scholar] [CrossRef]

- Ossipyan, Y.A.; Bobrov, V.S.; Grushko, Y.S.; Dilanyan, R.A.; Zharikov, O.V.; Lebyodkin, M.A.; Sheckhtman, V.S. On the Mechanical Properties of C60 Fullerite Crystals. Appl. Phys. Solids Surf. 1993, 56, 413–416. [Google Scholar] [CrossRef]

- Tycko, R.; Dabbagh, G.; Fleming, R.M.; Haddon, R.C.; Makhija, A.V.; Zahurak, S.M. Molecular Dynamics and the Phase Transition in Solid C60. Phys. Rev. Lett. 1991, 67, 1886–1889. [Google Scholar] [CrossRef]

- Johnson, R.D.; Yannoni, C.S.; Dorn, H.C.; Salem, J.R.; Bethune, D.S. C60 Rotation in the Solid State: Dynamics of a Faceted Spherical Top. Science 1992, 255, 1235–1238. [Google Scholar] [CrossRef]

- Johnson, R.D.; Yannoni, C.S.; Vries, M.S. de C60 Solid State Rotational Dynamics and Production and EPR Spectroscopy of Fullerenes Containing Metal Atoms. Nanotechnology 1992, 3, 164–166. [Google Scholar] [CrossRef]

- Maniwa, Y.; Mizoguchi, K.; Kume, K.; Kikuchi, K.; Ikemoto, I.; Suzuki, S.; Achiba, Y. NMR Investigation on the CS2- and Benzene-Grown C60 Crystals. Solid State Commun. 1991, 80, 609–612. [Google Scholar] [CrossRef]

- Lima, J.R.F.; Brandão, J.; Cunha, M.M.; Moraes, F. Effects of Rotation in the Energy Spectrum of C60. Eur. Phys. J. D 2014, 68, 94. [Google Scholar] [CrossRef] [Green Version]

- Wolski, P.; Nieszporek, K.; Panczyk, T. Multimodal, PH Sensitive, and Magnetically Assisted Carrier of Doxorubicin Designed and Analyzed by Means of Computer Simulations. Langmuir 2018, 34, 2543–2550. [Google Scholar] [CrossRef] [PubMed]

- Yang, S.; Wei, T.; Scheurell, K.; Kemnitz, E.; Troyanov, S.I. Chlorination-Promoted Skeletal-Cage Transformations of C88 Fullerene by C2 Losses and a C–C Bond Rotation. Chem. Eur. J. 2015, 21, 15138–15141. [Google Scholar] [CrossRef] [PubMed]

- Khalid, F.A.; Beffort, O.; Klotz, U.E.; Keller, B.A.; Gasser, P.; Vaucher, S. Study of Microstructure and Interfaces in an Aluminium–C60 Composite Material. Acta Mater. 2003, 51, 4575–4582. [Google Scholar] [CrossRef]

- Horikawa, T.; Kinoshita, T.; Suito, K.; Onodera, A. Compressibility Measurement of C60 Using Synchrotron Radiation. Solid State Commun. 2000, 114, 121–125. [Google Scholar] [CrossRef]

- Sundqvist, B. Fullerenes under High Pressures. Adv. Phys. 1999, 48, 1–134. [Google Scholar] [CrossRef]

- Spitsina, N.G.; Motyakin, M.V.; Bashkin, I.V.; Meletov, K.P. C60 Fullerene and Its Molecular Complexes under Axial and Shear Deformation. J. Phys. Condens. Matter 2002, 14, 11089–11092. [Google Scholar] [CrossRef]

- Giacalone, F.; Martín, N. Fullerene Polymers: Synthesis and Properties. Chem. Rev. 2006, 106, 5136–5190. [Google Scholar] [CrossRef]

- Makarova, T.L. Electrical and Optical Properties of Pristine and Polymerized Fullerenes. Semiconductors 2001, 35, 243–278. [Google Scholar] [CrossRef]

- Ren, S.; Yang, S.; Zhao, Y. Preparation and Tribological Studies of C60 Thin Film Chemisorbed on a Functional Polymer Surface. Langmuir 2004, 20, 3601–3605. [Google Scholar] [CrossRef] [Green Version]

- Seo, K.-J.; Kim, D.-E. Molecular Dynamics Investigation on the Nano-Mechanical Behaviour of C60 Fullerene and Its Crystallized Structure. Nanoscale 2020, 12, 9849–9858. [Google Scholar] [CrossRef]

- Nisha, M.S.; Mullai Venthan, S.; Senthil Kumar, P.; Singh, D. Tribological Properties of Carbon Nanotube and Carbon Nanofiber Blended Polyvinylidene Fluoride Sheets Laminated on Steel Substrates. Int. J. Chem. Eng. 2022, 2022, 1–6. [Google Scholar] [CrossRef]

- Ku, B.-C.; Han, Y.-C.; Lee, J.-E.; Lee, J.-K.; Park, S.-H.; Hwang, Y.-J. Tribological Effects of Fullerene (C60) Nanoparticles Added in Mineral Lubricants According to Its Viscosity. Int. J. Precis. Eng. Manuf. 2010, 11, 607–611. [Google Scholar] [CrossRef]

- Bubenchikov, M.A.; Bubenchikov, A.M.; Lun-Fu, A.V.; Ovchinnikov, V.A. Rotational Dynamics of Fullerenes in the Molecular Crystal of Fullerite. Phys. Status Solidi A 2021, 218, 2000174. [Google Scholar] [CrossRef]

- Lun-Fu, A.V.; Bubenchikov, A.M.; Bubenchikov, M.A.; Ovchinnikov, V.A. Numerical Simulation of Interaction between Kr+ Ion and Rotating C60 Fullerene towards for Nanoarchitectonics of Fullerene Materials. Crystals 2021, 11, 1204. [Google Scholar] [CrossRef]

- Won Kang, J.; Jung Hwang, H. Fullerene Shuttle Memory Device: Classical Molecular Dynamics Study. J. Phys. Soc. Jpn. 2004, 73, 1077–1081. [Google Scholar] [CrossRef]

- Sławianowski, J.J.; Kotowski, R.K. Classical Dynamics of Fullerenes. Z. Für Angew. Math. Phys. 2017, 68, 55. [Google Scholar] [CrossRef]

- Lun-Fu, A.V.; Bubenchikov, A.M.; Bubenchikov, M.A.; Ovchinnikov, V.A. Molecular Dynamics Study of Collective Behavior of Carbon Nanotori in Columnar Phase. Crystals 2021, 11, 1197. [Google Scholar] [CrossRef]

- Heiney, P.A.; Fischer, J.E.; McGhie, A.R.; Romanow, W.J.; Denenstein, A.M.; McCauley , J.P., Jr.; Smith, A.B.; Cox, D.E. Orientational Ordering Transition in Solid C60. Phys. Rev. Lett. 1991, 66, 2911–2914. [Google Scholar] [CrossRef]

- Sivkov, D.V.; Petrova, O.V.; Nekipelov, S.V.; Vinogradov, A.S.; Skandakov, R.N.; Bakina, K.A.; Isaenko, S.I.; Ob’edkov, A.M.; Kaverin, B.S.; Sivkov, V.N. The Formation of Nanoscale Closed Graphene Surfaces during Fullerite C60 Hot Isostatic Pressing. Appl. Sci. 2021, 11, 11646. [Google Scholar] [CrossRef]

- Baowan, D.; Hill, J.M. Mathematical Modeling of Interaction Energies between Nanoscale Objects: A Review of Nanotechnology Applications. Adv. Mech. Eng. 2016, 8, 168781401667702. [Google Scholar] [CrossRef] [Green Version]

- Thamwattana, N.; Baowan, D.; Hill, J.M. Continuum Modelling for Interactions Between Fullerenes and Other Carbon Nanostructures. J. Comput. Theor. Nanosci. 2009, 6, 972–984. [Google Scholar] [CrossRef]

- Gupta, S.S.; Batra, R.C. Elastic Properties and Frequencies of Free Vibrations of Single-Layer Graphene Sheets. J. Comput. Theor. Nanosci. 2010, 7, 2151–2164. [Google Scholar] [CrossRef]

- Tersoff, J. New Empirical Approach for the Structure and Energy of Covalent Systems. Phys. Rev. B 1988, 37, 6991–7000. [Google Scholar] [CrossRef] [PubMed]

- Kulagina, V.V.; Starostenkov, M.D.; Potekaev, A.I. Multiparticle effective interatomic potentials in computational materials science. Basic Probl. Mater. Sci. 2011, 8, 20–27. [Google Scholar]

- Ortega, J.M.; Poole, W.G. An Introduction to Numerical Methods for Differential Equations; Pitman: Marshfield, MA, USA, 1981; ISBN 978-0-273-01686-1. [Google Scholar]

- Arora, G.; Joshi, V.; Garki, I.S. Developments in Runge–Kutta Method to Solve Ordinary Differential Equations. In Recent Advances in Mathematics for Engineering; Ram, M., Ed.; CRC Press: Boca Raton, FL, USA , 2020; ISBN 978-0-429-20030-4. [Google Scholar]

- Girifalco, L.A. Interaction Potential for Carbon (C60) Molecules. J. Phys. Chem. 1991, 95, 5370–5371. [Google Scholar] [CrossRef]

- Girifalco, L.A. Extended Mie-Grüneisen Theory Applied to C60 in the Disordered Fcc Phase. Phys. Rev. B 1995, 52, 9910–9916. [Google Scholar] [CrossRef]

- Gray, R.C. Gyroscopic Principles and Applications. Nature 1944, 153, 277–278. [Google Scholar] [CrossRef] [Green Version]

- Usubamatov, R. New Analytical Approach for Finding the Gyroscope Forces and Its Properties. Asian J. Sci. Res. 2017, 10, 380–386. [Google Scholar] [CrossRef] [Green Version]

- Usubamatov, R. Physics of Gyroscope Nutation. AIP Adv. 2019, 9, 105101. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lun-Fu, A.V.; Bubenchikov, A.M.; Bubenchikov, M.A.; Ovchinnikov, V.A. Computational Analysis of Strain-Induced Effects on the Dynamic Properties of C60 in Fullerite. Crystals 2022, 12, 260. https://doi.org/10.3390/cryst12020260

Lun-Fu AV, Bubenchikov AM, Bubenchikov MA, Ovchinnikov VA. Computational Analysis of Strain-Induced Effects on the Dynamic Properties of C60 in Fullerite. Crystals. 2022; 12(2):260. https://doi.org/10.3390/cryst12020260

Chicago/Turabian StyleLun-Fu, Aleksandr V., Alexey M. Bubenchikov, Mikhail A. Bubenchikov, and Vyacheslav A. Ovchinnikov. 2022. "Computational Analysis of Strain-Induced Effects on the Dynamic Properties of C60 in Fullerite" Crystals 12, no. 2: 260. https://doi.org/10.3390/cryst12020260

APA StyleLun-Fu, A. V., Bubenchikov, A. M., Bubenchikov, M. A., & Ovchinnikov, V. A. (2022). Computational Analysis of Strain-Induced Effects on the Dynamic Properties of C60 in Fullerite. Crystals, 12(2), 260. https://doi.org/10.3390/cryst12020260