Inverse Colloidal Crystal Polymer Coating with Monolayer Ordered Pore Structure

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Nano-Colloids

2.3. Self-Assembly of CPC onto Lens Surface

2.4. Polymer Infiltration and Template Removal

2.5. Characterizations

3. Results and Discussion

3.1. Experimental Design and Feasibility

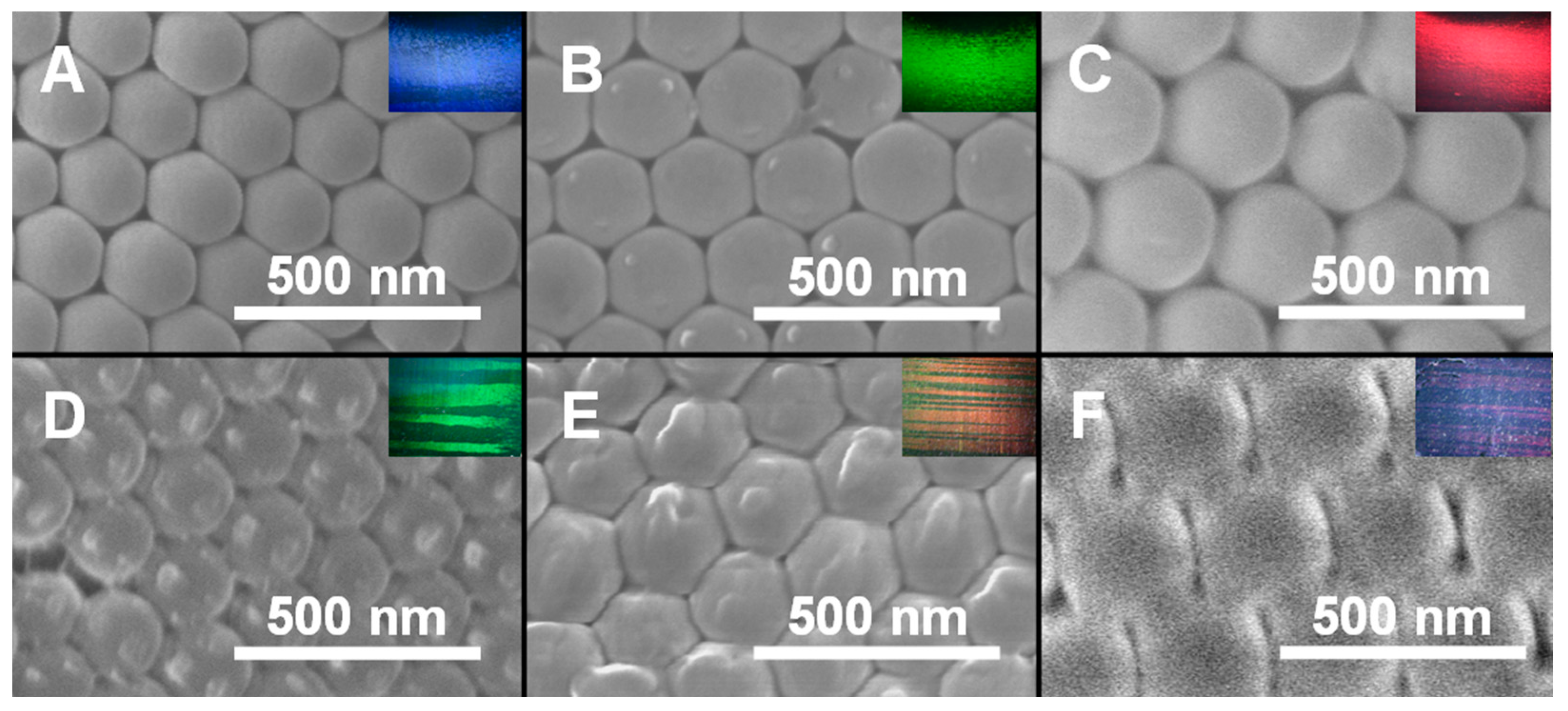

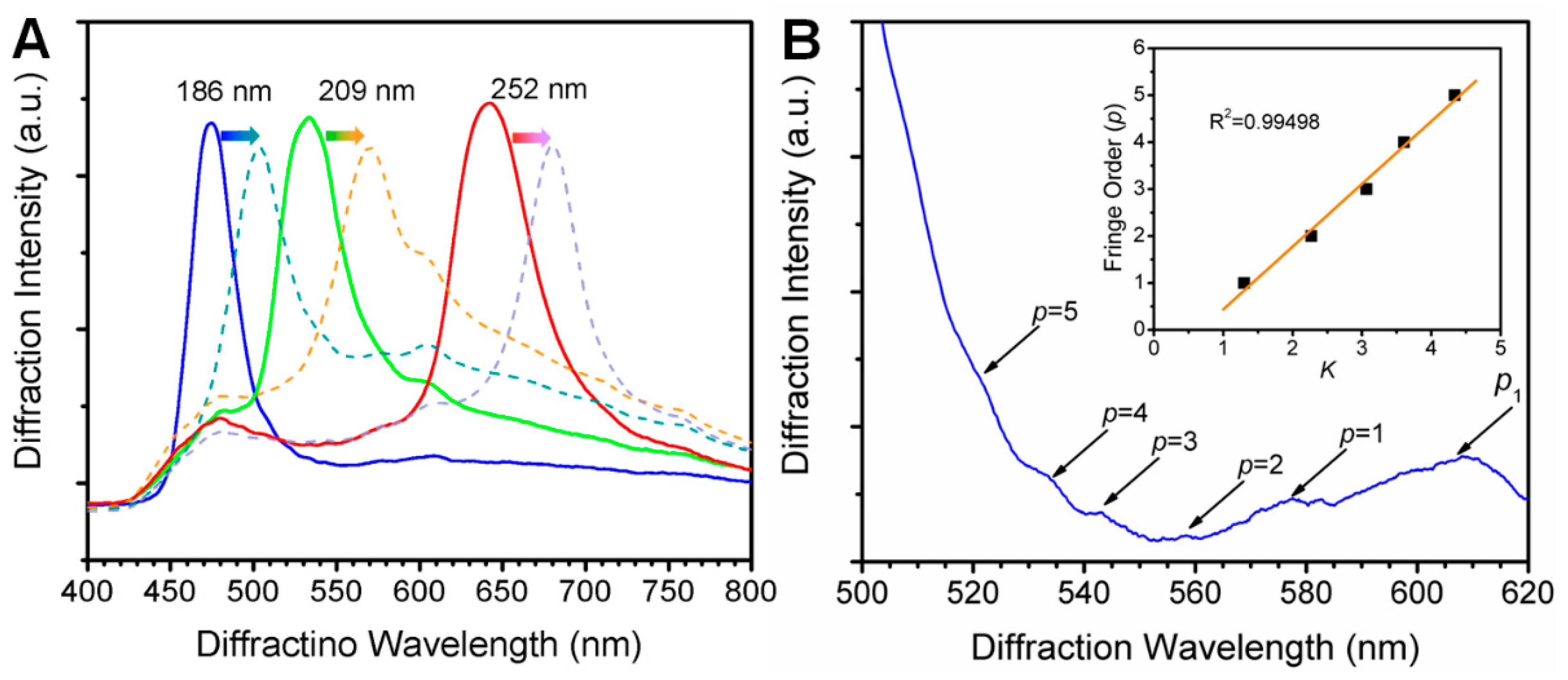

3.2. Diffraction Properties of CPCs

3.3. Effective Refractive Index Correction

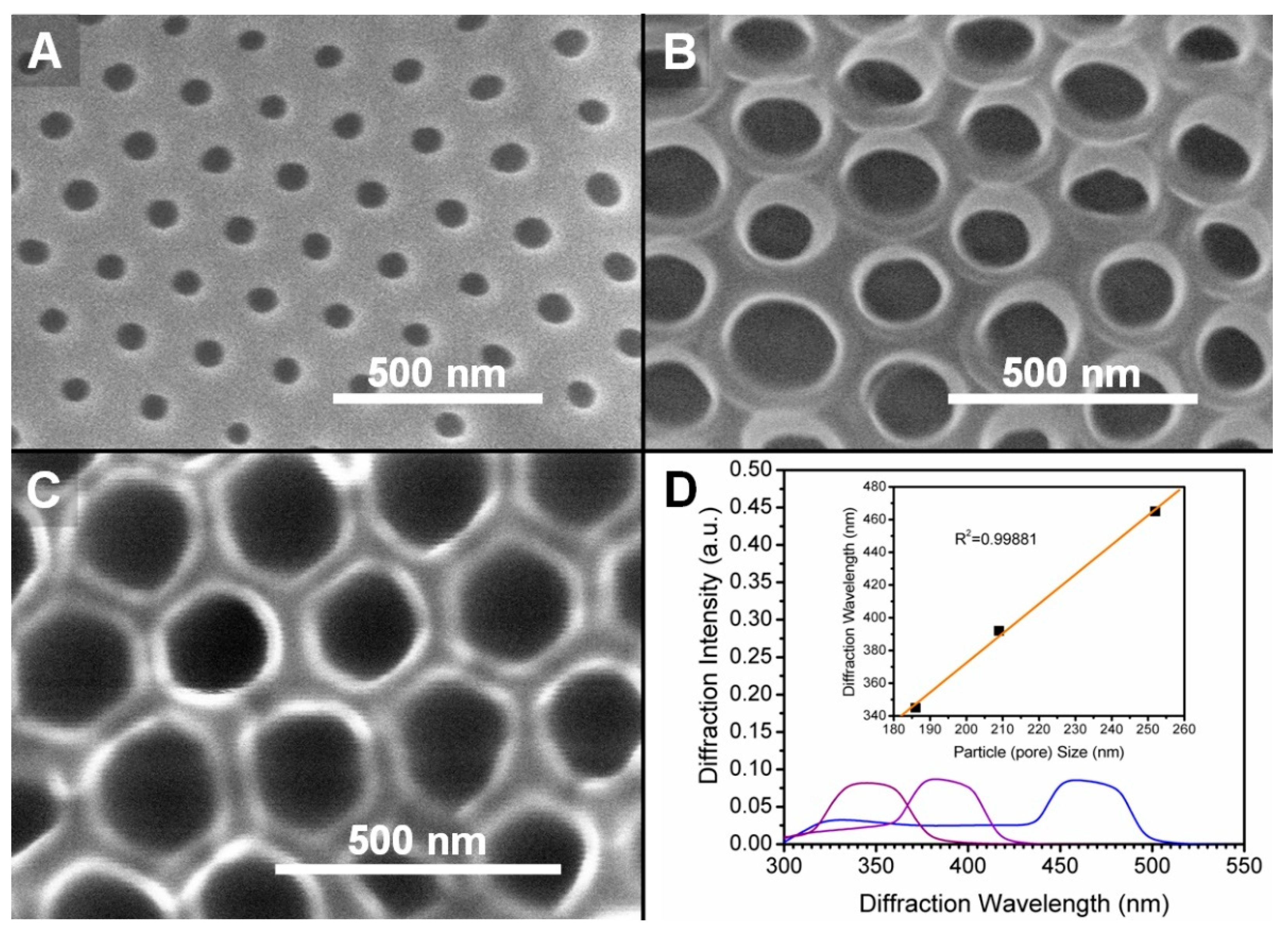

3.4. Characterization of IOC

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yablonovitch, E. Inhibited spontaneous emission in solid–state physics and electronics. Phys. Rev. Lett. 1987, 58, 2059–2062. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- John, S. Strong localization of photons in certain disordered dielectric superlattices. Phys. Rev. Lett. 1987, 58, 2486–2489. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ge, J.P.; Yin, Y.D. Responsive Photonic Crystals. Angew. Chem. Inter. Edit. 2011, 50, 1492–1522. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; Dong, Z.Q.; Chen, H.W.; Chen, Y.; Zhu, Z.G.; Shih, W.H. Two-Dimensional Photonic Crystals. Prog. Chem. 2018, 30, 775–784. [Google Scholar] [CrossRef]

- Shen, P.; Zhang, Y.; Cai, Z.; Liu, R.; Xu, X.; Li, R.; Wang, J.J.; Yang, D. Three-dimensional/two-dimensional photonic crystal hydrogels for biosensing. J. Mater. Chem. C 2021, 9, 5840–5857. [Google Scholar] [CrossRef]

- Tang, W.; Chen, C. Hydrogel-Based Colloidal Photonic Crystal Devices for Glucose Sensing. Polymers 2020, 12, 625. [Google Scholar] [CrossRef] [Green Version]

- Chu, Z.; Xue, C.; Shao, K.; Xiang, L.; Zhao, X.; Chen, C.; Pan, J.; Lin, D. Photonic Crystal-Embedded Molecularly Imprinted Contact Lenses for Controlled Drug Release. ACS Appl. Bio Mater. 2022, 5, 243–251. [Google Scholar] [CrossRef]

- Parker, A.; Welch, V.; Driver, D.; Martini, N. Opal analogue discovered in a weevil. Nature 2003, 426, 786–787. [Google Scholar] [CrossRef]

- Wang, Z.; Guo, Z. Biomimetic photonic structures with tunable structural colours: From natural to biomimetic to applications. J. Bionic Eng. 2018, 15, 1–33. [Google Scholar] [CrossRef]

- Xu, X.L.; Friedman, G.; Humfeld, K.D.; Majetich, S.A.; Asher, S.A. Synthesis and Utilization of Monodisperse Superparamagnetic Colloidal Particles for Magnetically Controllable Photonic Crystals. Chem. Mater. 2002, 14, 1249–1256. [Google Scholar] [CrossRef]

- Coukouma, A.E.; Asher, S.A. Increased volume responsiveness of macroporous hydrogels. Sens. Actuators B Chem. 2018, 255, 2900–2903. [Google Scholar] [CrossRef]

- Maity, A.; Mujumdar, S.; Polshettiwar, V. Self-assembled photonic crystals of monodisperse dendritic fibrous nanosilica for lasing: Role of fiber density. ACS Appl. Mater. Interfaces 2018, 10, 23392–23398. [Google Scholar] [CrossRef] [PubMed]

- Chae, S.S.; Kim, K.H.; Park, J.H.; Lee, K.H.; Han, S.W.; Oh, J.Y.; Baik, H.K.; Kim, Y.S. Ultrathin Photo-Oxidized Siloxane Layer for Extreme Wettability: Anti-Fogging Layer for Spectacles. Adv. Mater. Interfaces 2016, 3, 1500725. [Google Scholar] [CrossRef]

- Nakayama, N.; Hayashi, T. Synthesis of novel UV-curable difunctional thiourethane methacrylate and studies on organic–inorganic nanocomposite hard coatings for high refractive index plastic lenses. Prog. Org. Coat. 2008, 62, 274–284. [Google Scholar] [CrossRef]

- Zhao, Z.C.; Zhou, Y.; Tan, G.; Li, J. Research progress about the effect and prevention of blue light on eyes. Int. J. Ophthalmol. 2018, 11, 1999–2003. [Google Scholar] [CrossRef]

- Ouyang, X.; Yang, J.; Hong, Z.; Wu, Y.; Xie, Y.; Wang, G. Mechanisms of blue light-induced eye hazard and protective measures: A review. Biomed. Pharmacother. 2020, 130, 110577. [Google Scholar] [CrossRef]

- Lawrenson, J.G.; Hull, C.C.; Downie, L.E. The effect of blue-light blocking spectacle lenses on visual performance, macular healthand the sleep-wake cycle: A systematic review of the literature. Ophthalmic Physiol. Opt. 2017, 37, 644–654. [Google Scholar] [CrossRef] [Green Version]

- Chen, C.; Dong, Z.Q.; Xu, Y.; Wang, X.H.; Lu, H.; Qiu, Y.F.; Zhu, Z.G. Ultrathin colloidal crystal layer as transparent photonic films. Micro Nano Lett. 2019, 14, 1–4. [Google Scholar] [CrossRef]

- Wang, L.; Xu, Y.; Chu, Z.; Tang, W.; Qiu, Y.; Zhao, X.; Jiang, W.; Ye, J.; Chen, C. Rapid Coating of Ultraviolet Shielding Colloidal Crystals. Crystals 2020, 10, 502. [Google Scholar] [CrossRef]

- Wang, M.; Bai, J.; Shao, K.; Tang, W.; Zhao, X.; Lin, D.; Huang, S.; Chen, C.; Ding, Z.; Ye, J. Poly(vinyl alcohol) Hydrogels: The Old and New Functional Materials. Int. J. Polym. Sci. 2021, 2021, 2225426. [Google Scholar] [CrossRef]

- Chen, C.; Zhu, Z.G.; Shih, W.H.; Ge, Q.Q.; Liu, M.J.; Zhu, X.R. Facile preparation and self assembly of monodisperse polystyrene nanospheres for photonic crystals. J. Nanosci. Nanotechnol. 2015, 15, 3239–3243. [Google Scholar] [CrossRef] [PubMed]

- Hufziger, K.T.; Zrimsek, A.B.; Asher, S.A. Solid Deep Ultraviolet Diffracting Inverse Opal Photonic Crystals. ACS Appl. Nano Mater. 2018, 1, 7016–7024. [Google Scholar] [CrossRef]

- Jiang, P.; Bertone, J.F.; Hwang, K.S.; Colvin, V.L. Single-crystal colloidal multilayers of controlled thickness. Chem. Mater. 1999, 11, 2132–2140. [Google Scholar] [CrossRef]

- Cai, Z.; Smith, N.L.; Zhang, J.T.; Asher, S.A. Two-dimensional photonic crystal chemical and biomolecular sensors. Anal. Chem. 2015, 87, 5013–5025. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Hong, G.S.; Qi, L.M. Nanosphere Lithography at the Gas/Liquid Interface: A General Approach toward Free-Standing High-Quality Nanonets. Chem. Mater. 2010, 22, 476–481. [Google Scholar] [CrossRef]

- Mohamed, M.G.; Atayde, E.C.; Matsagar, B.M.; Na, J.; Yamauchi, Y.; Wu, K.C.W.; Kuo, S.W. Construction Hierarchically Mesoporous/Microporous Materials Based on Block Copolymer and Covalent Organic Framework. J. Taiwan Inst. Chem. Eng. 2020, 112, 180–192. [Google Scholar] [CrossRef]

- Mohamed, M.G.; EL-Mahdy, A.F.M.; Kotp, M.G.; Kuo, S.W. Advances in porous organic polymers: Syntheses, structures, and diverse applications. Mater. Adv. 2022, 3, 707–733. [Google Scholar] [CrossRef]

| Particle Size (nm) | λCPC Calculated (nm) | λCPC Detected (nm) | na1 | na2 | λCPC-PVA Caltulated (nm) | λCPC-PVA Detected (nm) |

|---|---|---|---|---|---|---|

| 186 | 442.68 | 473.97 | 1.560 | 1.659 | 508.03 | 503.76 |

| 209 | 497.42 | 533.56 | 1.563 | 1.660 | 571.90 | 570.39 |

| 252 | 599.76 | 642.85 | 1.562 | 1.654 | 689.05 | 680.59 |

| p | K | T (nm) | L | |

|---|---|---|---|---|

| 1 | 578.02 | 1.1261 | 3843 | 25 |

| 2 | 558.00 | 1.9640 | 4406 | 29 |

| 3 | 542.53 | 2.6539 | 4891 | 32 |

| 4 | 532.56 | 3.1197 | 5548 | 37 |

| 5 | 519.56 | 3.7540 | 5763 | 38 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Chu, Z.; Ning, X.; Huang, Z.; Tang, W.; Jiang, W.; Ye, J.; Chen, C. Inverse Colloidal Crystal Polymer Coating with Monolayer Ordered Pore Structure. Crystals 2022, 12, 378. https://doi.org/10.3390/cryst12030378

Wang L, Chu Z, Ning X, Huang Z, Tang W, Jiang W, Ye J, Chen C. Inverse Colloidal Crystal Polymer Coating with Monolayer Ordered Pore Structure. Crystals. 2022; 12(3):378. https://doi.org/10.3390/cryst12030378

Chicago/Turabian StyleWang, Likun, Zhaoran Chu, Xuanjun Ning, Ziwei Huang, Wenwei Tang, Weizhong Jiang, Jiayi Ye, and Cheng Chen. 2022. "Inverse Colloidal Crystal Polymer Coating with Monolayer Ordered Pore Structure" Crystals 12, no. 3: 378. https://doi.org/10.3390/cryst12030378