The Sensing Mechanism of InAlN/GaN HEMT

Abstract

:1. Introduction

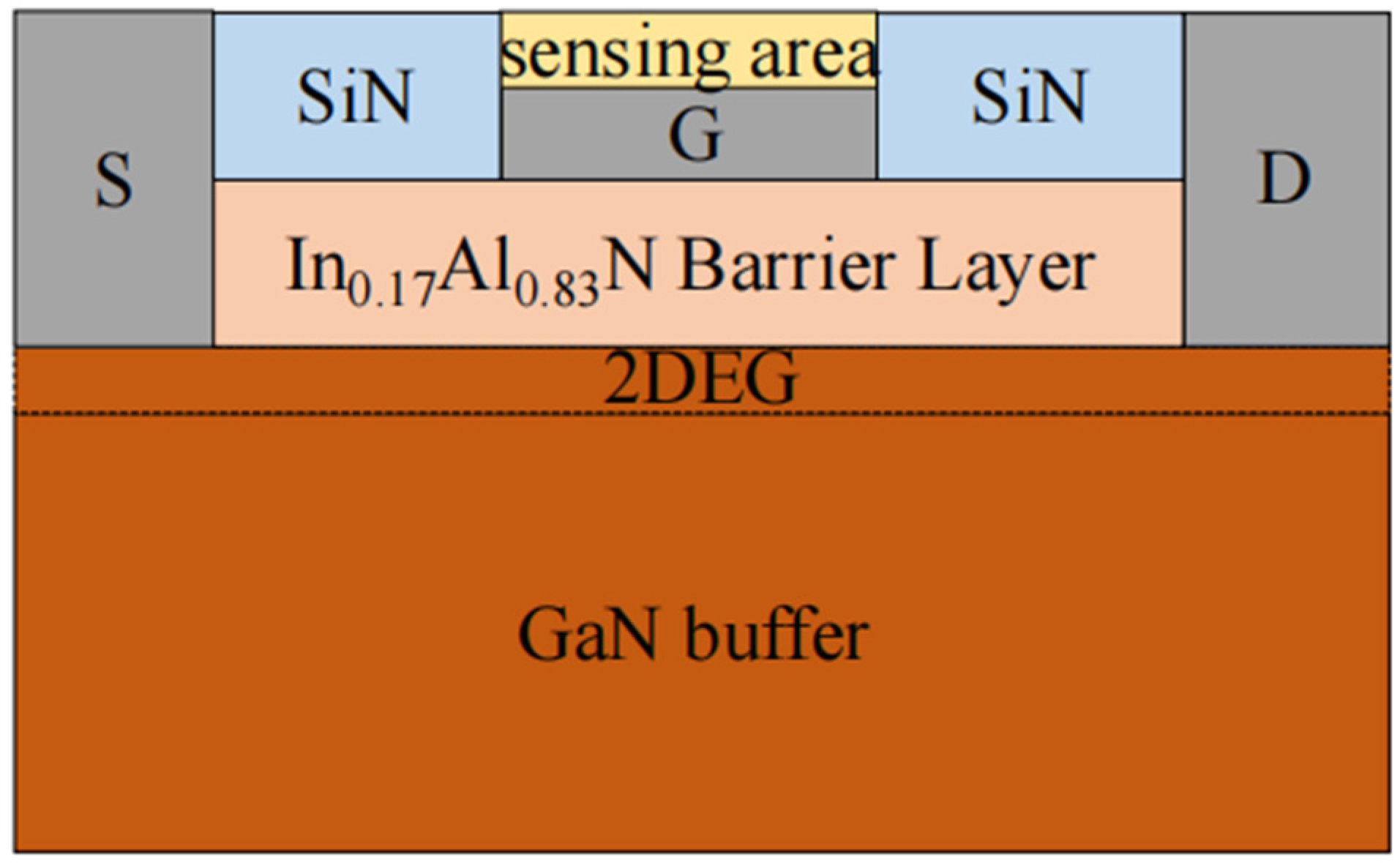

2. Device Structure and Theoretical Models

3. Results and Discussion

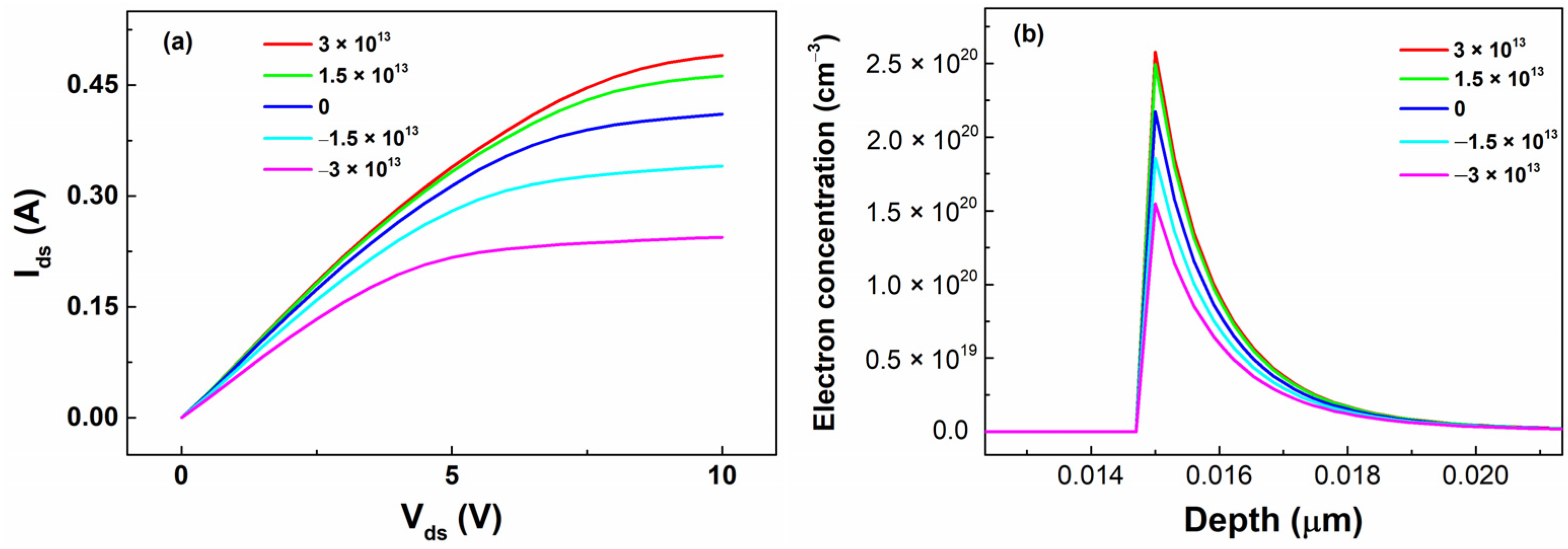

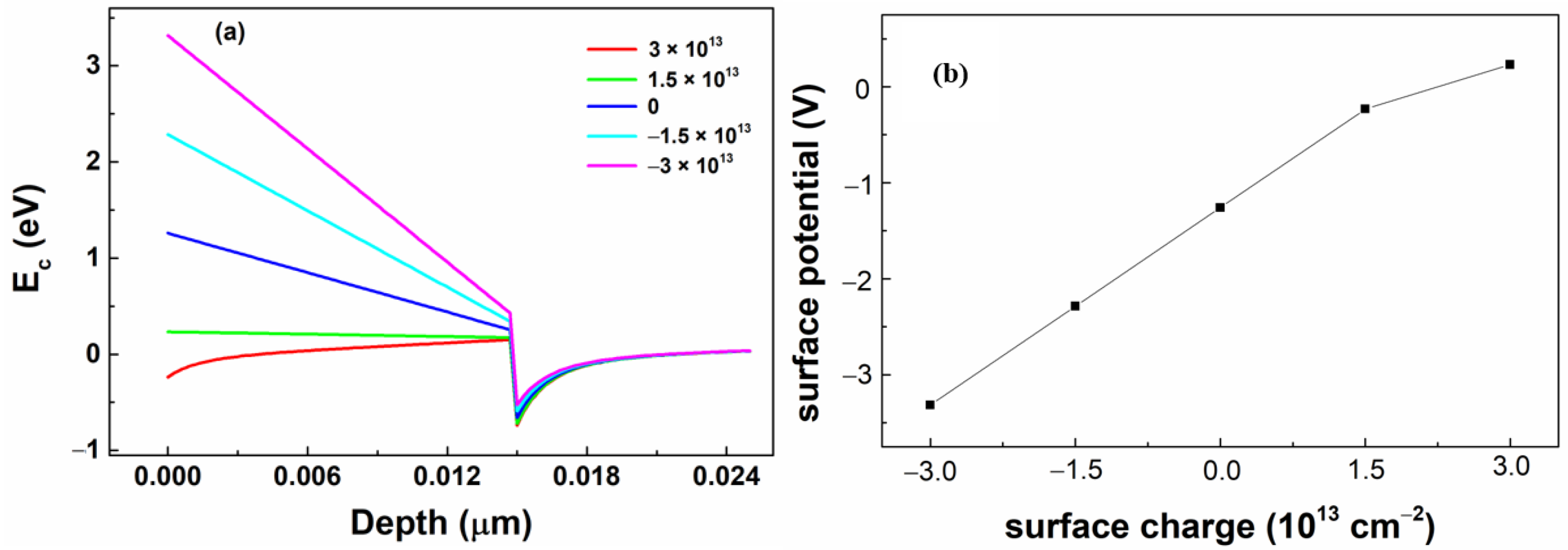

3.1. Influence of Surface Charge on Device Performance of InAlN/GaN HEMTs

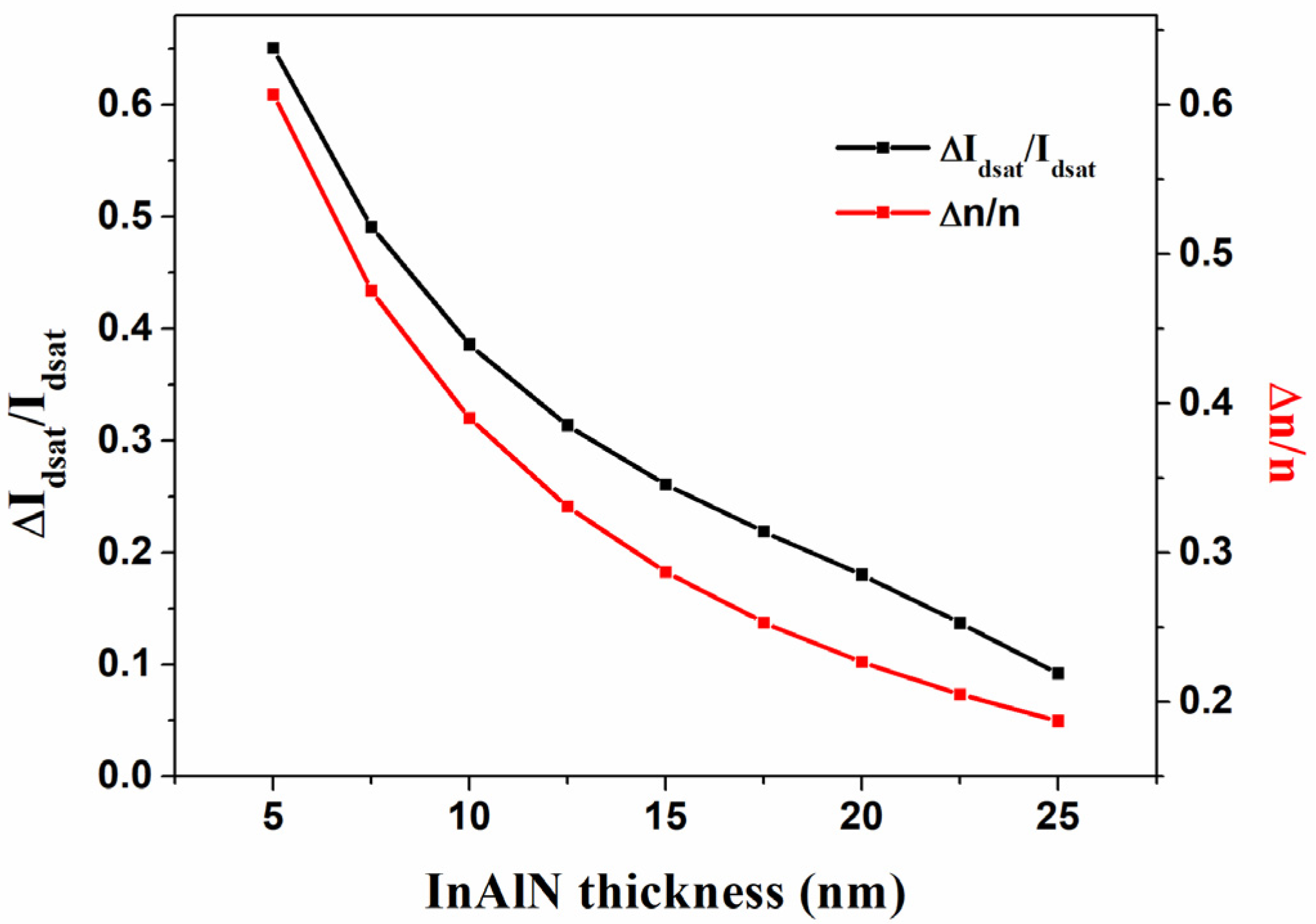

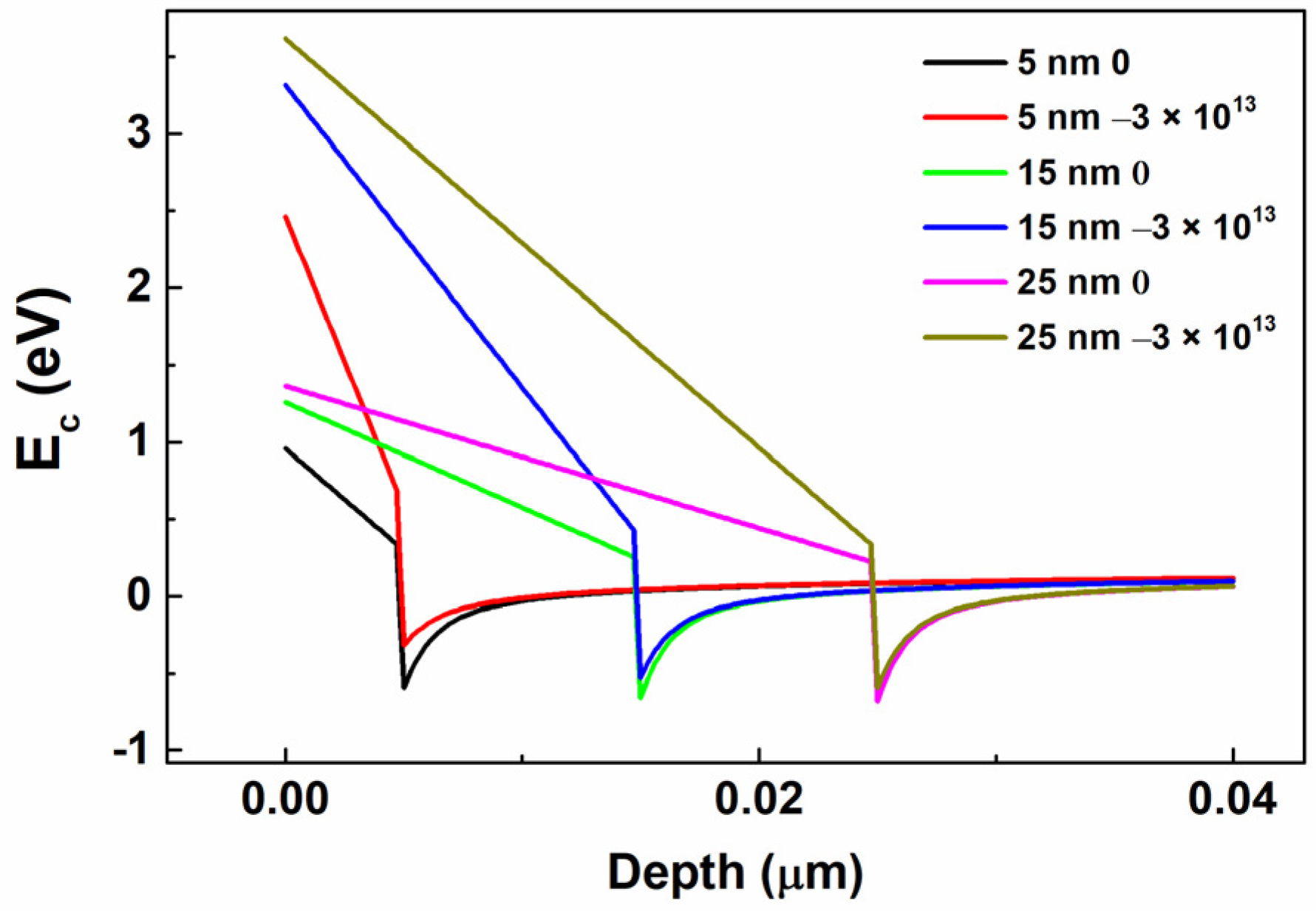

3.2. The Effect of InAlN Barrier Thickness on the Sensing Performance of InAlN/GaN HEMT Device

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Palacios, T.; Chakraborty, A.; Rajan, S.; Poblenz, C.; Keller, S.; DenBaars, S.P.; Speck, J.S.; Mishra, U.K. High-power AlGaN/GaN HEMTs for ka-band applications. IEEE Electron. Device Lett. 2005, 26, 781–783. [Google Scholar] [CrossRef] [Green Version]

- Driad, S.B.; Maher, H.; Defrance, N.; Hoel, V.; De Jaeger, J.C.; Renvoise, M.; Frijlink, P. AlGaN/GaN HEMTs on Silicon Substrate With 206-GHz FMAX. IEEE Electron. Device Lett. 2013, 34, 36–38. [Google Scholar] [CrossRef]

- Xu, R.; Chen, P.; Liu, M.H.; Zhou, J.; Li, Y.M.; Cheng, K.; Liu, B.; Chen, D.J.; Xie, Z.L.; Zhang, R.; et al. 3.4-kV AlGaN/GaN Schottky Barrier Diode on Silicon Substrate With Engineered Anode Structure. IEEE Electron. Device Lett. 2021, 42, 208–211. [Google Scholar] [CrossRef]

- Fitch, R.C.; Walker, D.E.; Green, A.J.; Tetlak, S.E.; Gillespie, J.K.; Gilbert, R.D.; Sutherlin, K.A.; Gouty, W.D.; James, P.; Theimer, J.P.; et al. Implementation of High-Power-Density X-Band AlGaN/GaN High Electron Mobility Transistors in a Millimeter-Wave Monolithic Microwave Integrated Circuit Process. IEEE Electron. Device Lett. 2015, 36, 1004–1007. [Google Scholar] [CrossRef]

- Sharma, N.; Mishra, S.; Singh, K.; Chaturvedi, N.; Chauhan, A.; Periasamy, C.; Kharbanda, D.K.; Parjapat, P.; Khanna, P.K.; Chaturvedi, N. High-resolution AlGaN/GaN HEMT-based electrochemical sensor for biomedical applications. IEEE Trans. Electron. Devices 2019, 67, 289–295. [Google Scholar] [CrossRef]

- Ibbetson, J.P.; Fini, P.T.; Ness, K.D.; DenBaars, S.P.; Speck, J.S.; Mishra, U.K. Polarization effects, surface states, and the source of electrons in AlGaN/GaN heterostructure field effect transistors. Appl. Phys. Lett. 2000, 77, 250–252. [Google Scholar] [CrossRef]

- Ould-Abbas, A.; Zeggaia, O.; Bouchaour, M.; Zeggai, H.; Sahouane, N.; Madani, M.; Trari, D.; Boukais, M.; Chabane-Sari, N.E. Study on functionalizing the surface of AlGaN/GaN high electron mobility transistor based sensors. J. Optoelectron. Adv. Mater. 2013, 15, 1323–1327. [Google Scholar]

- Ahn, J.; Kim, D.; Park, K.H.; Yoo, G.; Heo, J. Pt-decorated graphene gate AlGaN/GaN MIS-HEMT for ultrahigh sensitive hydrogen gas detection. IEEE Trans. Electron. Devices 2021, 68, 1255–1261. [Google Scholar] [CrossRef]

- Chaturvedi, N.; Singh, K.; Kachhawa, P.; Lossy, R.; Wuerfl, J. AlGaN/GaN HEMT based sensor and system for polar liquid detection. Sens. Actuators A Phys. 2020, 302, 111799. [Google Scholar] [CrossRef]

- Woo, K.; Kang, W.; Lee, K.; Lee, P.; Kim, Y.; Yoon, T.S.; Cho, C.Y.; Park, K.H.; Ha, M.W.; Lee, H.H. Enhancement of cortisol measurement sensitivity by laser illumination for AlGaN/GaN transistor biosensor. Biosens. Bioelectron. 2020, 159, 112186. [Google Scholar] [CrossRef]

- Dong, Y.; Son, D.H.; Dai, Q.; Lee, J.H.; Won, C.H.; Kim, J.G.; Chen, D.J.; Lee, J.H.; Lu, H.; Zhang, R.; et al. High sensitive pH sensor based on AlInN/GaN heterostructure transistor. Sensors 2018, 18, 1314. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Varghese, A.; Periasamy, C.; Bhargava, L. Fabrication and charge deduction based sensitivity analysis of GaN MOS-HEMT device for glucose, MIG, C-erbB-2, KIM-1, and PSA detection. IEEE Trans. Nanotechnol. 2019, 18, 747–755. [Google Scholar] [CrossRef]

- Cho, S.K.; Cho, W.J. High-Sensitivity pH sensor based on coplanar gate AlGaN/GaN metal-oxide-semiconductor high electron mobility transistor. Chemosensors 2021, 9, 42. [Google Scholar] [CrossRef]

- Nigam, A.; Sharma, N.; Tripathy, S.; Kumar, M. Development of semiconductor based heavy metal ion sensors for water analysis: A review. Sens. Actuators A Phys. 2021, 330, 112879. [Google Scholar] [CrossRef]

- Sokolovskij, R.; Zheng, H.Z.; Li, W.M.; Zhou, G.N.; Wang, Q.; Zhang, G.Q.; Yu, H.Y. Application of a gateless AlGaN/GaN HEMT sensor for diesel soot particulate detection. Sens. Actuators B Chem. 2021, 349, 130811. [Google Scholar] [CrossRef]

- Jia, X.L.; Chen, D.J.; Liu, L.; Lu, H.; Zhang, R.; Zheng, Y.D. Highly selective and sensitive phosphate anion sensors based on AlGaN/GaN high electron mobility transistors functionalized by ion imprinted polymer. Sci. Rep. 2016, 6, 27728. [Google Scholar] [CrossRef] [PubMed]

- Sokolovskij, R.; Zhang, J.; Zheng, H.; Li, W.M.; Jiang, Y.; Yang, G.Y.; Yu, H.Y.; Sarro, P.M.; Zhang, G.Q. The Impact of Gate Recess on the H2; Detection Properties of Pt-AlGaN/GaN HEMT Sensors. IEEE Sens. J. 2020, 20, 8947–8955. [Google Scholar] [CrossRef]

- Lee, C.T.; Chiu, Y.S. Gate-recessed AlGaN/GaN ISFET urea biosensor fabricated by photoelectrochemical method. IEEE Sens. J. 2015, 16, 1518–1523. [Google Scholar] [CrossRef]

- Ding, X.Z.; Miao, B.; Gu, Z.Q.; Wu, B.J.; Hu, Y.M.; Wang, H.; Zhang, J.; Wu, D.M.; Lu, W.H.; Li, J.D. Highly sensitive extended gate-AlGaN/GaN high electron mobility transistor for bioassay applications. RSC Adv. 2017, 7, 55835–55838. [Google Scholar] [CrossRef] [Green Version]

- Pyo, J.Y.; Jeon, J.H.; Koh, Y.; Cho, C.Y.; Park, H.H.; Park, K.H.; Lee, S.W.; Cho, W.J. AlGaN/GaN high-electron-mobility transistor pH sensor with extended gate platform. AIP Adv. 2018, 8, 85106. [Google Scholar] [CrossRef] [Green Version]

- Hao, Y.; Xue, J.S.; Zhang, J.C. Research progress in the group-III nitride InAlN semiconductorheterostructures. Sci. China Inform. Sci. 2012, 42, 1577–1587. [Google Scholar]

- Tülek, R.; Ilgaz, A.; Gökden, S.; Teke, A.; Öztürk, M.K.; Kasap, M.; Özçelik, S.; Arslan, E.; Özbay, E. Comparison of the trans-port properties of high quality AlGaN/AlN/GaN and AlInN/AlN/GaN two-dimensional electron gas heterostructures. J. Appl. Phys. 2009, 105, 13707. [Google Scholar] [CrossRef] [Green Version]

- Jia, X.L.; Huang, X.Y.; Yin, T.; Yang, L.H.; Chen, D.J. Ultrasensitive Detection of Phosphate Using Ion-Imprinted Polymer Functionalized AlInN/GaN High Electron Mobility Transistors. IEEE Electron. Device Lett. 2016, 37, 913–915. [Google Scholar] [CrossRef]

- Chapin, C.A.; Miller, R.A.; Dowling, K.M.; Chen, R.Q.; Senesky, D.G. InAlN/GaN high electron mobility micro-pressure sensors for high-temperature environments. Sens. Actuator A Phys. 2017, 263, 216–223. [Google Scholar] [CrossRef]

- Kong, Y.C.; Zheng, Y.D.; Chu, R.M.; Gu, S.L. Influence of Al-content on the property of the two-dimensional electron gases in AlxGa1-xN/GaN heterostructures. Acta Phys. Sin. 2003, 52, 1756–1760. [Google Scholar] [CrossRef]

- Amarnath, G.; Panda, D.K.; Lenka, T.R. Modeling and simulation of DC and microwave characteristics of AlInN (AlGaN)/AlN/GaN MOSHEMTs with different gate lengths. Int. J. Numer. Modell. Electron. Netw. Devices Fields 2019, 32, e2456. [Google Scholar] [CrossRef] [Green Version]

- Mohammadzamani, M.; Fathipour, M. An investigation of highly scaled III-nitride Gallium-face and Nitrogen-face HEMTs. Superlattices Microstruct. 2015, 78, 125–133. [Google Scholar] [CrossRef]

- Albrecht, J.D.; Wang, R.P.; Ruden, P.P.; Farahmand, M.; Brennan, K.F. Electron transport characteristics of GaN for high temperature device modeling. J. Appl. Phys. 1998, 83, 4777–4781. [Google Scholar] [CrossRef]

- Chang, Y.; Tong, K.Y.; Surya, C. Numerical simulation of current–voltage characteristics of AlGaN/GaN HEMTs at high temperatures. Semicond. Sci. Technol. 2005, 20, 188. [Google Scholar] [CrossRef]

- Braga, N.; Mickevicius, R.; Gaska, R.; Hu, X.; Shur, M.S.; Khan, M.A.; Simin, G.; Yang, J. Simulation of hot electron and quantum effects in AlGaN/GaN heterostructure field effect transistors. J. Appl. Phys. 2004, 95, 6409–6413. [Google Scholar] [CrossRef] [Green Version]

- Higashiwaki, M.; Matsui, T. MBE growth and device characteristics of InAlN/GaN HFETs. Phys. Status Solidi C 2005, 2, 2598–2601. [Google Scholar] [CrossRef]

- Kanaga, S.; Dutta, G.; Kushwah, B.; DasGupta, N.; DasGupta, A. Low Temperature and High Pressure Oxidized Al2O3 as Gate Dielectric for AlInN/GaN MIS-HEMTs. IEEE Trans. Device Mater. Reliab. 2020, 20, 613–621. [Google Scholar] [CrossRef]

- Ambacher, O.; Smart, J.; Shealy, J.R.; Weimann, N.G.; Chu, K.; Murphy, M.; Schaff, W.J.; Eastman, L.F.; Dimitrov, R.; Wittmer, L.; et al. Two-dimensional electron gases induced by spontaneous and piezoelectric polarization charges in N-and Ga-face AlGaN/GaN heterostructures. J. Appl. Phys. 1999, 85, 3222–3233. [Google Scholar] [CrossRef] [Green Version]

- Jogai, B. Influence of surface states on the two-dimensional electron gas in AlGaN/GaN heterojunction field-effect transistors. J. Appl. Phys. 2003, 93, 1631–1635. [Google Scholar] [CrossRef]

- Behmenburg, H.; Khoshroo, L.R.; Eickelkamp, M.; Mauder, C.; Fieger, M.; Ketteniss, N.; Woitok, J.; Wamwangi, D.; Wuttig, M.; Hernandez, S.E.; et al. Influence of barrier thickness on AlInN/AlN/GaN heterostructures and device properties. Phys. Status Solidi C 2009, 6, S1041–S1044. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; He, X.; Dong, Y.; Fu, S.; Liu, Y.; Chen, D. The Sensing Mechanism of InAlN/GaN HEMT. Crystals 2022, 12, 401. https://doi.org/10.3390/cryst12030401

Liu Y, He X, Dong Y, Fu S, Liu Y, Chen D. The Sensing Mechanism of InAlN/GaN HEMT. Crystals. 2022; 12(3):401. https://doi.org/10.3390/cryst12030401

Chicago/Turabian StyleLiu, Yanli, Xiao He, Yan Dong, Su Fu, Yuhui Liu, and Dunjun Chen. 2022. "The Sensing Mechanism of InAlN/GaN HEMT" Crystals 12, no. 3: 401. https://doi.org/10.3390/cryst12030401

APA StyleLiu, Y., He, X., Dong, Y., Fu, S., Liu, Y., & Chen, D. (2022). The Sensing Mechanism of InAlN/GaN HEMT. Crystals, 12(3), 401. https://doi.org/10.3390/cryst12030401