1. Introduction

Duplex stainless steels (DSS) are widely used in chemical and petrochemical industries and several offshore applications as a base material for objects such as pipelines, containers, and pressure vessels.

They have a combination of excellent corrosion resistance and mechanical properties. Duplex stainless steels have superior corrosion resistance, especially in an environment containing chloride ions, with a typical PREN of 35–40. A further advantage is that their high yield strength and tensile strength exceed those of both ferritic and austenitic stainless-steel grades [

1,

2].

The microstructure of duplex steels consists of two phases, namely the ferrite and austenite. The ferrite is ferromagnetic due to its body-centered cubic-crystal structure in contrast to the austenite which is a paramagnetic face-centered cubic phase [

3]. The usual composition of DSS is Cr 24–28%, Ni 4–8%, C < 0.1%, and Mo < 2.5%. Other alloying elements can be copper, titanium, and niobium. The high chromium and molybdenum content in duplex stainless steels can result in the formation of several intermetallic compound phases. The most important are the so-called σ (sigma) and χ (chi) phases, which can greatly degrade the toughness of the alloy.

In DSS, several phase transformations involving precipitation and segregation of new phases can occur in the temperature range of 300–1000 °C [

4,

5]. In terms of the resulting compound phases, two temperature ranges are usually distinguished [

4]. In the range of 300 to 500 °C, the G-phase which is rich in nickel and silicon and the chromium and molybdenum rich α’-phase precipitate. Above 600 °C temperature the chromium nitrides, the σ and χ phases which are rich in chromium and molybdenum and secondary austenite (γ

2) crystallise. These phases can cause a dramatic deterioration of the mechanical properties [

6,

7,

8].

Under the influence of heat input, the eutectoidal decomposition of metastable ferrite into secondary austenite and sigma phase occurs (α σ + γ

2) [

9,

10]. The sigma phase is a tetragonal lattice, brittle, paramagnetic compound phase, the appearance of which fundamentally changes the mechanical and corrosion-resistant properties of duplex stainless steels [

11,

12,

13]. This phase transition can occur due to the heat input of the weld deteriorating the corrosion-resistant and mechanical properties. Therefore, the non-destructive tests of this process, especially the magnetic ones have great practical importance [

14,

15,

16,

17].

Additionally, the kinetics of the eutectoidal decomposition of the ferrite phase and its effect on properties was studied using several microstructural investigation methods [

18,

19,

20,

21]. It is important to mention that the decomposition of the ferrite phase due to heat input is of great importance in welding technology [

22,

23].

2. Sample Preparation and Applied Measurements

In this work, the decomposition of the ferrite phase into secondary austenite and sigma phase was studied by magnetic, thermoelectric measurements, and backscattering electron diffractometry (EBSD). Tests were performed on 2507 duplex stainless steel. The nominal chemical composition of the tested AISI 2507 duplex stainless steel is shown in

Table 1.

The samples were cold rolled by a double cylinder rolling mill. A single stand reversing mill with 130 mm diameter rolls was used. The rolling speed was 11.7 m/min. The plates were cold rolled in one direction, through constant passes, to gradually reduce their thickness. A thickness reduction of 0.25 mm was used for each pass, to perform high cold deformation without strong bending. The rolling reductions (ε) of the samples were the following: 0%, 10.3%, 22.3%, 31.3%, 41.6%, 50.6%, and 61.9%. The reduction was calculated by the following equation:

where h is the thickness of the rolled sample and h

0 is the initial thickness.

After rolling, the samples were heat-treated uniformly at 850 °C for 30 min and cooled in the open air.

The Vickers hardness of the specimens was measured by a KB 250 BVRZ-type hardness tester (KB Prüftechnik GmbH, Hochdorf-Assenheim, Germany) with a load of 98.07 N.

The first magnetization curve and the hysteresis loop of the samples were measured by a Stablein-Steinitz type DC magnetometer (designed and made in our department). This magnetometer setup is a magnetic bridge that has two symmetrical yokes and a cross bridge. It consists of two facing U-shaped bulk soft-iron yokes with four field coils placed on the arms of the yokes. There is a bridge branch in the middle of the arms which is fluxless in case of geometrical and magnetic symmetry. If a sample is taken into the measuring air gap it upsets the symmetry of the yoke and there will be a magnetic flux though the bridge branch. The magnetic polarization of the sample can be measured in the function of the excitation magnetic field. A detailed description of the magnetometer can be found in our earlier paper [

24]. The highest excitation magnetic field which was used to magnetize the sample was approximately 2700 A/cm, which was high enough to reach the magnetic saturation of all tested samples.

The thermoelectric power measurement (TEP) was measured by a TechLab Trivolt PK120-type (TechLab, La Tannerie, France) TEP measuring instrument. The temperature difference between the ends of the sample was 10 °C and the measuring accuracy of the thermoelectric power (Seebeck-coefficient) was approximately 2 nV/K.

Electron backscattering diffraction (EBSD) measurements were performed by a Philips XL-30 scanning electron microscope supplied with a TSL OIM system. Samples were ground and polished in a classical way, but the final polishment was achieved by a 0.05 μm colloidal silica suspension for 30 min.

Longitudinal and transverse metallographic sections were prepared from each of the tested samples. The so-called Beraha etching agent (100 mL H2O, 20 mL HCl, 1 g potassium metabisulphite) was applied for sample preparation. This etchant makes the surface of ferrite grains dark while the austenitic grains remain glossy on metallographic images.

3. Results and Discussion

In the initial sample, the ratio of ferrite and austenite phases was almost the optimal 42–58% in terms of corrosive properties.

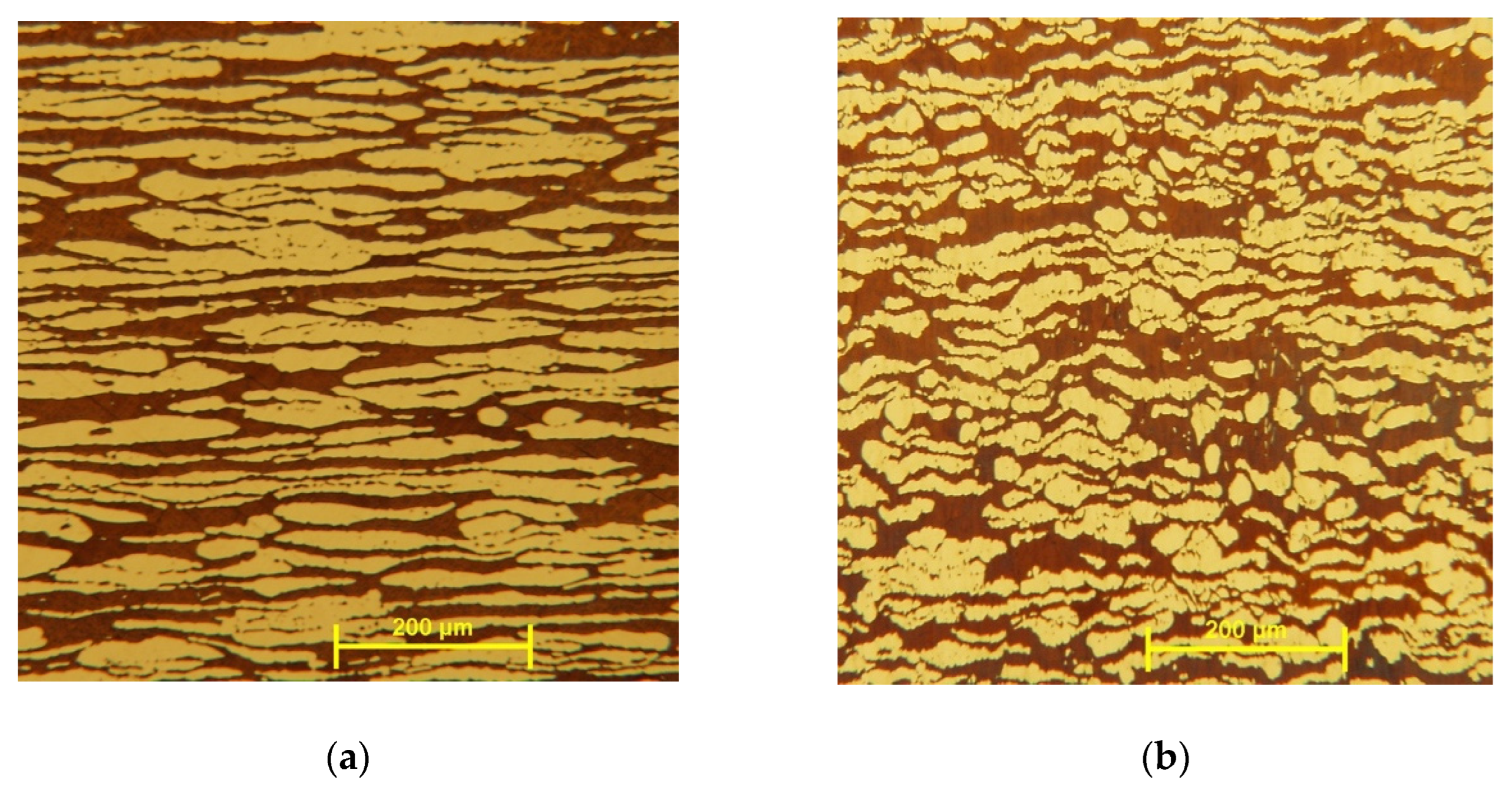

Figure 1a shows the initial microstructure with elongated grains, which is the supply state of the DSS sheet material. In

Figure 1b, it is observed that the ferrite and austenite grains are crushed and fragmented due to the applied 61.9% rolling reduction.

Due to the heat treatment, the decomposition of the ferrite phase into sigma phase (𝜎) and secondary austenite (γ

2) mainly started at the ferrite-austenite grain boundaries (

Figure 2a,b). The ferrite decomposition process was significantly enhanced by the previous plastic deformation. The ferrite grains of the strongly cold-rolled sample (ε = 61.9%) are practically completely decomposed and a huge amount of brittle and hard intermetallic compound phase, namely the sigma phase, precipitated. The volume ratio of the precipitated sigma phase could be up to 46% according to our EBSD measurements described later in this paper.

The Vickers hardness increased with a square root function trend for untreated samples (

Figure 3) due to cold rolling. The following function can be fitted to the measured points of the deformed but not heat-treated sample

(R

2 = 0.994). Where: ∆HV10 is the increase of hardness due to plastic deformation and ε is the rolling reduction. This increase in hardness was caused only by the increase in dislocation density. However, the hardness of the heat-treated samples was always significantly higher due to the appearance of the hard sigma phase.

The first magnetization curve and hysteresis loop of all tested samples were measured by the previously mentioned Stablein-Steinitz type DC magnetometer. As a demonstration, the saturation magnetic hysteresis loop of the sample in its original condition is shown in

Figure 4 and the measured points of magnetic polarization (

) in the function of the external field strength are shown. Where:

is the permeability of the vacuum and M is the magnetization of the sample.

It is known that the magnetic saturation magnetization (

) and the saturation polarization (

) is exactly linearly proportional to the volume ratio of the ferromagnetic phase in an alloy [

25]. The saturation magnetization (

) is the maximum magnetic moment per unit volume for a magnetic material. The value of these intrinsic magnetic properties is determined only by the number of Bohr magnetons in a unit volume of material [

26,

27]. Accordingly, the saturation polarization of pure iron is 2.15 T.

In the tested stainless steel, the ferrite was the only ferromagnetic phase because the austenite and sigma phases have paramagnetic properties. Considering that the ferrite content of the initial sample was 42% and the corresponding saturation polarization value was 0.56 T, we used the following formula to calculate the ferrite volume ratio of the samples.

where F is the volume ratio of the ferrite phase, μ

0M

S is the magnetic saturation polarization of the sample in Tesla, and M

s is the saturation magnetization in A/m units. The saturation polarization values and the corresponding calculated ferrite volume ratio in function of the rolling reduction are shown in

Figure 5a. It seems that the cold rolling did not affect the amount of the ferromagnetic phase. Therefore, the cold working did not result in the formation of strain-induced martensite in the investigated 2507 duplex stainless steel. This behavior is due to the stability of the austenite phase in 2507 DSS caused by its high nickel content [

28].

However, it was observed that the ferrite content decreased dramatically as a result of the heat treatment after cold rolling. In the case of the most highly formed sample (61.9%), the ferrite content decreased to 1.3%. The ferrite phase was considered to be completely decomposed and thus converted to the sigma phase and secondary austenite.

The decomposition of ferrite was monitored by thermoelectric power measurement (TEP) as well. The tendency of the TEP versus rolling reduction appeared very similar to the saturation polarization (

Figure 5). The TEP was practically independent of the deformation rate in samples that were not heat treated. However, the precipitation of the sigma phase due to the heat treatment significantly decreased its values.

Based on the above, there is a good correlation between the decomposition process of ferrite and the results of the magnetic saturation polarization and TEP measurements.

For heat-treated samples, magnetic saturation polarization and TEP show a similar trend (

Figure 5a,b). This is evident in

Figure 6, where saturation polarization is plotted against TEP values (

Figure 6).

Only the quantitative change of the ferrite phase with ferromagnetic properties could be detected by magnetic measurements. Therefore, electron backscattering diffraction (EBSD) measurements were performed to determine the amount of the sigma phase formed during the eutectoid decomposition of ferrite.

EBSD measurements of the samples with plastic deformation of 0%, 22.3%, 41.6%, and 61.9% were performed.

Figure 7 shows the phase maps of the specimens. The blue areas refer to ferrite, the green areas refer to austenite, and the yellow areas are the sigma-phase grains.

According to the EBSD measurements, the sigma-phase content of the specimens increased with increasing rolling reduction while the ferrite content decreased. The obtained volume ratio of the sigma phase is shown in

Table 2.

The measured ferrite phase ratio demonstrated a sufficient agreement with the results of the applied magnetic measurement (

Figure 5a). The differences can be considered natural due to the differences between the two measurement methods. It is important to emphasize that the saturation polarization measurement measures the total volume of the sample, in contrast with the EBSD method which determines the phase ratio based on a two-dimensional image taken from the sample surface.

It was found that the plastic deformation applied prior to heat treatment significantly enhanced the decomposition process of the ferrite phase. This phenomenon can be explained by two mechanisms.

The sigma-phase formation starts along the ferrite–austenite grain boundaries. Its rate-limiting process is the diffusion of chromium and molybdenum. The diffusion rate of these elements increased due to the increased dislocation density due to cold working.

Additionally, the deformation of stored energy improves the number of the sigma-phase nuclei which makes the precipitation process faster [

6,

9,

11].

From a practical point of view, it can be stated that the previous plastic deformation strongly increased the risk of sigma phase-induced embrittlement.

It was also found that the appearance of the sigma phase formed during the decomposition of ferrite could be sensitively detected by measuring magnetic saturation polarization and thermoelectric power measurement. Both measurement methods are suitable for the quantification of the formed sigma phase. However, for practical reasons the magnetic saturation polarization measurement seems more suitable for testing real engineering structures. The application of these non-destructive testing methods is recommended for testing the condition of duplex stainless steel structures applied at elevated temperatures.

4. Conclusions

The eutectoidal phase transformation of 2507 duplex stainless steel was investigated in this study. During this phase transformation, the metastable ferrite phase decomposed to secondary austenite and sigma phase. The sigma phase is a hard intermetallic phase that strongly effects the properties of DSS.

The effect of the previous cold working and heat treatment on the phase transformation was investigated. Samples were cold rolled with up to 61.9% rolling reduction and thereafter uniformly heat-treated at 850 °C for 30 min. The magnetic saturation polarization measured by a DC magnetometer was used to determine the ferrite content. Additionally, metallography, thermoelectric power measurement, electron beam scattering diffraction, and hardness testing were applied.

It was found that the cold rolling did not affect the amount of ferromagnetic phase. The amount of ferrite did not change due to plastic deformation, so the appearance of ferromagnetic strain-induced martensite could not be detected.

It has also been found that the cold rolling applied before the heat treatment significantly increased the rate of the eutectoidal decomposition process and thus the amount of sigma phase in the alloy. An increase in the amount of the sigma phase caused a significant increase in hardness.

The most important result of the tests performed is that the magnetic saturation polarization and thermoelectric power measurements were suitable for monitoring the microstructural changes of duplex stainless steels due to heat input. A near linear relationship was found between the magnetic saturation polarization and thermoelectric power results in regards to the tested duplex stainless steel specimens.