Experimental Study on the Influence of Dry–Wet Cycles on the Static and Dynamic Characteristics of Fiber-Modified Lime and Fly Ash-Stabilized Iron Tailings at Early Curing Age

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

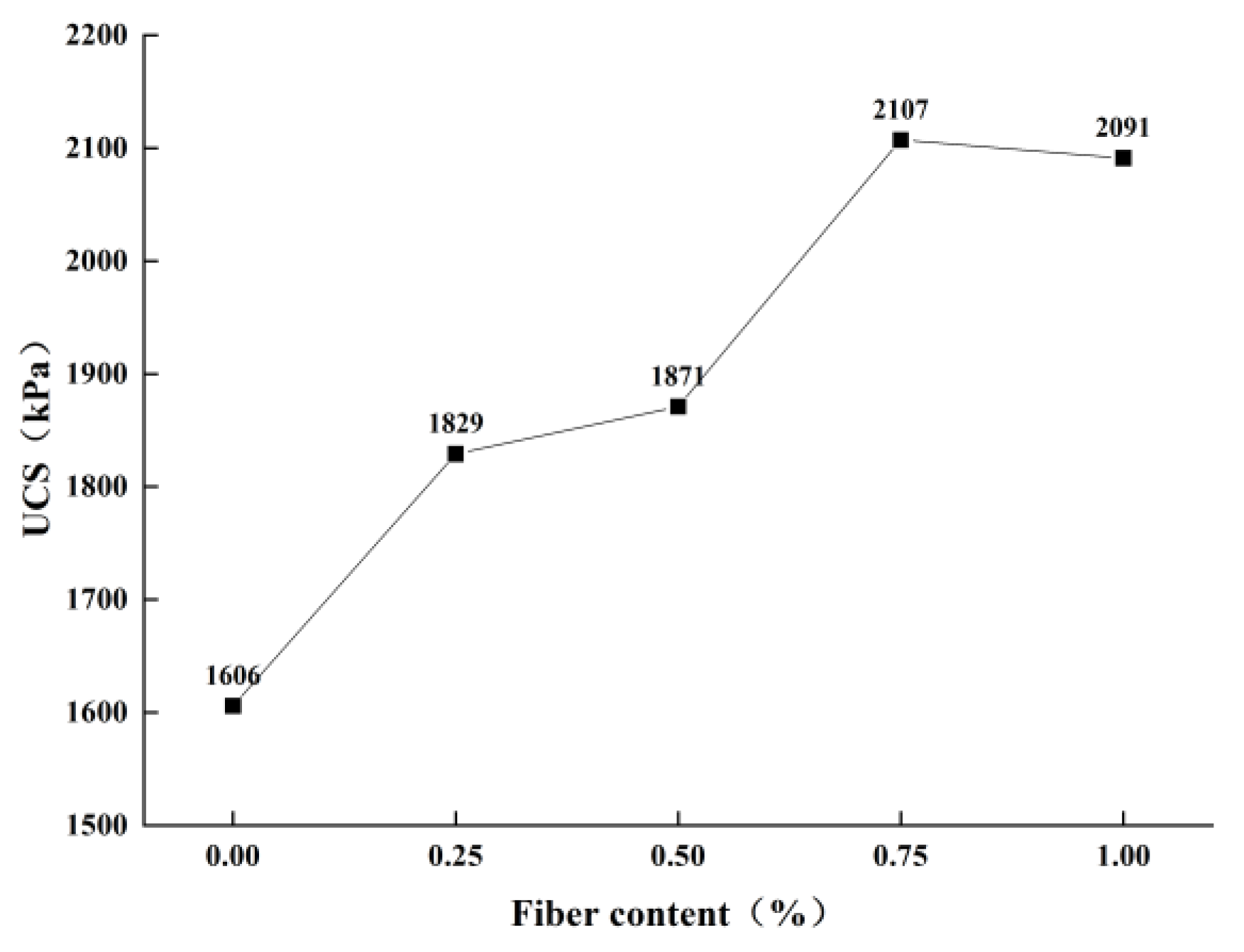

2.2. Test Scheme

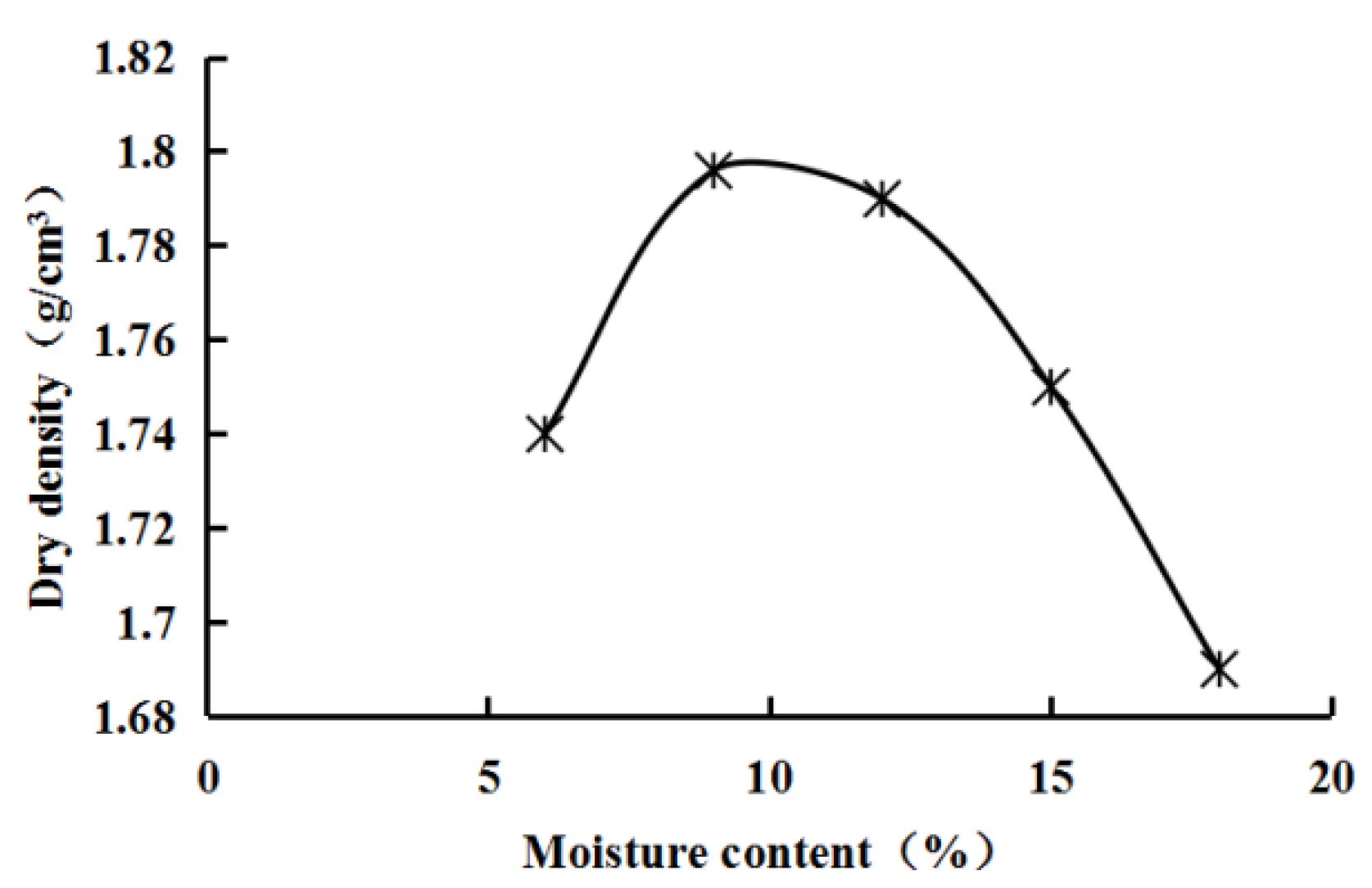

2.3. Sample Production

- (1)

- The iron tailings and clay were dried and crushed, and then passed through a 2 mm sieve plate to obtain iron tailings and clay less than 2 mm. We weighed a certain proportion of lime, fly ash, fiber, clay and iron tailings according to the test scheme, mixed the dry mixture evenly, and then added water to mix evenly to obtain the mixture, and put the mixture into plastic bags for 24 h.

- (2)

- After 24 h, we weighed the mixture of a certain quality and put it into the test mold coated with lubricant three times, and placed the upper and lower cushion blocks. Then, we placed the whole test mold on the pressure testing machine, applied pressure at the loading rate of 1 mm/min until the upper and lower cushion blocks were pressed into the top of the test mold, maintained the pressure for 2 min, released the pressure and removed the test mold.

- (3)

- We placed the test mold on the demolder and took out the sample. We wrapped the sample with plastic film and put it into the standard curing box for curing. The curing temperature was 20 ± 2 °C and the relative humidity was more than 95%.

- (4)

- After reaching the curing age of 7 days, the dry–wet cycle should be carried out. We first took out the sample, soaked it in water for 12 h, and then dried it naturally for 12 h. This is a dry–wet cycle. The method of natural air drying was to lay a layer of dry sand on the box, put a towel on the sand, and put the sample on the towel for air drying. When the number of dry and wet cycles reached the target number, we immersed the sample in water for 24 h and then conducted the test. The sample preparation process is shown in Figure 4.

2.4. Sample Method

2.4.1. UCS Test

2.4.2. Splitting Tensile Strength Test

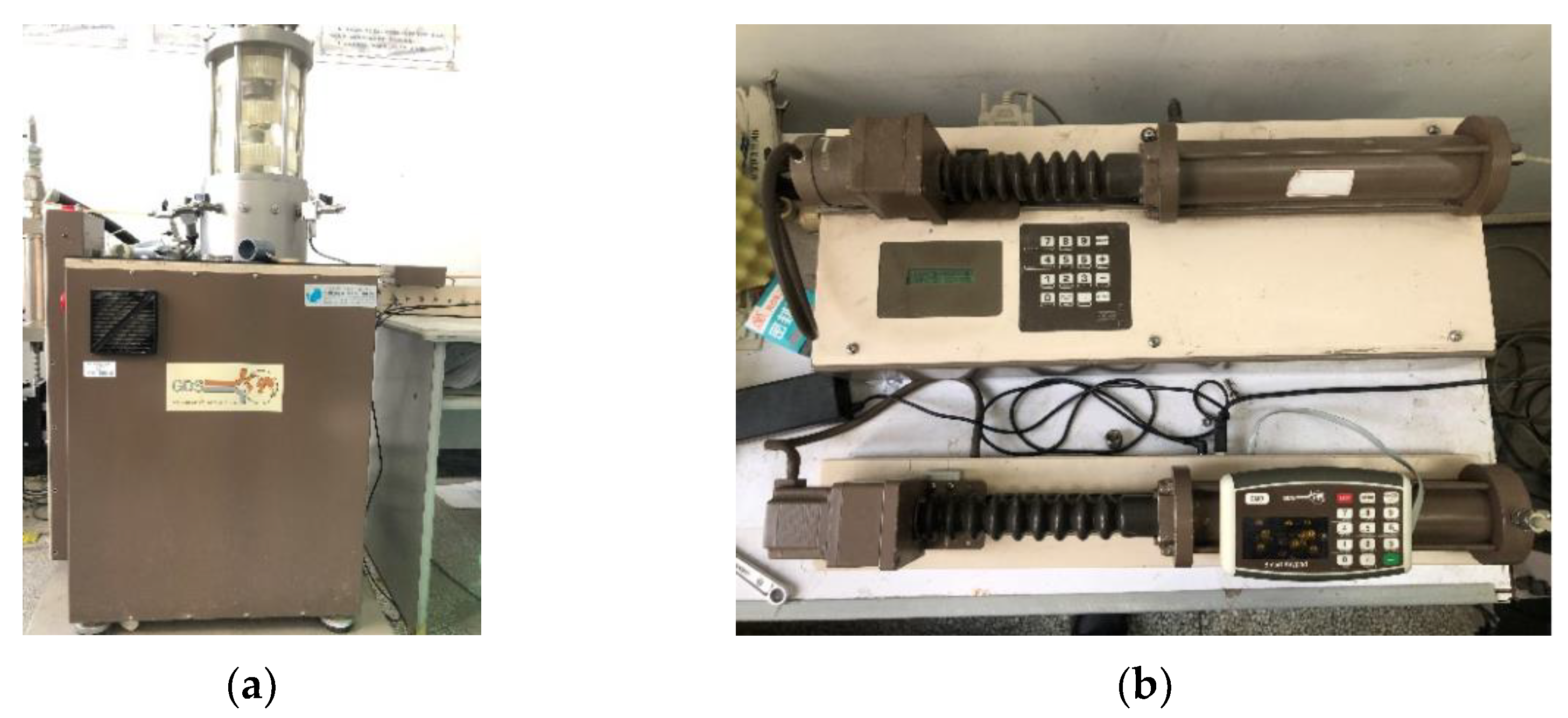

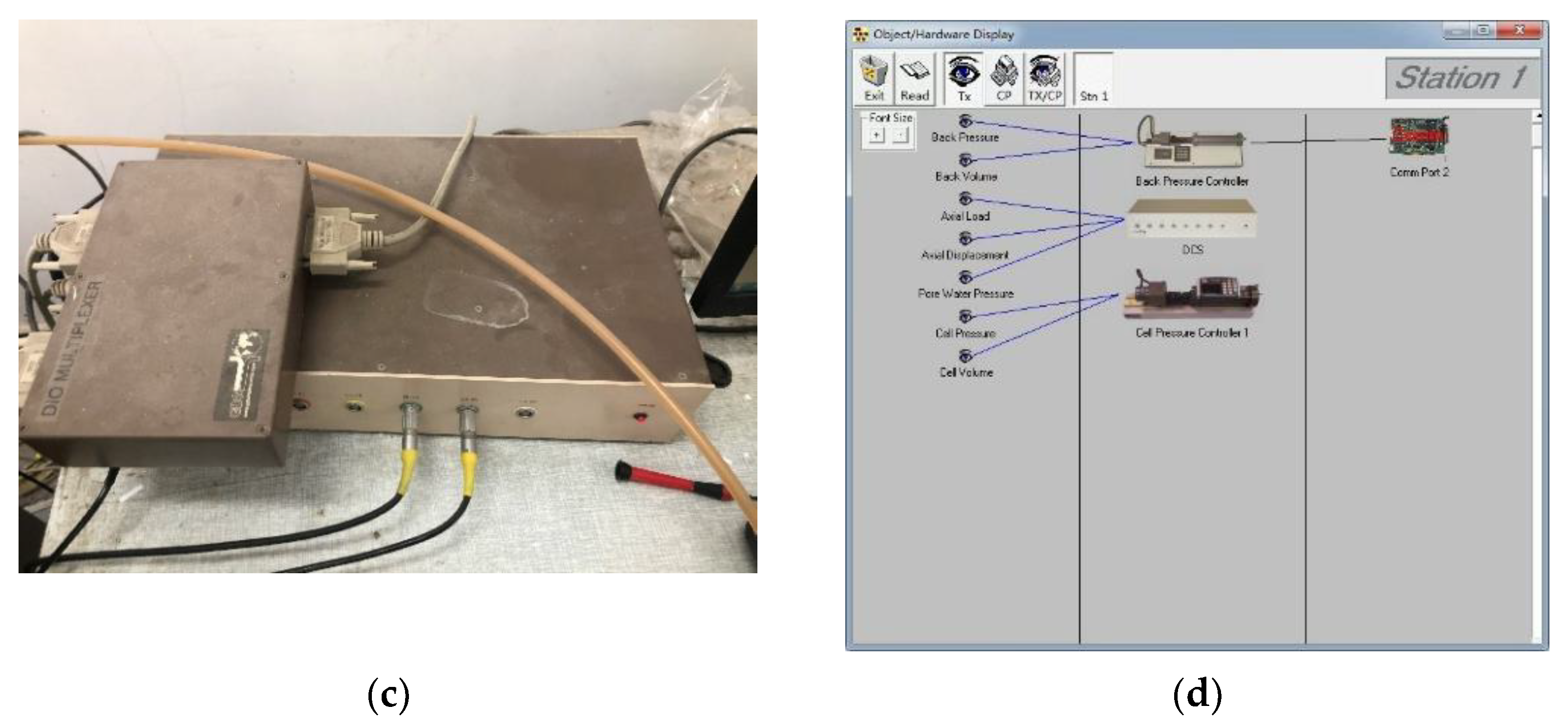

2.4.3. Dynamic Triaxial Test

3. Results and Discussions

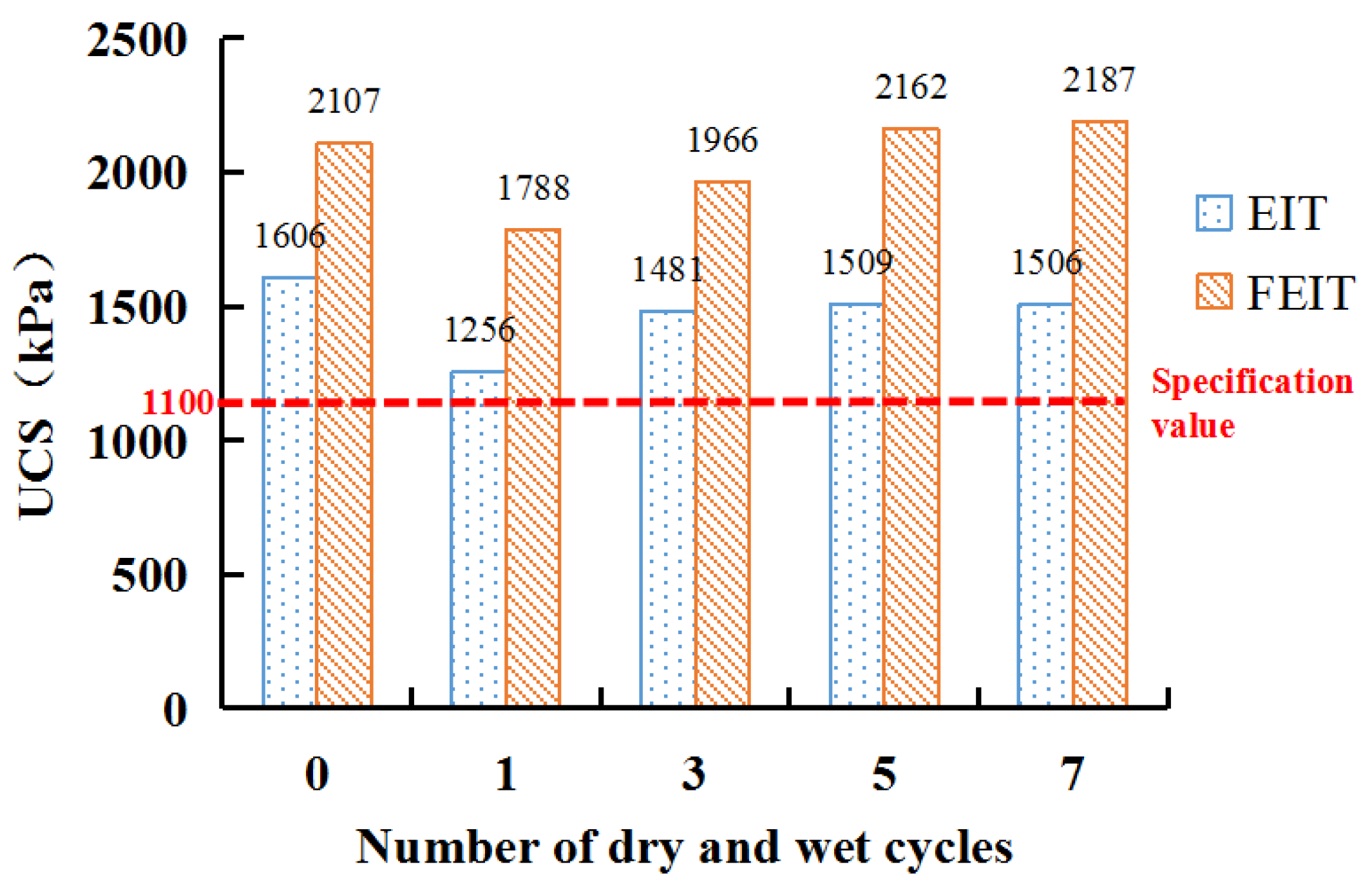

3.1. Effect of Dry–Wet Cycles on Unconfined Compressive Strength

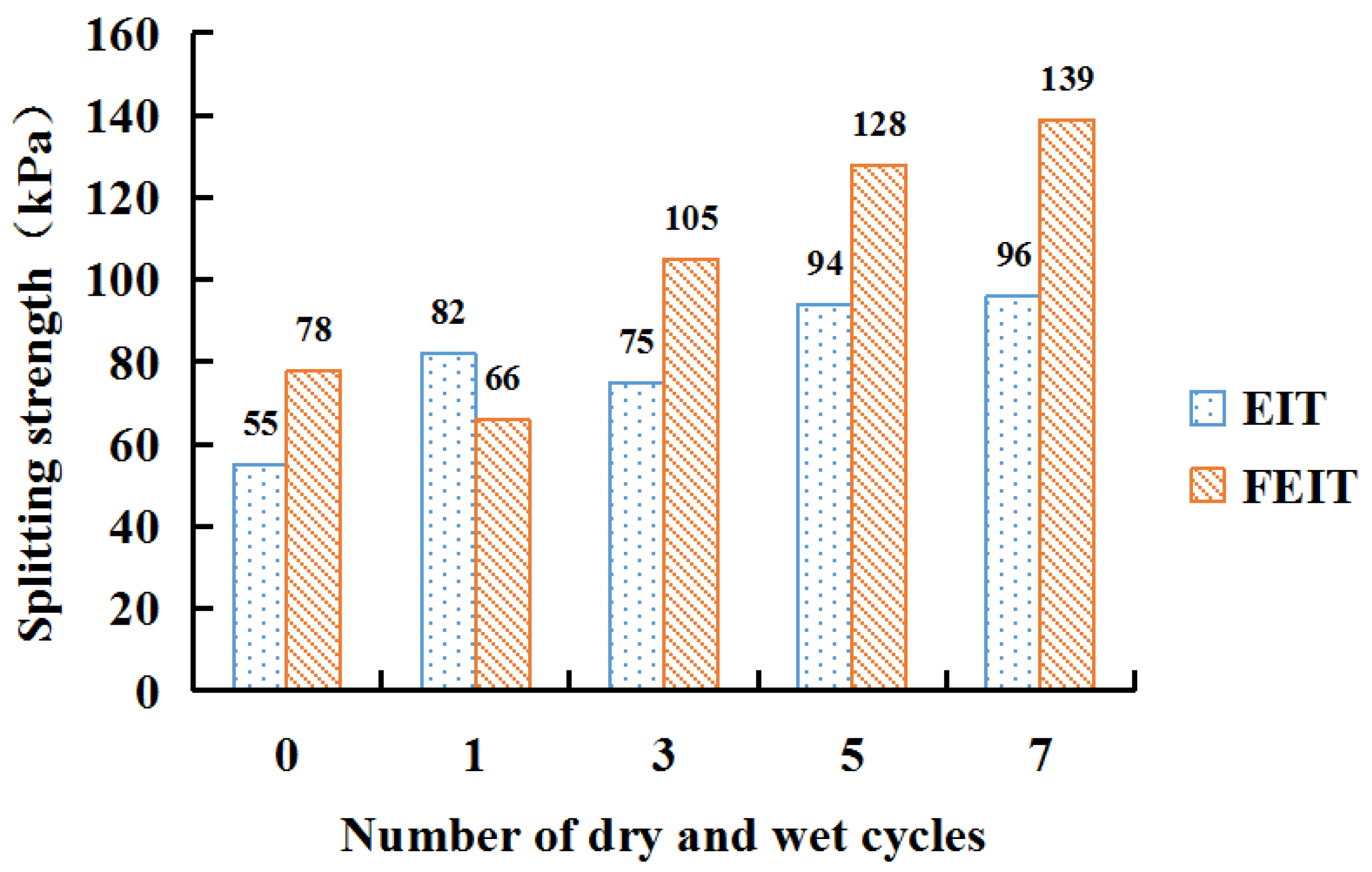

3.2. Effect of Dry–Wet Cycles on Splitting Compressive Strength

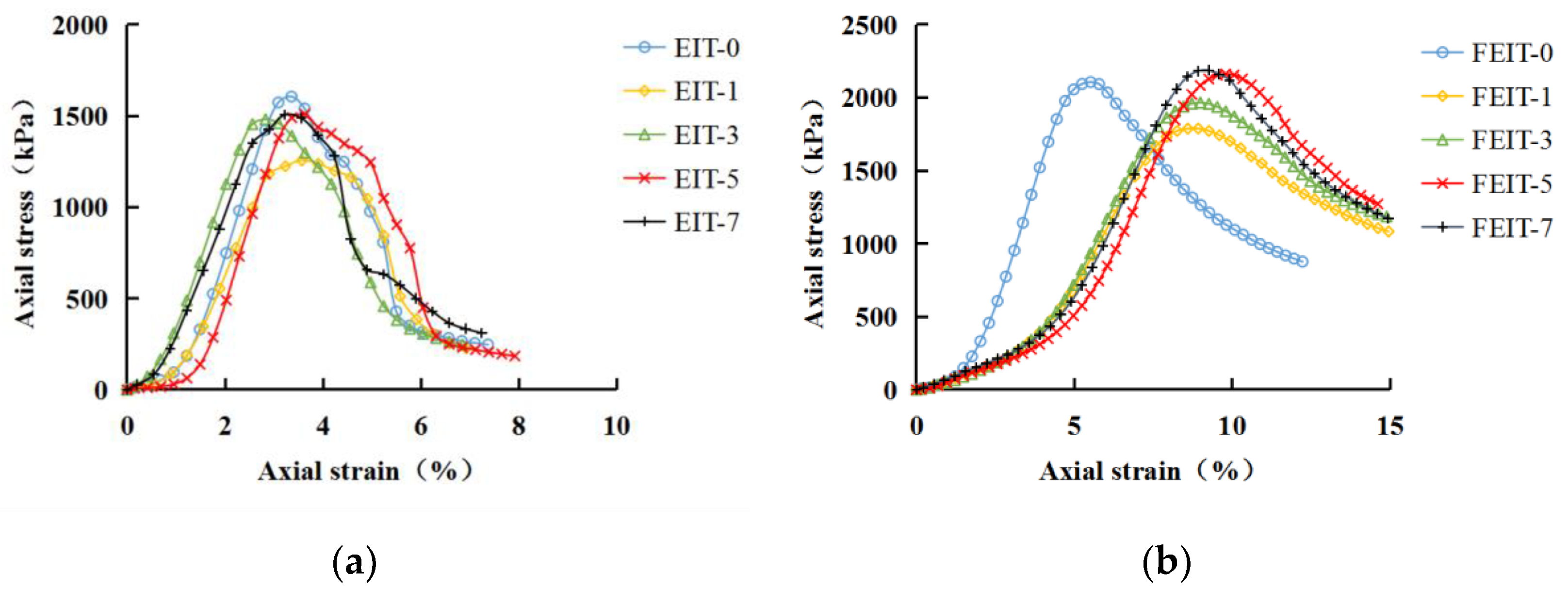

3.3. Influence of Dry–Wet Cycles on Dynamic Characteristics

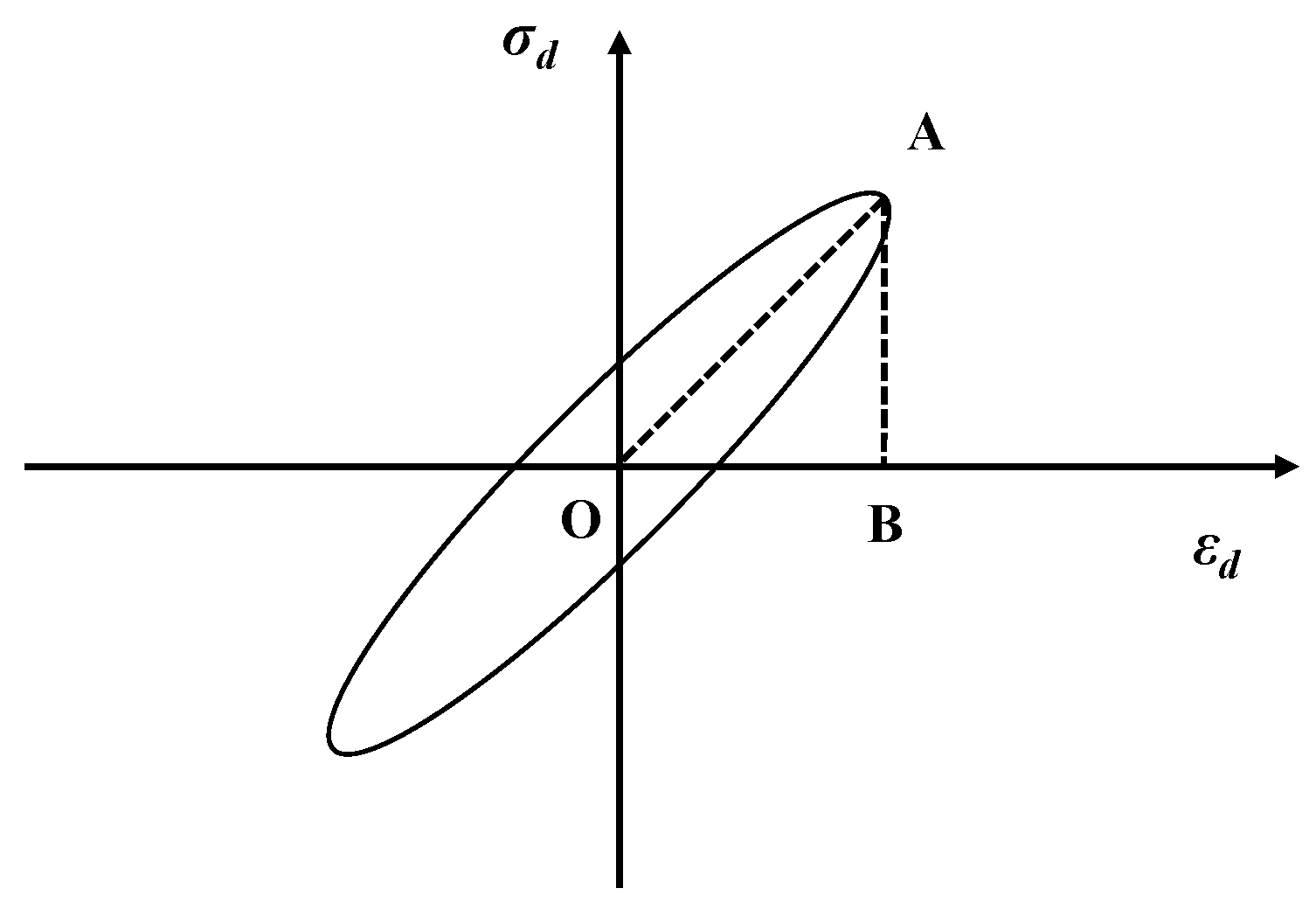

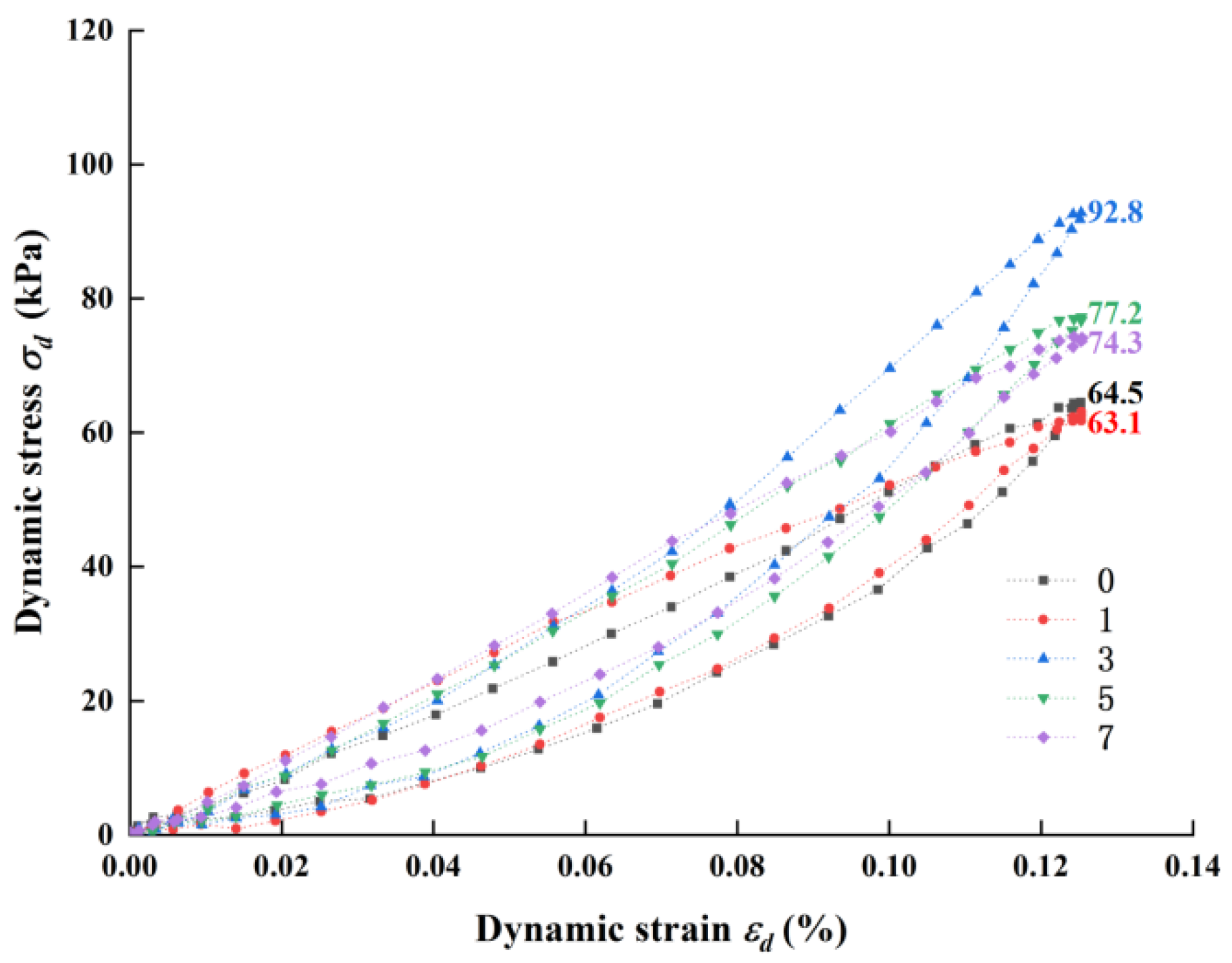

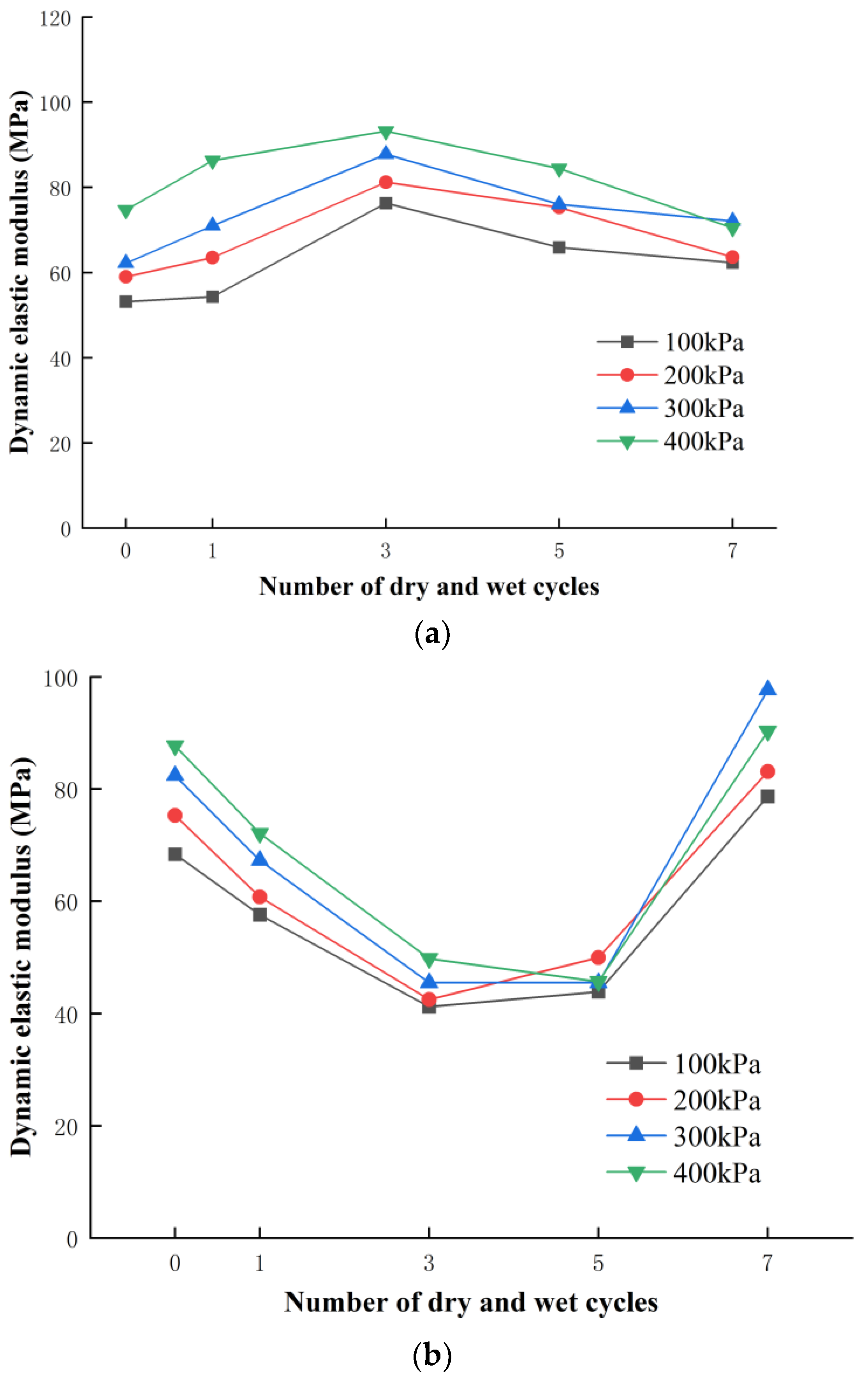

3.3.1. Effect of Dry–Wet Cycles on Dynamic Elastic Modulus Ed

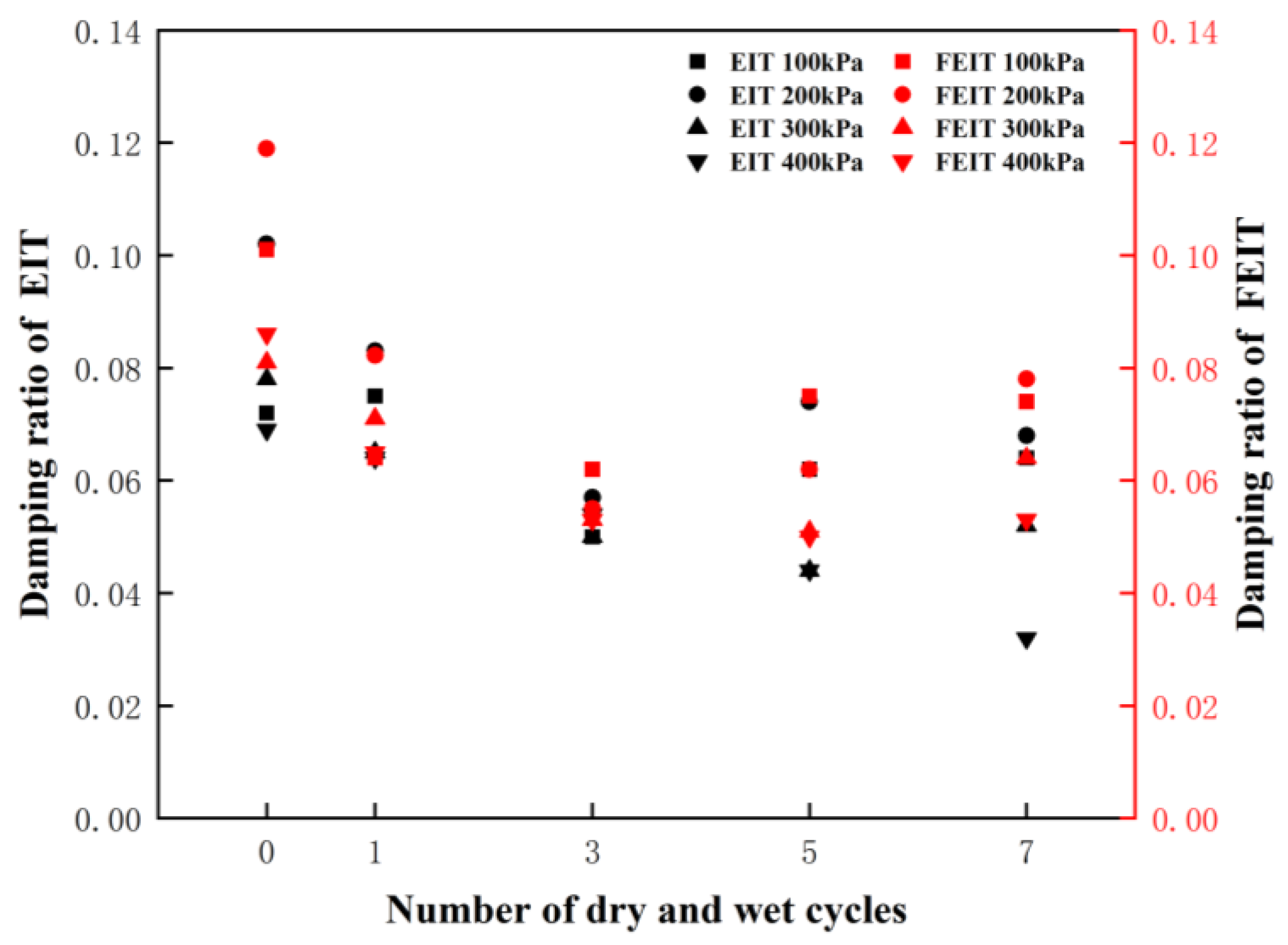

3.3.2. Effect of Dry–Wet Cycles on Damping Ratio λ

4. Conclusions

- (1)

- The UCS of EIT and FEIT decreased after a dry–wet cycle, and then gradually increased and stabilized. Under different dry–wet cycles, the UCS of FEIT is greater than that of EIT, and the dry–wet cycles promote the UCS of FEIT.

- (2)

- The splitting strength of EIT and FEIT increased with the number of dry–wet cycles. The tensile strength of FEIT is better than that of EIT, and the dry–wet cycles only play a small role in promoting the splitting strength of FEIT.

- (3)

- The dynamic stress of EIT and FEIT increased after seven dry–wet cycles. The dry–wet cycle is the main factor affecting the change in the dynamic elastic modulus of EIT and FEIT. Under the same confining pressure, the dynamic elastic modulus of EIT first increases and then decreases with the increase in dry–wet cycle times. On the contrary, the dynamic elastic modulus of FEIT first decreases and then increases with the increase in dry–wet cycle times. After seven dry–wet cycles, FEIT has better resistance to dynamic load deformation than EIT. The damping ratio of EIT and FEIT decreases with the increase in dry–wet cycles, and then tends to be stable. The damping ratio of FEIT is greater than that of EIT, and the dry–wet cycles can promote the vibration resistance of FEIT.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, N.; Lv, S.; Wang, W.; Guo, J.; Jiang, P.; Liu, Y. Experimental investigations on the mechanical behavior of iron tailings powder with compound admixture of cement and nano-clay. Constr. Build. Mater. 2020, 254, 119259. [Google Scholar] [CrossRef]

- Chu, C.; Zhang, F.; Wu, D.; Zhan, M.; Liu, Y. Study on Mechanical Properties of the Expansive Soil Treated with Iron Tailings Sand. Adv. Civ. Eng. 2021, 2021, 9944845. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, Z.; Yin, S.; Yu, L.A.-O. Utilization of Iron Tailings Sand as an Environmentally Friendly Alternative to Natural River Sand in High-Strength Concrete: Shrinkage Characterization and Mitigation Strategies. Materials 2020, 13, 5614. [Google Scholar] [CrossRef] [PubMed]

- Hu, L.; Wu, H.; Zhang, L.; Zhang, P.; Wen, Q. Geotechnical Properties of Mine Tailings. J. Mater. Civ. Eng. 2017, 29, 4016220. [Google Scholar] [CrossRef]

- Stoltz, G.; Cuisinier, O.; Masrouri, F. Weathering of a lime-treated clayey soil by drying and wetting cycles. Eng. Geol. 2014, 181, 281–289. [Google Scholar] [CrossRef]

- Ying, Z.; Cui, Y.-J.; Benahmed, N.; Duc, M. Changes of small strain shear modulus and microstructure for a lime-treated silt subjected to wetting-drying cycles. Eng. Geol. 2021, 293, 106334. [Google Scholar] [CrossRef]

- Wu, Y.; Shi, K.; Han, Y.; Han, T.; Yu, J.; Li, D. Experimental Study on Strength Characteristics of Expansive Soil Improved by Steel Slag Powder and Cement Under Dry–Wet Cycles. Iran. J. Sci. Technol. Trans. Civ. Eng. 2021, 45, 941–952. [Google Scholar] [CrossRef]

- Xu, J.; Ren, C.; Wang, S.; Gao, J.; Zhou, X. Permeability and Microstructure of a Saline Intact Loess after Dry-Wet Cycles. Adv. Civ. Eng. 2021, 2021, 6653697. [Google Scholar] [CrossRef]

- Ziaie moayed, R.; Alibolandi, M.; Lahiji, B. Impacts of freezing-thawing and wetting-drying cycles on a silt stabilized by lime and waste silica. Environ. Eng. Manag. J. 2018, 17, 2905–2913. [Google Scholar] [CrossRef]

- Atma, P.; Sanandam, B.; Budhaditya, H.; Ankit, G.; Sekharan, S.; Qinhua, W. Probabilistic analysis of soil suction and cracking in fibre-reinforced soil under drying–wetting cycles in India. Environ. Geotech. 2019, 6, 188–203. [Google Scholar]

- Kamaruddin, F.A.; Anggraini, V.; Kim Huat, B.; Nahazanan, H. Wetting/Drying Behavior of Lime and Alkaline Activation Stabilized Marine Clay Reinforced with Modified Coir Fiber. Materials 2020, 13, 2753. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Hao, Y.; Wang, Z.; Cheng, L.; Li, J. Experimental study on dynamic strength properties of compacted loess under wetting-drying cycles. Chin. J. Rock Mech. Geotech. Eng. 2020, 39, 1242–1251. (In Chinese) [Google Scholar]

- Hu, Z.; Ai, P.; Li, Z.; Ma, Q.; Li, L. Experimental study on dynamic strength properties of compacted loess under wetting-drying cycles. Rock Soil Mech. 2021, 42, 2722–2732. (In Chinese) [Google Scholar]

- Jiang, P.; Chen, Y.; Wang, W.; Yang, J.; Wang, H.; Li, N.; Wang, W. Flexural behavior evaluation and energy dissipation mechanisms of modified iron tailings powder incorporating cement and fibers subjected to freeze-thaw cycles. J. Clean. Prod. 2022, 351, 131527. [Google Scholar] [CrossRef]

- JTG3430-2020 Test Methods of Soils for Highway Engineering; China Communications Press: Beijing, China, 2020. (In Chinese)

- Bai, W.; Kong, L.; Guo, A. Effects of physical properties on electrical conductivity of compacted lateritic soil. J. Rock Mech. Geotech. Eng. 2013, 5, 406–411. [Google Scholar] [CrossRef] [Green Version]

- JTG/T F20-2015 Construction Guidelines for Highway Basw and Subbase; China Communications Press: Beijing, China, 2015. (In Chinese)

- JTG E51–2009 Test Methods of Materials Stabilized with Inorganic Binders for Highway Engineering; China Communications Press: Beijing, China, 2009. (In Chinese)

- Wang, W.; Liu, J.; Li, N.; Ma, L. Mechanical properties and micro mechanism of Nano-SiO2 modified coastal cement soil at short age. Acta Mater. Compos. Sin. 2021, 39, 1706–1719. (In Chinese) [Google Scholar] [CrossRef]

- Du, J.; Liu, B.; Wang, Z.; Zheng, G.; Jiang, N.-J.; Zhou, M.; Zhou, H. Dynamic behavior of cement-stabilized organic-matter-disseminated sand under cyclic triaxial condition. Soil Dyn. Earthq. Eng. 2021, 147, 106777. [Google Scholar] [CrossRef]

- Zhang, J.; Cao, J.; Huang, S.; Shi, B. Experimental study on the dynamic shear modulus and damping ratio of saturated sand under cyclic loading. Mater. Technol. 2021, 55, 741–749. [Google Scholar] [CrossRef]

- Chen, Z.; Xu, H.; Cheng, M.; Lu, H.; Wang, Z.; Feng, P. Dynamic Triaxial Test and Microscopic Study of Solidified Muddy Soil With Different Mixing Ratios and Curing Ages. Front. Mater. 2021, 8, 326. [Google Scholar] [CrossRef]

- Wang, R.; Hu, Z.; Ren, X.; Li, F.; Zhang, F. Dynamic modulus and damping ratio of compacted loess under long-term traffic loading. Road Mater. Pavement Des. 2021, 1–15. [Google Scholar] [CrossRef]

- Liu, F.; Zhou, Z.; Ma, W.; Zhang, S.; Sun, Z. Dynamic Parameters and Hysteresis Loop Characteristics of Frozen Silt Clay under Different Cyclic Stress Paths. Adv. Mater. Sci. Eng. 2021, 2021, 3763181. [Google Scholar] [CrossRef]

- Tang, C.-S.; Wang, D.-Y.; Zhu, C.; Zhou, Q.-Y.; Xu, S.-K.; Shi, B. Characterizing drying-induced clayey soil desiccation cracking process using electrical resistivity method. Appl. Clay Sci. 2018, 152, 101–112. [Google Scholar] [CrossRef]

- Hu, Z.; Peng, K.; Li, L.; Ma, Q.; Xiao, H.; Li, Z.; Ai, P. Effect of Wetting-Drying Cycles on Mechanical Behaviour and Electrical Resistivity of Unsaturated Subgrade Soil. Adv. Civ. Eng. 2019, 2019, 3465327. [Google Scholar] [CrossRef]

- Zhao, G.; Yan, H.; Yan, Y.; Gao, S.; Fan, D.; He, Y.; Wang, Y. Experimental study on the dynamic properties of lime-solidified soft soil under cyclic loading. Arab. J. Geosci. 2020, 13, 671. [Google Scholar] [CrossRef]

- Zhang, D. Experimental Study of Strength Characteristics of Lime Stabilized Soil in Drying and Wetting Cycles. J. Shanghai Jiaotong Univ. 2011, 45, 128–132. (In Chinese) [Google Scholar]

- Zhang, Y.; Zhang, X.; Zhang, H. Test research of geotechnique textile soil reinforcement mechanism and engineering application. Rock Soil Mech. 2005, 26, 1323–1326. (In Chinese) [Google Scholar]

- Fakhrabadi, A.; Ghadakpour, M.; Choobbasti, A.J.; Kutanaei, S.S. Evaluating the durability, microstructure and mechanical properties of a clayey-sandy soil stabilized with copper slag-based geopolymer against wetting-drying cycles. Bull. Eng. Geol. Environ. 2021, 80, 5031–5051. [Google Scholar] [CrossRef]

- Jiang, Y.J.; Ni, C.Y.; Sha, H.W.; Li, Z.-H.; Cai, L.-Y. Deterioration characteristics of cement-improved loess under dry-wet and freeze-thaw cycles. PLoS ONE 2021, 16, e0253199. [Google Scholar] [CrossRef]

- Horpibulsuk, S.; Suksiripattanapong, C.; Samingthong, W.; Rachan, R.; Arulrajah, A. Durability against Wetting–Drying Cycles of Water Treatment Sludge–Fly Ash Geopolymer and Water Treatment Sludge–Cement and Silty Clay–Cement Systems. J. Mater. Civil Eng. 2015, 28, 04015078. [Google Scholar] [CrossRef]

- Ma, D.; Kong, S.; Li, Z.; Zhang, Q.; Wang, Z.; Zhou, Z. Effect of wetting-drying cycle on hydraulic and mechanical properties of cemented paste backfill of the recycled solid wastes. Chemosphere 2021, 282, 131163. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, S.; Ji, E.; Fu, Z. Tensile fracture properties of gravelly soil reinforced by polypropylene fiber. Rock Soil Mech. 2021, 42, 2713–2721. (In Chinese) [Google Scholar]

- Yu, S.; Qu, S.; Yang, L.; Zeng, Q.; Wang, H. Research on the Saturated Cohesive Soil with Strain Controlled Dynamic Triaxial Test. J. Railw. Enginee Ring Soc. 2019, 36, 24–28. (In Chinese) [Google Scholar]

- Lu, Z.; Zhao, Y.; Xian, S.; Yao, H. Experimental Study on Dynamic Resilient Modulus of Lime-Treated Expansive Soil. Adv. Mater. Sci. Eng. 2020, 2020, 3272681. [Google Scholar] [CrossRef] [Green Version]

- Wang, M.; Shan, Z.; Wang, Y.; Di, S. Dynamic elastic moduli and damping ratios of marine sediments at zhoushan daishan based on dynamic triaxial tests under strain control. Chin. J. Rock Mech. Geotech. Eng. 2014, 33, 1503–1512. (In Chinese) [Google Scholar]

- Abbaspour, M.; Narani, S.S.; Aflaki, E.; Nejad, F.M. Dynamic characteristics of a sandy subgrade reinforced by waste tire textile fibres. Int. J. Pavement Eng. 2020, 21, 1–16. [Google Scholar] [CrossRef]

| Component | CaO | Al2O3 | Fe2O3 | MgO | Other |

|---|---|---|---|---|---|

| Content (%) | 89.4 | 0.25 | 0.18 | 1.76 | 8.41 |

| Component | CaO | Al2O3 | Fe2O3 | SiO2 | Burn Vector | Other |

|---|---|---|---|---|---|---|

| Content (%) | 8.86 | 25.31 | 12.44 | 35.56 | 4.52 | 13.31 |

| Component | Fe2O3 | Al2O3 | SiO2 | CaO | MgO | Nb2O5 | K2O | Other |

|---|---|---|---|---|---|---|---|---|

| Content (%) | 22.94 | 4.31 | 21.15 | 24.78 | 6.59 | 6.89 | 2.45 | 10.89 |

| Component | Fe2O3 | Al2O3 | SiO2 | CaO | Nb2O5 | K2O | Other |

|---|---|---|---|---|---|---|---|

| Content (%) | 15.63 | 13.47 | 50.25 | 2.54 | 5.78 | 5.67 | 6.66 |

| Fiber Type | Diameter (μm) | Length (mm) | Density (g/cm3) | Tensile Strength (MPa) | Elastic Modulus (GPa) |

|---|---|---|---|---|---|

| Polypropylene fiber | 18~48 | 6 | 0.91 | >350 | >3.85 |

| NO | Curing Age (d) | Dry–Wet Cycles | Test Type | Loading Rate/mm·min−1 | Confining Pressure/kPa | Number of Dynamic Load Cycles |

|---|---|---|---|---|---|---|

| EIT, FEIT | 7 | 0, 1, 3, 5, 7 | UCS test | 1 | — | — |

| Splitting tensile test | 1 | — | — | |||

| Dynamic triaxial test | — | 100, 200, 300, 400 | 1000 |

| Scholar | Soil | Curing Agent | Comparison of UCS Strength after 7 Dry–Wet Cycles/kPa |

|---|---|---|---|

| Alireza et al. [30] | Clay/sand | Copper slag (CS) | <0.6 MPa |

| Jiang et al. [31] | Loess | Cement | 1.04~1.48 MPa |

| Suksun et al. [32] | Clay/silt | Fly ash + cement | <2 MPa |

| Dan et al. [33] | Red sandstone | Cement + gypsum | <3.5 MPa |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, P.; Zhou, X.; Qian, J.; Li, N. Experimental Study on the Influence of Dry–Wet Cycles on the Static and Dynamic Characteristics of Fiber-Modified Lime and Fly Ash-Stabilized Iron Tailings at Early Curing Age. Crystals 2022, 12, 568. https://doi.org/10.3390/cryst12050568

Jiang P, Zhou X, Qian J, Li N. Experimental Study on the Influence of Dry–Wet Cycles on the Static and Dynamic Characteristics of Fiber-Modified Lime and Fly Ash-Stabilized Iron Tailings at Early Curing Age. Crystals. 2022; 12(5):568. https://doi.org/10.3390/cryst12050568

Chicago/Turabian StyleJiang, Ping, Xuhui Zhou, Jian Qian, and Na Li. 2022. "Experimental Study on the Influence of Dry–Wet Cycles on the Static and Dynamic Characteristics of Fiber-Modified Lime and Fly Ash-Stabilized Iron Tailings at Early Curing Age" Crystals 12, no. 5: 568. https://doi.org/10.3390/cryst12050568

APA StyleJiang, P., Zhou, X., Qian, J., & Li, N. (2022). Experimental Study on the Influence of Dry–Wet Cycles on the Static and Dynamic Characteristics of Fiber-Modified Lime and Fly Ash-Stabilized Iron Tailings at Early Curing Age. Crystals, 12(5), 568. https://doi.org/10.3390/cryst12050568