Characterization of ZTA Composite Ceramic/Ti6Al4V Alloy Joints Brazed by AgCu Filler Alloy Reinforced with One-Dimensional Al18B4O33 Single Crystal

Abstract

:1. Introduction

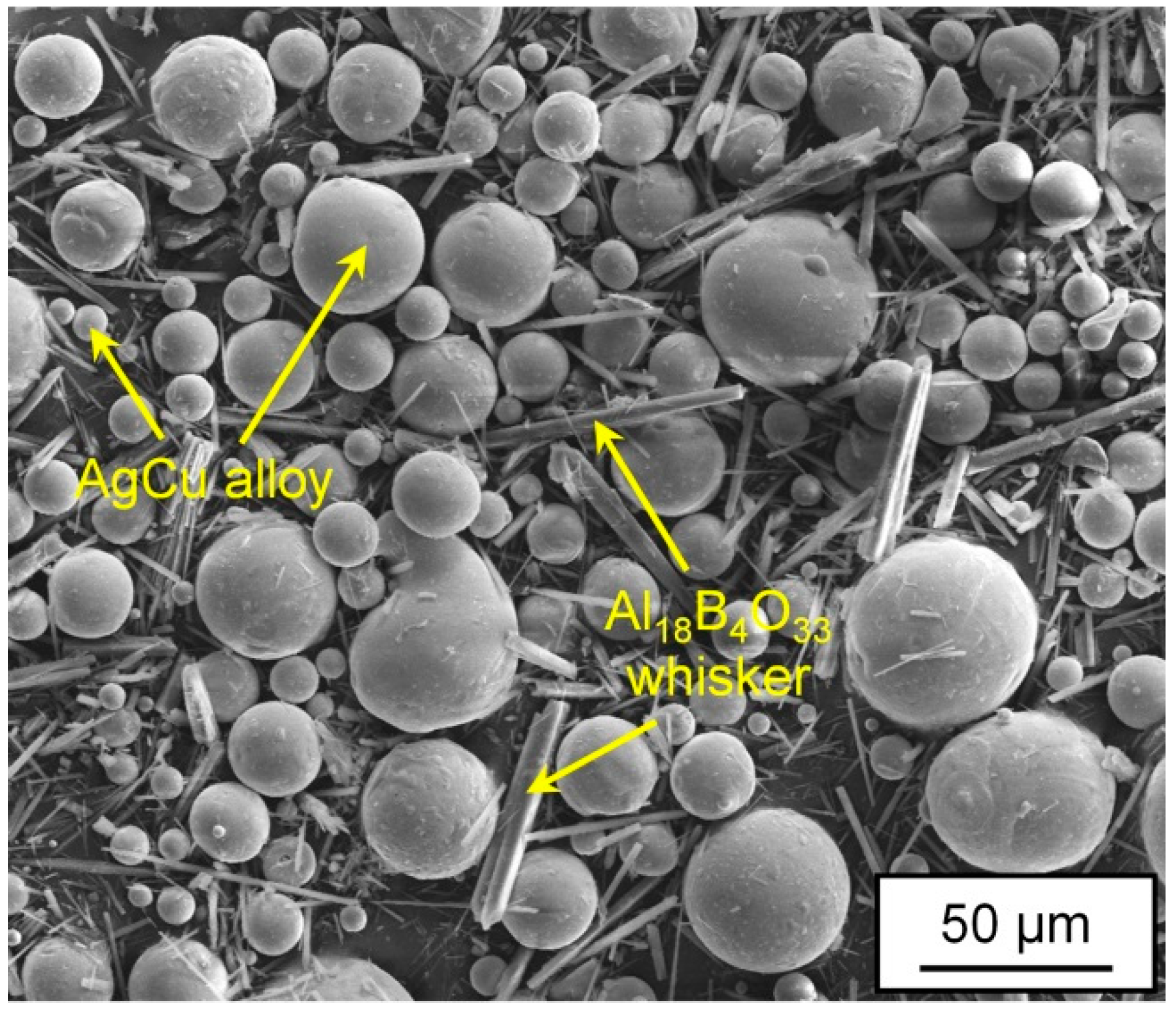

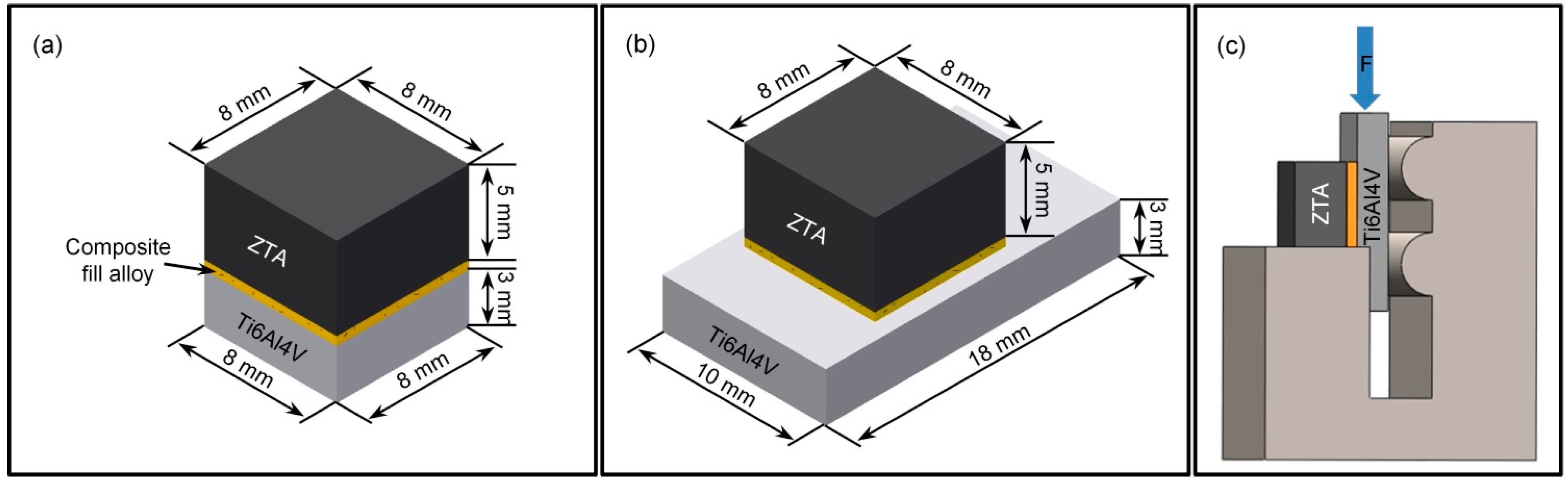

2. Materials and Methods

3. Results and Discussion

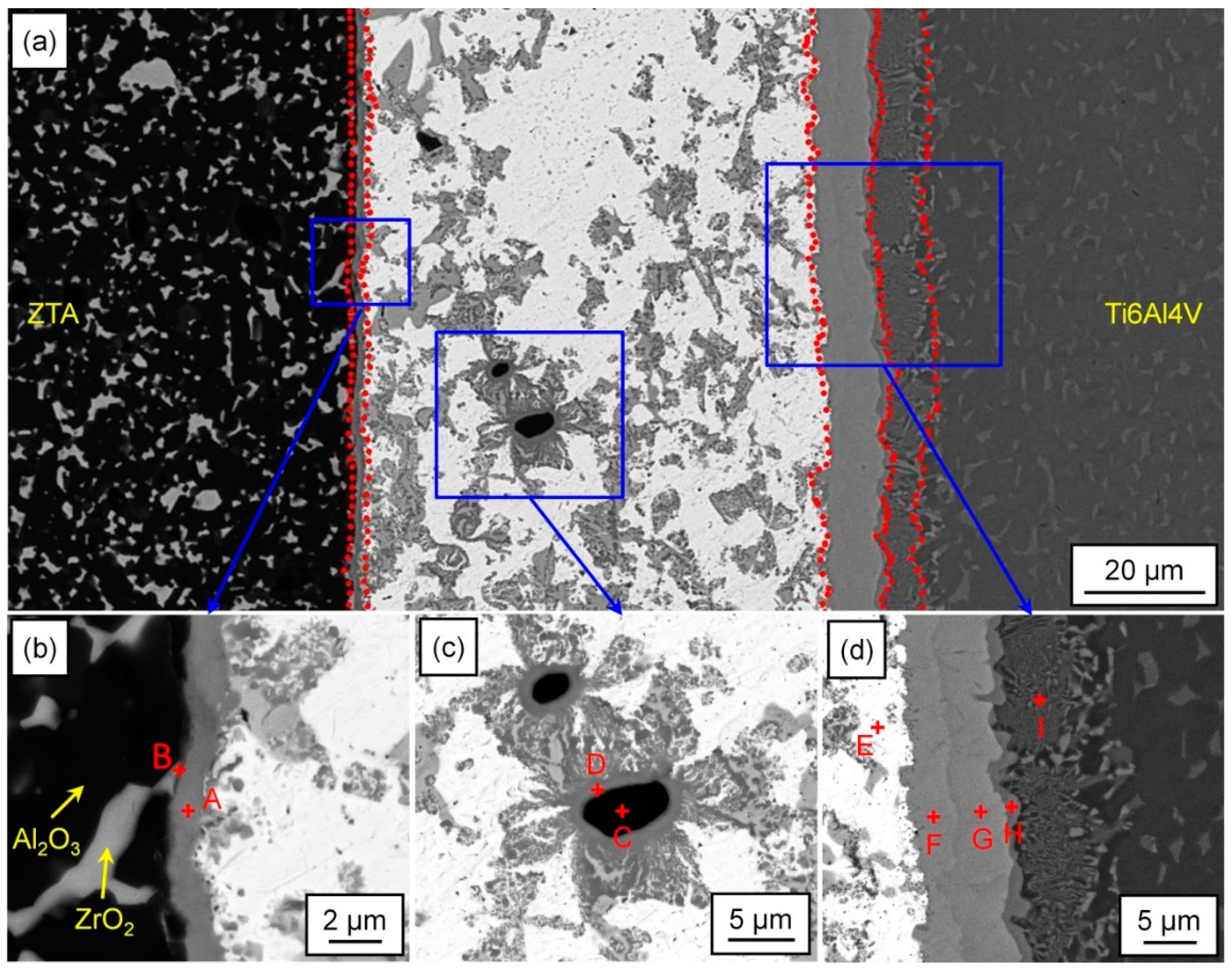

3.1. Characterization of the ZTA/AgCu + ABOw/Ti6Al4V Brazing Joint

3.2. Effect of Brazing Temperature on the Microstructure of the ZTA/AgCu + ABOw/Ti6Al4V Joints

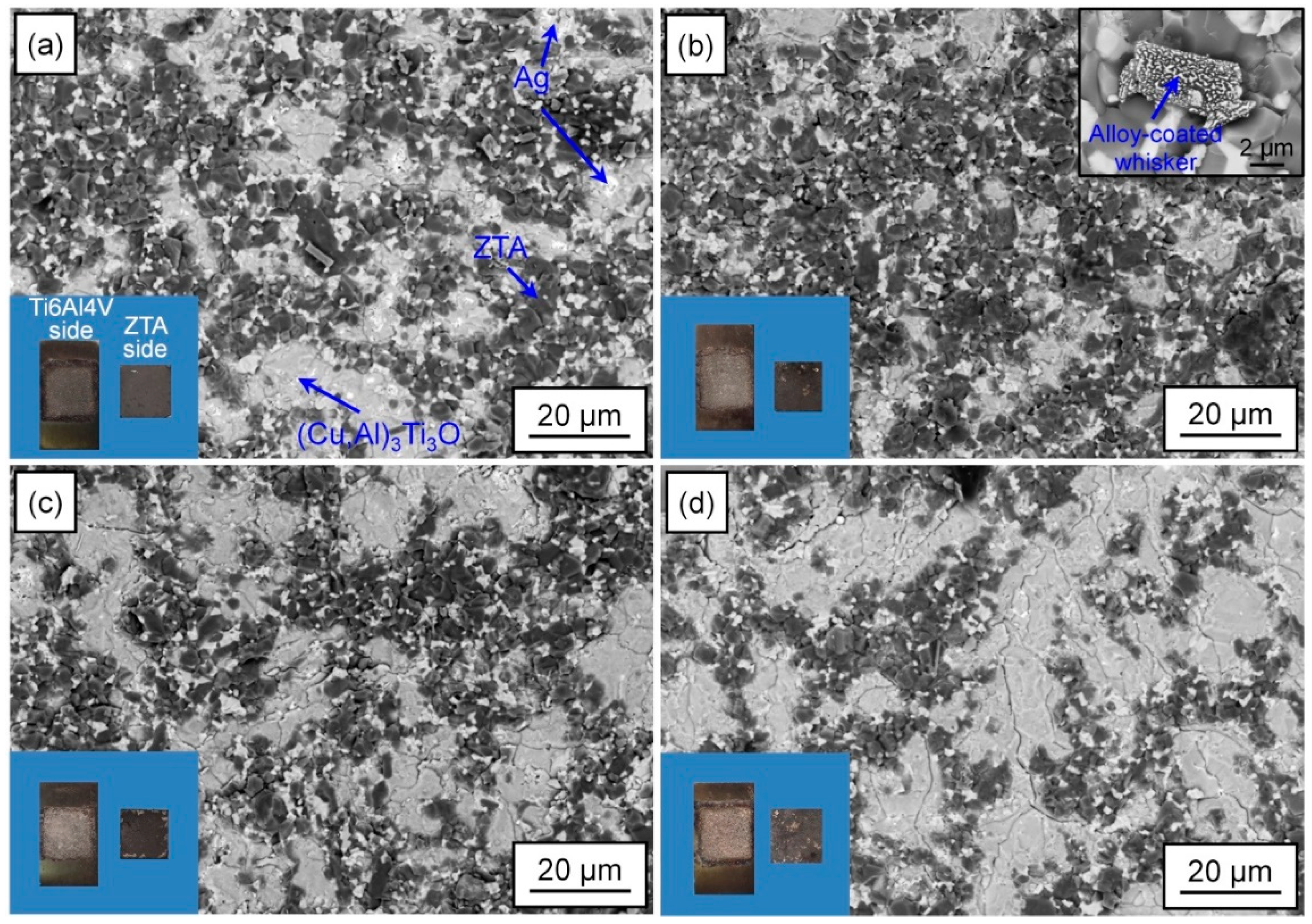

3.3. Effect of Brazing Temperature on the Microstructure of the ZTA/AgCu + ABOw/Ti6Al4V Joints

4. Conclusions

- (1)

- The added Al18B4O33 whiskers reacted with the liquid alloy during the brazing process, and continuous (Cu,Al)3Ti3O layers in contact with the residual whiskers and nano-sized (Cu,Al)3Ti3O particles around the whiskers formed in the brazing seam. Compared with the microstructure of the ZTA/AgCu/Ti6Al4V joint obtained at the same temperature, the thickness of the reaction layers in the ZTA/AgCu + ABOw/Ti6Al4V joint was reduced, which was probably because of the consumption and fetter of the Cu and Ti elements by the whiskers.

- (2)

- With the increase in the brazing temperature, the whiskers gradually transformed into nano-sized (Cu,Al)3Ti3O particles. Over the brazing temperature range of 800~875 °C, the increase in the thickness of the (Cu,Al)3Ti3O layer on ZTA and that of the Ti-Cu compound region were relatively moderate, while the thickness of the diffusion region on the Ti6Al4V side prominently increased.

- (3)

- The consumption of Ti and Cu by the whiskers at relatively low brazing temperatures could induce weak interconnection between the ceramic substrate and the brazing seam. The strength of the ZTA/AgCu + ABOw/Ti6Al4V joints reached the maximum value of 56 MPa when the joint was fabricated at 850 °C. The addition of whiskers in the brazing alloy can help to extend the temperature window for obtaining ZTA/Ti6Al4V joints with shear strength values higher than 50 MPa.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zadorozhnaya, O.Y.; Khabas, T.A.; Tiunova, O.V.; Malykhin, S.E. Effect of grain size and amount of zirconia on the physical and mechanical properties and the wear resistance of zirconia-toughened alumina. Ceram. Int. 2020, 46, 9263–9270. [Google Scholar] [CrossRef]

- Naga, S.M.; Awaad, M.; Bondioli, F.; Fino, P.; Hassan, A.M. Thermal diffusivity of ZTA composites with different YSZ quantity. J. Alloys Compd. 2017, 695, 1859–1862. [Google Scholar] [CrossRef]

- Lopes, A.C.O.; Coelho, P.G.; Witek, L.; Benalcázar Jalkh, E.B.; Gênova, L.A.; Monteiro, K.N.; Cesar, P.F.; Lisboa-Filho, P.N.; Bergamo, E.T.P.; Ramalho, I.S. Microstructural, mechanical, and optical characterization of an experimental aging-resistant zirconia-toughened alumina (ZTA) composite. Dent. Mater. 2020, 36, e365–e374. [Google Scholar] [CrossRef] [PubMed]

- Ali, M.; Knowles, K.M.; Mallinson, P.M.; Fernie, J.A. Microstructural evolution and characterisation of interfacial phases in Al2O3/Ag-Cu-Ti/Al2O3 braze joints. Acta Mater. 2015, 96, 143–158. [Google Scholar] [CrossRef]

- Ali, M.; Knowles, K.M.; Mallinson, P.M.; Fernie, J.A. Interfacial reactions between sapphire and Ag-Cu-Ti-based active braze alloys. Acta Mater. 2016, 103, 859–869. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Liu, J.Y.; Wang, T.P. Microstructure and brazing mechanism of porous Si3N4/Invar joint brazed with Ag-Cu-Ti/Cu/Ag-Cu multi-layered filler. J. Mater. Sci. Technol. 2018, 34, 713–719. [Google Scholar] [CrossRef]

- Jasim, K.M.; Hashim, F.A.; Yousif, R.H.; Rawlings, R.D.; Boccaccini, A.R. Actively brazed alumina to alumina joints using CuTi, CuZr and eutectic AgCuTi filler alloys. Ceram. Int. 2010, 36, 2287–2295. [Google Scholar] [CrossRef]

- Wang, X.; Li, C.; Si, X.; Qi, J.; Feng, J.; Cao, J. Brazing ZTA ceramic to TC4 alloy using the Cu foam as interlayer. Vacuum 2018, 155, 7–15. [Google Scholar] [CrossRef]

- Shi, J.M.; Ma, N.; Zhang, L.X.; Feng, J.C. Residual stress and fracture strength of brazed joint of ceramic and titanium alloy with the aid of laser deposited functionally graded material layers. J. Manuf. Process. 2018, 34, 495–502. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, M.; Zhang, H.; Wen, Z.; Chang, M.; Feng, G.; Deng, D. Fabrication of reliable ZTA composite/Ti6Al4V alloy joints via vacuum brazing method: Microstructural evolution, mechanical properties and residual stress prediction. J. Eur. Ceram. Soc. 2021, 41, 4273–4283. [Google Scholar] [CrossRef]

- Song, X.G.; Cao, J.; Wang, Y.F.; Feng, J.C. Effect of Si3N4-particles addition in Ag-Cu-Ti filler alloy on Si3N4/TiAl brazed joint. Mater. Sci. Eng. A 2011, 528, 5135–5140. [Google Scholar] [CrossRef]

- Yang, Z.; Lin, J.; Wang, Y.; Wang, D. Characterization of microstructure and mechanical properties of Al2O3/TiAl joints vacuum-brazed with Ag-Cu-Ti + W composite filler. Vacuum 2017, 143, 294–302. [Google Scholar] [CrossRef]

- Li, C.; Huang, C.; Chen, L.; Si, X.; Chen, Z.; Qi, J.; Huang, Y.; Feng, J.; Cao, J. Microstructure and mechanical properties of the SiC/Nb joint brazed using AgCuTi + B4C composite filler metal. Int. J. Refract. Met. Hard Mater. 2019, 85, 105049. [Google Scholar] [CrossRef]

- Tebeta1, R.T.; Fattahi1, A.M.; Ahmed, N.A. Experimental and numerical study on HDPE/SWCNT nanocomposite elastic properties considering the processing techniques effect. Microsyst. Technol. 2020, 26, 2423–2441. [Google Scholar] [CrossRef]

- Fattahi1, A.M.; Mondali, M. Theoretical study of stress transfer in platelet reinforced composites. J. Theor. Appl. Mech. 2014, 52, 3–14. [Google Scholar]

- Tao, X.; Wang, X.; Li, X. Nanomechanical Characterization of One-Step Combustion-Synthesized Al4B2O9 and Al18B4O33 Nanowires. Nano Lett. 2007, 7, 3172–3176. [Google Scholar] [CrossRef] [PubMed]

- Duan, W.; Yin, X.; Li, Q.; Liu, X.; Cheng, L.; Zhang, L. Synthesis and microwave absorption properties of SiC nanowires reinforced SiOC ceramic. J. Eur. Ceram. Soc. 2014, 34, 257–266. [Google Scholar] [CrossRef]

- Lin, J.; Huang, Y.; Zhang, H. Crack healing and strengthening of SiC whisker and ZrO2 fiber reinforced ZrB2 ceramics. Ceram. Int. 2014, 40, 16811–16815. [Google Scholar] [CrossRef]

- He, P.; Yang, M.; Lin, T.; Jiao, Z. Improving the strength of brazed joints with in situ synthesized TiB whiskers. J. Alloys Compd. 2011, 509, L289–L292. [Google Scholar] [CrossRef]

- Ba, J.; Li, H.; Ren, B.; Qi, B.; Zheng, X.; Ning, R.; Qi, J.; Cao, J.; Cai, W.; Feng, J. In situ formation of TiB whiskers to reinforce SiO2-BN/Ti6Al4V brazed joints. Ceram. Int. 2019, 45, 8054–8057. [Google Scholar] [CrossRef]

| Point | Element | Possible Phase | ||||||

|---|---|---|---|---|---|---|---|---|

| Ag | Cu | Ti | Al | O | V | Zr | ||

| A | 2.0 | 34.3 | 33.9 | 9.0 | 17.8 | - | 3.0 | (Cu,Al)3Ti3O |

| B | 0.2 | 9.7 | 67.2 | 0.2 | 21.7 | 0.3 | 0.7 | TiO |

| C | - | 3.5 | 4.8 | 35.2 | 56.5 | - | - | ABOw |

| D | - | 36.4 | 35.0 | 14.1 | 14.5 | - | - | (Cu,Al)3Ti3O |

| E | 81.7 | 9.1 | 0.7 | 8.2 | - | 0.3 | - | Ag(s,s) |

| F | - | 58.2 | 40.3 | 0.7 | - | 0.8 | - | Ti3Cu4 |

| G | - | 45.3 | 49.3 | 1.6 | - | 3.8 | - | TiCu |

| H | - | 31.7 | 59.3 | 4.1 | - | 4.9 | - | Ti2Cu |

| I | - | 12.7 | 71.1 | 8.8 | - | 7.4 | - | α-Ti + β-Ti |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Jin, Z.; Feng, G.; Cao, J.; Zhang, H.; Deng, D. Characterization of ZTA Composite Ceramic/Ti6Al4V Alloy Joints Brazed by AgCu Filler Alloy Reinforced with One-Dimensional Al18B4O33 Single Crystal. Crystals 2022, 12, 933. https://doi.org/10.3390/cryst12070933

Wang Y, Jin Z, Feng G, Cao J, Zhang H, Deng D. Characterization of ZTA Composite Ceramic/Ti6Al4V Alloy Joints Brazed by AgCu Filler Alloy Reinforced with One-Dimensional Al18B4O33 Single Crystal. Crystals. 2022; 12(7):933. https://doi.org/10.3390/cryst12070933

Chicago/Turabian StyleWang, Yifeng, Zhouxin Jin, Guangjie Feng, Jian Cao, Hao Zhang, and Dean Deng. 2022. "Characterization of ZTA Composite Ceramic/Ti6Al4V Alloy Joints Brazed by AgCu Filler Alloy Reinforced with One-Dimensional Al18B4O33 Single Crystal" Crystals 12, no. 7: 933. https://doi.org/10.3390/cryst12070933

APA StyleWang, Y., Jin, Z., Feng, G., Cao, J., Zhang, H., & Deng, D. (2022). Characterization of ZTA Composite Ceramic/Ti6Al4V Alloy Joints Brazed by AgCu Filler Alloy Reinforced with One-Dimensional Al18B4O33 Single Crystal. Crystals, 12(7), 933. https://doi.org/10.3390/cryst12070933