Performance Investigation of a Proposed Flipped npn Microstructure Silicon Solar Cell Using TCAD Simulation

Abstract

1. Introduction

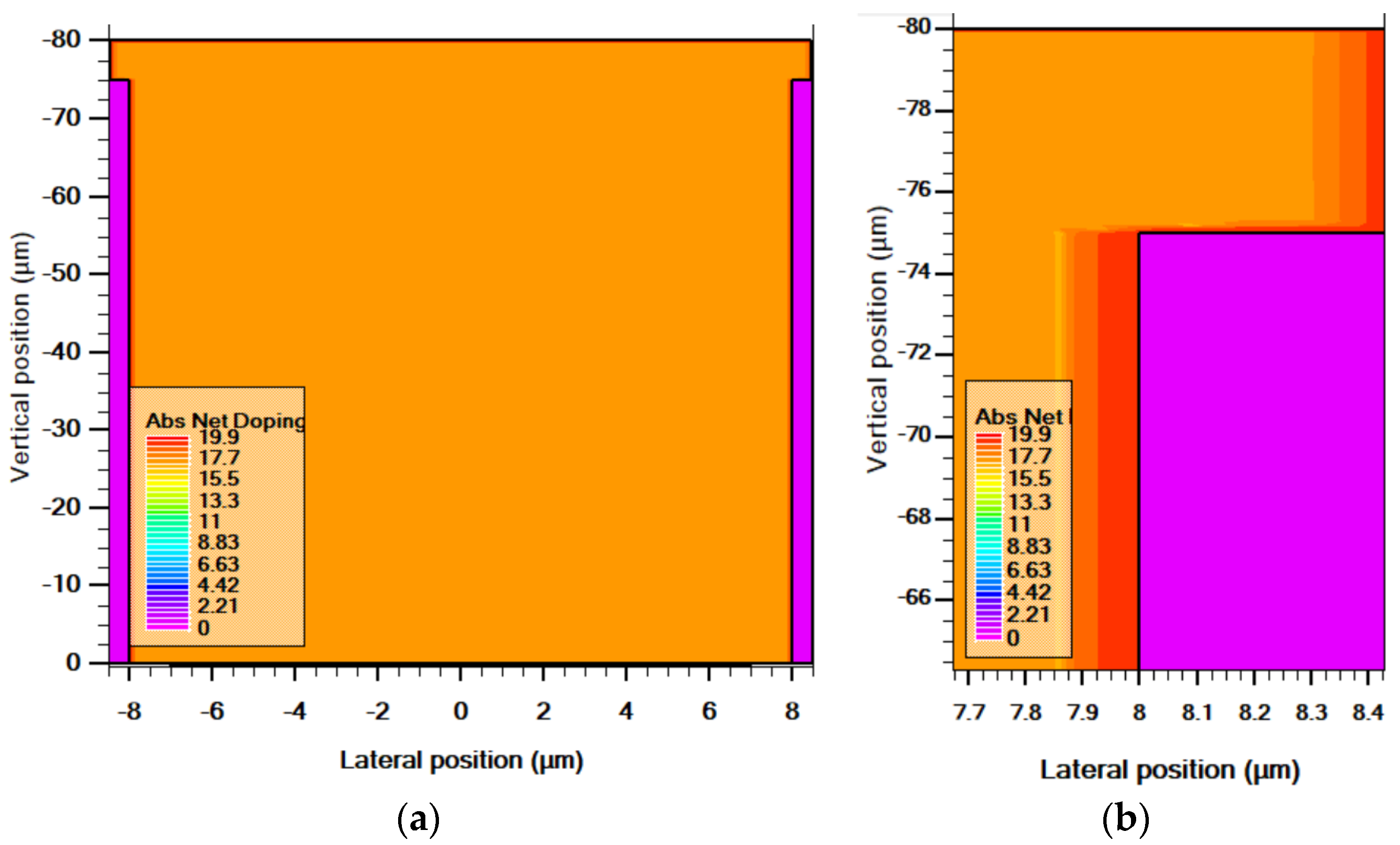

2. Key Design Parameters of the Proposed Flipped npn Microstructure

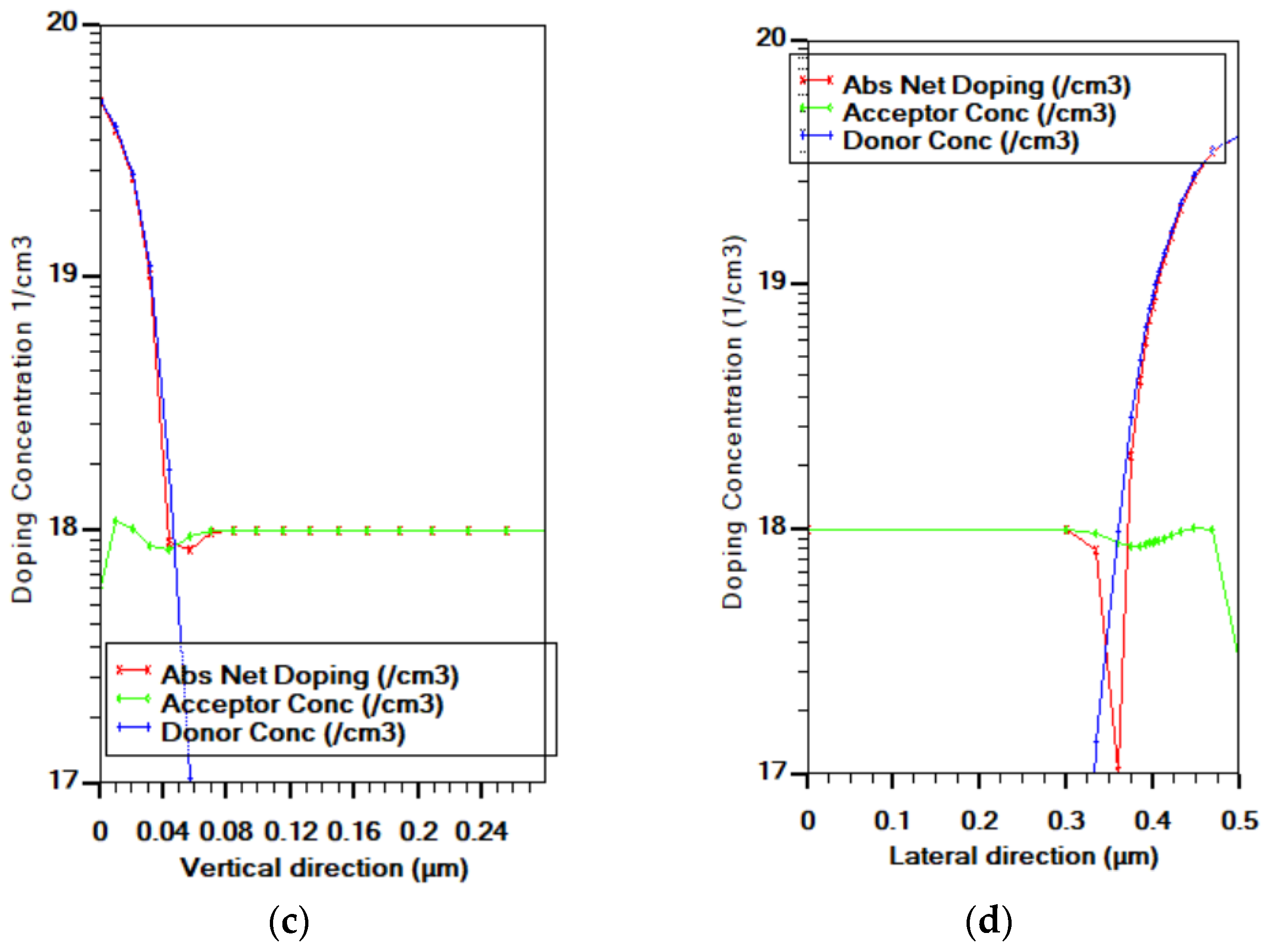

3. Simulation of the Proposed Flipped npn Microstructure Using SILVACO TCAD

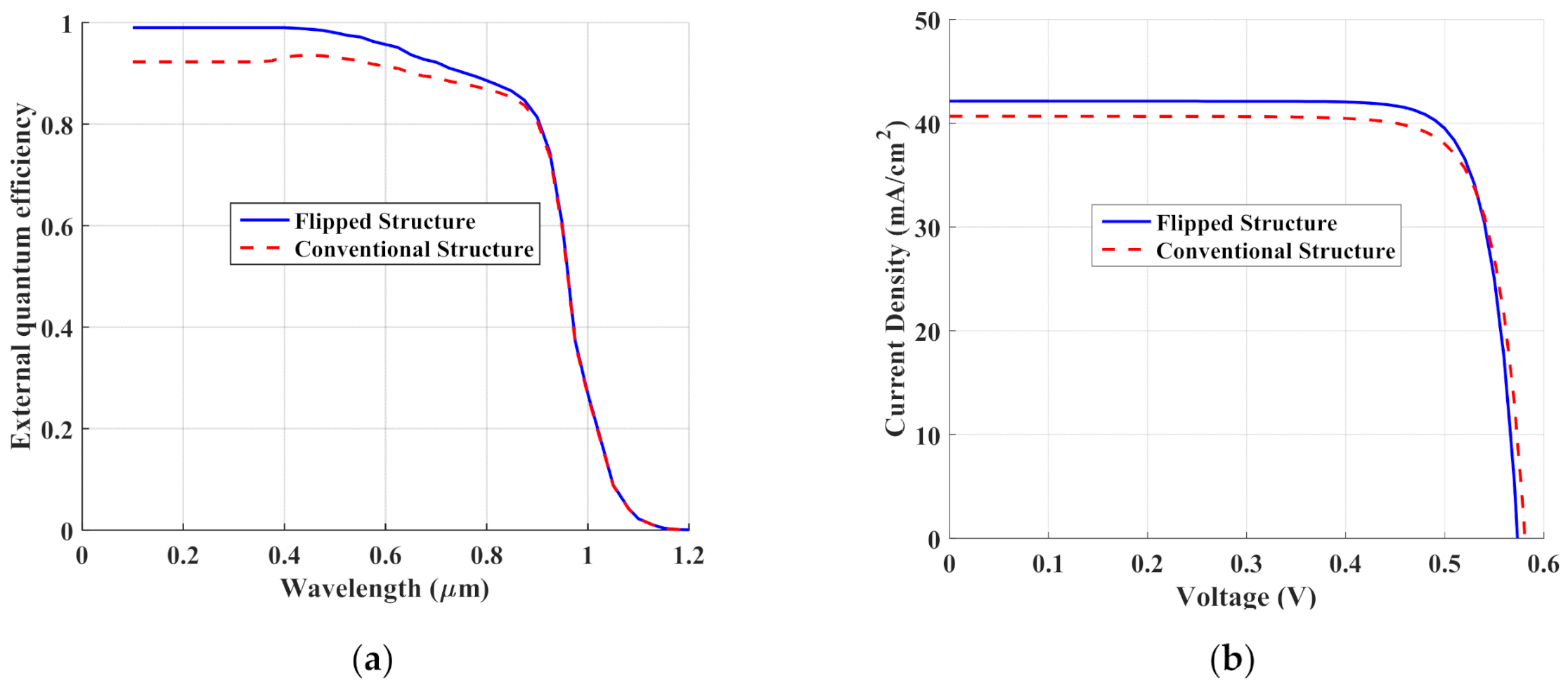

3.1. Effect of Different n+ Sidewall Emitter Surface Treatments

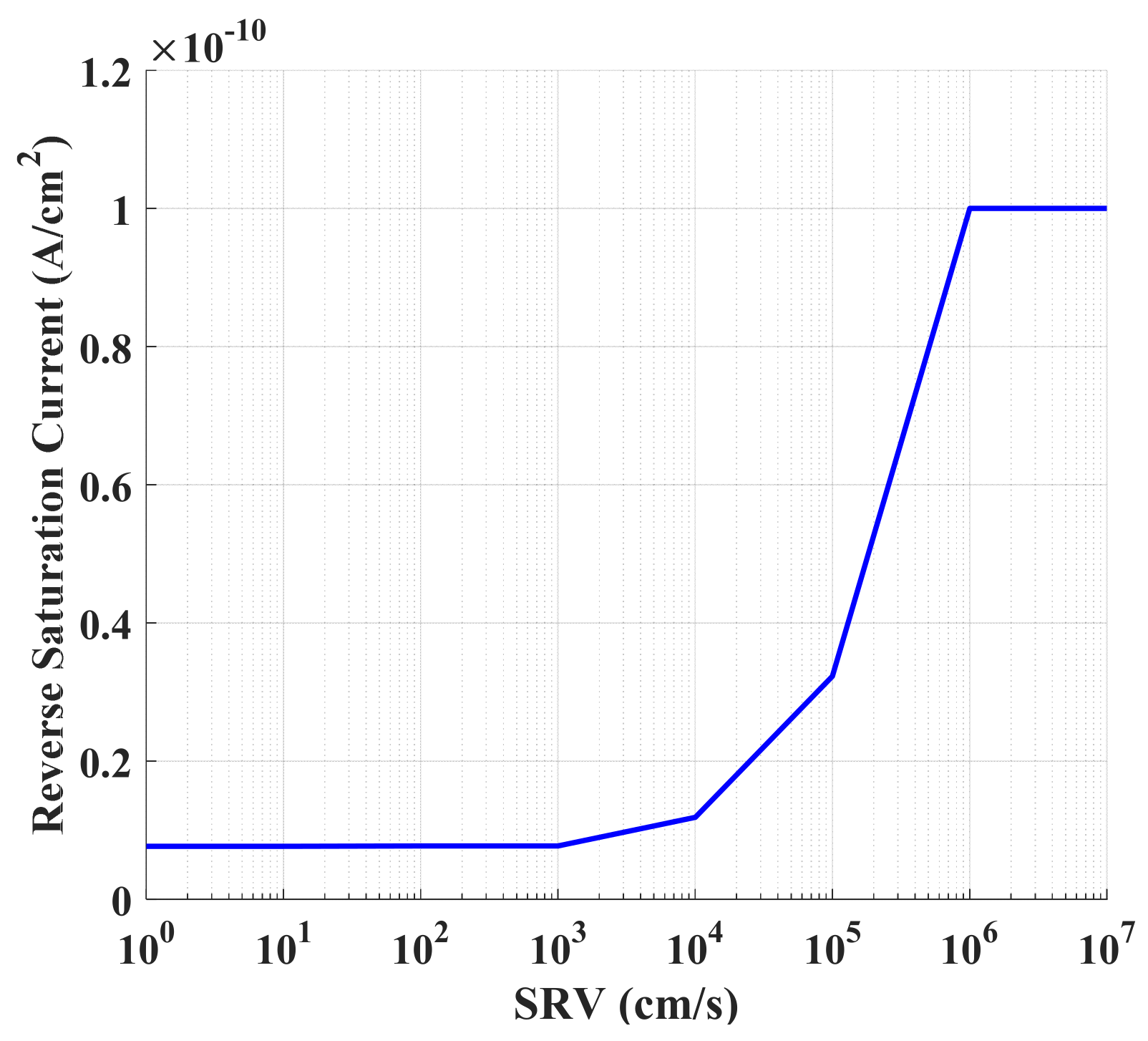

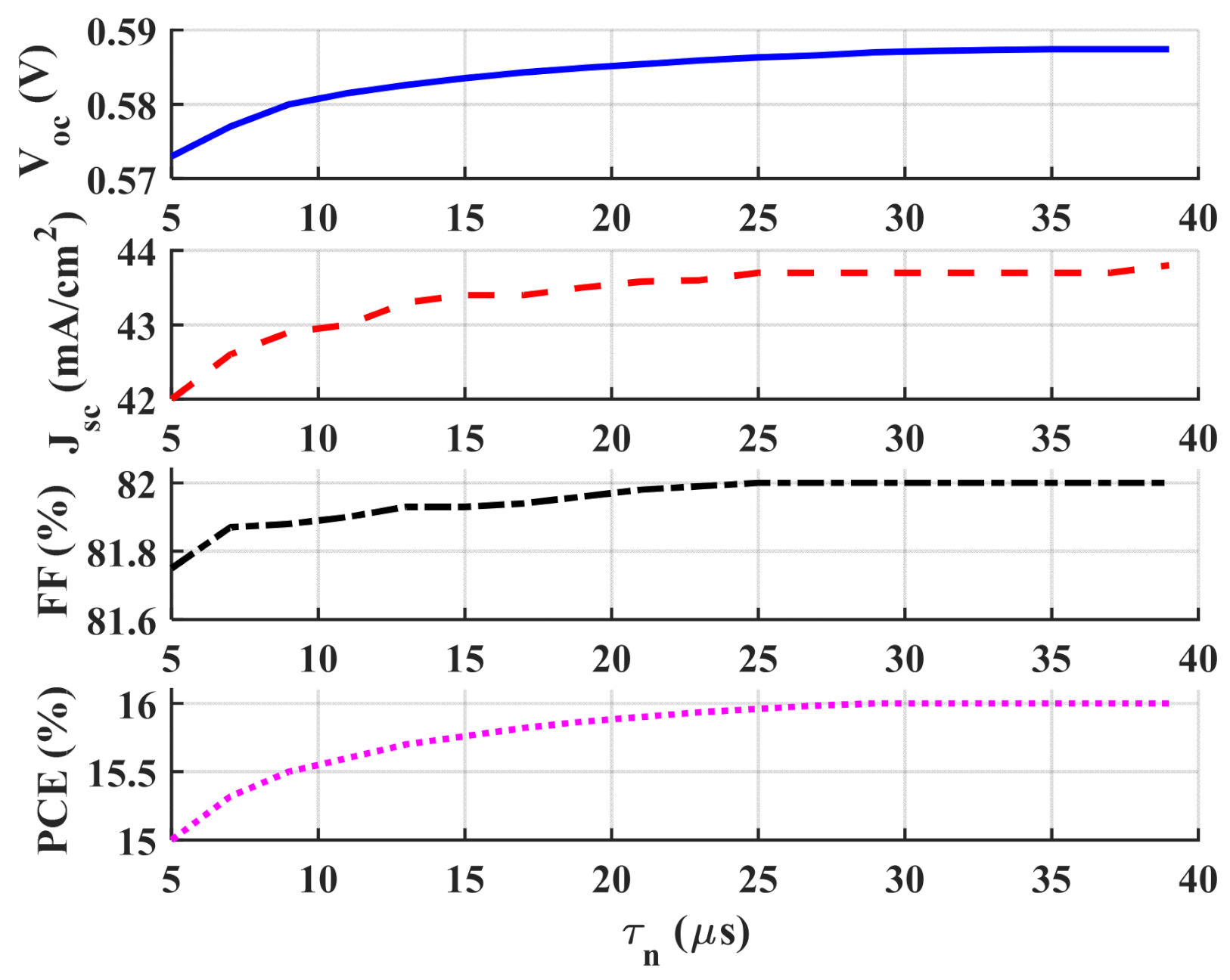

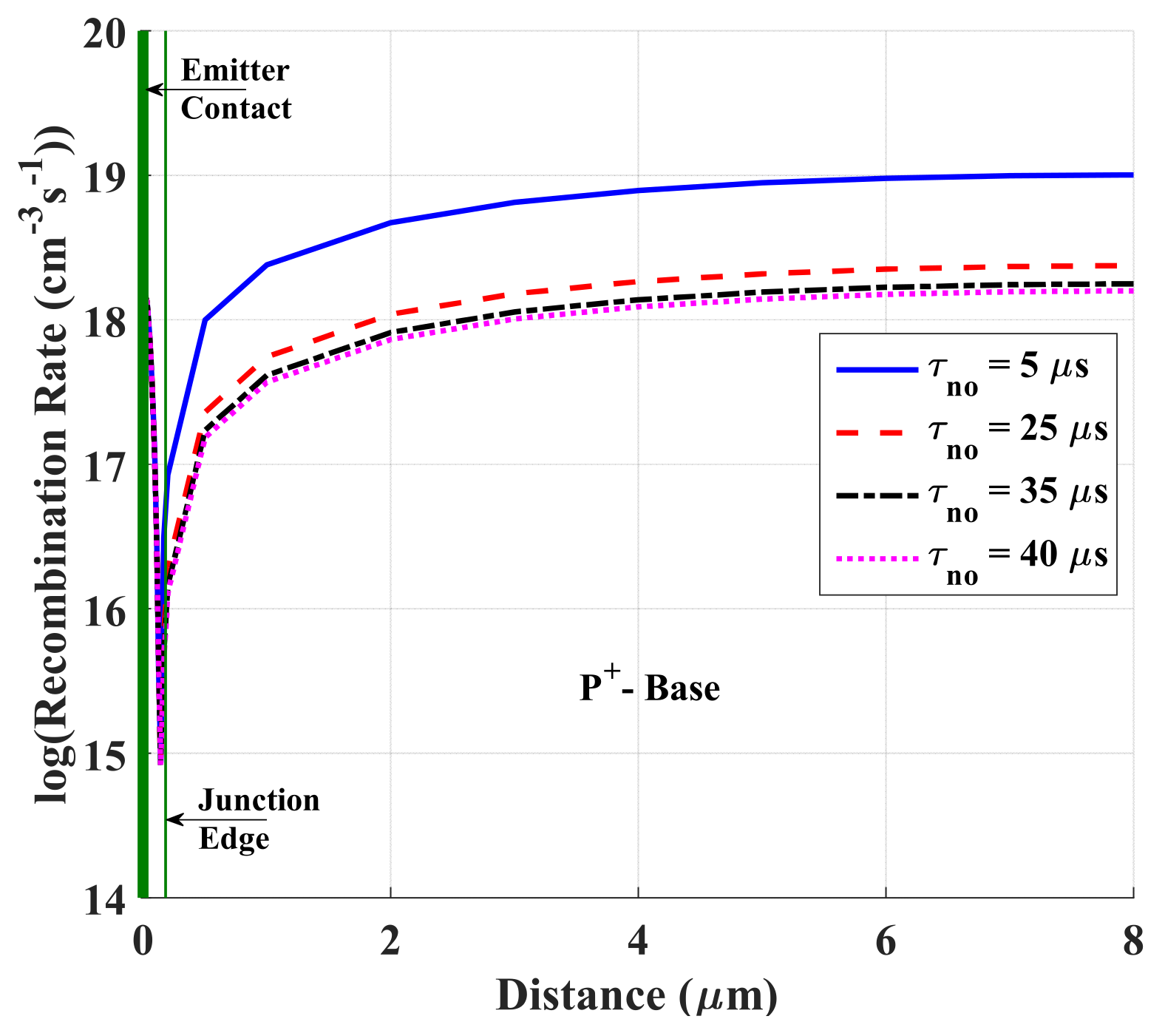

3.2. Effect of Different p+ Base Lifetime Variation

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Subramanian, M.; Nagarajan, B.; Ravichandran, A.; Subhash Betageri, V.; Thirunavukkarasu, G.S.; Jamei, E.; Seyedmahmoudian, M.; Stojcevski, A.; Mekhilef, S.; Minnam Reddy, V.R. Optimization of Effective Doping Concentration of Emitter for Ideal c-Si Solar Cell Device with PC1D Simulation. Crystals 2022, 12, 244. [Google Scholar] [CrossRef]

- Chigondo, F. From metallurgical-grade to solar-grade silicon: An overview. Silicon 2018, 10, 789–798. [Google Scholar] [CrossRef]

- Green, M.A.; Hishikawa, Y.; Warta, W.; Dunlop, E.D.; Levi, D.H.; Hohl-Ebinger, J.; Ho-Baillie, A.W. Solar cell efficiency tables (version 50). Prog. Photovolt. Res. Appl. 2017, 25, 668–676. [Google Scholar] [CrossRef]

- Zhou, L.; Xu, Y.; Tan, S.; Liu, M.; Wan, Y. Simulation of Amorphous Silicon Carbide Photonic Crystal Absorption Layer for Solar Cells. Crystals 2022, 12, 665. [Google Scholar] [CrossRef]

- Goodrich, A.; Hacke, P.; Wang, Q.; Sopori, B.; Margolis, R.; James, T.L.; Woodhouse, M. A wafer-based monocrystalline silicon photovoltaics road map: Utilizing known technology improvement opportunities for further reductions in manufacturing costs. Sol. Energy Mater. Sol. Cells 2013, 114, 110–135. [Google Scholar] [CrossRef]

- Kayes, B.M.; Atwater, H.A.; Lewis, N.S. Comparison of the device physics principles of planar and radial p-n junction nanorod solar cells. J. Appl. Phys. 2005, 97, 114302. [Google Scholar] [CrossRef]

- Garnett, E.; Yang, P. Light trapping in silicon nanowire solar cells. Nano Lett. 2010, 10, 1082–1087. [Google Scholar] [CrossRef]

- Lee, H.J. TCAD Simulation of Silicon Pillar Array Solar Cells. J. Semicond. Disp. Technol. 2017, 16, 65–69. [Google Scholar]

- Zhang, Y.; Liu, H. Nanowires for High-Efficiency, Low-Cost Solar Photovoltaics. Crystals 2019, 9, 87. [Google Scholar] [CrossRef]

- Elbersen, R.; Vijselaar, W.; Tiggelaar, R.M.; Gardeniers, H.; Huskens, J. Fabrication and doping methods for silicon nano-and micropillar arrays for solar-cell applications: A review. Adv. Mater. 2015, 27, 6781–6796. [Google Scholar] [CrossRef]

- Huang, B.R.; Yang, Y.K.; Lin, T.C.; Yang, W.L. A simple and low-cost technique for silicon nanowire arrays based solar cells. Sol. Energy Mater. Sol. Cells 2012, 98, 357–362. [Google Scholar] [CrossRef]

- Fan, Z.; Zhang, W.; Fu, Y.; Yan, L.; Ma, X. Facile synthesis of silicon micropillar arrays using extreme ultraviolet lithography and Ag-assisted chemical etching method. J. Phys. Chem. C 2016, 120, 6824–6834. [Google Scholar] [CrossRef]

- Dou, B.; Jia, R.; Li, H.; Chen, C.; Ding, W.; Meng, Y.; Xing, Z.; Liu, X.; Ye, T. High performance radial pn junction solar cell based on silicon nanopillar array with enhanced decoupling mechanism. Appl. Phys. Lett. 2012, 101, 183901. [Google Scholar] [CrossRef]

- Yang, T.C.; Lee, B.S.; Yen, T.J. Minimizing reflection losses from metallic electrodes and enhancing photovoltaic performance using the Si-micrograting solar cell with vertical sidewall electrodes. Appl. Phys. Lett. 2012, 101, 103902. [Google Scholar]

- Zhang, Y.; Fan, Z.; Zhang, W.; Ma, Q.; Jiang, Z.; Ma, D. High performance hybrid silicon micropillar solar cell based on light trapping characteristics of Cu nanoparticles. AIP Adv. 2018, 8, 055309. [Google Scholar] [CrossRef]

- Sahbel, A.; Hassan, N.; Abdelhameed, M.M.; Zekry, A. Experimental performance characterization of photovoltaic modules using DAQ. Energy Procedia 2013, 36, 323–332. [Google Scholar] [CrossRef][Green Version]

- Putnam, M.C.; Boettcher, S.W.; Kelzenberg, M.D.; Turner-Evans, D.B.; Spurgeon, J.M.; Warren, E.L.; Briggs, R.M.; Lewis, N.S.; Atwater, H.A. Si microwire-array solar cells. Energy Environ. Sci. 2010, 3, 1037–1041. [Google Scholar] [CrossRef]

- Zekry, A.; Shaker, A.; Salem, M. Solar cells and arrays: Principles, analysis, and design. In Advances in Renewable Energies and Power Technologies, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2018; Volume 1, pp. 3–56. [Google Scholar]

- Salem, M.S.; Alzahrani, A.J.; Ramadan, R.A.; Alanazi, A.; Shaker, A.; Abouelatta, M.; Zekry, A. Physically based analytical model of heavily doped silicon wafers based proposed solar cell microstructure. IEEE Access 2020, 8, 138898–138906. [Google Scholar] [CrossRef]

- Basyoni, M.S.; Zekry, A.; Shaker, A. Investigation of base high doping impact on the npn solar cell microstructure performance using physically based analytical model. IEEE Access 2021, 9, 16958–16966. [Google Scholar] [CrossRef]

- Salem, M.S.; Zekry, A.; Shaker, A.; Abouelatta, M. Design and simulation of proposed low cost solar cell structures based on heavily doped silicon wafers. In Proceedings of the 2016 IEEE 43rd Photovoltaic Specialists Conference (PVSC), Portland, OR, USA, 5–10 June 2016. [Google Scholar] [CrossRef]

- Salem, M.; Zekry, A.; Abouelatta, M.; Alshammari, M.T.; Alanazi, A.; Al-Dhlan, K.A.; Shaker, A. Influence of base doping level on the npn microstructure solar cell performance: A TCAD study. Opt. Mater. 2021, 121, 111501. [Google Scholar] [CrossRef]

- Salem, M.S.; Zekry, A.; Shaker, A.; Abouelatta, M.; Abdolkader, T.M. Performance enhancement of a proposed solar cell microstructure based on heavily doped silicon wafers. Semicond. Sci. Technol. 2019, 34, 035012. [Google Scholar] [CrossRef]

- Athena User’s Manual, Silvaco Inc., Santa Clara, USA. Available online: https://silvaco.com/products/tcad/process_simulation/athena/athena.html (accessed on 1 June 2022).

- Atlas User’s Manual, Silvaco Inc., Santa Clara, USA. Available online: https://silvaco.com/products/tcad/device_simulation/atlas/atlas.html (accessed on 1 June 2022).

- Del Alamo, J.; Swirhun, S.; Swanson, R.M. Simultaneous measurement of hole lifetime, hole mobility and bandgap narrowing in heavily doped n-type silicon. In Proceedings of the 1985 International Electron Devices Meeting, Washington, DC, USA, 1–4 December 1985. [Google Scholar] [CrossRef]

- Del Alamo, J.A.; Swanson, R.M. The physics and modeling of heavily doped emitters. IEEE Trans. Electron Devices 1984, 12131, 1878–1888. [Google Scholar] [CrossRef]

- Zekry, A. The dependence of diffusion length, lifetime and emitter Gummel-number on temperature and doping. Arch. Elektrotechnik 1992, 75, 147–154. [Google Scholar] [CrossRef]

- Zekry, A.; Gerlach, W. Reduction of the current gain of the npn transistor component of a thyristor due to the doping concentration of the p-base. IEEE Trans. Electron Devices 1988, 35, 365–372. [Google Scholar] [CrossRef]

- Zekry, A.; Shaker, A.; Ossaimee, M.; Salem, M.S.; Abouelatta, M. A comprehensive semi-analytical model of the polysilicon emitter contact in bipolar transistors. J. Comput. Electron. 2018, 17, 246–255. [Google Scholar] [CrossRef]

- Da, Y.; Xuan, Y. Role of surface recombination in affecting the efficiency of nanostructured thin-film solar cells. Opt. Express 2013, 21, A1065–A1077. [Google Scholar] [CrossRef] [PubMed]

- Morales-Vilches, A.B.; Voz, C.; Colina, M.; Munoz-Martin, D.; Martin, I.; Ortega, P.R.; Alcubilla, R. Study of the surface recombination velocity for ultraviolet and visible laser-fired contacts applied to silicon heterojunction solar cells. IEEE J. Photovolt. 2015, 5, 1006–1013. [Google Scholar] [CrossRef]

- Eberle, R.; Fell, A.; Niewelt, T.; Schindler, F.; Schubert, M.C. Analysis of temperature dependent surface recombination properties. AIP Conf. Proc. 2019, 2147, 140001. [Google Scholar] [CrossRef]

- Benmoussa, D. Study the effect of surface recombination velocity on performance of solar cells based SiGe. In Proceedings of the 4th International Conference on Automation, Control Engineering and Computer Science (ACECS-2017), Tangier, Morocco, 28–30 March 2017. [Google Scholar]

- Ali, K.; Khan, H.M.; Anmol, M.; Ahmad, I.A.; Farooq, W.A.; Al-Asbahi, B.A.; Ghaithan, H.M. Effect of surface recombination velocity (SRV) on the efficiency of silicon solar cell. J. Optoelectron. Adv. Mater. 2022, 22, 251–255. [Google Scholar]

- Stokkan, G.; Song, A.; Ryningen, B. Investigation of the Grain Boundary Character and Dislocation Density of Different Types of High Performance Multicrystalline Silicon. Crystals 2018, 8, 341. [Google Scholar] [CrossRef]

- Gatz, S.; Bothe, K.; Müller, J.; Dullweber, T.; Brendel, R. Analysis of local Al-doped back surface fields for high efficiency screen-printed solar cells. Energy Procedia 2011, 8, 318–323. [Google Scholar] [CrossRef]

- Khokhar, M.Q.; Hussain, S.Q.; Zahid, M.A.; Pham, D.P.; Cho, E.-C.; Yi, J. Numerical Simulation and Experiment of a High-Efficiency Tunnel Oxide Passivated Contact (TOPCon) Solar Cell Using a Crystalline Nanostructured Silicon-Based Layer. Appl. Sci. 2022, 12, 392. [Google Scholar] [CrossRef]

- Rahman, M.Z.; Khan, S.I. Advances in surface passivation of c-Si solar cells. Mater. Renew. Sustain. Energy 2012, 1, 1–11. [Google Scholar] [CrossRef]

- Ghannam, M.Y.; Kamal, H.A. Modeling surface recombination at the p-type Si/SiO2 interface via dangling bond amphoteric centers. Adv. Condens. Matter Phys. 2014, 2014, 857907. [Google Scholar] [CrossRef]

- Sze, S.M.; Lee, M.K. Semiconductor Devices: Physics and Technology. In Physics and Technology, 3rd ed.; Wiley Global Education: Hoboken, NJ, USA, 2012. [Google Scholar]

- Cuevas, A.; Macdonald, D. Measuring and interpreting the lifetime of silicon wafers. Sol. Energy 2004, 76, 255–262. [Google Scholar] [CrossRef]

- The Minority Carrier Lifetime in Silicon Wafer. Available online: https://meroli.web.cern.ch/lecture_lifetime.html (accessed on 15 November 2021).

| Jsc (mA/cm2) | Voc (V) | FF (%) | PCE (%) | |

|---|---|---|---|---|

| Conventional | 40.70 | 0.580 | 80.30 | 14.50 |

| Flipped | 42.12 | 0.573 | 81.75 | 15.00 |

| Jo1 (A/cm2) | n1 | Jo2 (A/cm2) | n2 | Rs (mΩcm2) | Voc,ana (mV) | Voc,TCAD (mV) | |

|---|---|---|---|---|---|---|---|

| Flipped | 2.46 × 10−9 | 1.651 | 7.68 × 10−12 | 0.998 | 6.78 | 0.579 | 0.573 |

| Conventional | 3.99 × 10−8 | 1.847 | 6.02 × 10−13 | 0.909 | 68.05 | 0.586 | 0.580 |

| Jsc (mA/cm2) | Voc (V) | FF (%) | PCE (%) | |

|---|---|---|---|---|

| All models are enabled | 43.81 | 0.588 | 82.03 | 16.05 |

| SRH: disabled | 44.13 | 0.597 | 82.72 | 16.55 |

| SRH and Auger: disabled | 44.19 | 0.605 | 82.87 | 16.84 |

| SRH, Auger and BGN: disabled | 44.19 | 0.647 | 83.67 | 18.17 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salem, M.S.; Zekry, A.; Shaker, A.; Abouelatta, M.; ElBanna, M.M.; Almurayziq, T.S.; Ramadan, R.A.; Alshammari, M.T. Performance Investigation of a Proposed Flipped npn Microstructure Silicon Solar Cell Using TCAD Simulation. Crystals 2022, 12, 959. https://doi.org/10.3390/cryst12070959

Salem MS, Zekry A, Shaker A, Abouelatta M, ElBanna MM, Almurayziq TS, Ramadan RA, Alshammari MT. Performance Investigation of a Proposed Flipped npn Microstructure Silicon Solar Cell Using TCAD Simulation. Crystals. 2022; 12(7):959. https://doi.org/10.3390/cryst12070959

Chicago/Turabian StyleSalem, Marwa S., Abdelhalim Zekry, Ahmed Shaker, Mohamed Abouelatta, Mohamed M. ElBanna, Tariq S. Almurayziq, Rabie A. Ramadan, and Mohammad T. Alshammari. 2022. "Performance Investigation of a Proposed Flipped npn Microstructure Silicon Solar Cell Using TCAD Simulation" Crystals 12, no. 7: 959. https://doi.org/10.3390/cryst12070959

APA StyleSalem, M. S., Zekry, A., Shaker, A., Abouelatta, M., ElBanna, M. M., Almurayziq, T. S., Ramadan, R. A., & Alshammari, M. T. (2022). Performance Investigation of a Proposed Flipped npn Microstructure Silicon Solar Cell Using TCAD Simulation. Crystals, 12(7), 959. https://doi.org/10.3390/cryst12070959