1. Introduction

Murals in ancient tombs provide crucial information for studying the class hierarchy of ancient societies and the culture of their ruling classes. Preserving these murals requires studies on the materials and techniques used to create the pieces, including the analysis of pigments, techniques, and tomb wall components.

The murals in the Goa-ri Tomb in Goyeong-gun, North Gyeongsang Province, Republic of Korea, are known to have been painted during the Great Gaya period in the 6th century. As the only surviving tomb murals from the Great Gaya period, they have immense value as cultural heritage from ancient times and serve as crucial subjects for studies on tomb murals in Korea.

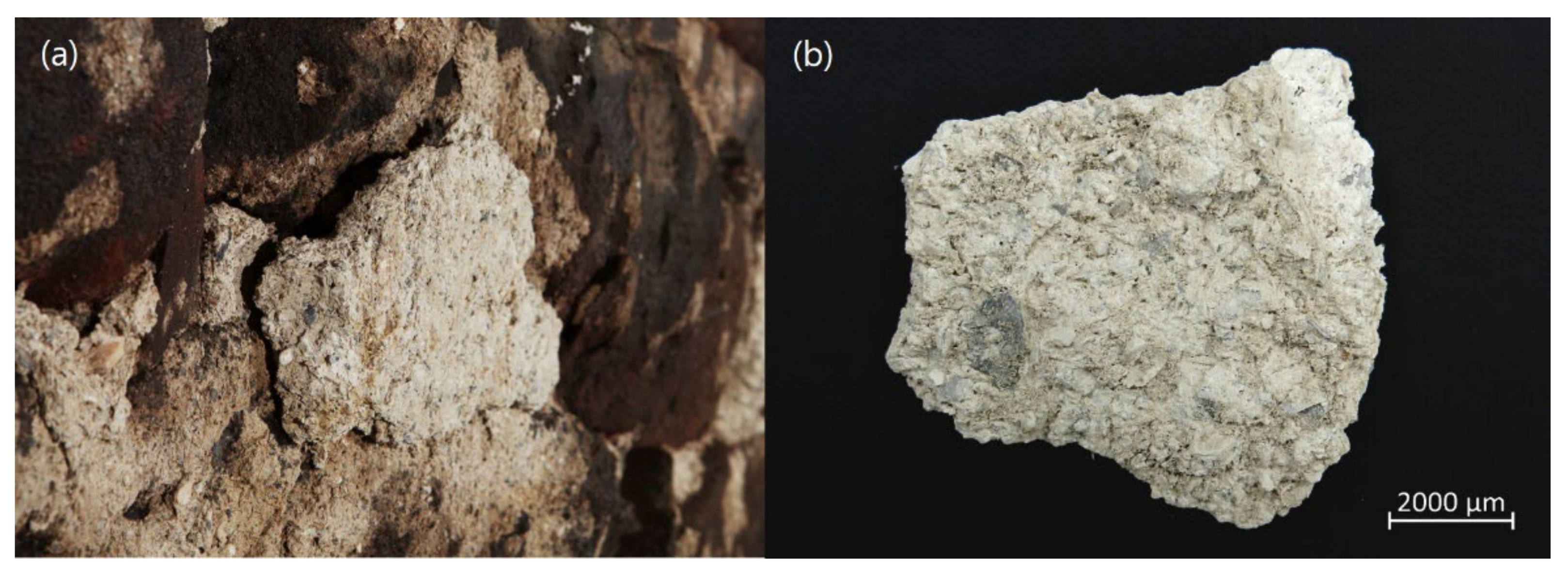

The Goa-ri Tomb is a stone chamber tomb in burial mounds discovered in 1963. The tomb walls are made of natural rocks covered with plaster, on which the murals were painted (

Figure 1). Excluding the paintings on the ceiling and main chamber, most of the wall murals were missing at the time of their discovery [

1,

2]. According to previous literature, the plaster used on the mural walls was created by mixing inorganic materials. A chemical composition analysis showed that the materials were likely shell fragments [

3,

4].

Mural walls can be damaged for a multitude of reasons. In particular, the source and processing method of the plaster ingredients used for the walls affect the walls’ durability. The murals in the Goa-ri Tomb are placed in a closed and humid underground environment. For these murals, the wall materials are closely related to their conservation. Therefore, an accurate understanding of the cause of wall damage requires clear identification of the plaster ingredients.

This study used morphological analysis to identify the materials used for the wall plaster in the Goa-ri Tomb and elucidate the wall manufacturing techniques by determining the processing conditions for the plaster ingredients through a calcination experiment.

2. Materials and Methods

Figure 2 describes the research process used to identify the wall-building techniques. First, the material characteristics and ingredients of the plaster used on the tomb walls were identified through chemical analysis. Then, the processing techniques for the plaster were identified by calcinating the ingredients and analyzing their physical properties.

2.1. Materials

Figure 3,

Figure 4 and

Figure 5 and

Table 1 show the samples used to identify the plaster ingredients and compare the processing conditions. These samples were collected from the western wall of the main chamber. The samples were grouped into fragments, presumed to be of shells, and fine powder.

The reference group includes samples for identifying ingredients and processing characteristics at different calcination temperatures. The samples for ingredient identification were collected from the shells of oysters, manila clams, surf clams, large clams, and corb clams. These five species were selected based on the location of the Goa-ri Tomb, the production volume of the ingredients, the ease of pulverization, and the amount of white powder generated. The samples were collected from the southern coast of Korea and provided by the Traditional Material Bank of the Korea National University of Culture Heritage.

To identify the processing status of the plaster, the samples were calcinated at three temperatures: 650 °C, 750 °C, and 850 °C. The material subject to the calcination experiment was selected based on the plaster ingredient identification results.

2.2. Optical Microscopy and Scanning Electron Microscopy (SEM)

The surfaces and microstructures of the samples were observed to morphologically identify the ingredients used in the wall plaster and the processing status at different calcination temperatures. The sample surfaces were observed using an optical microscope (Axio Zoom V16, Carl Zeiss, Jena, Germany). In contrast, the observation of the microstructures used a high-resolution field emission scanning electron microscope (JSM-7610F, JEOL, Akishima, Japan). The sample surfaces were coated with platinum, followed by a backscattered electron scanning image (BESI) analysis to obtain a clearer image with higher contrast.

2.3. X-ray Diffractometer (XRD)

The crystal structure of the plaster samples and the reference samples were analyzed using an X-ray diffractometer (MiniFlex 600, Rigaku, Tokyo, Japan). The analysis was conducted under the following conditions: X-ray tube accelerating voltage 40 kV, current 15 mA, scanning angle (2θ) 3–90°, scanning step 0.02°, and scanning speed 2°/min. Minerals were identified from the X-ray diffraction patterns using Rigaku’s peak matching software, PDXL(ver 2.7.2.0, Rigaku, Tokyo, Japan), and comparing the patterns with the International Centre for Diffraction Data (ICDD) cards.

2.4. Particle Size Analysis (PSA)

A particle size analysis was performed to verify the particle size distribution of the plaster used for the tomb murals and compare the particle size distribution at different calcination temperatures. The analysis was conducted using a standard stainless sieve (JIS Z 8801, Kenis, Osaka, Japan), following the particle size test method of the Korea Standards (KS F 2302). Powder sizes smaller than fine-grained powder were analyzed using a laser diffraction particle size analysis (1090L, CILAS, Orleans, France). The particles were classified based on particle sizes by measuring the weight of the remaining samples per the United States Department of Agriculture (USDA) and International Union of Soil Sciences (ISSS) standards and shown in cumulative percentages.

2.5. Calcination Experiment

A calcination experiment was conducted with an electronic furnace (KK80, Elim Global, Yongin, Korea) to identify processing characteristics at different calcination temperatures. The calcination conditions were determined based on previous studies on manufacturing techniques applied in traditional oyster shell white [

5] and used 1 kg of the samples at each temperature. The temperature was raised 3 °C per minute and maintained for 4 h once the target temperature was achieved. It was then lowered at the same rate afterward.

3. Results

3.1. Properties of Plaster

The wall plaster used in the Goa-ri Tomb is made of white particles and does not contain sand. Semi-transparent crystalline materials with irregular shapes are mixed with black or gray fragments. The gray fragments mixed in the plaster vary in size, and some yellow fragments were also found. The plaster samples show many indentations, presumably caused by the surface of plant stems cut into 0.5- to 1 cm-long pieces (

Figure 6).

Figure 7a,b shows the particle distribution ratio of plaster. Particles of 0.2 mm or larger are estimated to be shells, and it is confirmed that they occupy about 45% or more. As a result of laser particle size analysis on particles of fine grain or smaller classified in the plaster, the ratio of less than 25 μm was high, and the ratio of particles of 10–50 μm was high compared to the ratio of particles of approximately 10 μm or less.

For precise analysis of the materials consisting of the plaster, the samples were divided into possible shell fragments and aggregates of fine powder. An XRD analysis of the fragment samples (PF) and the fine powder aggregates (PFP) showed that the diffraction peak is 29.4° and 39.3°; thus, the main component was identified as calcite, mostly consisting of calcium carbonate (CaCO

3) (

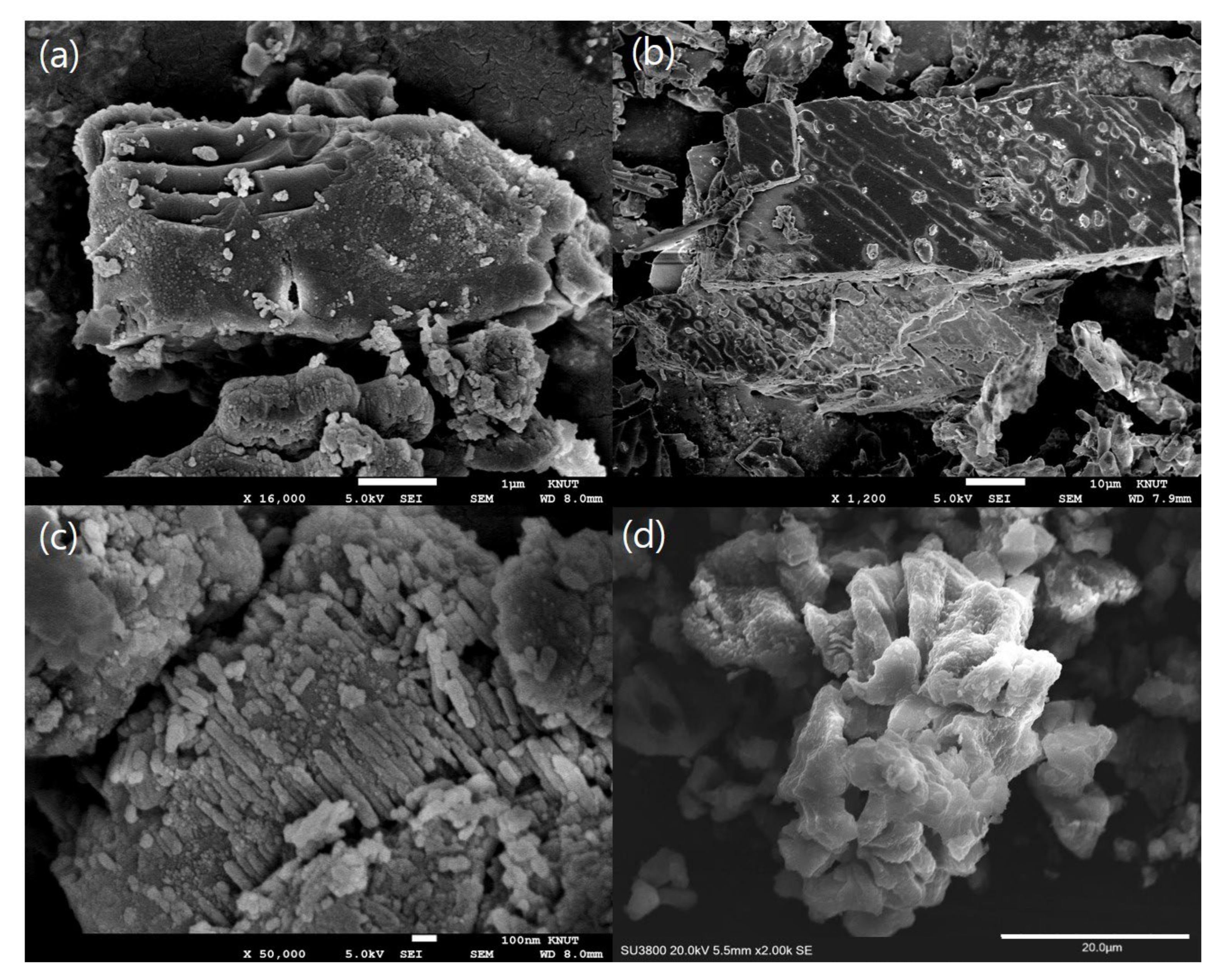

Figure 7c). The microstructures of the samples include polygonal, pillar-type, and plate-type structures of calcite particles aggregated in different sizes and shapes (

Figure 8a). Most of the PF particles had sharp edges and showed bedded structures where the particles were stacked in long plates (

Figure 8b). In particular, the PFP particles consisted of shapeless particles and polygonal particles in bedded structures. Those with bedded structures formed plate-type structures. However, they were observed to be in the process of changing into shapeless chunks with small surfaces (

Figure 8c,d). The plate-type—bedded structures observed in the samples were found in organisms rather than minerals. The shapeless particles seem to have been created by recrystallization after decarboxylation caused by the calcination process.

3.2. The Plaster’s Material Identification

To identify the plaster material, the morphological classification of the shell fragments was performed. The layered structure of the foliar and the shape of the radial ribs in the shells suggest that they are bivalves [

6] (

Figure 9 and

Figure 10a). In general, to classify shells to the species level, the shape of the shell (accuration rate, expansion rate), the structure of the shell surface (existence of growth line or longitudinal rib), and the shape of the umbo should be considered [

7]. However, it is not easy to classify samples lacking some morphological characteristics to the species level. Therefore, the characteristics appearing in the shells of plaster were compared with the characteristics of other shells.

A light brown layer is observed on the surface of the plaster shell sample. This is presumed to be the shell epidermis formed in the outermost layer of the shell. Under the shell epidermis, the prismatic layer (or chalky layer) and the nacreous layer (or folia layer) appear repeatedly (

Figure 9a and

Figure 10a). As a result of observation after washing for a clear comparison of the shell, a glossy nacreous layer (or folia layer) and an adductor muscle scar were identified on the ventral of the shell. The shell section is confirmed in the form of a lens-like prismatic layer (or chalky layer) inserted between the nacreous layer (or folia layer). The prismatic layer (or chalky layer) is opaque and milky white, but the nacreous layer (or folia layer) appears as translucent yellow (

Figure 9c,d and

Figure 10a). As a result of comparing the cross-sectional structure of other shells, it is confirmed that the characteristics observed in the shells of Goa-ri Tomb wall plaster are similar to those of the oyster shells (

Figure 10 and

Figure 11). Therefore, the material used for the plaster is suggested to be of the family Ostreidae.

3.3. Properties of the Calcinated Shells

Oyster shells were selected for the calcination experiment, given the material identification results for the mural wall plaster. The weight loss caused by decarboxylation varied depending on the calcination temperature. The sample calcinated at 850 °C (CC8) lost 48% of its weight, and most of the lost weight was converted to calcium oxide or quick lime (CaO).

A naked-eye observation of each sample confirmed variations depending on the calcination temperature. The sample calcinated at 650 °C, maintained its shell shape after calcination and manifested a dark gray color. At higher temperatures, the samples lost their ability to maintain their shell shapes and showed whiter colors (

Figure 5). The findings indicate a process where the organic materials in the shells are degraded and converted into carbons by the calcination process and then are removed as carbon dioxide gas at higher temperatures [

5].

An observation of the crystalline structures at different calcination temperatures showed that the samples calcinated at 650 °C and 750 °C had crystalline structures of CaCO

3 and CaO. The sample calcinated at 850 °C only showed CaO structures. In contrast, the sample calcinated at 750 °C showed a higher peak strength for CaO and a lower peak strength for CaCO

3. The XRD spectrum of the samples indicates a process whereby the CaCO

3 in the shells is converted to calcium oxide at higher temperatures (

Figure 12).

Based on these findings, the microstructures of the shell particles were observed. The calcinated samples showed clusters of polygonal particles of different sizes. The experiment confirmed a process of particles in plate-type–bedded structures converting into shapeless particles followed by recrystallization (

Figure 13). The samples calcinated at 650 °C (CC6) and 750 °C (CC7) mostly showed plate-type–bedded structures, whereas the sample calcinated at 850 °C (CC8) had smaller shapeless particles with sharp edges.

The distribution of particles constituting the smaller than the fine-grained size of shells was identified at different calcination temperatures (

Figure 13,

Table 2). The particle size distribution graph of the samples calcinated at 650 °C and 750 °C showed a bimodal distribution, and the graph of the sample calcinated at 850 °C showed a unimodel distribution. It was confirmed that the mean diameter (D50) and the volume moment mean (D [4,3]) tended to decrease as the calcination temperatures increased (

Figure 14). The results reflect changes in particle structure and size according to the change in calcination temperature, and are confirmed to be similar to previous studies that the specific surface area of shells decreases due to sintering during heat treatment [

9,

10].

4. Discussion

The plaster used in the Goa-ri Tomb was made of processed oyster shells. The inner surface area of the tomb suggests that a large number of shells were used, and calcinating oyster shells created the plaster. The ventral surfaces and microstructures of the oyster shells suggest that heat was not evenly distributed across the shells during the calcination process.

A multitude of black shell fragments is found in the Goa-ri Tomb plaster. Oyster shells turn black when calcinated at 700 °C or lower without sufficient oxygen. The glossy chitin layer in the ventral side of the oyster shells also shows signs of calcination at low temperatures. It has been reported that chitin is fully disintegrated between 200 °C and 330 °C. Therefore, glossy shells indicate thermal treatment at fairly low temperatures.

The deformed shell fragment microstructures observed in the Goa-ri Tomb plaster indicate that the calcination process stopped as calcium carbonate (CaCO3) particles decomposed into calcium oxide (CaO) particles. It means that many of the shells were incompletely calcinated because of the lack of heat.

The calcination experiment found that shapeless particles in the tomb mural plaster are mostly created at a calcination temperature of 850 °C. However, particles with plate-type–bedded structures or plate-type particles turning into shapeless particles were mostly found at calcination temperatures of 650 °C and 750 °C. The findings indicate the coexistence of completely calcinated and incompletely calcinated particles in the plaster. Even though a minimum of 800 °C is required to calcinate oyster shells, the tomb’s creators seem to have lacked the time and techniques to calcinate a sufficient amount of shells.

Based on the findings, the following conclusions can be drawn about the materials and techniques used for the tomb murals in the Goa-ri Tomb. First, the murals were created on walls built with plaster made with calcinated oyster shells and not mixed with sand. Second, the pressure marks on the plaster suggest that it was created by combining only calcinated shells and plant fibers, even though no fiber can be found in the plaster today.

The use of incompletely calcinated particles without clay, sand, or other soil materials can significantly reduce the plaster’s strength and durability. In general, slaked lime is mixed with soil, sand, or other aggregates to increase its strength, durability, and surface hardness [

11]. However, the Goa-ri Tomb used weaker and less durable plaster made of incompletely calcinated shells, which seems to have caused the extensive exfoliation of the plaster from the wall surfaces.

5. Conclusions

This study analyzed the materials used in the walls of the Goa-ri Tomb from the Great Gaya period to identify the wall-building techniques used and obtain information on ancient mural techniques, including the plaster processing techniques used by ancient Great Gaya artisans.

As mentioned, the plaster used on the Goa-ri Tomb walls was confirmed to be made of oyster shells. The existence of many incompletely calcinated shell particles in the plaster indicates that the calcination temperature was not high enough (650–850 °C) or the heat was not evenly distributed. In addition, the damage to the Goa-ri Tomb walls can be attributed to the characteristics of the incompletely calcinated shells in the plaster.

The finding that oyster shells were used in the Goa-ri Tomb plaster offers a piece of critical evidence for identifying the key techniques used for mural creation in the Great Gaya period. Moreover, the findings on the materials will help determine the conservation status of the tomb murals and provide the information required for effective and systemic conservation.

Author Contributions

Conceptualization, H.S.L.; methodology, H.S.L.; software, H.H.L.; validation, K.S.H.; formal analysis, H.H.L.; investigation, Y.G.Y.; resources, H.H.L.; data curation, Y.G.Y.; writing—original draft preparation, Y.G.Y.; writing—review and editing, K.S.H.; visualization, Y.G.Y.; supervision, H.S.L.; project administration, H.S.L.; funding acquisition, H.S.L. All authors have read and agreed to the published version of the manuscript.

Funding

This paper was supported by Konkuk University in 2020.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kim, W.-R. A Report of Mural Tomb in Goa-dong, Goryeong. Korean J. Art. Hist. 1964, 5, 499–501. [Google Scholar]

- Lee, G.-M.; Lee, H.-S.; Han, G.-S. The Research of Condition for Mural Tomb in Goa-ri, Goryeong in Gaya period. MUNHWAJAE Korean J. Cult. Herit. Stud. 2015, 48, 44–61. [Google Scholar]

- Moon, H.-S.; Hong, J.-W.; Hwang, J.-J.; Kim, S.-G.; Cho, N.-C. Scientific Analysis of Ancient Mural Pigments (Focus on Mural Pigments at Daeungjeon Hall of Bongjeongsa Temple and Ancient Tomb in Goadong). MUNHWAJAE Korean J. Cult. Herit. Stud. 2002, 35, 160–184. [Google Scholar]

- Lee, H.-S.; Lee, H.-H.; Lee, G.-M.; Han, G.-S. Study on the Manufacturing Technology of Mural Tomb in Goa-dong of Daegaya Period. J. Conserv. Sci. 2014, 30, 457–466. [Google Scholar] [CrossRef] [Green Version]

- Lee, H.-H.; Kim, S.-G.; Kim, H.-J.; Jeong, H.-Y. Investigation of the Korean Traditional Hobun(Oyster shell W.) Manufacturing Technique: Centering on Calcination Method. J. Conserv. Sci. 2008, 23, 103–118. [Google Scholar]

- Melbourne, R.C.; Robert, E.P.; Robert, S.P. Functional ulrtamorphology of the dissonconch values of the oyster(Crassostrea virginica). Proc. Natl. Shellfish. Assoc. 1980, 70, 139–183. [Google Scholar]

- Gong, D.-Y.; Lee, S.-J. Fossil Scaphopods from the Hagjeon Formation and the Duho Formation, the Cenozoic Pohang Basin, Korea. MUNHWAJAE Korean J. Cult. Herit. Stud. 2012, 45, 218–231. [Google Scholar]

- Antonio, G.C.; Elizabeth, M.H.; Alicia, G.S. Structure and crystallography of foliated and chalk shell microstructures of the oyster Magallana: The same materials grown under different conditions. Sci. Rep. 2018, 8, 1–12. [Google Scholar]

- Chen, C.; Zhao, C.; Liang, C.; Pang, K. Calcination and sintering characteristics of limestone under O2/CO2 combustion atmosphere. Fuel Process Technol. 2007, 88, 171–178. [Google Scholar] [CrossRef]

- Lee, J.-W.; Choi, S.-H.; Kim, S.-H.; Cha, W.-S.; Kim, K.-J.; Moon, B.-K. Mineralogical Changes of Oyster Shells by Calcination: A Comparative Study with Limestone. Econ. Environ. Geol. 2018, 51, 485–492. [Google Scholar]

- Peroni, S.; Tersigni, C.; Torraca, G.; Cerea, S.; Forti, M.; Guidobaldi, F.; Rossi-Doria, P.; De Rege, A.; Picchi, D.; Pietrafitta, F.J.; et al. Lime based mortars for the repair of ancient masonry and possible substitutes. In Mortars, Cements and Grouts Used in the Conservation of Historic Buildings, Rome, Italy, 3-6.11.1981; ICCROM: Rome, Italy, 1982. [Google Scholar]

Figure 1.

Overview of murals in the Goa-ri Tomb. (a) Outside. (b) Mural paintings of ceiling on burial chamber. (c) Status of burial chamber. (d) Mural painting details.

Figure 1.

Overview of murals in the Goa-ri Tomb. (a) Outside. (b) Mural paintings of ceiling on burial chamber. (c) Status of burial chamber. (d) Mural painting details.

Figure 2.

Flowchart of a research process for discovering wall manufacturing techniques.

Figure 2.

Flowchart of a research process for discovering wall manufacturing techniques.

Figure 3.

Plaster sample by control group: (a) Sampling points. (b) Plaster sample details.

Figure 3.

Plaster sample by control group: (a) Sampling points. (b) Plaster sample details.

Figure 4.

Shell samples for identification of materials by the experimental group: (a) CR-A (b) CR-B. (c) CR-C. (d) CR-D. (e) CR-E.

Figure 4.

Shell samples for identification of materials by the experimental group: (a) CR-A (b) CR-B. (c) CR-C. (d) CR-D. (e) CR-E.

Figure 5.

Calcinated samples by the experimental group: (a) CC6. (b) CC7. (c) CC8.

Figure 5.

Calcinated samples by the experimental group: (a) CC6. (b) CC7. (c) CC8.

Figure 6.

Surface of plaster: (a) Image of indentations, presumably caused by the surface of plant stems. (b) Image of gray fragments (like shell) mixed in the plaster.

Figure 6.

Surface of plaster: (a) Image of indentations, presumably caused by the surface of plant stems. (b) Image of gray fragments (like shell) mixed in the plaster.

Figure 7.

(a) Particle size distribution of plaster sieved using standard stainless sieves. (b) Graph of laser diffraction particle size analysis for plaster. (c) X-ray diffractometer (XRD) spectrum of plaster.

Figure 7.

(a) Particle size distribution of plaster sieved using standard stainless sieves. (b) Graph of laser diffraction particle size analysis for plaster. (c) X-ray diffractometer (XRD) spectrum of plaster.

Figure 8.

Scanning electron microscope (SEM) image: (a) Plaster. (b) PF. (c,d) PFP.

Figure 8.

Scanning electron microscope (SEM) image: (a) Plaster. (b) PF. (c,d) PFP.

Figure 9.

Sample details of shell fragment in plaster: (a,b) Surface of shell fragment. (c) Ventral of the shell. (d) Optical images of glossy area by chitinous substance in nacreous layer (or folia layer).

Figure 9.

Sample details of shell fragment in plaster: (a,b) Surface of shell fragment. (c) Ventral of the shell. (d) Optical images of glossy area by chitinous substance in nacreous layer (or folia layer).

Figure 10.

Comparison between the cross-section of shell fragments in plaster and oyster shell: (

a) Cross-section of shell fragment in plaster. (

b) Cross-section of oyster shell (Reprinted with permission from Ref. [

8]. Copyright 2018, copyright Antonio, G.C et al., licensed under CC-BY 4.0. (

c) Optical images of cross-sectional shell fragment in plaster. (

d) Optical images of cross-sectional oyster shell.

Figure 10.

Comparison between the cross-section of shell fragments in plaster and oyster shell: (

a) Cross-section of shell fragment in plaster. (

b) Cross-section of oyster shell (Reprinted with permission from Ref. [

8]. Copyright 2018, copyright Antonio, G.C et al., licensed under CC-BY 4.0. (

c) Optical images of cross-sectional shell fragment in plaster. (

d) Optical images of cross-sectional oyster shell.

Figure 11.

Optical images of cross-sectional sample: (a) CR-A. (b) CR-B. (c) CR-C. (d) CR-D. (e) CR-E.

Figure 11.

Optical images of cross-sectional sample: (a) CR-A. (b) CR-B. (c) CR-C. (d) CR-D. (e) CR-E.

Figure 12.

X-ray diffractograms (XRD) of calcinated samples: (a) CC6. (b) CC7. (c) CC8.

Figure 12.

X-ray diffractograms (XRD) of calcinated samples: (a) CC6. (b) CC7. (c) CC8.

Figure 13.

Scanning electron microscope (SEM) image: (a) CC6. (b) CC7. (c,d) CC8.

Figure 13.

Scanning electron microscope (SEM) image: (a) CC6. (b) CC7. (c,d) CC8.

Figure 14.

Particle size distribution graphs: (a) CC6. (b) CC7. (c) CC8.

Figure 14.

Particle size distribution graphs: (a) CC6. (b) CC7. (c) CC8.

Table 1.

Sample details: summary of sample description used during this study.

Table 1.

Sample details: summary of sample description used during this study.

| Classification | Sample Code | Description |

|---|

| Control Group | Plaster | PF | Fragment in plaster |

| PFP | Fine powder in plaster |

| Experimental Group | Identification of Material | CR-A | Oyster shell |

| CR-B | Manila clam shell |

| CR-C | Surf clam shell |

| CR-D | Large clam shell |

| CR-E | Corb shell |

| Calcination of Material | CC6 | Calcinated 650 °C |

| CC7 | Calcinated 750 °C |

| CC8 | Calcinated 850 °C |

Table 2.

The distribution of particles of samples at different calcination temperatures (units: μm).

Table 2.

The distribution of particles of samples at different calcination temperatures (units: μm).

| Classification | Calcinated at 650 °C | Calcinated at 750 °C | Calcinated at 850 °C |

|---|

| Diameter at 10% | 4.95 | 2.46 | 3.33 |

| Diameter at 50% | 18.59 | 15.00 | 16.64 |

| Diameter at 90% | 61.27 | 50.82 | 31.04 |

| Mean diameter | 26.85 | 21.66 | 17.16 |

| D [4,3] | 26.846 | 21.66 | 17.16 |

| D [3,2] | 10.892 | 7.326 | 8.53 |

| Mode | 15.00 | 45.00 | 22.00 |

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).