Al-Si@Al(OH)3 Nanosheets Composite for Enhanced Efficient Strategy to Synthesize Al-Si@Al2O3 Core-Shell Structure

Abstract

:1. Introduction

2. Experiments

3. Results and Discussion

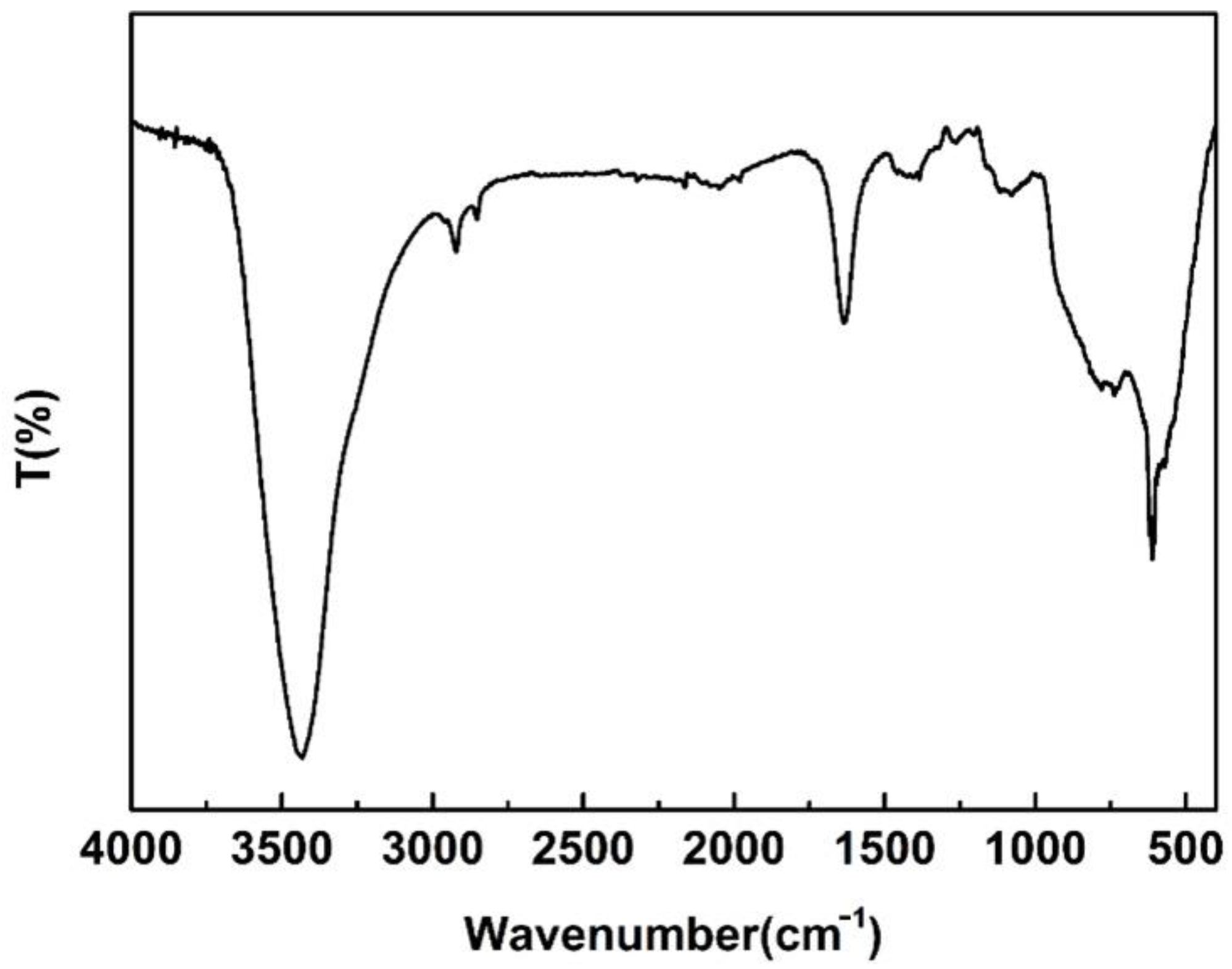

3.1. Analysis of Samples

3.2. Impact of Silicon Morphology

4. Conclusions

- The comparison of the microstructure between the hydrothermal and water bath methods revealed that the hydrothermal method was a better way to prepare the Al-Si@Al(OH)3 nanosheets than the water bath method. Overall, the reaction time rendered little effect on the structure of the Al-Si@Al(OH)3 nanosheets.

- The SEM images and pore size analysis demonstrated that the average thickness of the nanoflakes decreased with the increase in the Si content. Moreover, the distribution density of the Al(OH)3 nanosheets remained constant when the mean particle size of Al-Si exceeded 38 μm.

- The nucleation site of the Al(OH)3 nanoflakes was on the interface between the silicon and the aluminum matrix in the initial stage. Relative to the area of the eutectic Si and Al matrix, the area of the primary Si was finally covered by the Al(OH)3 nanosheets.

Author Contributions

Funding

Conflicts of Interest

Abbreviations

References

- Singh, R.; Bhateria, R. Core-shell nanostructures: A simplest two-component system with enhanced properties and multiple applications. Environ. Geochem. Health 2020, 43, 2459–2482. [Google Scholar] [CrossRef]

- Chang, Y.C.; Lin, Y.W. MoS2@SnO2 core-shell sub-microspheres for high efficient visible-light photodegradation and photocatalytic hydrogen production. Mater. Res. Bull. 2020, 129, 110912. [Google Scholar] [CrossRef]

- Zou, Q.C.; Jie, J.C.; Shen, Z.F.; Han, N.; Li, T.J. A new concept of Al-Si alloy with core-shell structure as phase change materials for thermal energy storage. Mater. Lett. 2019, 237, 193–196. [Google Scholar] [CrossRef]

- Liu, X.M.; Niu, C.G.; Zhen, X.P.; Wang, J.D.; Su, X.T. Novel approach for synthesis of boehmite nanostructures and their conversion to aluminum oxide nanostructures for remove Congo red. J. Colloid Interface Sci. 2015, 452, 116–125. [Google Scholar] [CrossRef]

- Wang, Y.P.; Hao, X.Q.; Wang, G.R.; Jin, Z.L. Rational design of a core–shell-shaped flowerlike Mn0.05Cd0.95S@NiAl-LDH structure for efficient hydrogen evolution. Catal. Lett. 2021, 151, 634–647. [Google Scholar] [CrossRef]

- Li, G.X.; Wu, C.; Dong, P.; Ji, D.; Zhang, Y.F. Core–Shell HZSM-5@silicalite-1 composite: Controllable synthesis and catalytic performance in alkylation of toluene with methanol. Catal. Lett. 2020, 150, 1923–1931. [Google Scholar] [CrossRef]

- Yang, L.Q.; Liu, Y.L.; Wang, L.; Zhao, Z.J.; Xing, C.J.; Shi, S.H.; Yuan, M.L.; Ge, Z.M.; Cai, Z.Y. Co5.47N/rGO@NF as a high-performance bifunctional catalyst for urea-assisted hydrogen evolution. Catal. Lett. 2019, 149, 3111–3118. [Google Scholar] [CrossRef]

- Xie, C.; Zhao, Y.B.; Song, Y.X.; Liu, Y.J.; Wang, Y.Y.; Yang, P. Effect of cores on photoluminescence of hybrid SiO2-coated CdTe quantum dots. J. Nanosci. Nanotechnol. 2020, 20, 5478–5485. [Google Scholar] [CrossRef]

- Yao, C.L.; Zhu, J.M. Synthesis, characterization and photocatalytic activity of Au/SiO2@TiO2 core-shell microspheres. J. Braz. Chem. Soc. 2020, 31, 589–596. [Google Scholar] [CrossRef]

- Gandomi, F.; Sobhani-Nasab, A.; Pourmasoud, S.; Eghbali-Arani, M.; Rahimi-Nasrabadi, M. Synthesis of novel Fe3O4@SiO2@Er2TiO5 superparamagnetic core–shell and evaluation of their photocatalytic capacity. J. Mater. Sci. Mater. Electron. 2020, 31, 10553–10563. [Google Scholar] [CrossRef]

- Han, D.D.; Xiao, N.R.; Liu, B.; Song, G.X.; Ding, J. One-pot synthesis of core/shell-structured NiS@onion-like carbon nanocapsule as a high-performance anode material for Lithium-ion batteries. Mater. Lett. 2017, 196, 119–122. [Google Scholar] [CrossRef]

- Li, S.T.; Shi, G.M.; Liang, J.S.; Dong, X.L.; Shi, F.N.; Yang, L.M.; Lv, S.H. Core-shell structured Co@CN nanocomposites as highly efficient dual function catalysts for reduction of toxic contaminants and hydrogen evolution reaction. Nanotechnology 2019, 31, 065701. [Google Scholar] [CrossRef]

- Quan, F.; Wu, Q.H.; Mao, A.Q.; Zuo, D.S.; Wang, B.; Yu, H.Y. Cu/Ag core/shell particles via modified arc discharge method. Int. J. Mater. Res. 2018, 109, 270–272. [Google Scholar] [CrossRef]

- Ren, Y.Y.; Yang, X.J.; Li, L.L.; Li, C.L.; Zhang, X.H.; Lu, Z.M.; Yu, X.F. Pd@Pt core–shell nanoflowers as efficient catalyst toward methanol oxidation. Catal. Lett. 2020, 150, 3415–3423. [Google Scholar] [CrossRef]

- Wang, Z.T. Cycloaddition of propargylic amines and CO2 by Ni@Pd nanoclusters confined within metal–organic framework cavities in aqueous solution. Catal. Lett. 2020, 150, 2352–2364. [Google Scholar] [CrossRef]

- Zhang, X.T.; He, N.; Liu, C.Y.; Guo, H.C. Pt–Cu alloy nanoparticles encapsulated in silicalite-1 molecular sieve: Coke-resistant catalyst for alkane dehydrogenation. Catal. Lett. 2019, 149, 974–984. [Google Scholar] [CrossRef]

- He, F.; Sui, C.; He, X.D.; Li, M.W. Comparison of structure and phase change characteristic of microencapsulated core/shell Al–Si alloy microparticles synthesized by two methods. J. Sol-Gel Sci. Technol. 2015, 76, 1–10. [Google Scholar] [CrossRef]

- Daraio, D.; Villoria, J.; Ingram, A.; Alexiadis, A.; Stitt, E.H.; Munnoch, A.L.; Marigo, M. Using Discrete Element method (DEM) simulations to reveal the differences in the γ-Al2O3 to α-Al2O3 mechanically induced phase transformation between a planetary ball mill and an attritor mill. Miner. Eng. 2020, 155, 106374. [Google Scholar] [CrossRef]

- Liu, G.G.; Ye, H.Q.; Dai, Y.N.; Yu, L.Y.; Jiang, H.; Zhou, Y.H.; Han, K. A facile method for in situ growing nano-flaky γ-Al2O3 on the surface of Al–Si alloy sphere. J. Alloys Compd. 2015, 647, 18–23. [Google Scholar] [CrossRef]

- Dai, Y.N.; Liu, G.G.; LI, W.; Han, K.; Zhou, Y.H.; Ye, H.Q. Preparation and catalytic application Al-Si@Al2O3 core-shell structured carrier. Nonferrous Met. Sci. Eng. 2016, 7, 42–48. [Google Scholar]

- Hearn, W.; Bogno, A.A.; Spinelli, J.; Valloton, J.; Henein, H. Microstructure Solidification Maps for Al-10 Wt Pct Si Alloys. Metall. Mater. Trans. A 2019, 50, 1333–1345. [Google Scholar] [CrossRef]

- Cai, Z.Y.; Zhang, C.; Wang, R.C.; Peng, C.; Qiu, K.; Wang, N.G. Effect of solidification rate on the coarsening behavior of precipitate in rapidly solidified Al-Si alloy. Prog. Nat. Sci. Mater. Int. 2016, 26, 391–397. [Google Scholar] [CrossRef]

- Cai, Z.Y.; Zhang, C.; Wang, R.C.; Peng, C.Q.; Wu, X.; Li, H.P.; Yang, M. Improvement of deformation capacity of gas-atomized hypereutectic Al-Si alloy powder by annealing treatment. Trans. Nonferrous Met. Soc. China 2018, 28, 1475–1483. [Google Scholar] [CrossRef]

- Cai, Z.Y.; Wang, R.C.; Zhang, C.; Peng, C.Q.; Xie, L.C.; Wang, L.Q. Characterization of rapidly solidified al-27 si hypereutectic alloy: Effect of solidification condition. J. Mater. Eng. Perform. 2015, 24, 1226–1236. [Google Scholar] [CrossRef]

- Godart, P.; Fischman, J.; Seto, K.; Hart, D. Hydrogen production from aluminum-water reactions subject to varied pressures and temperatures. Int. J. Hydrogen Energy 2019, 44, 11448–11458. [Google Scholar] [CrossRef]

| Sample | Si Content/at. % | Mean Size/μm |

|---|---|---|

| Al-12Si(A17) | 12 | 75 |

| Al-20Si(A23) | 20 | 38 |

| Al-20Si(A27) | 20 | 75 |

| Al-30Si(A37) | 30 | 75 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, Y.; Chen, P.; Wang, Y.; Li, C. Al-Si@Al(OH)3 Nanosheets Composite for Enhanced Efficient Strategy to Synthesize Al-Si@Al2O3 Core-Shell Structure. Crystals 2022, 12, 1137. https://doi.org/10.3390/cryst12081137

Lin Y, Chen P, Wang Y, Li C. Al-Si@Al(OH)3 Nanosheets Composite for Enhanced Efficient Strategy to Synthesize Al-Si@Al2O3 Core-Shell Structure. Crystals. 2022; 12(8):1137. https://doi.org/10.3390/cryst12081137

Chicago/Turabian StyleLin, Yuhui, Panyu Chen, Ying Wang, and Chengdong Li. 2022. "Al-Si@Al(OH)3 Nanosheets Composite for Enhanced Efficient Strategy to Synthesize Al-Si@Al2O3 Core-Shell Structure" Crystals 12, no. 8: 1137. https://doi.org/10.3390/cryst12081137

APA StyleLin, Y., Chen, P., Wang, Y., & Li, C. (2022). Al-Si@Al(OH)3 Nanosheets Composite for Enhanced Efficient Strategy to Synthesize Al-Si@Al2O3 Core-Shell Structure. Crystals, 12(8), 1137. https://doi.org/10.3390/cryst12081137