Laser Additive Manufacturing of Bulk Silicon Nitride Ceramic: Modeling versus Integral Transform Technique with Experimental Correlation

Abstract

:1. Introduction

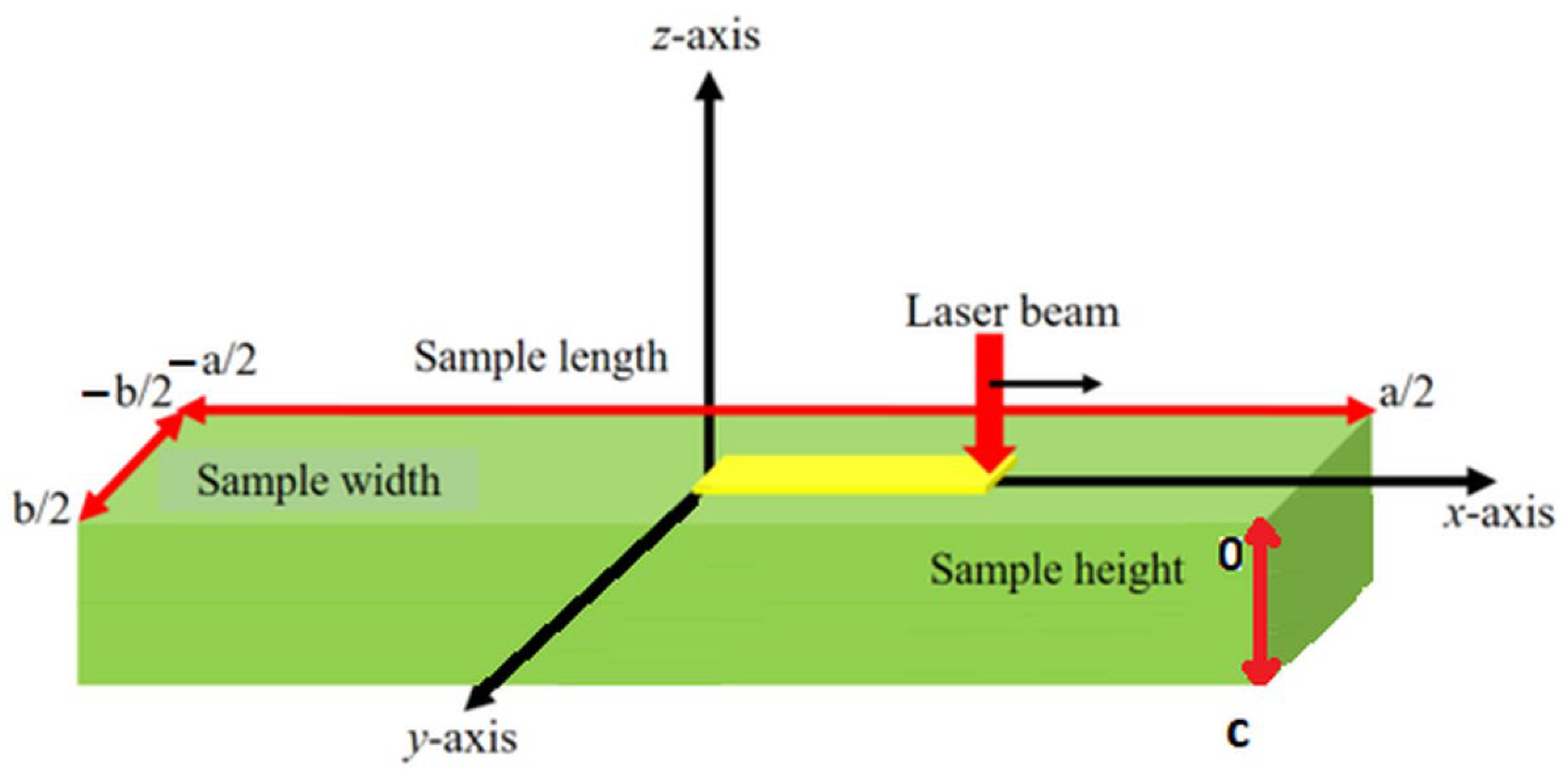

2. Mathematical Model

3. Methodology and Simulations

4. Results and Discussion

5. Conclusions

- The thermal field value increases rapidly at the irradiation site due to the heat propagation with an infinite speed (Fourier equation). The thermal conductivity in ceramics stays lower compared to metals, thereby limiting the heat expansion within the surrounding zones resulting in heat accumulation and a very high temperature rise.

- A correlation was shown between the laser scanning speed and thermal distribution intensity. Thus, whenever the laser scanning speed increases, less photons interact and transfer energy to the sample, resulting in a lower thermal distribution intensity.

- In laser additive manufacturing of ceramics, the laser beam energy absorption is split via surface or during propagation trough bulk, respectively. This depends on surface morphology, crystalline status, and processing history.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mahmood, M.A.; Popescu, A.C.; Mihailescu, I.N. Metal Matrix Composites Synthesized by Laser-Melting Deposition: A Review. Materials 2020, 13, 2593. [Google Scholar] [CrossRef] [PubMed]

- Mahmood, M.A.; Popescu, A.C.; Oane, M.; Ristoscu, C.; Chioibasu, D.; Mihai, S.; Mihailescu, I.N. Three-Jet Powder Flow and Laser–Powder Interaction in Laser Melting Deposition: Modelling Versus Experimental Correlations. Metals 2020, 10, 1113. [Google Scholar] [CrossRef]

- Sing, S.L. Perspectives on Additive Manufacturing Enabled BetaTitanium Alloys for Biomedical Applications. Int. J. Bioprint. 2022, 8, 478. [Google Scholar] [CrossRef]

- Amit Bandyopadhyay, Yanning Zhang & Bonny Onuike, Additive Manufacturing of Bimetallic Structures. Available online: https://www.tandfonline.com/loi/nvpp20 (accessed on 15 June 2022).

- Gong, X.; Zeng, D.; Groeneveld-Meijer, W.; Manogharan, G. Additive manufacturing: A machine learning model of process-structure-property linkages for machining behavior of Ti-6Al-4V, Additive manufacturing: A machine learning model of process-structureproperty linkages for machining behavior of Ti-6Al-4V. Mater. Sci. Add. Manuf. 2022, 1, 6. [Google Scholar] [CrossRef]

- Mahmood, M.A.; Popescu, A.C.; Hapenciuc, C.L.; Ristoscu, C.; Visan, A.I.; Oane, M.; Mihailescu, I.N. Estimation of clad geometry and corresponding residual stress distribution in laser melting deposition: Analytical modeling and experimental correlations. Int. J. Adv. Manuf. Technol. 2020, 111, 77–91. [Google Scholar] [CrossRef]

- Olakanmi, E.O.; Cochrane, R.F.; Dalgarno, K.W. A review on selective laser sintering/melting (SLS/SLM) of aluminium alloy powders: Processing, microstructure, and properties. Prog. Mater. Sci. 2015, 74, 401–477. [Google Scholar] [CrossRef]

- Akita, M.; Uematsu, Y.; Kakiuchi, T.; Nakajima, M.; Kawaguchi, R. Defect-dominated fatigue behavior in type 630 stainless steel fabricated by selective laser melting. Mater. Sci. Eng. A 2016, 666, 19–26. [Google Scholar] [CrossRef]

- Schwab, H.; Palm, F.; Kühn, U.; Eckert, J. Microstructure and mechanical properties of the near-beta titanium alloy Ti-5553 processed by selective laser melting. Mater. Des. 2016, 105, 75–80. [Google Scholar] [CrossRef]

- Liu, Y.J.; Li, S.J.; Wang, H.L.; Hou, W.T.; Hao, Y.L.; Yang, R.; Sercombe, T.B.; Zhang, L.C. Microstructure, defects and mechanical behavior of beta-type titanium porous structures manufactured by electron beam melting and selective laser melting. Acta Mater. 2016, 113, 56–67. [Google Scholar] [CrossRef]

- Averyanova, M.; Bertrand, P.; Verquin, B. Manufacture of Co-Cr dental crowns and bridges by selective laser Melting technology. Virtual Phys. Prototyp. 2011, 6, 179–185. [Google Scholar] [CrossRef]

- Harrison, N.J.; Todd, I.; Mumtaz, K. Reduction of micro-cracking in nickel superalloys processed by Selective Laser Melting: A fundamental alloy design approach. Acta Mater. 2015, 94, 59–68. [Google Scholar] [CrossRef]

- Konrad, W. Net Shaped High Performance Oxide Ceramic Parts by Selective Laser Melting. Phys. Procedia 2010, 5, 587–594. [Google Scholar] [CrossRef]

- Li, J.F.; Li, L.; Stott, F.H. Comparison of volumetric and surface heating sources in the modeling of laser melting of ceramic materials. Int. J. Heat Mass Transf. 2004, 47, 1159–1174. [Google Scholar] [CrossRef]

- Shukla, P.P.; Lawrence, J. Examination of temperature distribution and the thermal effects on Si3N4 engineering ceramics during fibre laser surface treatment. Opt. Lasers Eng. 2011, 49, 998–1011. [Google Scholar] [CrossRef]

- Shukla, P.P.; Lawrence, J. Investigation of Temperature Distribution During CO2 Laser and Fibre Laser Processing of a Si3N4 Engineering Ceramic by Means of a Computational and Experimental Approach. Lasers Eng. 2013, 27, 135–160. [Google Scholar]

- Bucă, A.M.; Oane, M.; Mahmood, M.A.; Mihăilescu, I.N.; Popescu, A.C.; Sava, B.A.; Ristoscu, C. Non-fourier estimate of electron temperature in case of femtosecond laser pulses interaction with metals. Metals 2020, 10, 606. [Google Scholar] [CrossRef]

- Hodge, N.E.; Ferencz, R.M.; Solberg, J.M. Implementation of a thermomechanical model for the simulation of selective laser melting. Comput. Mech. 2014, 54, 33–51. [Google Scholar] [CrossRef]

- King, W.; Anderson, A.T.; Ferencz, R.M.; Hodge, N.E.; Kamath, C.; Khairallah, S.A. Overview of modelling and simulation of metal powder bed fusion process at Lawrence Livermore National Laboratory. Mater. Sci. Technol. 2015, 31, 957–968. [Google Scholar] [CrossRef]

- Li, Y.; Gu, D. Thermal behavior during selective laser melting of commercially pure titanium powder: Numerical simulation and experimental study. Addit. Manuf. 2014, 1, 99–109. [Google Scholar] [CrossRef]

- Roberts, I.A.; Wang, C.J.; Esterlein, R.; Stanford, M.; Mynors, D.J. A three-dimensional finite element analysis of the temperature field during laser melting of metal powders in additive layer manufacturing. Int. J. Mach. Tools Manuf. 2009, 49, 916–923. [Google Scholar] [CrossRef]

- Marion, G.; Cailletaud, G.; Colin, C.; Mazière, M. A finite element model for the simulation of direct metal deposition. In Proceedings of the International Congress on Applications of Lasers & Electro-Optics, Laser Institute of America, Orlando, FL, USA, 14–18 October 2018; pp. 834–841. [Google Scholar] [CrossRef]

- Oane, M.; Mahmood, M.A.; Popescu, A. A State-of-the-Art Review on Integral Transform Technique in Laser-Material Interaction: Fourier and Non-Fourier Heat Equations. Materials 2021, 14, 4733. [Google Scholar] [CrossRef] [PubMed]

- Mihăilescu, C.N.; Oane, M.; Mihăilescu, N.; Ristoscu, C.; Mahmood, M.A.; Mihăilescu, I.N. A New Approach to Solve Non-Fourier Heat Equation via Empirical Methods Combined with the Integral Transform Technique in Finite Domains. In Matrix Theory—Classics and Advances; IntechOpen: Rijeka, Croatia, 2022. [Google Scholar] [CrossRef]

- Wei, Z.-H.; Cheng, L.-J.; Ma, Y.-X.; Chen, A.-N.; Guo, X.-F.; Wu, J.-M.; Shi, Y.-S. Direct fabrication mechanism of pre-sintered Si3N4 ceramic with ultra-high porosity by laser additive manufacturing. Scr. Mater. 2019, 173, 91–95. [Google Scholar] [CrossRef]

- Minasyan, T.; Liu, L.; Aghayana, M.; Kollo, L.; Kamboj, N.; Aydinyan, S.; Hussainova, I. A novel approach to fabricate Si3N4 by selective laser melting. Ceram. Int. 2018, 44, 13689–13694. [Google Scholar] [CrossRef]

- Chen, H.; Sun, Y.; Yuan, W.; Pang, S.; Yan, W.; Shi, Y. A Review on Discrete Element Method Simulation in Laser Powder Bed Fusion Additive Manufacturing. Chin. J. Mech. Eng. Addit. Manuf. Front. 2022, 1, 100017. [Google Scholar] [CrossRef]

- Bouabbou, A.; Vaudreuil, S. Understanding laser-metal interaction in selective laser melting additive manufacturing through numerical modelling and simulation: A review. Virtual Phys. Prototyp. 2022, 17, 543–562. [Google Scholar] [CrossRef]

- Zhang, Z.; Modest, M.F. Temperature-Dependent Absorptances of Ceramics for Nd:YAG and CO2 Laser Processing Applications. J. Heat Transf. 1998, 120, 322–327. [Google Scholar] [CrossRef]

- Tsarkova, O.G. Optical and Thermal Properties of Metals, Ceramics, and CVD Diamond Films upon High-Temperature Laser Heating. Phys. Wave Phenom. 2007, 15, 12–45. [Google Scholar] [CrossRef]

| Parameter Name | Value (Units) |

|---|---|

| Density | 3200 (kg/m3) |

| Room temperature | 25 (°C) |

| Specific heat | 900 (J/kg-K) |

| Thermal conductivity | 15 (W/mK) |

| Laser absorption coefficient | 0.90 |

| Laser beam spot diameter | 3.0 (mm) |

| Emissivity | 0.40 |

| Laser wavelength | 1.075 (µm) |

| Type of laser | Continuous wave Fiber laser |

| Laser Power (W) | Laser Scanning Speed (mm/min) | Maximum Temperature in the Case of Current Simulation (°C) | Maximum Temperature in the Case of FE Simulation [15] (°C) | Maximum Temperature in Experiments [15] (°C) |

|---|---|---|---|---|

| 143.25 | 100 | 2245 | 2236 | 2269 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mihailescu, C.N.; Oane, M.; Sava, B.A.; Popescu, A.C.; Elisa, M.; Mahmood, M.A.; Mihailescu, N.; Filip, A.V.; Anghel, S.A.; Mihailescu, I.N.; et al. Laser Additive Manufacturing of Bulk Silicon Nitride Ceramic: Modeling versus Integral Transform Technique with Experimental Correlation. Crystals 2022, 12, 1155. https://doi.org/10.3390/cryst12081155

Mihailescu CN, Oane M, Sava BA, Popescu AC, Elisa M, Mahmood MA, Mihailescu N, Filip AV, Anghel SA, Mihailescu IN, et al. Laser Additive Manufacturing of Bulk Silicon Nitride Ceramic: Modeling versus Integral Transform Technique with Experimental Correlation. Crystals. 2022; 12(8):1155. https://doi.org/10.3390/cryst12081155

Chicago/Turabian StyleMihailescu, Cristian N., Mihai Oane, Bogdan A. Sava, Andrei C. Popescu, Mihail Elisa, Muhammad Arif Mahmood, Natalia Mihailescu, Ana V. Filip, Sinziana Andreea Anghel, Ion N. Mihailescu, and et al. 2022. "Laser Additive Manufacturing of Bulk Silicon Nitride Ceramic: Modeling versus Integral Transform Technique with Experimental Correlation" Crystals 12, no. 8: 1155. https://doi.org/10.3390/cryst12081155

APA StyleMihailescu, C. N., Oane, M., Sava, B. A., Popescu, A. C., Elisa, M., Mahmood, M. A., Mihailescu, N., Filip, A. V., Anghel, S. A., Mihailescu, I. N., & Ristoscu, C. (2022). Laser Additive Manufacturing of Bulk Silicon Nitride Ceramic: Modeling versus Integral Transform Technique with Experimental Correlation. Crystals, 12(8), 1155. https://doi.org/10.3390/cryst12081155