SiO2 Nanoparticles as New Repairing Treatments toward the Pietraforte Sandstone in Florence Renaissance Buildings

Abstract

1. Introduction

2. Experimental Section

2.1. Materials and Reagents for Synthesis

2.2. Synthesis of SiO2 Nanoparticles

2.3. Preparation of SiO2 Nanodispersion

2.4. Pietraforte Sandstone Collection, Consolidation Treatments and Characterization

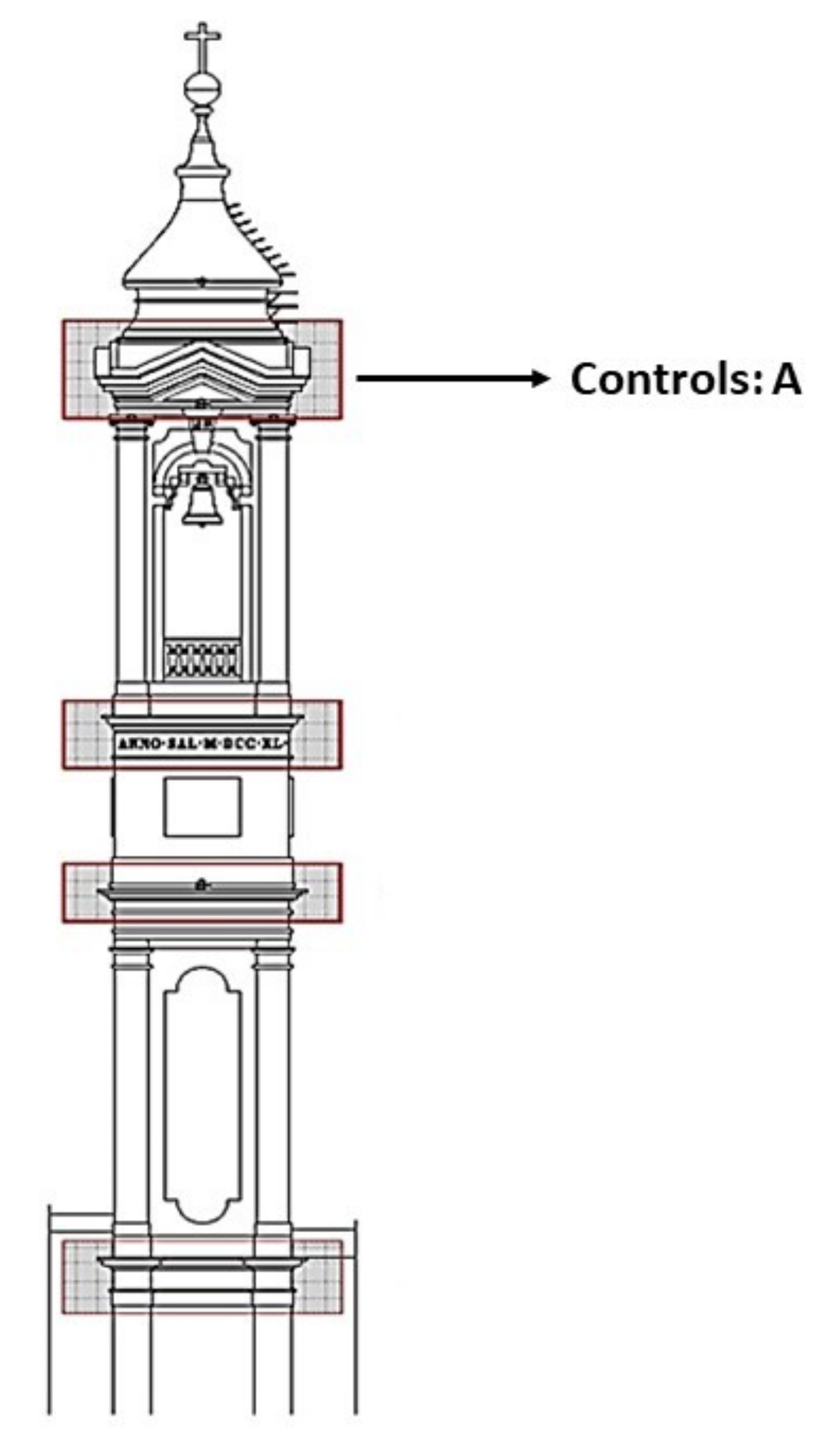

2.4.1. Samples Collection

2.4.2. Consolidation Treatments of Pietraforte Samples

2.5. Characterization Measurements

2.5.1. Textural Properties

2.5.2. Physical Properties

- -

- real density (γ), = Wd/Vr;

- -

- bulk density (γs) = Wd/Vb;

- -

- total open porosity P% = (Vb − Vr)/Vb · 100;

- -

- water imbibition coefficient ICw%, (expressed in weight) = (Ww − Wd)/Wd · 100;

- -

- water imbibition coefficient ICv%, (expressed in volume) = ICw · γs · 100;

- -

- water saturation index SI% = ICv/P · 100.

2.5.3. Capillary Absorption and Contact Angle Determination

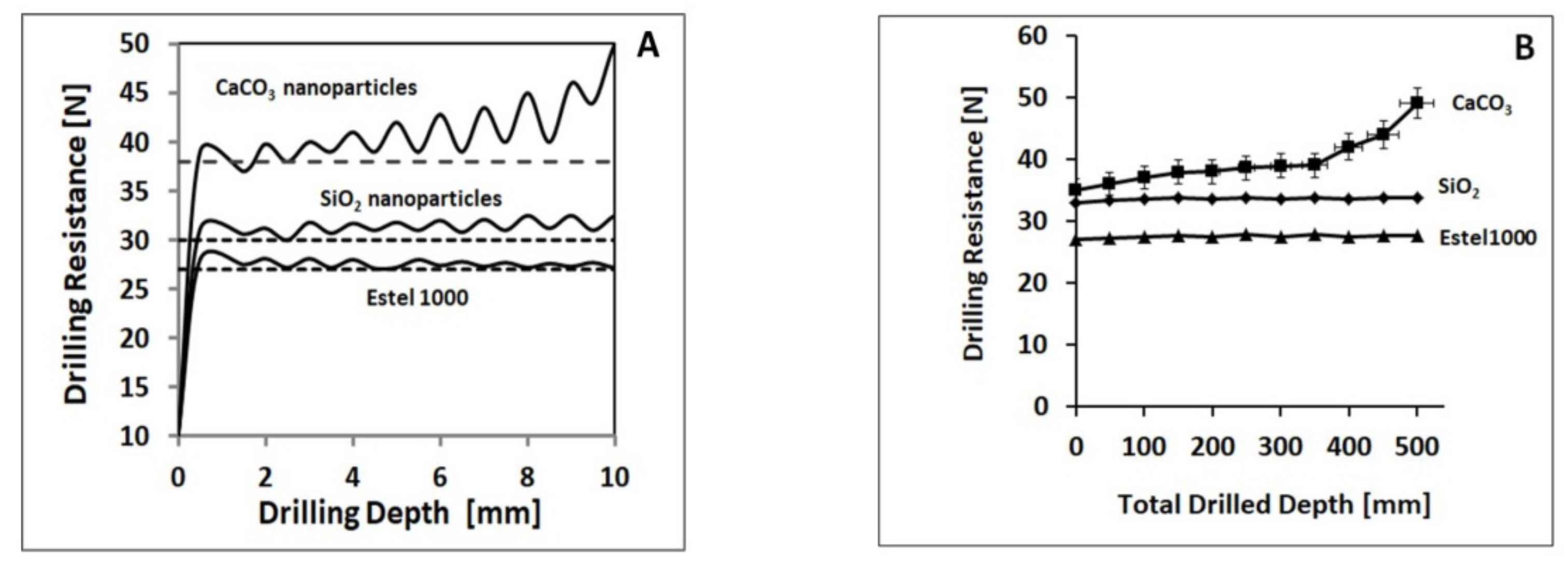

2.5.4. Effectiveness of Consolidation: Surface Hardness, Drilling Resistance Measurement Test, and Tensile Strength

2.5.5. Water Vapor Permeability (Pv%)

2.5.6. Treatment Efficiency (%)

2.5.7. Water Adsorption Coefficient (Cw)

2.5.8. The Water Vapor Resistance Factor (μ)

2.5.9. Colorimetric Measurements to Evaluate Color Alteration

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sartori, R. Pietre e Marmi di Firenze. Notizie storiche, antiche cave, genesi e presenza nei Monumenti. Alinea Firenze 2002, 1, 1–96. [Google Scholar]

- Cipriani, C.; Malesani, P. Ricerche sulle arenarie, XIII. La Pietraforte. Boll. Soc. Geol. It. 1966, 85, 299–332. [Google Scholar]

- Corti, L.; Muccini, U. Il Restauro della Facciata e della Torre di Palazzo Vecchio (2002–2004); Polistampa: Firenze, Italy, 2007; Volume 1, pp. 1000–1014. [Google Scholar]

- Caselli, G. Interventi di Conservazione e Restauro Sulla Facciata di Palazzo Medici Riccardi (2003–2007): Note Sulla Ricerca di un Equilibrio Critico; Emmebi Edizioni: Firenze, Italy, 2007; Volume 16–17, pp. 1000–1008. [Google Scholar]

- Gurrieri, F. La città a pezzi, pezzi di città: Distacchi lapidei a Firenze: (1977–2009); Polistampa: Firenze, Italy, 2009; Volume 1, pp. 1–128. [Google Scholar]

- Available online: https://www.ctseurope.com/it/249-estel-1000 (accessed on 22 June 2022).

- Lukaszewicz, J.W. The influence of ageing of polyalkoxysilane gel on the properties of stone consolidated with silicon esters. In Proceedings of the VIth International Congress on Deterioration and Conservation of Stone, Torun, Poland, 12–14 September 1988; pp. 182–193. [Google Scholar]

- Tana, F.; Messori, M.; Contini, D.; Cigada, A.; Valente, T.; Variola, F.; De Nardo, L.; Bondioli, F. Synthesis and characterization of scratch-resistant hybrid coatings based on non-hydrolytic sol-gel ZrO2 nanoparticles. Prog. Org. Coat. 2017, 103, 60–68. [Google Scholar] [CrossRef]

- Chelazzi, D.; Camerini, R.; Giorgi, R.; Baglioni, P. Nanomaterials for the Consolidation of Stone Artifacts. In Advanced Materials for the Conservation of Stone; Hosseini, M., Karapanagiotis, I., Eds.; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar] [CrossRef]

- Borgioli, L. Le superfici decorate dell’Architettura: Interventi tra tradizione e nuove tecnologie. In Proceedings of the SAP—Società Archeologica, Trento, Italy, 7–8 October 2019. [Google Scholar]

- Indart, A.Z.; Arce, P.L. Silica nanoparticles (SiO2): Influence of relative humidity in stone consolidation. J. Cult. Herit. 2016, 18, 258–270. [Google Scholar] [CrossRef]

- Daniele, V.; Taglieri, G. Ca(OH)2 nanoparticle characterization: Microscopic investigation of their application on natural stones. WIT Trans. Eng. Sci. 2011, 72, 55–66. [Google Scholar] [CrossRef]

- Columbu, S.; Usai, M.; Rispoli, C.; Fancello, D. Lime and Cement Plasters from 20th Century Buildings: Raw Materials and Relations between Mineralogical-Petrographic Characteristics and Chemical-Physical Compatibility with the Limestone Substrate. Minerals 2022, 12, 226. [Google Scholar] [CrossRef]

- Borsoi, G. Nanostructured lime-based materials for the conservation of calcareous substrates. A + BE Archit. Built Environ. 2017, 8, 1–200. [Google Scholar] [CrossRef]

- Valentini, F.; Pallecchi, P.; Relucenti, M.; Donfrancesco, O.; Sottili, G.; Pettiti, I.; Mussi, V. Characterization of Calcium Carbonate Nanoparticles with Architectural Application for the Consolidation of Pietraforte. Anal. Lett. 2022, 55, 93–108. [Google Scholar] [CrossRef]

- Wen, Y.; Qing, H.; Shu, H.; Liu, Q. Evaluating the Protective Effects of Calcium Carbonate Coating on Sandstone Cultural Heritage. Coatings 2021, 11, 1534. [Google Scholar] [CrossRef]

- Roveri, M.; Gherardi, F.; Goidanich, S.; Gulotta, D.; Castelvetro, V.; Fischer, R.; Winandy, L.; Weber, J.; Toniolo, L. Self-cleaning and antifouling nanocomposites for stone protection: Properties and performances of stone-nanomaterial systems. Mater. Sci. Eng. 2018, 364, 012070. [Google Scholar] [CrossRef]

- Helmi, F.; Mohamed, H.; Yasser, K. Using nanocomposites in the consolidation and protection of sandstones. Int. J. Conserv. Sci. 2016, 7, 29–40. [Google Scholar]

- Pinna, D.; Galeotti, M.; Perito, B.; Daly, G.; Salvadori, B. In situ long-term monitoring of recolonization by fungi and lichens after innovative and traditional conservative treatments of archaeological stones in Fiesole (Italy). Int. Biodeterior. Biodegrad. 2018, 132, 49–58. [Google Scholar] [CrossRef]

- Iucolano, F.; Colella, A.; Liguori, B.; Calcaterra, D. Suitability of silica nanoparticles for tuff consolidation. Constr. Build. Mater. 2019, 202, 73–81. [Google Scholar] [CrossRef]

- Colella, A.; Capasso, I.; Iucolano, F. Comparison of Latest and Innovative Silica-Based Consolidants for Volcanic Stones. Materials 2021, 14, 2513. [Google Scholar] [CrossRef]

- Wenwu, C.; Pengfei, D.; Pengbo, Y.; Jingke, Z. Effect of inorganic silicate consolidation on the mechanical and durability performance of sandstone used in historical sites. Constr. Build. Mater. 2016, 121, 445–452. [Google Scholar] [CrossRef]

- Domingo, C.; Alvarez De Buergo, M.; Sánchez-Cortés, S.; Fort, R.; García-Ramos, J.V.; Gomez-Heras, M. Possibilities of monitoring the polymerization process of silicon-based water repellents and consolidants in stones through infrared and Raman spectroscopy. Prog. Org. Coat 2008, 63, 5–12. [Google Scholar] [CrossRef]

- Shahzad, K.M.; Adewunmi, A.A.; Sultan, A.S.; Al-Hamad, M.; Mehmood, U. Recent Advances in Nanoparticles Enhanced Oil Recovery: Rheology, Interfacial Tension, Oil Recovery, and Wettability Alteration. J. Nanomater. 2017, 2017, 15. [Google Scholar] [CrossRef]

- Franzoni, E.; Graziani, G.; Sassoni, E.; Bacilieri, G.; Griffa, M.; Lura, P. Solvent-based ethyl silicate for stone consolidation: Influence of the application technique on penetration depth, efficacy and pore occlusion. Mater. Struct. 2015, 48, 3503–3515. [Google Scholar] [CrossRef]

- Bergamonti, L.; Bondioli, F.; Alfieri, I.; Alinovi, S.; Lorenzi, A.; Predieri, G.; Lottici, P.P. Weathering resistance ofPMMA/SiO2/ZrO2 hybrid coatings for sandstone conservation. Polym. Degrad. Stab. 2018, 147, 274–283. [Google Scholar] [CrossRef]

- Stucchi, N.M.E.; Tesser, E.; Antonelli, F.; Benedetti, A. Synthesis and characterization of nanosilica products for the consolidation of stones. In Proceedings of the IMEKO TC-4 International Conference on Metrology for Archaeology and Cultural Heritage, Florence, Italy, 4–6 December 2019. [Google Scholar]

- Buosi, C.; Columbu, S.; Ennas, G.; Pittau, P.; Scanu, G.G. Mineralogical, Petrographic, and Physical Investigations on Fossiliferous Middle Jurassic Sandstones from Central Sardinia (Italy) to Define Their Alteration and Experimental Consolidation. Geoheritage 2019, 11, 729–749. [Google Scholar] [CrossRef]

- Stöber, W.; Fink, A.; Bohn, E. Controlled growth of monodisperse silica spheres in the micron size range. J. Colloid Interface Sci. 1968, 26, 62–69. [Google Scholar] [CrossRef]

- Joni, I.M.; Vanitha, M.; Panatarani, C.; Faizal, F. Dispersion of amorphous silica nanoparticles via beads milling process and their particle size analysis, hydrophobicity and anti-bacterial activity. Adv. Powder Technol. 2020, 31, 370–380. [Google Scholar] [CrossRef]

- Ente Italiano di Normazione, UNI EN 15801. Conservazione dei Beni Culturali—Metodi di Prova-Determinazione Dell’assorbimento Dell’acqua per Capillarità. 2010. Available online: http://store.uni.com/catalogo/uni-en-15801-2010 (accessed on 4 February 2010).

- Ente Italiano di Normazione, UNI EN 15802. Cultural Heritage—Natural and Artificial Stones—Determination of Static Contact Angle on Laboratory Specimens. 2010. Available online: http://store.uni.com/catalogo/uni-en-15802-2010 (accessed on 4 February 2010).

- Gurvitschj, L.G. Methods of Humidity Deetermination. Part II: Determination of material humidity. J. Russ. Phys. Chem. Soc. Petersb. 1915, 47, ii713–ii764. [Google Scholar] [CrossRef][Green Version]

- Barrett, E.P.; Joyner, L.G.; Halenda, P.P. The Determination of Pore Volume and Area Distributions in Porous Substances. I. Computations from Nitrogen Isotherms. J. Am. Chem. Soc. 1951, 73, 373–380. [Google Scholar] [CrossRef]

- Barsottelli, M.; Fratini, F.; Giorgetti, G.; Manganelli Del Fà, C. Microfabric and alteration in the Carrara Marble: A preliminary study. Sci. Technol. Cult. Herit. 1998, 7, 109–120. [Google Scholar]

- Barsottelli, M.; Cellai, G.F.F.; Fratini, I.; Manganelli Del Fà, C. The hygrometric behaviour of some artificial stone materials used as elements of masonry walls. Mater. Struct. 2001, 34, 211–216. [Google Scholar] [CrossRef]

- Cantisani, E.; Pecchioni, E.; Fratini, F.; Garzonio, C.A.; Malesani, P.; Molli, G. Thermal stress in the Apuan marbles: Relationship between microstructure and petrophysical charac-teristics. Int. J. Rock Mech. Min. Sci. 2009, 46, 128–137. [Google Scholar] [CrossRef]

- Fratini, F.; Cantisani, E.; Pecchioni, E.; Pandeli, E.; Vettori, S. Pietra Alberese: Building Material and Stone for Lime in the Florentine Territory (Tuscany, Italy). Heritage 2020, 3, 84. [Google Scholar] [CrossRef]

- Pamplona, M.; Kocher, M.; Snethlage, M.; Barros, L. Drilling resistance: Overview and outlook. Zeitschrift-Deutschen Gesellschaft fur Geowissenschaften 2007, 158, 665–676. [Google Scholar] [CrossRef]

- Delgado Rodrigues, J.; Costa, D. A New Method for Data Correction in Drill Resistance Tests for the Effect of Drill Bit Wear. Int. J. Restor. Int. Z. Für Bauinstandsetz. 2004, 10, 1–18. [Google Scholar]

- ASTM C297/C297M; Standard Test Method for Flatwise Tensile Strength of Sandwich Constructions. Ontario Provincial Standards: London, UK, 2015.

- EN 1015-18:2002; Methods of Test for Mortar for Masonry-Part 18: Determination of Water Absorption Coefficient Due to Capillary Action of Hardened Mortar. CEN: London, UK, 2016.

- Olaoye, T.S.; Dewsbury, M.; Kunzel, H.A. Method for Establishing a Hydrothermally Controlled Test Room for Measuring the Water Vapor Resistivity. Charact. Constr. Mater. Energ. 2021, 14, 4. [Google Scholar] [CrossRef]

- Hill, B.; Roger, T.; Vorhagen, F.W. Comparative analysis of the quantization of color spaces on the basis of the CIELAB color-difference formula. ACM Trans. Graph. 1997, 16, 109–154. [Google Scholar] [CrossRef]

- Delgado Rodrigues, J.; Ferreira Pinto, A.P. Laboratory and onsite study of barium hydroxide as a consolidant for high porosity limestones. J. Cult. Herit. 2015, 19, 467–476. [Google Scholar] [CrossRef]

- Gheno, G.; Badetti, E.; Brunelli, A.; Ganzerla, R.; Marcomini, A. Consolidation of Vicenza, Arenaria and Istria stones: A comparison between nano-based products and acrylate derivatives. J. Cult. Herit. 2018, 32, 44–52. [Google Scholar] [CrossRef]

- Yevgeniy, S.; Murtada, S.A.; Abduljamiu, A.; Theis, S.; Sidqi, A.A.-K.; Shirish, P.; Murtadha, J.; Al, T.; Khalid, M.A. Carbonate Rock Chemical Consolidation Methods: Advancement and Applications. Energy Fuels 2022, 36, 4186–4197. [Google Scholar] [CrossRef]

- Sassoni, E.; Franzoni, E.; Pigino, B.; Scherer, G.W.; Naidu, S. Consolidation of calcareous and siliceous sandstones by hydroxyapatite: Comparison with a TEOS-based consolidant. J. Cult. Herit. 2013, 14, e103–e108. [Google Scholar] [CrossRef]

- Di Maio, L.; Coppola, B.; Courard, L.; Michel, F.; Incarnato, L.; Scarfato, P. Data on thermal conductivity, water vapour permeability and water absorption of a cementitious mortar containing end-of-waste plastic aggregates. Data Brief 2018, 18, 1057–1063. [Google Scholar] [CrossRef]

- Zornoza-Indart, A.; Lopez-Arce, P.; Leal, N.; Simão, J.; Zoghlami, K. Consolidation of a Tunisian bioclastic calcarenite: From conventional ethyl silicate products to nanostructured and nanoparticle based consolidants. Constr. Build. Mater. 2016, 116, 188–202. [Google Scholar] [CrossRef]

- Lukaszewicz, J.W. The influence of pre-consolidation with ethyl silicate on soluble salts removal and deep consolidation. In Proceedings of the 8th International Congress on Deterioration and Conservation of Stone, Berlin, Germany, 30 September–4 October 1996; pp. 1203–1214. [Google Scholar]

- Ferreira Pinto, A.P.; Delgado Rodrigues, J. Impacts of consolidation procedures on colour and absorption kinetics of carbonate stones. Stud. Conserv. 2014, 59, 79–90. [Google Scholar] [CrossRef]

- Petcu, C.; Alexandrescu, E.; Bălan, A.; Tănase, M.A.; Cinteză, L.O. Synthesis and Characterisation of Organo-Modified Silica Nanostructured Films for the Water-Repellent Treatment of Historic Stone Buildings. Coatings 2020, 10, 1010. [Google Scholar] [CrossRef]

- Pecchioni, E.; Vettori, S.; Cantisani, E.; Fratini, F.; Ricci, M.; Garzonio, C.A. Chemical and mineralogical studies of the red chromatic alteration of Florentine Pietra Serena sandstone. Eur. J. Mineral. 2016, 28, 449–458. [Google Scholar] [CrossRef]

- Chabuk, A.; Al-Ansari, N.; Hussain, H.M.; Knutsson, S.; Pusch, R.; Laue, J. Combining GIS Applications and Method of Multi-Criteria Decision-Making (AHP) for Landfill Siting in Al-Hashimiyah Qadhaa, Babylon, Iraq. Sustainability 2017, 9, 1932. [Google Scholar] [CrossRef]

- Aldoasri, M.A.; Darwish, S.S.; Adam, M.A.; Elmarzugi, N.A.; Ahmed, S.M. Performance of Clay, SiO2, Ca(OH)2, CaCO3 Polymeric Nanocomposites for Conservation and Preservation of Limestone Artworks. Preprints 2018, 1, 1–29. [Google Scholar] [CrossRef]

- Mun, E.A.; Hannell, C.; Rogers, S.E.; Hole, P.; Williams, A.C.; Williams, V.V. On the Role of Specific Interactions in the Diffusion of Nanoparticles in Aqueous Polymer Solutions. Langmuir 2014, 30, 308–317. [Google Scholar] [CrossRef]

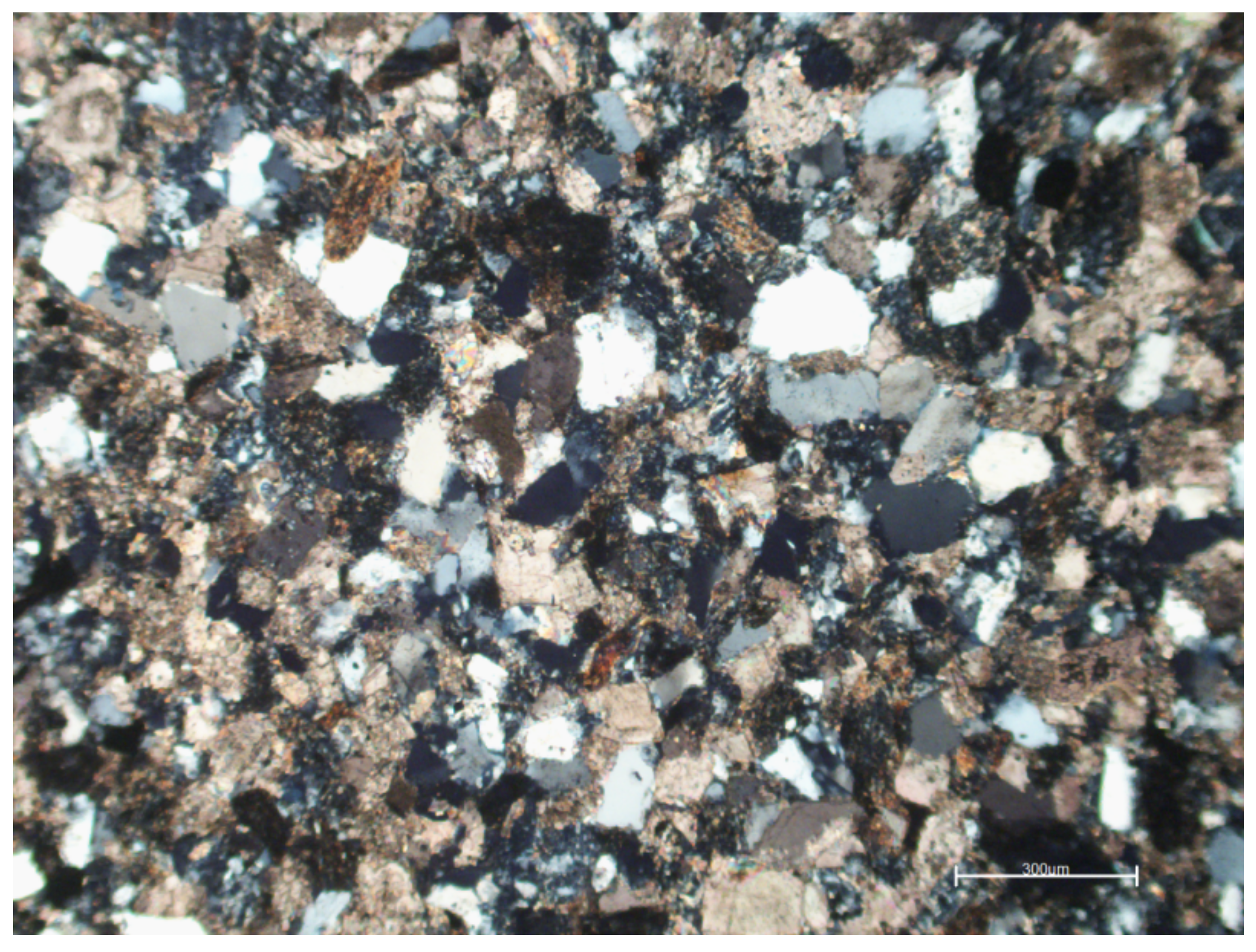

| Materials | Lithological Type | Geological Formation | Age | Historic Quarries | Petrographic Classification | Distinguishing Features |

|---|---|---|---|---|---|---|

| Pietraforte sandstone | Sedimentary rock | The Pietraforte Formation is an allochthonous unit of the Ligurian domain in the northern Apennines | Cretaceous Superior (90–70 Ma) | Reliefs on the left bank of the Arno river near Florence (Costa San Giorgio, Boboli, Bello sguardo Monte Ripaldi) | Fine grains lithic sandstone |

|

| Absorption of water at atmospheric pressure | 0.80% |

| Apparent density | 2.74 Kg/m3 |

| Open porosity | 1.40% |

| Flexural strength with a concentrated load | 32 MPa |

| Compressive strength | 198 MPa |

| Slip resistance | 38 USRV |

| Freezing UNI6506 | did not freeze |

| Samples | Dimensions (cm) and Shape | Treatments |

|---|---|---|

| A | 3 × 10 × 20 cm3 rectangular parallelepiped | No treatment (the control) |

| B | 5 × 5 × 10 cm3 prismatic samples | SiO2-Capillary absorption |

| C | 5 × 5 × 5 cm3 cubic samples | SiO2-Brushing treatment |

| D | 5 × 5 × 10 cm3 prismatic samples | CaCO3-Capillary absorption |

| E | 5 × 5 × 5 cm3 cubic samples | CaCO3-Brushing treatment |

| F | 5 × 5 × 10 cm3 prismatic samples | Estel 1000-Capillary absorption |

| G | 5 × 5 × 5 cm3 cubic samples | Estel 1000-Brushing absorption |

| Samples | γ (g/cm3) | γs (g/cm3) | Surface Area (m2/g) | Total Pore Volume (cm3/g) | Ptot (%) | Total Porosity Decomposition (%) | ||

|---|---|---|---|---|---|---|---|---|

| Micro | Meso | Macro | ||||||

| Pietraforte control sample A | 2.71 ± 0.01 | 2.56 ± 0.01 | 7.2 ± 0.5 | 0.0120 | 5.70 ± 0.14 | 2.70 ± 0.01 | 3.00 ± 0.01 | ---- |

| Treatments | Adsorbent Amount of Products (a) [kg m−2] | Penetration Rate (b) [mm/min0.5] |

|---|---|---|

| Capillary SiO2-application (sample B) | 6.0 (±0.02) | 7.6 |

| Brushing SiO2-application (sample C) | 4.0 (±0.02) | 6.8 |

| Capillary CaCO3-application (sample D) | 8.0 (±0.01) | 10.1 |

| Brushing CaCO3-application (sample E) | 6.0 (±0.03) | 9.3 |

| Capillary Estel1000-application (sample F) | 3.2 (±0.04) | 4.2 |

| Brushing Estel1000-application (sample G) | 2.4 (±0.05) | 3.4 |

| Samples | Surface Area (m2/g) | Total Pore Volume (cm3/g) | ICw (%) | ICv (%) | Ptot (%) | SI (%) |

|---|---|---|---|---|---|---|

| A (control) | 7.2 ± 0.5 | 0.0120 | 1.80 ± 0.03 | 4.60 ± 0.07 | 5.70 ± 0.14 | 83 ± 1.51 |

| C this work | 5.5 ± 0.5 | 0.0065 | 1.60 ± 0.02 | 4.40 ± 0.05 | 7.21 ± 0.11 | 61 ± 2.01 |

| E this work | 3.2 ± 0.5 | 0.0049 | 1.40 ± 0.03 | 4.20 ± 0.01 | 8.40 ± 0.10 | 50 ± 2.32 |

| G this work | 6.6 ± 0.5 | 0.0083 | 1.72 ± 0.04 | 4.52 ± 0.07 | 6.28 ± 0.12 | 72 ± 1.86 |

| Sample | Contact Angle | Increment of Superficial Hardness | DRm [N] | Tensile Strength |

|---|---|---|---|---|

| (ϑ ± 3°) | (%) | l = drill bit ∅ 5 (mm) | (MPa) | |

| A (control) | 48 | - | - | 13.6 (± 1.2) |

| C this work | 80 | 35 | 34 | 29.8 (± 2.2) |

| E this work | 159 | 80 | 36 | 36.7 (± 2.2) |

| G this work | 49 | 22 | 27 | 14.5 (± 2.3) |

| Treated Samples | ET (%) Immediately after Applying and Drying the Products | ET (%) after 6 Months from the First Application | P (%) Immediately after Applying and Drying the Products | P (%) after 6 Months from the First Application |

|---|---|---|---|---|

| A (control) | - | - | 30 | 30 |

| C | 86 | 86 | 34 | 34 |

| E | 95 | 63 | 58 | 55 |

| G | 70 | 70 | 57 | 57 |

| Samples | Water Adsorb. Coeff. (Cw) | μ | Tensile Strenght [MPa] | References |

|---|---|---|---|---|

| A (Control) | 2.5 | 27 | 13.6 | This work |

| C | 2.0 | 30 | 29.8 | This work |

| E | 1.8 | 50 | 36.7 | This work |

| G | 2.1 | 54 | 14.5 | This work |

| Pietra Serena (Control) | 2.2 | 29 | 8.2 | [48] |

| HAP-treated | 2.1 | 35 | 9.7 | [48] |

| TEOS-treated | 1.4 | 55 | 10.0 | [48] |

| Reference | n. r (a) | n. r. | n. r. | [49] |

| LWM10 | 32 | 13 | n. r. | [49] |

| LWM25 | 45 | 25 | n. r. | [49] |

| LWM50 | 61 | 48 | n. r. | [49] |

| GS Untreated (Control) | 4.4 | 18.8 | 4.1 (±0.9) | [48] |

| HAP-treated | 4.5 | 21.1 | 5.0 (±0.9) | [48] |

| TEOS-treated | 0.3 | 28.7 | 5.4 (±1.2) | [48] |

| PS Untreated (Control) | 2.2 | 29.3 | 8.2 (±2.2) | [48] |

| HAP-treated | 2.1 | 35.0 | 9.7 (±2.3) | [48] |

| TEOS-treated | 1.4 | 54.9 | 10.0 (±1.6) | [48] |

| Samples | L* | a* | b* | ΔE* | ΔC* | ΔH* |

|---|---|---|---|---|---|---|

| A (control) | 75.8 | 0.1 | 1.8 | ---- | ---- | ---- |

| C this work | 75.7 | 0.1 | 1.8 | 0.1 | 0.1 | 0.1 |

| E this work | 76.0 | 0.2 | 1.9 | 0.2 | 0.2 | 0.1 |

| G this work | 77.2 | 0.3 | 2.0 | 3.2 | 0.9 | 0.3 |

| Risk of Incompatibility | Colour Difference | Treatments |

|---|---|---|

| Low | ΔE* < 3 | C and E samples |

| Medium | 3 < ΔE* < 5 | G sample |

| High | ΔE* > 5 | - |

| Applied Treatment Materials | ΔL* | Δa* | Δb* | ΔE | References |

|---|---|---|---|---|---|

| The samples treated with CaCO3/Polymer nanocomposites | −1.21 | −0.34 | 0.33 | 1.30 | [55] |

| The samples treated with Ca (OH)2/Polymer nanocomposites | 1.41 | −0.60 | −2.42 | 2.86 | [56] |

| The samples treated with Clay/Polymer nanocomposites | 1.68 | −0.22 | −1.09 | 2.01 | [56] |

| The samples treated with SiO2/Polymer nanocomposites | 0.16 | −0.06 | −0.29 | 0.33 | [56] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Valentini, F.; Pallecchi, P.; Relucenti, M.; Donfrancesco, O.; Sottili, G.; Pettiti, I.; Mussi, V.; De Angelis, S.; Scatigno, C.; Festa, G. SiO2 Nanoparticles as New Repairing Treatments toward the Pietraforte Sandstone in Florence Renaissance Buildings. Crystals 2022, 12, 1182. https://doi.org/10.3390/cryst12091182

Valentini F, Pallecchi P, Relucenti M, Donfrancesco O, Sottili G, Pettiti I, Mussi V, De Angelis S, Scatigno C, Festa G. SiO2 Nanoparticles as New Repairing Treatments toward the Pietraforte Sandstone in Florence Renaissance Buildings. Crystals. 2022; 12(9):1182. https://doi.org/10.3390/cryst12091182

Chicago/Turabian StyleValentini, Federica, Pasquino Pallecchi, Michela Relucenti, Orlando Donfrancesco, Gianluca Sottili, Ida Pettiti, Valentina Mussi, Sara De Angelis, Claudia Scatigno, and Giulia Festa. 2022. "SiO2 Nanoparticles as New Repairing Treatments toward the Pietraforte Sandstone in Florence Renaissance Buildings" Crystals 12, no. 9: 1182. https://doi.org/10.3390/cryst12091182

APA StyleValentini, F., Pallecchi, P., Relucenti, M., Donfrancesco, O., Sottili, G., Pettiti, I., Mussi, V., De Angelis, S., Scatigno, C., & Festa, G. (2022). SiO2 Nanoparticles as New Repairing Treatments toward the Pietraforte Sandstone in Florence Renaissance Buildings. Crystals, 12(9), 1182. https://doi.org/10.3390/cryst12091182