Effect of Laser Energy Density on the Microstructure and Microhardness of Inconel 718 Alloy Fabricated by Selective Laser Melting

Abstract

:1. Introduction

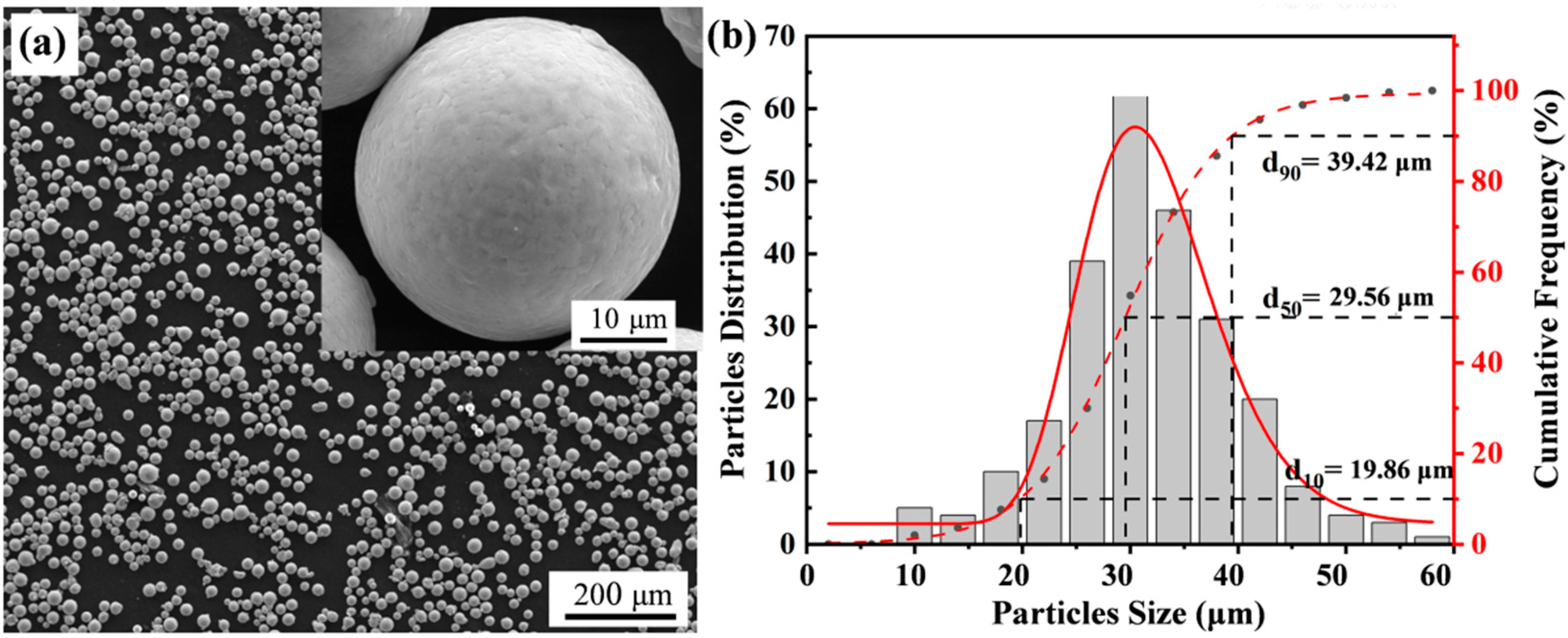

2. Materials and Methods

2.1. Materials and Experimental Equipment

2.2. Sample Fabrications and Characterization

3. Results and Discussion

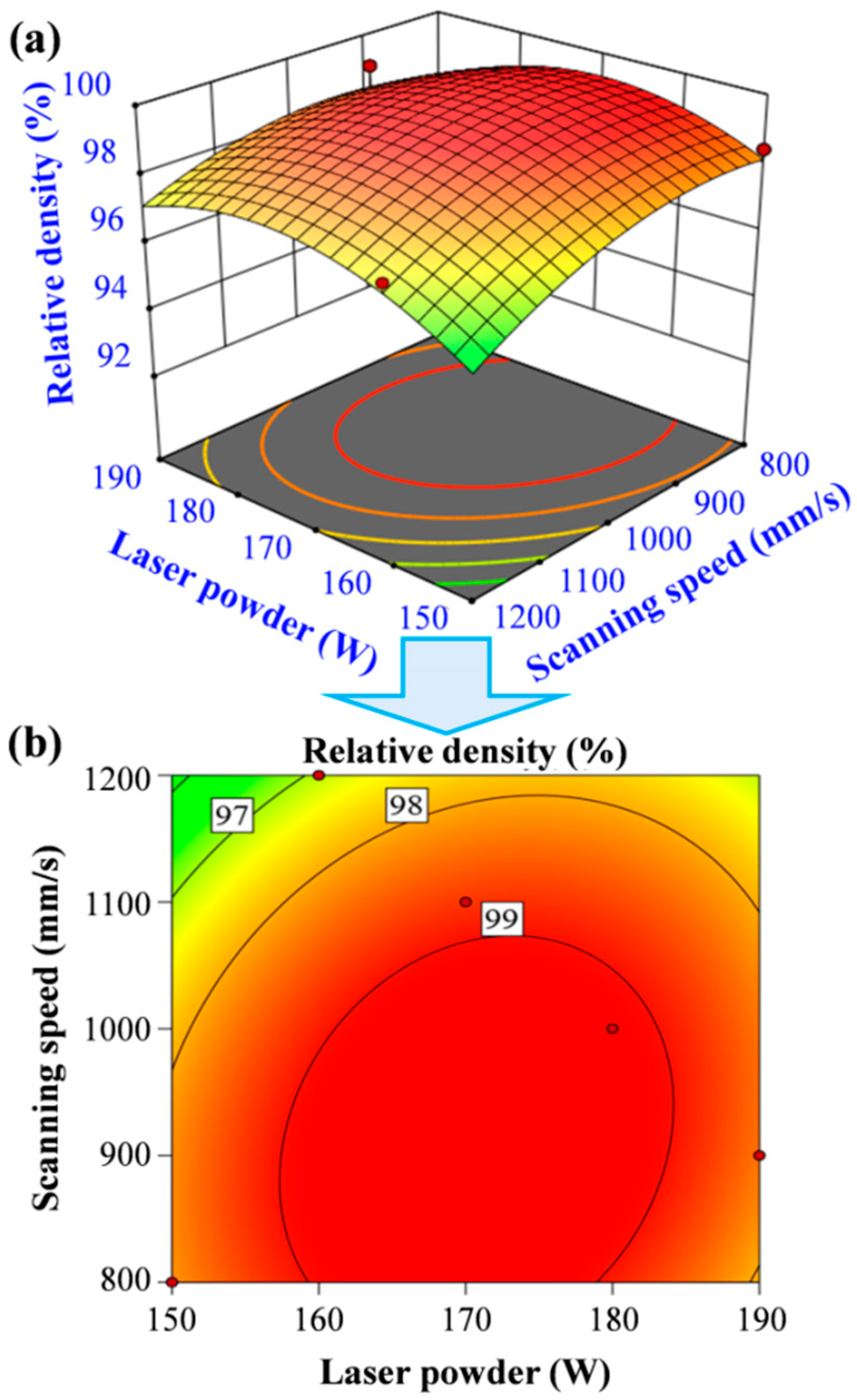

3.1. Effect of Laser Energy Density on Relative Density

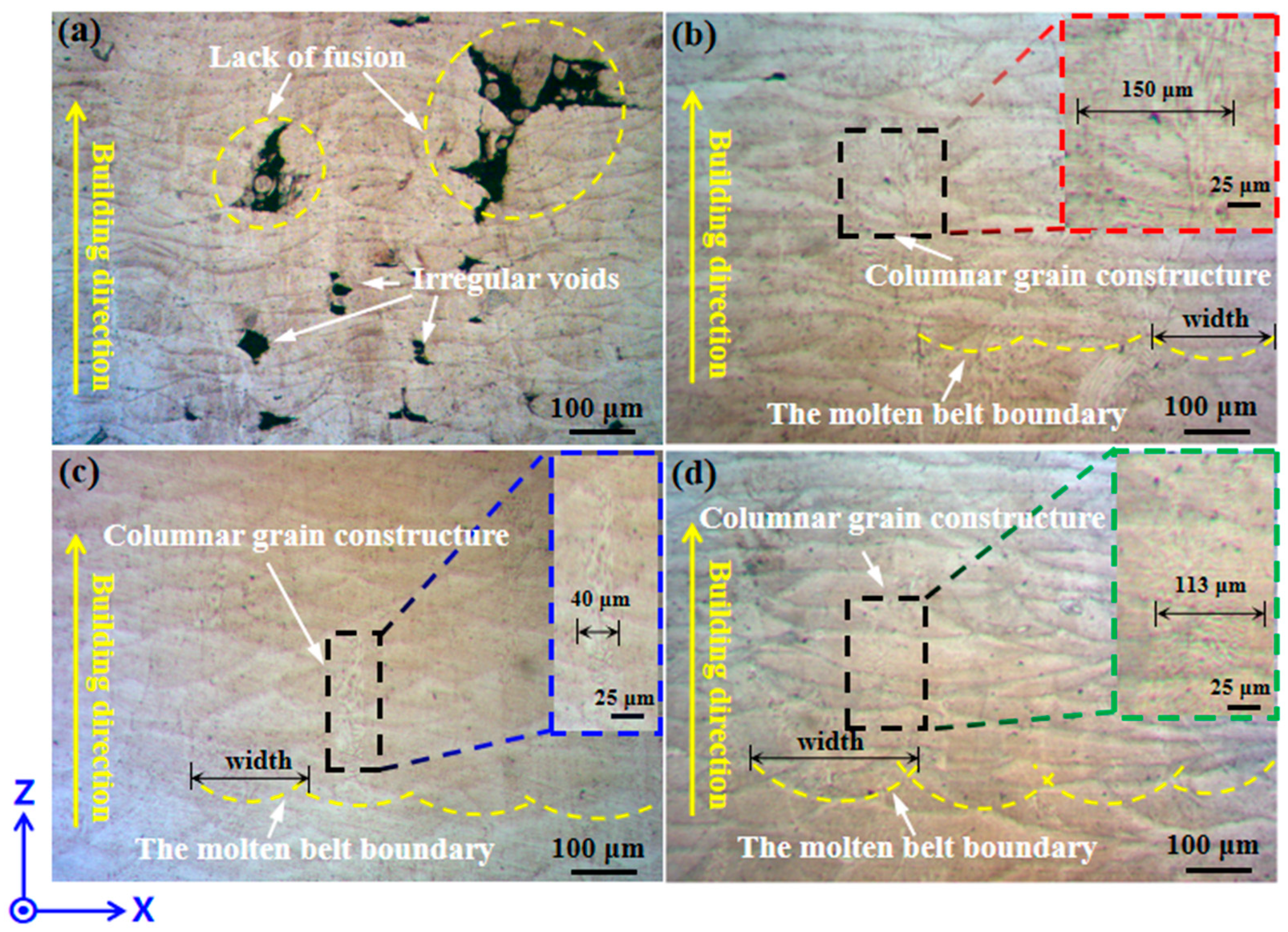

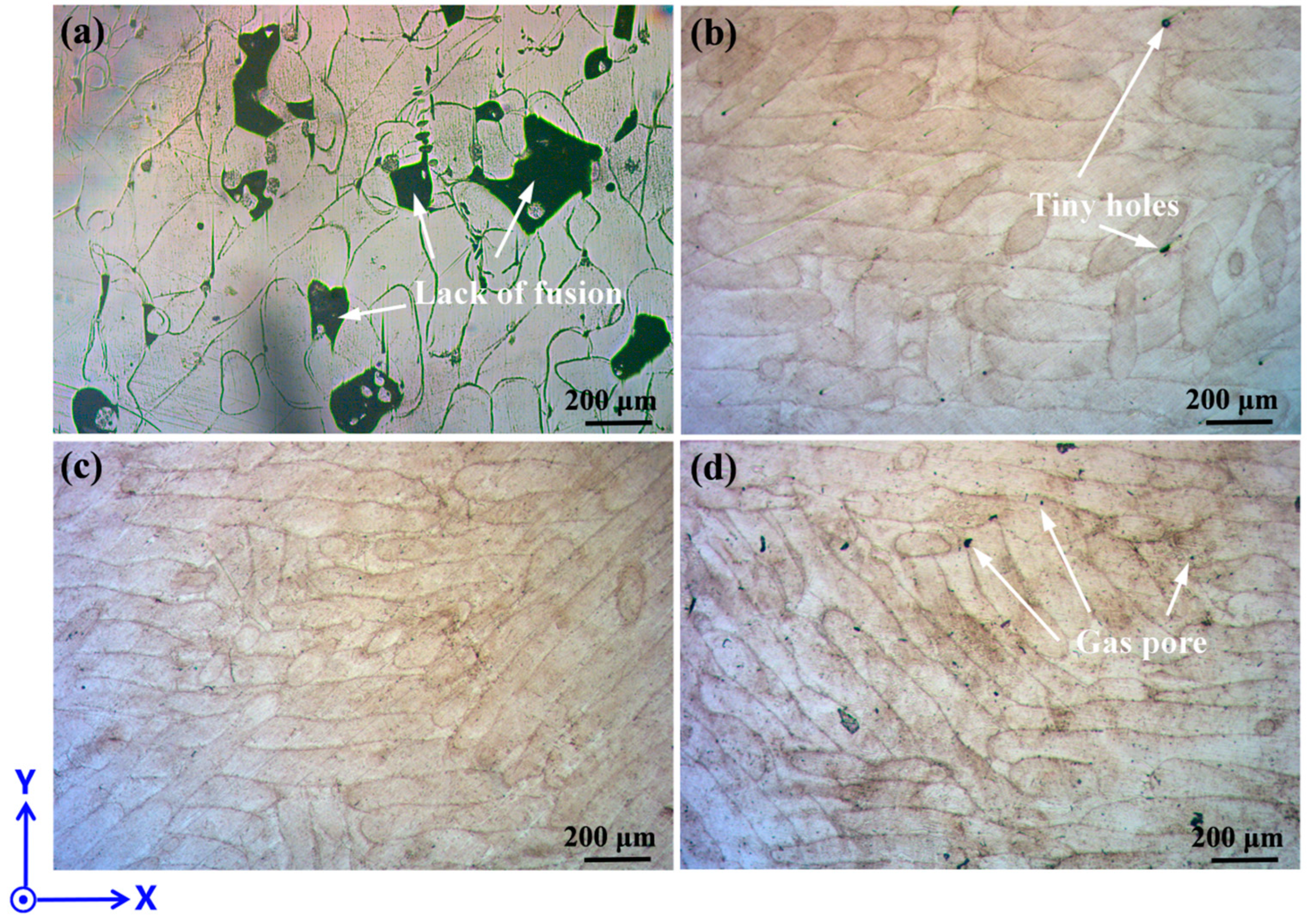

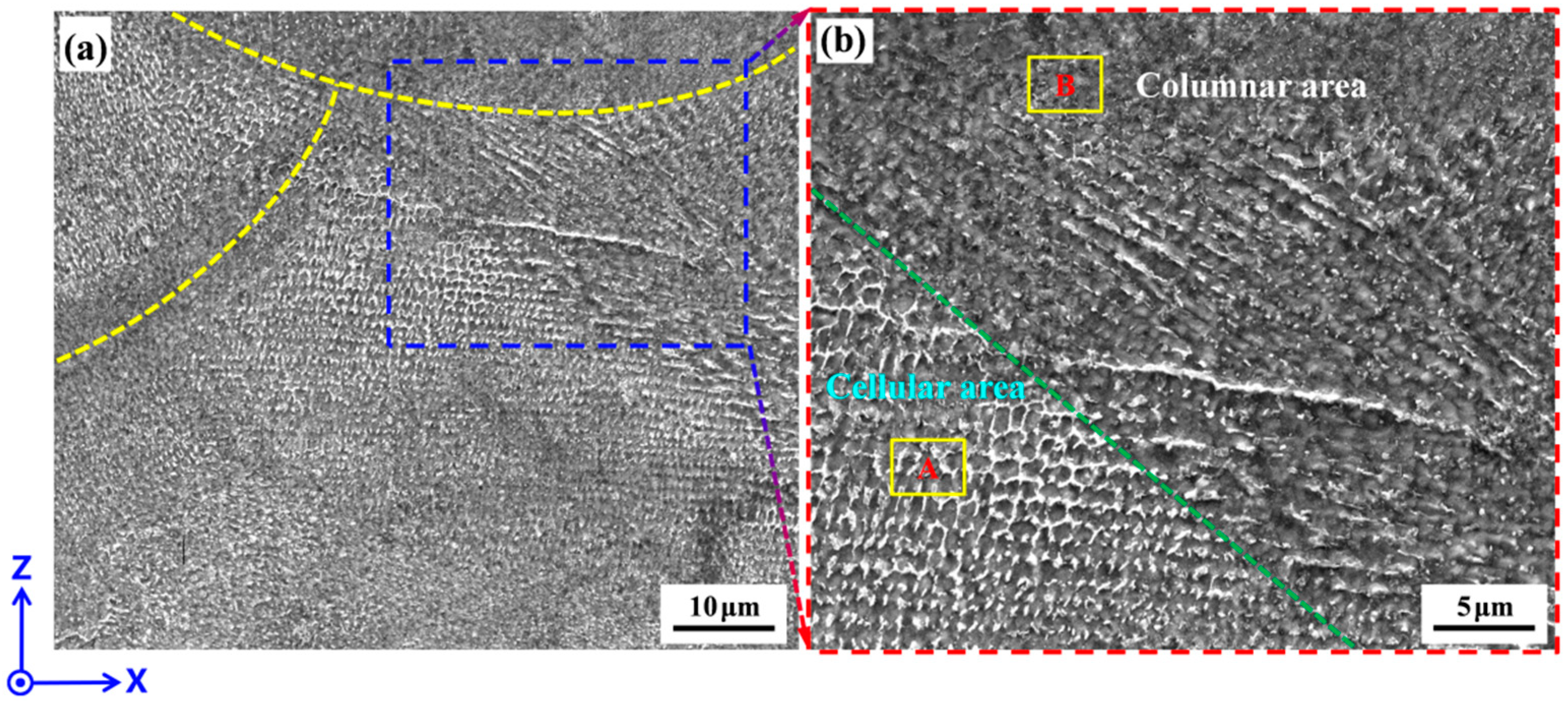

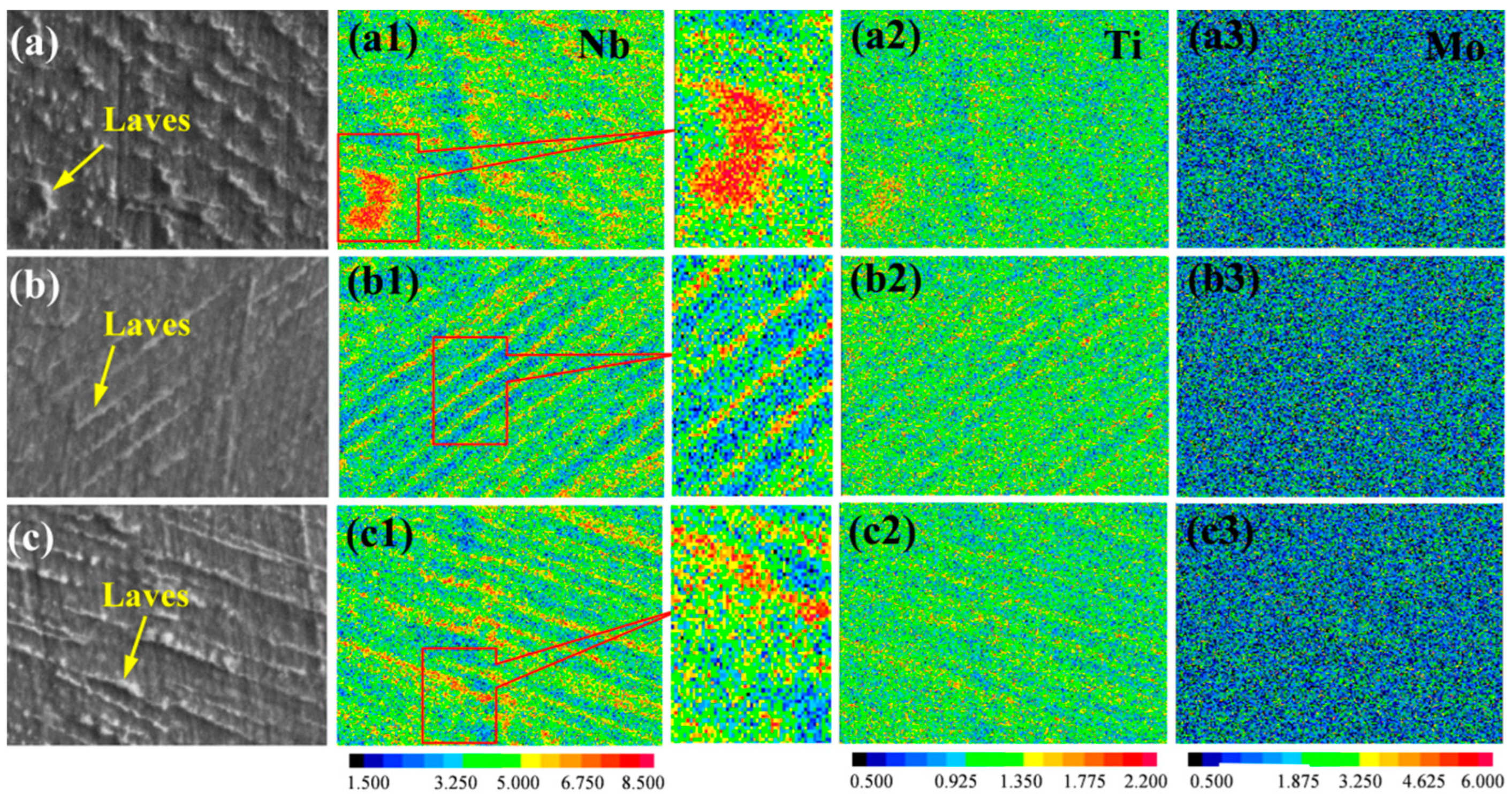

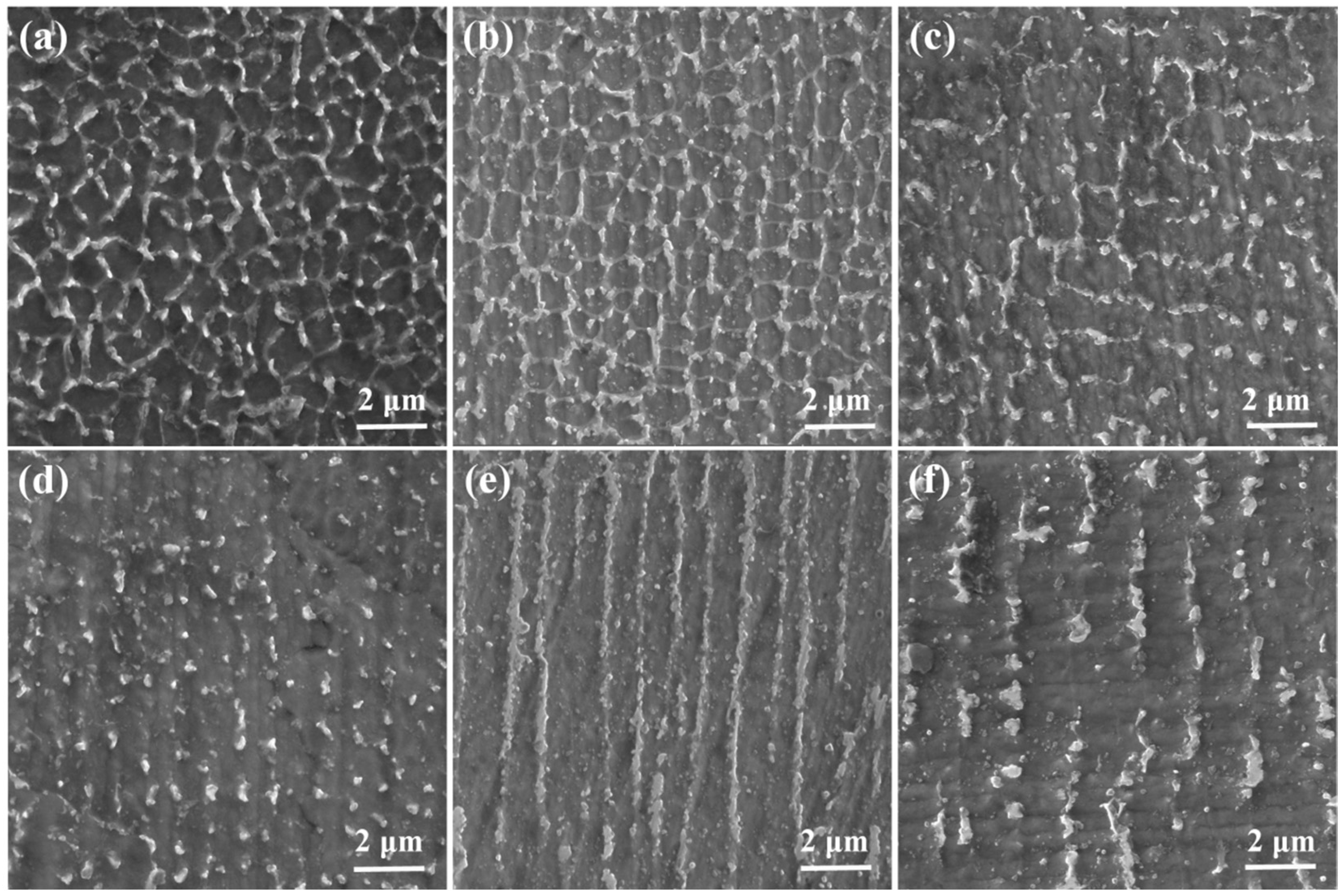

3.2. Microstructure Analysis

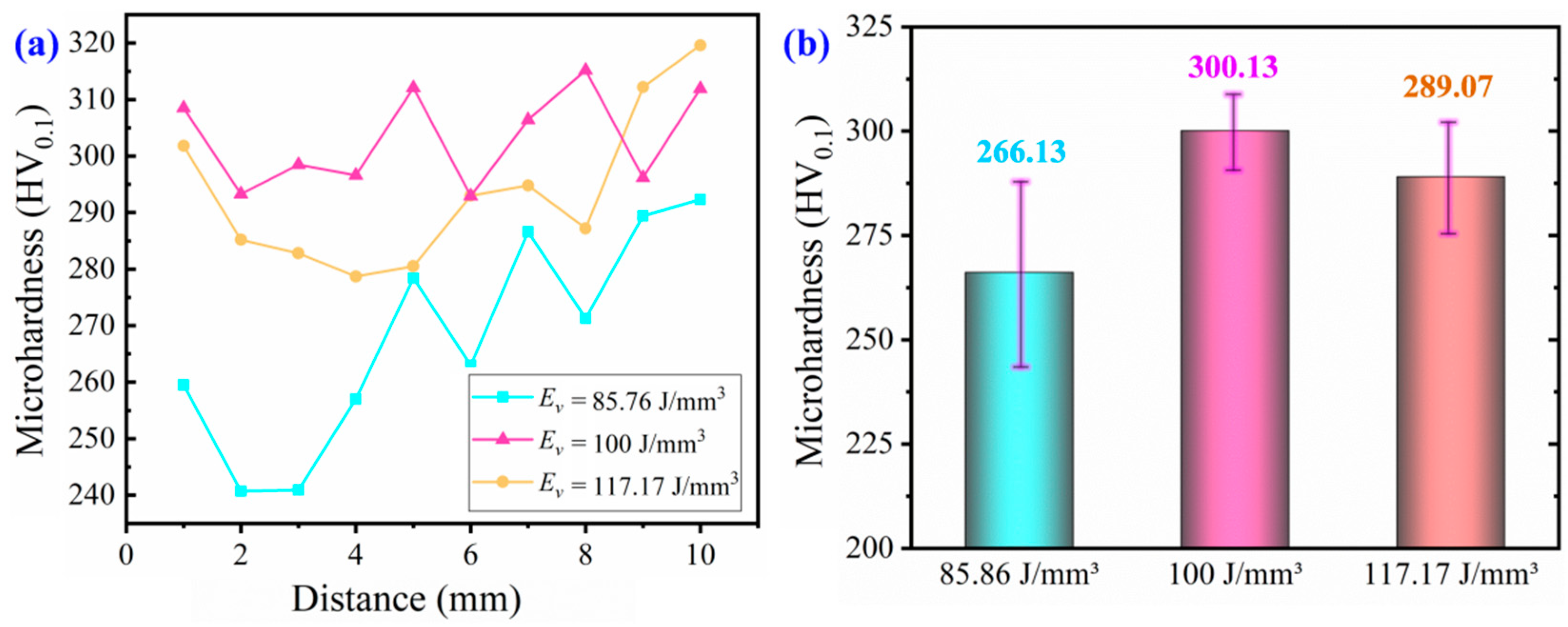

3.3. Microhardness Distribution

4. Conclusions

- The relative density firstly increased and then decreased slightly with the increase in the laser volume energy density. When the laser volume energy density was 100 J/mm3, the material density reached a peak value of 99.53%.

- When the laser energy density was 41.67 J/mm3, the insufficient energy input resulted in poor melt pool fluidity and insufficient filling of the inter-particle voids, which resulted in the appearance of many discrete melt pools. The proper increase in Ev benefited the improvement of densification. However, an excessive value of laser energy density (117.17 J/mm3) resulted in high thermal stress and elements’ evaporation, causing the appearance of gas pores, which will damage the mechanical properties of the sample.

- When the Ev rose from 85.86 J/mm3 to 100 J/mm3, the microhardness of the Inconel 718 alloy fabricated by the SLM process firstly increased from 266.13 HV0.1 to 300.13 HV0.1. When the Ev further increased to 117.17 J/mm3, the microhardness showed a slight decrease to 289.07 HV0.1. The fluctuation of the microhardness was related to the densification degree, microstructure uniformity, and precipitation phase content of Inconel 718 alloy.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, Y.; Yu, J.; Lin, X.; Guo, P.; Yu, X.; Zhang, S.; Liu, J.; Huang, W. Passive Behavior of Laser Directed Energy Deposited Inconel 718 after Homogenization and Aging Heat Treatment. Corros. Sci. 2022, 205, 110439. [Google Scholar] [CrossRef]

- Rai, A.K.; Paul, C.P.; Mishra, G.K.; Singh, R.; Rai, S.K.; Bindra, K.S. Study of Microstructure and Wear Properties of Laser Borided Inconel 718. J. Mater. Process. Technol. 2021, 298, 117298. [Google Scholar] [CrossRef]

- Ji, H.; Song, Q.; Wang, R.; Cai, W.; Liu, Z. Evaluation and Prediction of Pore Effects on Single-Crystal Mechanical and Damage Properties of Selective Laser Melted Inconel-718. Mater. Des. 2022, 219, 110807. [Google Scholar] [CrossRef]

- Yoo, J.; Kim, S.; Jo, M.C.; Park, H.; Jung, J.E.; Do, J.; Yun, D.W.; Kim, I.S.; Choi, B.G. Investigation of Hydrogen Embrittlement Properties of Ni-Based Alloy 718 Fabricated via Laser Powder Bed Fusion. Int. J. Hydrogen Energy 2022, 47, 18892–18910. [Google Scholar] [CrossRef]

- Blakey-Milner, B.; Gradl, P.; Snedden, G.; Brooks, M.; Pitot, J.; Lopez, E.; Leary, M.; Berto, F.; du Plessis, A. Metal Additive Manufacturing in Aerospace: A Review. Mater. Des. 2021, 209, 110008. [Google Scholar] [CrossRef]

- Shao, S.; Khonsari, M.M.; Guo, S.; Meng, W.J.; Li, N. Overview: Additive Manufacturing Enabled Accelerated Design of Ni-Based Alloys for Improved Fatigue Life. Addit. Manuf. 2019, 29, 100779. [Google Scholar] [CrossRef]

- Sreeramagiri, P.; Bhagavatam, A.; Ramakrishnan, A.; Alrehaili, H.; Dinda, G.P. Design and Development of a High-Performance Ni-Based Superalloy WSU 150 for Additive Manufacturing. J. Mater. Sci. Technol. 2020, 47, 20–28. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, L.; Lin, X.; Yang, H.; Huang, W. The Formation and Dissolution Mechanisms of Laves Phase in Inconel 718 Fabricated by Selective Laser Melting Compared to Directed Energy Deposition and Cast. Compos. Part B Eng. 2022, 239, 109994. [Google Scholar] [CrossRef]

- De Bartolomeis, A.; Newman, S.T.; Jawahir, I.S.; Biermann, D.; Shokrani, A. Future Research Directions in the Machining of Inconel 718. J. Mater. Process. Technol. 2021, 297, 117260. [Google Scholar] [CrossRef]

- Sugihara, T.; Enomoto, T. High Speed Machining of Inconel 718 Focusing on Tool Surface Topography of CBN Tool. Procedia Manuf. 2015, 1, 675–682. [Google Scholar] [CrossRef] [Green Version]

- Umbrello, D. Investigation of Surface Integrity in Dry Machining of Inconel 718. Int. J. Adv. Manuf. Technol. 2013, 69, 2183–2190. [Google Scholar] [CrossRef]

- Zheng, Y.; Liu, F.; Zhang, W.; Liu, F.; Huang, C.; Gao, J.; Li, Q. The Microstructure Evolution and Precipitation Behavior of TiB2/Inconel 718 Composites Manufactured by Selective Laser Melting. J. Manuf. Process. 2022, 79, 510–519. [Google Scholar] [CrossRef]

- Vrancken, B.; Thijs, L.; Kruth, J.P.; Van Humbeeck, J. Heat Treatment of Ti6Al4V Produced by Selective Laser Melting: Microstructure and Mechanical Properties. J. Alloys Compd. 2012, 541, 177–185. [Google Scholar] [CrossRef]

- Chen, L.Y.; Liang, S.X.; Liu, Y.; Zhang, L.C. Additive Manufacturing of Metallic Lattice Structures: Unconstrained Design, Accurate Fabrication, Fascinated Performances, and Challenges. Mater. Sci. Eng. R Rep. 2021, 146, 100648. [Google Scholar] [CrossRef]

- Zhu, G.; Pan, W.; Wang, R.; Wang, D.; Shu, D.; Zhang, L.; Dong, A.; Sun, B. Microstructures and Mechanical Properties of GTD222 Superalloy Fabricated by Selective Laser Melting. Mater. Sci. Eng. A 2021, 807, 140668. [Google Scholar] [CrossRef]

- Hosseini, E.; Popovich, V.A. A Review of Mechanical Properties of Additively Manufactured Inconel 718. Addit. Manuf. 2019, 30, 100877. [Google Scholar] [CrossRef]

- Zhang, S.; Lin, X.; Wang, L.; Yu, X.; Hu, Y.; Yang, H.; Lei, L.; Huang, W. Strengthening Mechanisms in Selective Laser-Melted Inconel718 Superalloy. Mater. Sci. Eng. A 2021, 812, 141145. [Google Scholar] [CrossRef]

- Sui, S.; Tan, H.; Chen, J.; Zhong, C.; Li, Z.; Fan, W.; Gasser, A.; Huang, W. The Influence of Laves Phases on the Room Temperature Tensile Properties of Inconel 718 Fabricated by Powder Feeding Laser Additive Manufacturing. Acta Mater. 2019, 164, 413–427. [Google Scholar] [CrossRef]

- Amato, K.N.; Gaytan, S.M.; Murr, L.E.; Martinez, E.; Shindo, P.W.; Hernandez, J.; Collins, S.; Medina, F. Microstructures and Mechanical Behavior of Inconel 718 Fabricated by Selective Laser Melting. Acta Mater. 2012, 60, 2229–2239. [Google Scholar] [CrossRef]

- Lv, J.; Luo, K.; Lu, H.; Wang, Z.; Liu, J.; Lu, J. Achieving High Strength and Ductility in Selective Laser Melting Ti-6Al-4V Alloy by Laser Shock Peening. J. Alloys Compd. 2022, 899, 163335. [Google Scholar] [CrossRef]

- Yi, J.H.; Kang, J.W.; Wang, T.J.; Wang, X.; Hu, Y.Y.; Feng, T.; Feng, Y.L.; Wu, P.Y. Effect of Laser Energy Density on the Microstructure, Mechanical Properties, and Deformation of Inconel 718 Samples Fabricated by Selective Laser Melting. J. Alloys Compd. 2019, 786, 481–488. [Google Scholar] [CrossRef]

- Pede, D.; Li, M.; Virovac, L.; Poleske, T.; Balle, F.; Mu, C. Microstructure and Corrosion Resistance of Novel β-Type Titanium Alloys Manufactured by Selective Laser Melting. J. Mater. Res. Technol. 2022, 19, 4598–4612. [Google Scholar] [CrossRef]

- Riemer, A.; Leuders, S.; Thöne, M.; Richard, H.A.; Tröster, T.; Niendorf, T. On the Fatigue Crack Growth Behavior in 316L Stainless Steel Manufactured by Selective Laser Melting. Eng. Fract. Mech. 2014, 120, 15–25. [Google Scholar] [CrossRef]

- Cruz, V.; Chao, Q.; Birbilis, N.; Fabijanic, D.; Hodgson, P.D.; Thomas, S. Electrochemical Studies on the Effect of Residual Stress on the Corrosion of 316L Manufactured by Selective Laser Melting. Corros. Sci. 2020, 164, 108314. [Google Scholar] [CrossRef]

- Lu, Y.; Wu, S.; Gan, Y.; Huang, T.; Yang, C.; Junjie, L.; Lin, J. Study on the Microstructure, Mechanical Property and Residual Stress of SLM Inconel-718 Alloy Manufactured by Differing Island Scanning Strategy. Opt. Laser Technol. 2015, 75, 197–206. [Google Scholar] [CrossRef]

- Ivanov, D.; Travyanov, A.; Petrovskiy, P.; Cheverikin, V.; Alekseeva, E.; Khvan, A.; Logachev, I. Evolution of Structure and Properties of the Nickel-Based Alloy EP718 after the SLM Growth and after Different Types of Heat and Mechanical Treatment. Addit. Manuf. 2017, 18, 269–275. [Google Scholar] [CrossRef]

- Wang, L.-Z.; Wang, S.; Wu, J.-J. Experimental Investigation on Densification Behavior and Surface Roughness of AlSi10Mg Powders Produced by Selective Laser Melting. Opt. Laser Technol. 2017, 96, 88–96. [Google Scholar] [CrossRef]

- Wen, Z.; Song, X.; Chen, D.; Fan, T.; Liu, Y.; Cai, Q. Electrospinning Preparation and Microstructure Characterization of Homogeneous Diphasic Mullite Ceramic Nanofibers. Ceram. Int. 2020, 46, 12172–12179. [Google Scholar] [CrossRef]

- Song, X.; Zhang, K.; Song, Y.; Duan, Z.; Liu, Q.; Liu, Y. Morphology, Microstructure and Mechanical Properties of Electrospun Alumina Nanofibers Prepared Using Different Polymer Templates: A Comparative Study. J. Alloys Compd. 2020, 829, 154502. [Google Scholar] [CrossRef]

- Wang, R.; Chen, C.; Liu, M.; Zhao, R.; Xu, S.; Hu, T.; Shuai, S.; Liao, H.; Ke, L.; Vanmeensel, K.; et al. Effects of Laser Scanning Speed and Building Direction on the Microstructure and Mechanical Properties of Selective Laser Melted Inconel 718 Superalloy. Mater. Today Commun. 2022, 30, 103095. [Google Scholar] [CrossRef]

- Pan, H.; Dahmen, T.; Bayat, M.; Lin, K.; Zhang, X. Independent Effects of Laser Power and Scanning Speed on IN718’s Precipitation and Mechanical Properties Produced by LBPF plus Heat Treatment. Mater. Sci. Eng. A 2022, 849, 143530. [Google Scholar] [CrossRef]

- Liu, X.B.; Xiao, H.; Xiao, W.J.; Song, L.J. Microstructure and Crystallographic Texture of Laser Additive Manufactured Nickel-Based Superalloys with Different Scanning Strategies. Crystals 2021, 11, 591. [Google Scholar] [CrossRef]

- Ravichander, B.B.; Mamidi, K.; Rajendran, V.; Farhang, B.; Ganesh-Ram, A.; Hanumantha, M.; Shayesteh Moghaddam, N.; Amerinatanzi, A. Experimental Investigation of Laser Scan Strategy on the Microstructure and Properties of Inconel 718 Parts Fabricated by Laser Powder Bed Fusion. Mater. Charact. 2022, 186, 111765. [Google Scholar] [CrossRef]

- Wang, W.; Wang, S.; Zhang, X.; Chen, F.; Xu, Y.; Tian, Y. Process Parameter Optimization for Selective Laser Melting of Inconel 718 Superalloy and the Effects of Subsequent Heat Treatment on the Microstructural Evolution and Mechanical Properties. J. Manuf. Process. 2021, 64, 530–543. [Google Scholar] [CrossRef]

- Zhu, L.; Xu, Z.F.; Liu, P.; Gu, Y.F. Effect of Processing Parameters on Microstructure of Laser Solid Forming Inconel 718 Superalloy. Opt. Laser Technol. 2018, 98, 409–415. [Google Scholar] [CrossRef]

- Liu, H.; Guo, K.; Sun, J.; Shi, H. Effect of Nb Addition on the Microstructure and Mechanical Properties of Inconel 718 Fabricated by Laser Directed Energy Deposition. Mater. Charact. 2022, 183, 111601. [Google Scholar] [CrossRef]

- Chen, Y.; Guo, Y.; Xu, M.; Ma, C.; Zhang, Q.; Wang, L.; Yao, J.; Li, Z. Study on the Element Segregation and Laves Phase Formation in the Laser Metal Deposited IN718 Superalloy by Flat Top Laser and Gaussian Distribution Laser. Mater. Sci. Eng. A 2019, 754, 339–347. [Google Scholar] [CrossRef]

- Kim, H.; Cong, W.; Zhang, H.C.; Liu, Z. Laser Engineered Net Shaping of Nickel-Based Superalloy Inconel 718 Powders onto Aisi 4140 Alloy Steel Substrates: Interface Bond and Fracture Failure Mechanism. Materials 2017, 10, 341. [Google Scholar] [CrossRef]

- Ma, M.; Wang, Z.; Zeng, X. Effect of Energy Input on Microstructural Evolution of Direct Laser Fabricated IN718 Alloy. Mater. Charact. 2015, 106, 420–427. [Google Scholar] [CrossRef]

- McLouth, T.D.; Witkin, D.B.; Bean, G.E.; Sitzman, S.D.; Adams, P.M.; Lohser, J.R.; Yang, J.M.; Zaldivar, R.J. Variations in Ambient and Elevated Temperature Mechanical Behavior of IN718 Manufactured by Selective Laser Melting via Process Parameter Control. Mater. Sci. Eng. A 2020, 780, 139184. [Google Scholar] [CrossRef]

- Moussaoui, K.; Rubio, W.; Mousseigne, M.; Sultan, T.; Rezai, F. Effects of Selective Laser Melting Additive Manufacturing Parameters of Inconel 718 on Porosity, Microstructure and Mechanical Properties. Mater. Sci. Eng. A 2018, 735, 182–190. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, C.; Liu, W.; Ma, Y.; Tang, S.; Liang, C.; Cai, Q.; Zhang, C. Optimization of Parameters in Laser Powder Deposition AlSi10Mg Alloy Using Taguchi Method. Opt. Laser Technol. 2019, 111, 470–480. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, C.; Liu, W.; Ma, Y.; Zhang, C.; Liang, C.; Cai, Q. Laser Powder Deposition Parametric Optimization and Property Development for Ti-6Al-4V Alloy. J. Mater. Eng. Perform. 2018, 27, 5613–5621. [Google Scholar] [CrossRef]

- Kladovasilakis, N.; Charalampous, P.; Tsongas, K.; Kostavelis, I.; Tzovaras, D.; Tzetzis, D. Influence of Selective Laser Melting Additive Manufacturing Parameters in Inconel 718 Superalloy. Materials 2022, 15, 1362. [Google Scholar] [CrossRef] [PubMed]

- Su, C.H.; Rodgers, K.; Chen, P.; Rabenberg, E.; Gorti, S. Design, Processing, and Assessment of Additive Manufacturing by Laser Powder Bed Fusion: A Case Study on INCONEL 718 Alloy. J. Alloys Compd. 2022, 902, 163735. [Google Scholar] [CrossRef]

- Liu, F.; Lin, X.; Leng, H.; Cao, J.; Liu, Q.; Huang, C.; Huang, W. Microstructural Changes in a Laser Solid Forming Inconel 718 Superalloy Thin Wall in the Deposition Direction. Opt. Laser Technol. 2013, 45, 330–335. [Google Scholar] [CrossRef]

- Wang, H.; Wang, L.; Cui, R.; Wang, B.; Luo, L.; Su, Y. Differences in Microstructure and Nano-Hardness of Selective Laser Melted Inconel 718 Single Tracks under Various Melting Modes of Molten Pool. J. Mater. Res. Technol. 2020, 9, 10401–10410. [Google Scholar] [CrossRef]

- King, W.E.; Barth, H.D.; Castillo, V.M.; Gallegos, G.F.; Gibbs, J.W.; Hahn, D.E.; Kamath, C.; Rubenchik, A.M. Observation of Keyhole-Mode Laser Melting in Laser Powder-Bed Fusion Additive Manufacturing. J. Mater. Process. Technol. 2014, 214, 2915–2925. [Google Scholar] [CrossRef]

- Wang, L.; Cui, R.; Li, B.-Q.; Jia, X.; Yao, L.-H.; Su, Y.-Q.; Guo, J.-J.; Liu, T. Influence of Laser Parameters on Segregation of Nb during Selective Laser Melting of Inconel 718. China Foundry 2021, 18, 379–388. [Google Scholar] [CrossRef]

- Wan, H.Y.; Zhou, Z.J.; Li, C.P.; Chen, G.F.; Zhang, G.P. Effect of Scanning Strategy on Grain Structure and Crystallographic Texture of Inconel 718 Processed by Selective Laser Melting. J. Mater. Sci. Technol. 2018, 34, 1799–1804. [Google Scholar] [CrossRef]

- Deng, D.; Peng, R.L.; Brodin, H.; Moverare, J. Microstructure and Mechanical Properties of Inconel 718 Produced by Selective Laser Melting: Sample Orientation Dependence and Effects of Post Heat Treatments. Mater. Sci. Eng. A 2018, 713, 294–306. [Google Scholar] [CrossRef]

- Parimi, L.L.; Ravi, G.; Clark, D.; Attallah, M.M. Microstructural and Texture Development in Direct Laser Fabricated IN718. Mater. Charact. 2014, 89, 102–111. [Google Scholar] [CrossRef]

- Choi, J.P.; Shin, G.H.; Yang, S.; Yang, D.Y.; Lee, J.S.; Brochu, M.; Yu, J.H. Densification and Microstructural Investigation of Inconel 718 Parts Fabricated by Selective Laser Melting. Powder Technol. 2017, 310, 60–66. [Google Scholar] [CrossRef]

- Olakanmi, E.O. Selective Laser Sintering/Melting (SLS/SLM) of Pure Al, Al-Mg, and Al-Si Powders: Effect of Processing Conditions and Powder Properties. J. Mater. Process. Technol. 2013, 213, 1387–1405. [Google Scholar] [CrossRef]

- Park, J.H.; Bang, G.B.; Lee, K.A.; Son, Y.; Kim, W.R.; Kim, H.G. Effect on Microstructural and Mechanical Properties of Inconel 718 Superalloy Fabricated by Selective Laser Melting with Rescanning by Low Energy Density. J. Mater. Res. Technol. 2021, 10, 785–796. [Google Scholar] [CrossRef]

| Elements | Ni | Cr | Nb | Mo | Ti | Al | Co | Fe |

|---|---|---|---|---|---|---|---|---|

| Inconel 718 | 51.13 | 19.34 | 5.14 | 3.04 | 0.93 | 0.58 | 0.03 | Balanced |

| Parameters | Level 1 | Level 2 | Level 3 | Level 4 | Level 5 |

|---|---|---|---|---|---|

| A: Laser power (W) | 160 | 170 | 180 | 190 | 200 |

| B: Scanning speed (mm/s) | 800 | 900 | 1000 | 1100 | 1200 |

| C: Scanning interval (mm) | 0.06 | 0.07 | 0.08 | 0.09 | 0.1 |

| Runs | Laser Power (W) | Scanning Speed (mm/s) | Scanning Interval (mm) | Volume Energy Density (J/mm3) | Relative Density (%) |

|---|---|---|---|---|---|

| 1 | 150 | 800 | 0.06 | 104.17 | 99.12 |

| 2 | 150 | 900 | 0.07 | 79.37 | 99.26 |

| 3 | 150 | 1000 | 0.08 | 62.50 | 96.13 |

| 4 | 150 | 1100 | 0.09 | 50.51 | 95.43 |

| 5 | 150 | 1200 | 0.10 | 41.67 | 92.28 |

| 6 | 160 | 800 | 0.07 | 95.24 | 99.68 |

| 7 | 160 | 900 | 0.08 | 74.07 | 98.33 |

| 8 | 160 | 1000 | 0.09 | 59.26 | 97.55 |

| 9 | 160 | 1100 | 0.10 | 48.48 | 94.48 |

| 10 | 160 | 1200 | 0.06 | 74.07 | 98.62 |

| 11 | 170 | 800 | 0.08 | 88.54 | 99.57 |

| 12 | 170 | 900 | 0.09 | 69.96 | 98.63 |

| 13 | 170 | 1000 | 0.10 | 56.67 | 97.43 |

| 14 | 170 | 1100 | 0.06 | 85.86 | 99.23 |

| 15 | 170 | 1200 | 0.07 | 67.46 | 97.55 |

| 16 | 180 | 800 | 0.09 | 83.33 | 99.15 |

| 17 | 180 | 900 | 0.10 | 66.67 | 98.02 |

| 18 | 180 | 1000 | 0.06 | 100 | 99.53 |

| 19 | 180 | 1100 | 0.07 | 77.92 | 98.92 |

| 20 | 180 | 1200 | 0.08 | 62.50 | 98.21 |

| 21 | 190 | 800 | 0.10 | 79.17 | 98.5 |

| 22 | 190 | 900 | 0.06 | 117.28 | 98.92 |

| 23 | 190 | 1000 | 0.07 | 90.48 | 99.43 |

| 24 | 190 | 1100 | 0.08 | 71.97 | 97.88 |

| 25 | 190 | 1200 | 0.09 | 58.64 | 96.84 |

| Element (Wt. %) | Ni | Cr | Fe | Nb | Mo | Ti | Al |

|---|---|---|---|---|---|---|---|

| White area (A) | 48.528 | 17.681 | 16.974 | 7.898 | 3.175 | 1.259 | 0.463 |

| Dark area (B) | 49.490 | 18.714 | 18.213 | 5.164 | 2.882 | 1.041 | 0.445 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, J.; Wu, Z.; Niu, J.; Song, Y.; Liang, C.; Yang, K.; Chen, Y.; Liu, Y. Effect of Laser Energy Density on the Microstructure and Microhardness of Inconel 718 Alloy Fabricated by Selective Laser Melting. Crystals 2022, 12, 1243. https://doi.org/10.3390/cryst12091243

Xu J, Wu Z, Niu J, Song Y, Liang C, Yang K, Chen Y, Liu Y. Effect of Laser Energy Density on the Microstructure and Microhardness of Inconel 718 Alloy Fabricated by Selective Laser Melting. Crystals. 2022; 12(9):1243. https://doi.org/10.3390/cryst12091243

Chicago/Turabian StyleXu, Jing, Zichun Wu, Jianpeng Niu, Yufeng Song, Chaoping Liang, Kai Yang, Yuqiang Chen, and Yang Liu. 2022. "Effect of Laser Energy Density on the Microstructure and Microhardness of Inconel 718 Alloy Fabricated by Selective Laser Melting" Crystals 12, no. 9: 1243. https://doi.org/10.3390/cryst12091243

APA StyleXu, J., Wu, Z., Niu, J., Song, Y., Liang, C., Yang, K., Chen, Y., & Liu, Y. (2022). Effect of Laser Energy Density on the Microstructure and Microhardness of Inconel 718 Alloy Fabricated by Selective Laser Melting. Crystals, 12(9), 1243. https://doi.org/10.3390/cryst12091243